Open cut tunnel and bridge combined underpinning integrated construction method

A construction method, technology of open-cut tunnels, applied in excavation, bridges, bridge construction, etc., can solve problems such as heavy traffic flow, difficulty in meeting the goal of normal passage of upper bridges, and inability of tunnels to pass through under or in the middle of pile foundations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

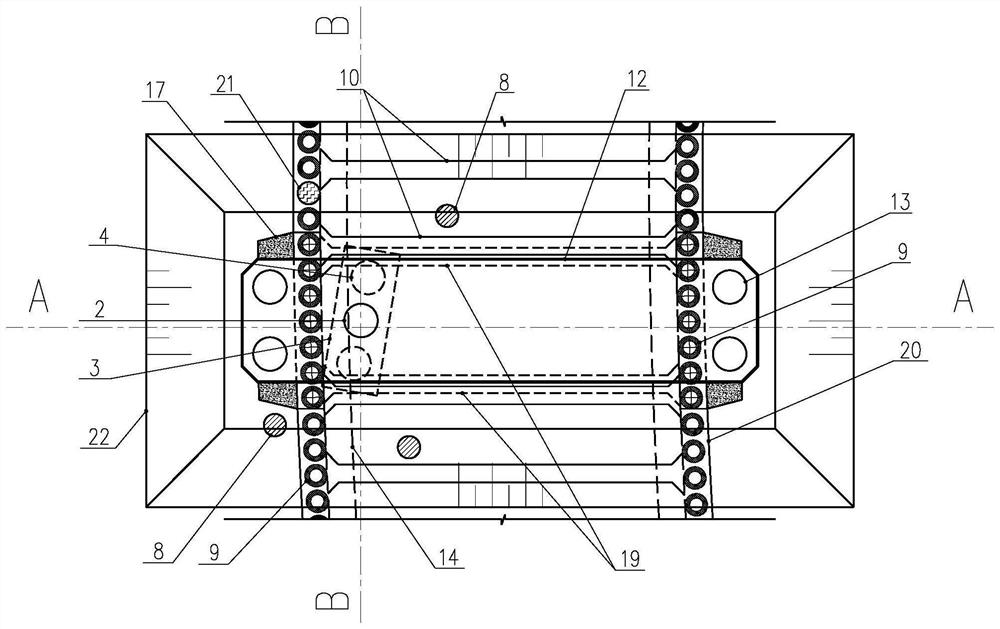

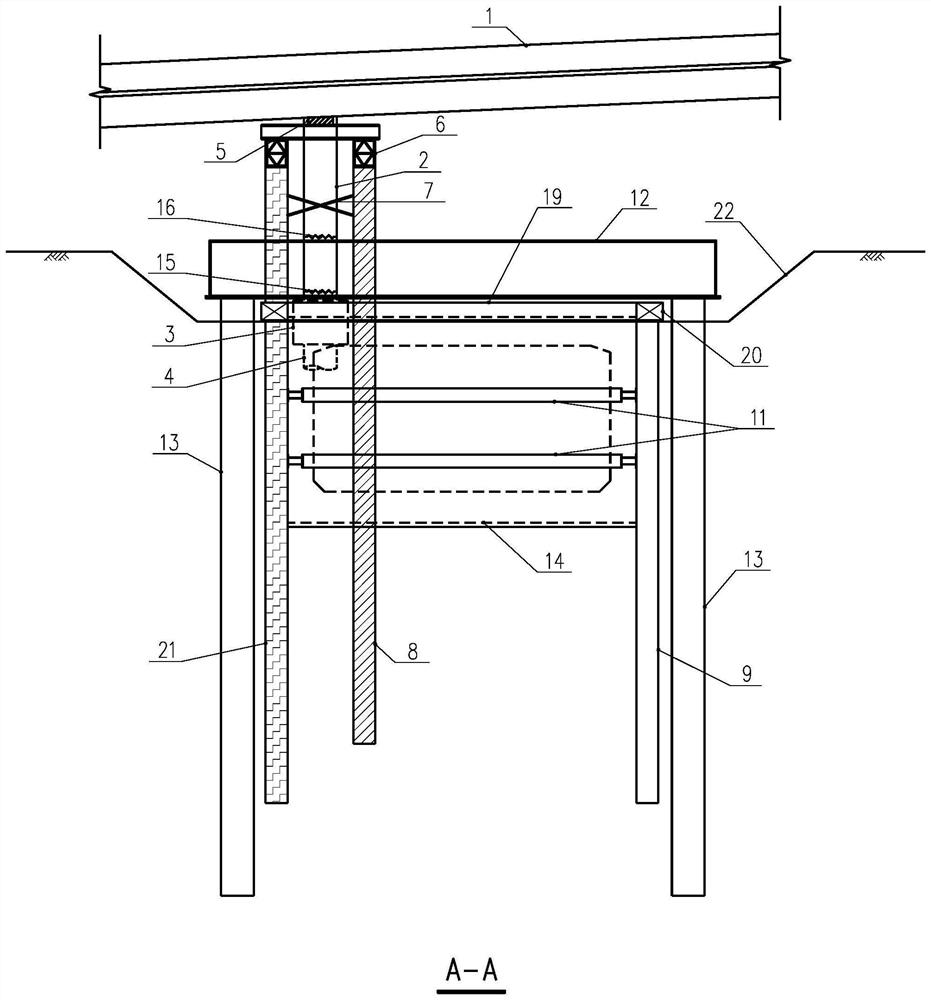

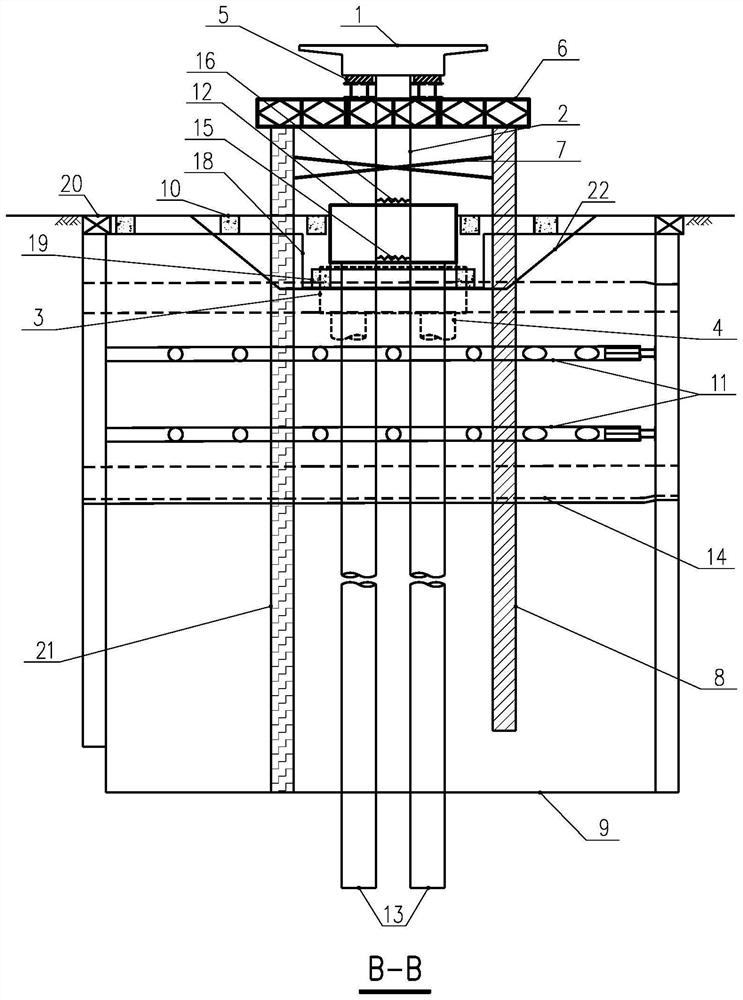

[0037] Combine below Figure 1 to Figure 3 , describe in detail the open-cut tunnel combined with bridge underpinning integrated construction method of the present invention.

[0038] Please refer to Figure 1 to Figure 3 , an integrated construction method for open-cut tunnels combined with bridge underpinning, the construction method comprising the following steps:

[0039] Step S1, constructing supporting piles 8, underpinning piles 13, foundation pit enclosure piles 9 in adjacent areas and shared enclosure piles 21 around the old cap 3;

[0040] Step S2, setting the auxiliary pier 6, under the action of the jacking monitoring system 5, the auxiliary pier 6 lifts the holding force, and the auxiliary pier 6 is used to carry out the construction of the hoop 7 to the column 2, so that the column below the hoop 7 of the auxiliary pier 6 is constructed. in a state of zero stress;

[0041] Step S3, excavation is carried out around the underpinning platform 12 to be built to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com