Prestressing force square pile precast pile tip and its processing method

A prefabricated pile tip, prestressed technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of unsteady vibration, increase construction difficulty, labor and time consuming, etc., to ensure product quality and overcome construction difficulties. , the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with specific examples, but not limited to specific implementation.

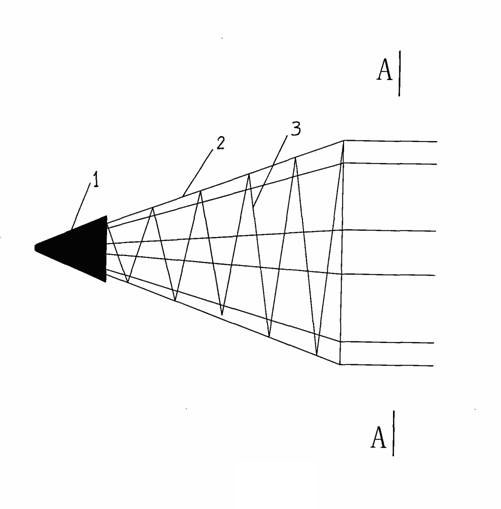

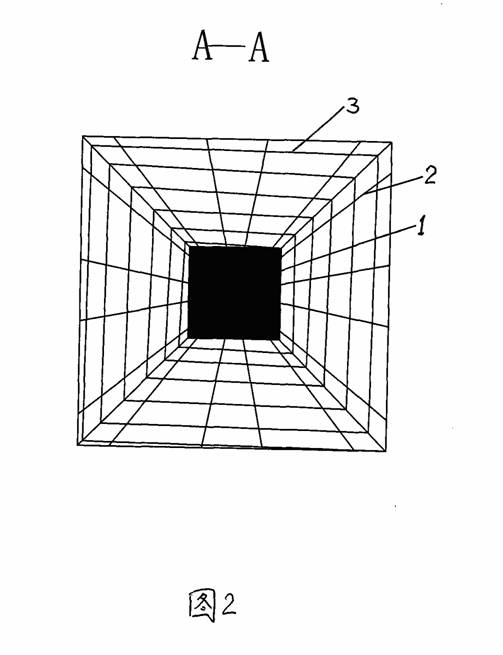

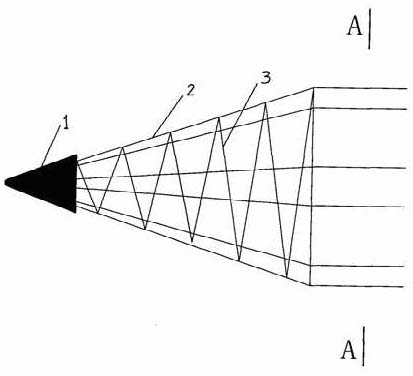

[0015] Produced as follows figure 1 , 2 The prefabricated pile tip of the prestressed square pile shown in the figure, the inner side of the steel tip 1 is equipped with welded high-strength spiral rib steel anchor bar 2, the outer layer of the anchor bar is bound by dense, equidistant and inclined annular spiral stirrups 3, and poured concrete Prestressed tendon holes 4 are reserved in the body, and the prestressed tendon holes and anchor bars are distributed at intervals.

[0016] Firstly, the steel plate at the tip of the pile is cut according to the specifications and welded diagonally, and the middle hole of the tip of the welding pile is plugged with Φ18 short ribs to form a piece. After the finished piece is installed vertically on the special welding frame, the anchor bar is bent according to the pre-processing, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com