High-temperature-resistant organic/inorganic hybrid polymer filtrate reducer and preparation method thereof

A fluid loss control agent, high temperature resistant technology, applied in the field of drilling fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

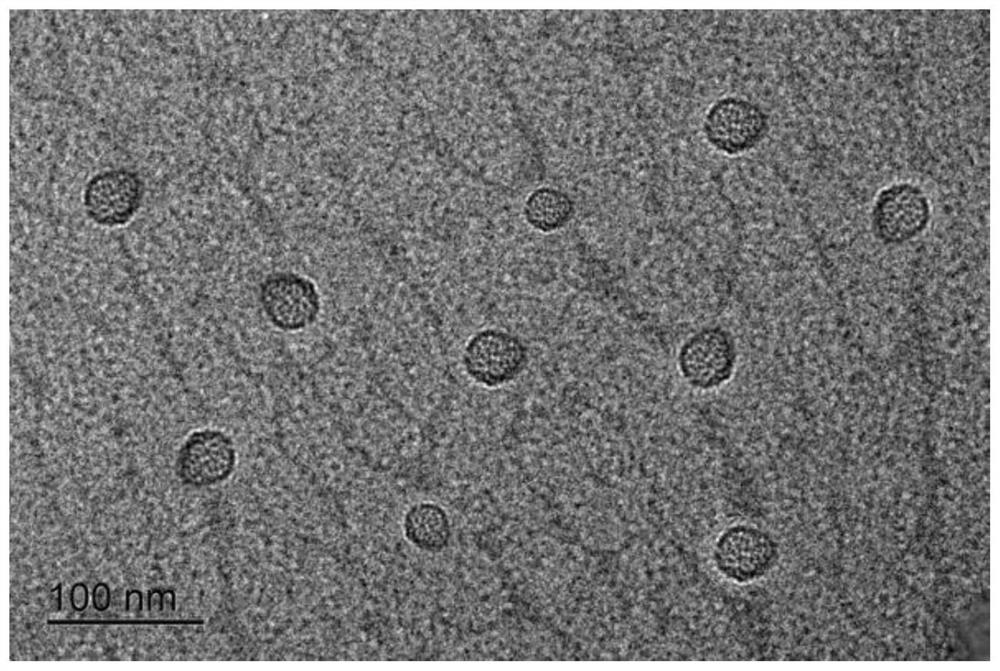

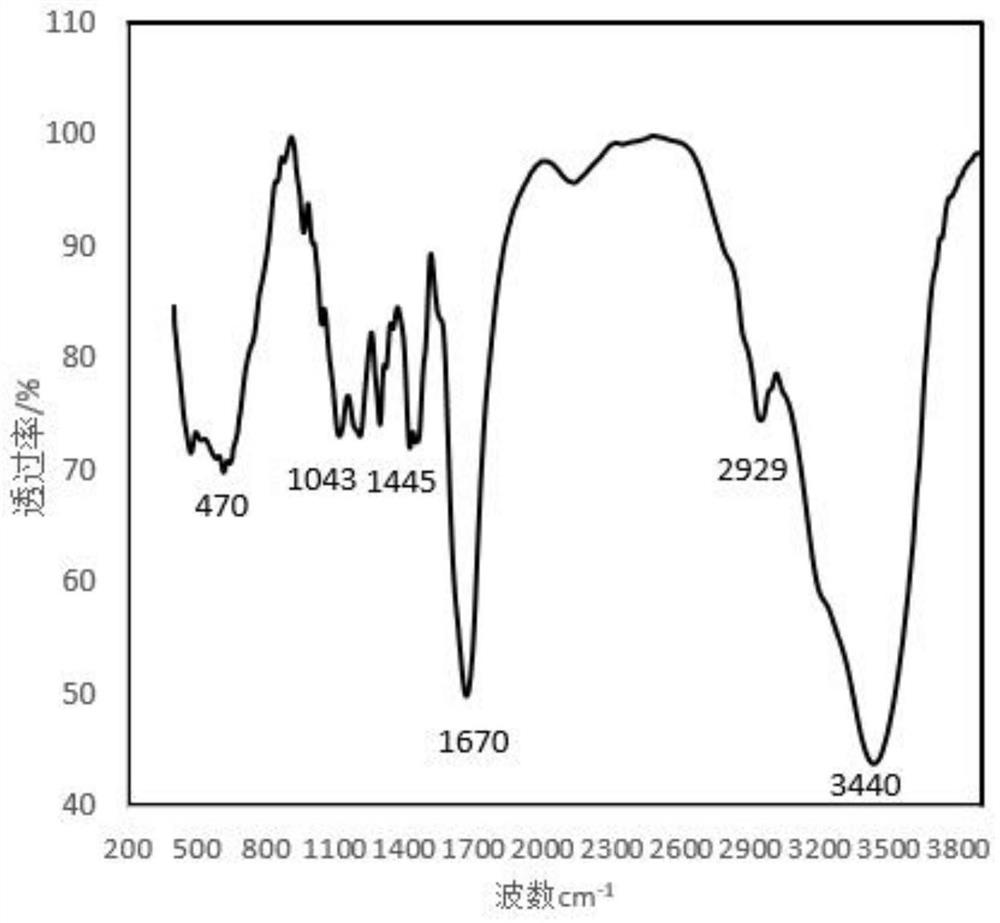

[0024] Mix 18g of acrylamide, 6mL of N-vinylpyrrolidone and 6g of dimethyldiallylammonium chloride in 100mL of deionized water, dissolve and stir evenly, and add sodium hydroxide and stir to adjust the pH to 9. Take another Erlenmeyer flask, add 100mL deionized water and 0.5g modified nano-silica to it, and use an ultrasonic disperser to ultrasonically disperse for 25min to prepare a modified nano-silica suspension. Then, the mixed solution was transferred to a 250mL three-necked flask, heated under nitrogen protection, and 10mL of modified nano-silica suspension was added, the temperature was raised to 70°C, and 0.6g of ammonium persulfate and 0.6g of sulfurous acid were added to the three-necked flask. Sodium hydrogen, stirred and reacted for 7h, a milky white viscous liquid was obtained. The prepared primary product was cooled to room temperature, then placed in a vacuum drying oven at 65° C. for 24 hours, ground and pulverized to obtain a fluid loss reducer for water-based...

Embodiment 2

[0026] Mix 18g of acrylamide, 3mL of N-vinylpyrrolidone and 9g of dimethyldiallylammonium chloride in 100mL of deionized water, dissolve and stir evenly, and the rest of the preparation steps are exactly the same as in Example 1.

Embodiment 3

[0028] Mix 15g of acrylamide, 6mL of N-vinylpyrrolidone and 9g of dimethyldiallylammonium chloride in 100mL of deionized water, dissolve and stir evenly, and the rest of the preparation steps are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com