Structural column steel formwork

A technology for constructing columns and steel formwork, applied in the field of structural column steel formwork, can solve the problems of structural column quality and appearance defects, inconvenient pouring and vibrating, inconvenient installation, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

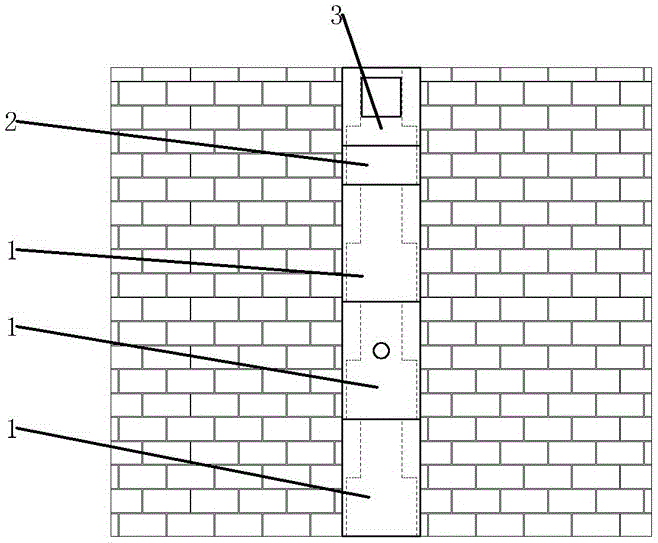

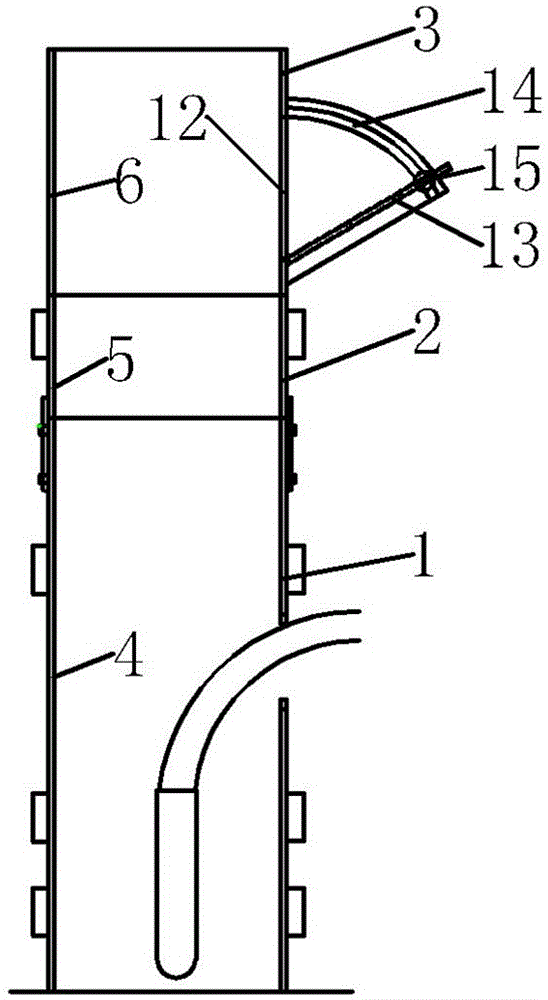

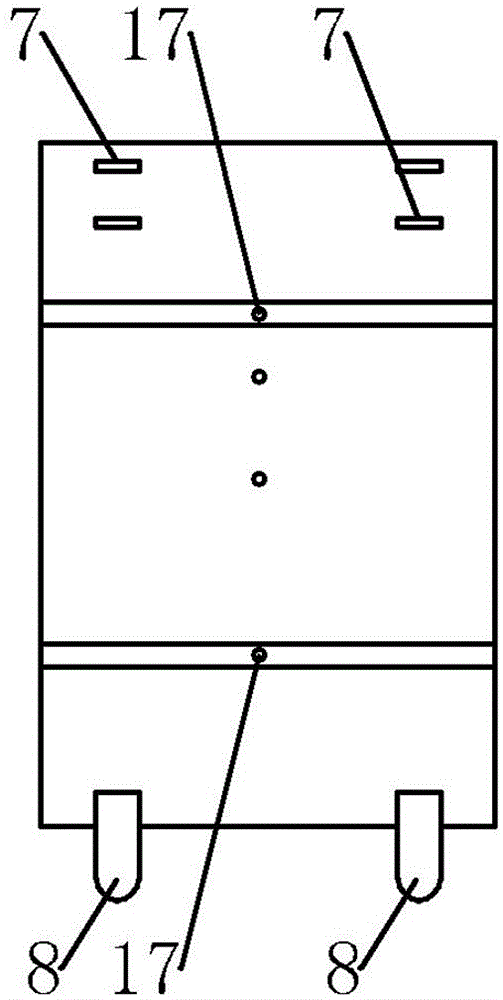

[0015] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the structural column steel formwork provided by the present invention includes a front formwork and a back formwork, and the front formwork includes a plurality of front standard formworks 1, a front motorized formwork 2 and a front pouring formwork 3, and the front formwork is generally provided with some pouring and vibration The back formwork only has sealing and auxiliary locking functions for matching the front formwork. The back formwork includes the back standard formwork 4, the back motorized formwork 5 and the back pouring formwork 6 that match the height of the front formwork. The upper end of the front standard formw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com