Movable concrete mechanical vibrating device

A technology of concrete machinery and vibrating device, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of low vibrating efficiency, increase the labor burden of staff, etc., and achieve high vibrating efficiency, saving manpower, The effect of increasing the vibrating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

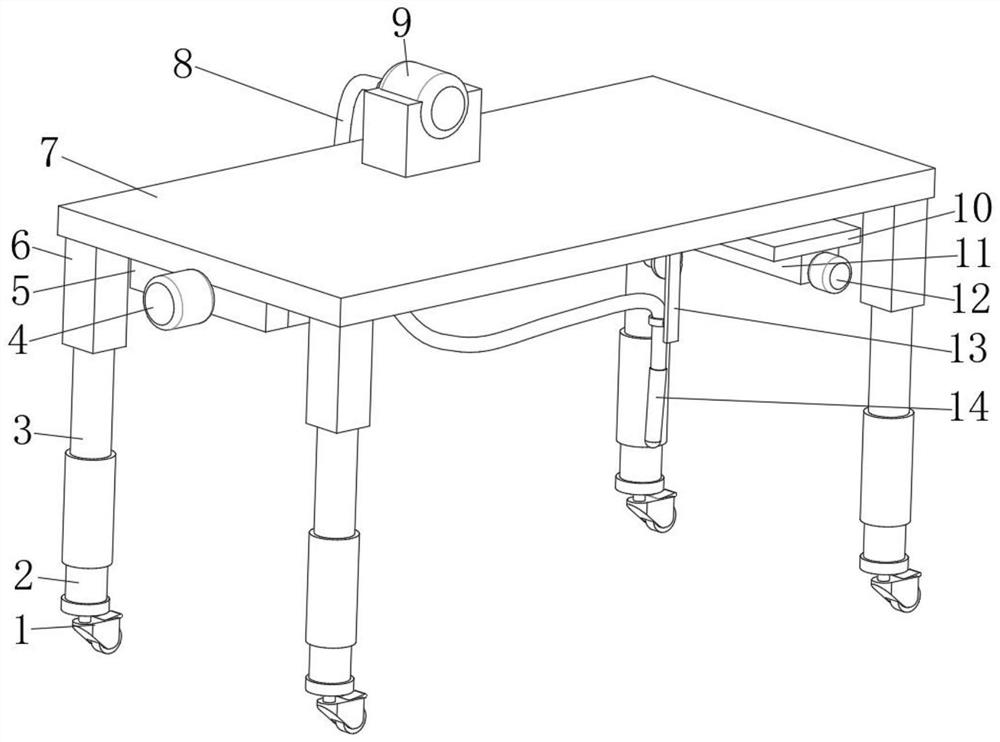

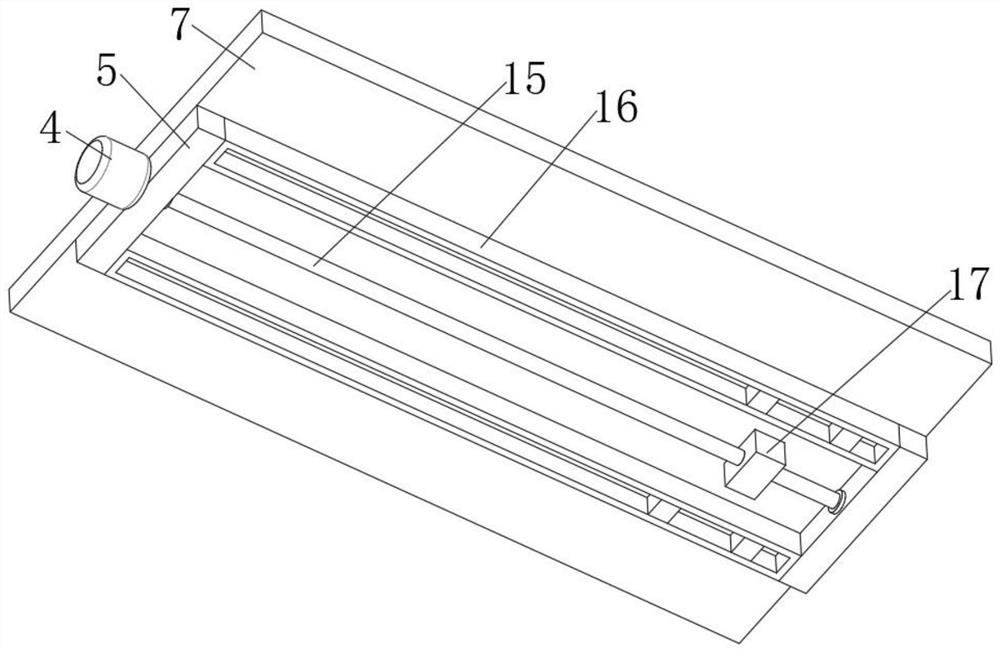

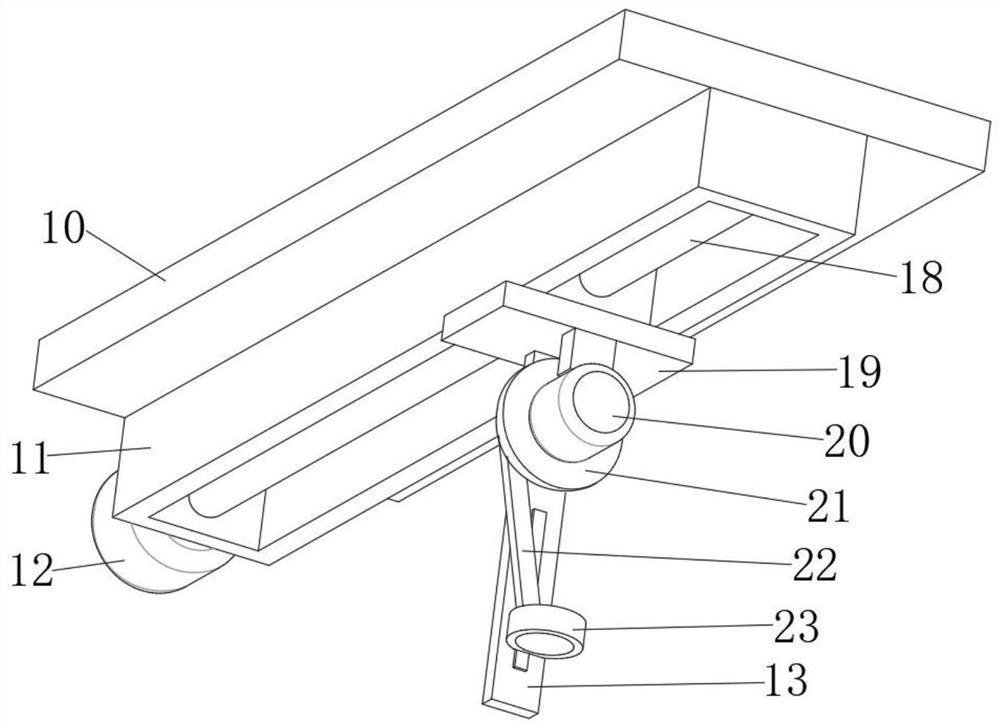

[0025] refer to Figure 1-4 , a mobile concrete mechanical vibration device, including a top plate 7, two symmetrically distributed first installation blocks 16 are fixed on the bottom outer wall of the top plate 7 by screws, and the bottom outer wall of the first installation block 16 has a first rectangular groove , the inner walls of the left and right sides of the first rectangular groove are fixed with the first sliding rail by screws, and the inner wall of the first sliding rail is slidably connected with the slider, and the outer wall of the bottom of the slider is fixed with the first movable plate 10 by screws, and the first The top outer wall of the movable plate 10 is fixed with the first movable block 17 by screws, the front side outer wall of the first installation block 16 is fixed with the mounting plate 5 by screws, and the front side outer wall of the mounting plate 5 is fixed with the first motor 4 by screws, The output shaft of the first motor 4 is fixedly c...

Embodiment 2

[0034] refer to Figure 4 , a mobile concrete mechanical vibrating device. Compared with Embodiment 1, this embodiment also includes a connecting plate 25 fixed on the peripheral outer wall of the mounting column 2 by screws, and the top outer wall of the connecting plate 25 is provided with threaded holes. The inner wall of the hole is threadedly connected with a third threaded rod 24 , and the bottom outer wall of the third threaded rod 24 is fixed with a support foot 26 .

[0035] When the device is in use, the third threaded rod 24 is rotated so that the supporting feet 26 touch the ground to support and fix the device, which is conducive to the stable operation of the vibrating concrete work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com