Construction method for special structure layer of cone bottom wheat-immersion

A special structure and construction method technology, applied in special structures, special buildings, building components, etc., can solve problems such as failure of construction in the next process, impact on structural safety, difficulty in concrete pouring, etc., to ensure cross-sectional size and visual quality, Ensure strength and overall stability, and reduce the effect of steel pipe support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

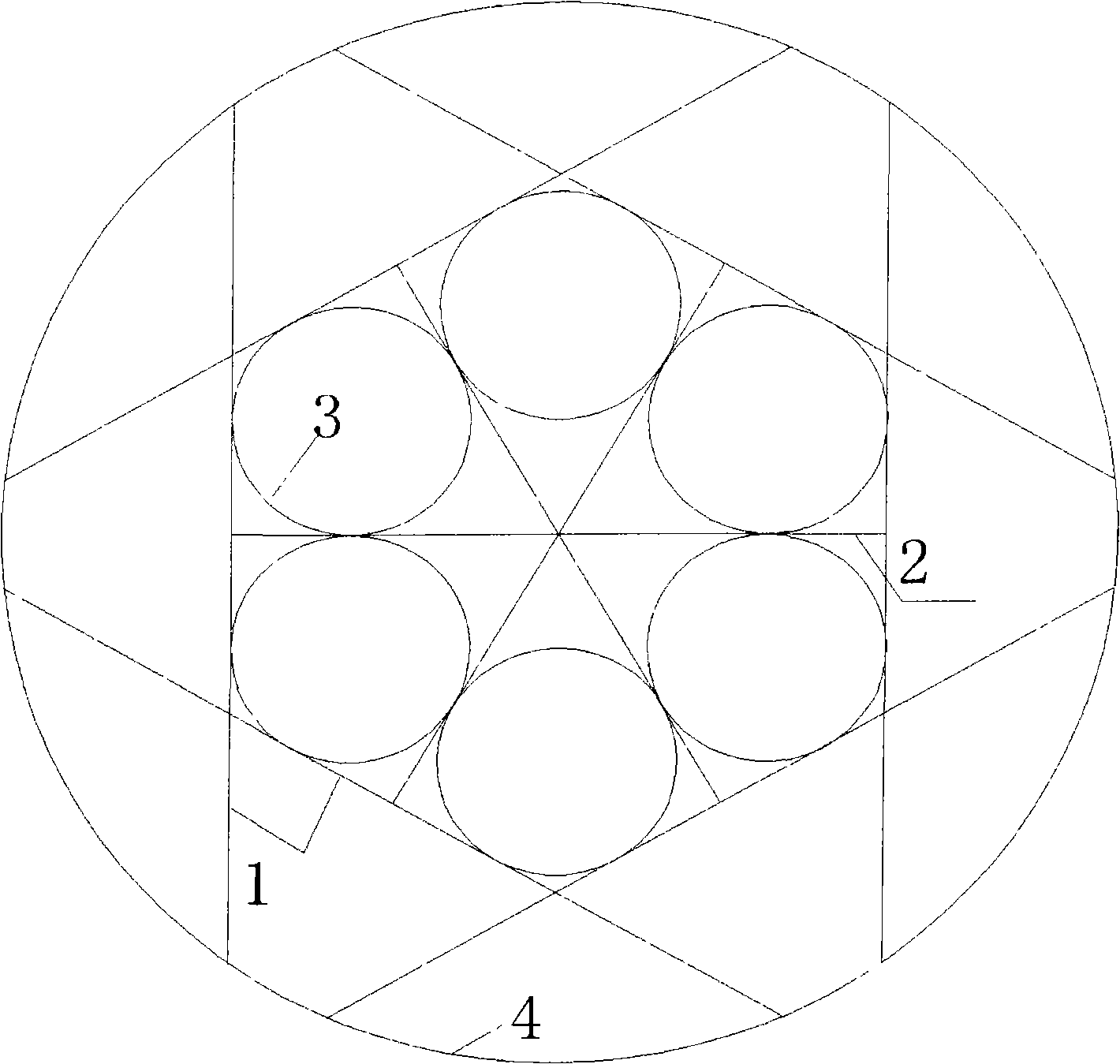

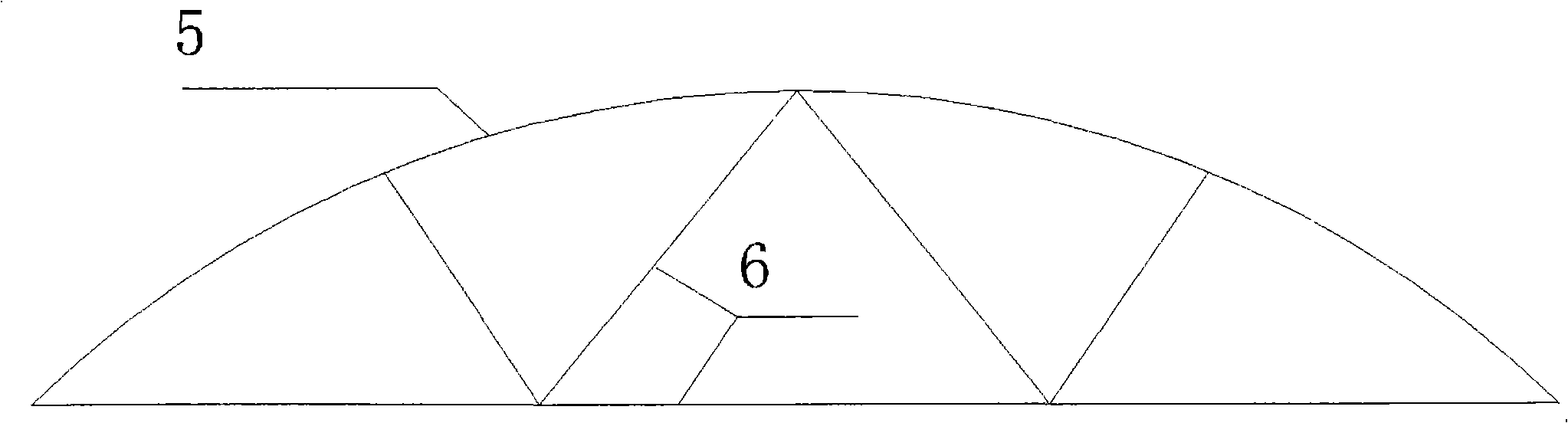

Embodiment 1

[0027] Use ink lines to pop up the details of all concrete beam members and reserved holes on the lower flat-bottomed wheat soaking layer circular plate; Set up the brackets in sequence, the vertical poles in the brackets are erected along the direction of the special-shaped beams and the rice-shaped beams, the horizontal poles should form oblique staggered, the number of vertical poles passing through the oblique lap joints is 4, and the distance between the vertical poles is 800mm Set up, the distance between the horizontal bars is 1000mm, set up the vertical scissors brace of the beam on the bottom frame body of each beam; The upper limit of the laying arching height is 3‰, the laying arching height of the special-shaped beam base form is 1.5‰, and the round beam does not have arching; the beam end embedded parts of the special-shaped beam are hoisted in place and installed to the predetermined position; The steel pipes are used to set up a frame for binding the beam reinfo...

Embodiment 2

[0030] Use ink lines to pop up the details of all concrete beam members and reserved holes on the lower flat-bottomed wheat soaking layer circular plate; Set up the brackets in sequence, the vertical poles in the brackets are erected along the direction of the special-shaped beams and the rice-shaped beams, the horizontal poles should form oblique staggered, the number of vertical poles passing through the oblique lap joints is 3, and the distance between the vertical poles is 700mm Set up, the distance between the horizontal bars is 900mm, and set up the vertical scissors brace of the beam on the bottom frame of each beam; The upper limit of the laying arch height is 2.5‰, the laying arch height of the special-shaped beam bottom form is 1.0‰, and the round beam does not have arching; the beam end embedded parts of the special-shaped beam are hoisted in place and installed to the predetermined position; The steel pipes are used to set up a frame for binding the beam reinforcem...

Embodiment 3

[0033]Use ink lines to pop up the details of all concrete beam members and reserved holes on the lower flat-bottomed wheat soaking layer circular plate; Set up the brackets in sequence, the vertical poles in the brackets are erected along the direction of the special-shaped beams and the rice-shaped beams, the horizontal poles should form oblique staggered, the number of vertical poles passing through the oblique lap joints is 5, and the vertical pole spacing is 900mm Set up, the distance between the horizontal bars is 1200mm, set up the vertical scissors brace of the beam on the bottom frame of each beam; The upper limit of the laying arch height is 2.8‰, the laying arch height of the special-shaped beam base form is 1.3‰, and the round beam does not have arching; the beam end embedded parts of the special-shaped beam are hoisted in place and installed to the predetermined position; The steel pipes are used to set up a frame for binding the beam reinforcement, and the beam re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com