Assembly type concrete plate

A concrete slab and prefabricated technology, which is applied to roads, pavements paved with prefabricated blocks, roads, etc., can solve the problems of large size, easily damaged prefabricated concrete slabs, increased road joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The present invention also provides a preparation method for the above-mentioned prefabricated concrete slab, comprising the following steps:

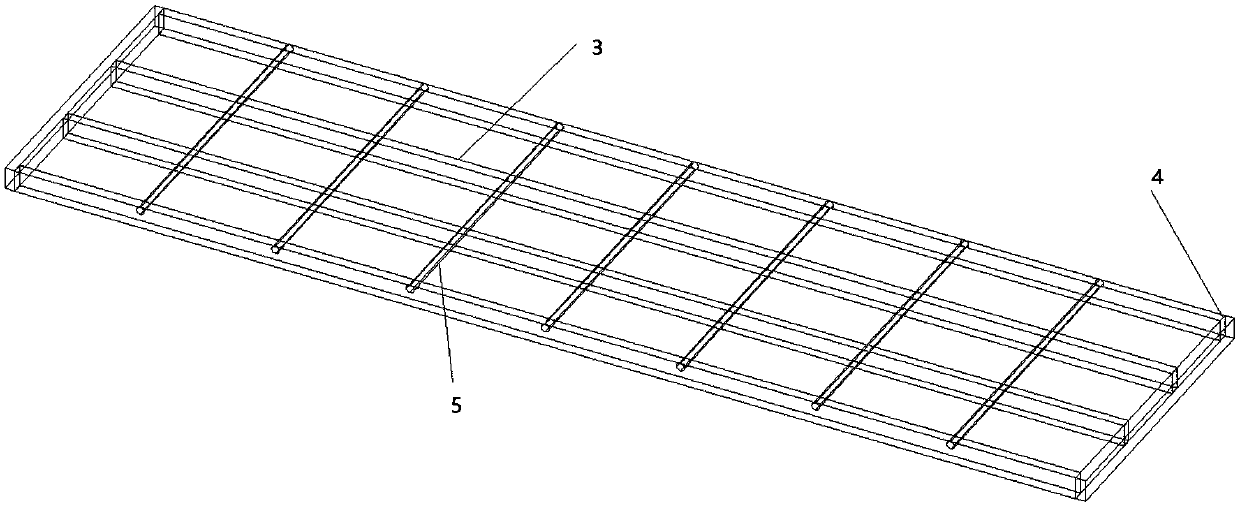

[0063] Step 1: According to the size of the prefabricated concrete slab to be prepared, select the corresponding first steel 3 and the second steel 5, and cut and shape them;

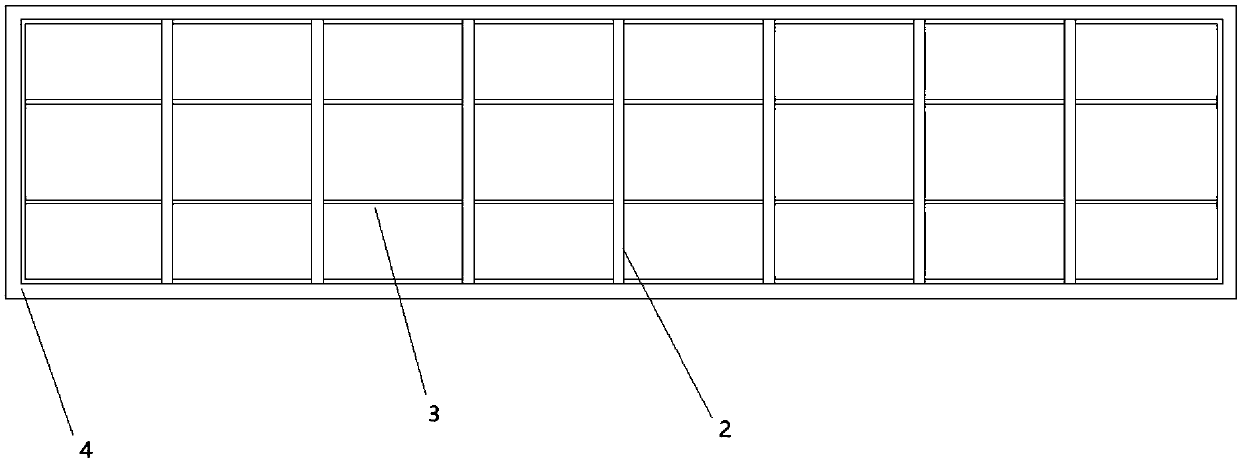

[0064] Step 2: connecting the first steel 3 and the second steel 5 to form a steel grid 2;

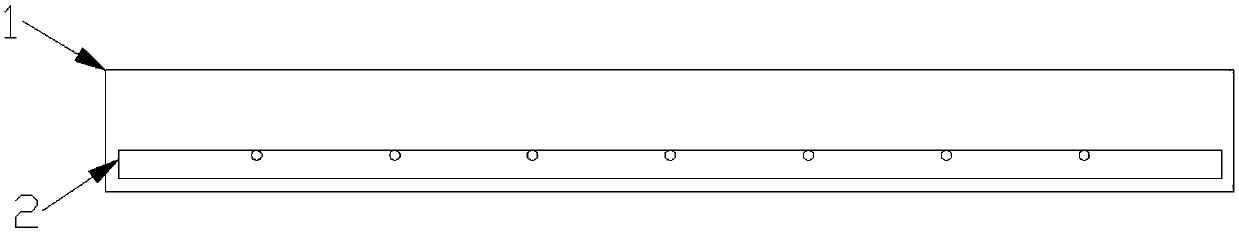

[0065] Step 3: Fix the steel grid 2 at a position close to the bottom of the formwork of the concrete 1, and then pour high-strength concrete 1 into the formwork;

[0066] Step 4: Carry out formwork removal and maintenance according to the "Technical Specifications for Highway Cement Concrete Pavement Maintenance" until the strength meets the requirements for use;

[0067] The flat steel is connected to the round steel by pressure welding, and the flat steel is welded to the flat steel.

[0068] Preferably, step 2 further includes connecting both ends of the fir...

Embodiment 1

[0074] The size of the prefabricated concrete slab (length × width × thickness): 1500mm × 500mm × 90mm, steel type: steel grid, steel ratio: 1.00%, concrete strength: c55, vertical distance from the central axis of the steel to the bottom of the slab: 2cm, Longitudinal flat steel of the first type steel and frame body: 3 pieces of 30mm×5mm q345 flat steel, second type steel: horizontal round steel.

Embodiment 2

[0076] The size of the prefabricated concrete slab (length × width × thickness): 1500mm × 500mm × 90mm, steel type: steel grid, steel ratio: 1.00%, concrete strength: c55, vertical distance from the central axis of the steel to the bottom of the slab: 2cm, Longitudinal flat steel of the first type steel and frame body: 3 pieces of 30mm×5mm q345 flat steel, second type steel: horizontal round steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com