Traction runway for automobile safety crash laboratory and layered construction method of the traction runway

A technology of automobile safety and layered construction, applied in the field of automobile crash test, can solve the problems of inability to carry out crash test, inaccurate crash test, affecting the flatness of the ground, etc., to achieve the effects of vibration compaction, risk reduction, and ease of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention are described below in conjunction with accompanying drawing:

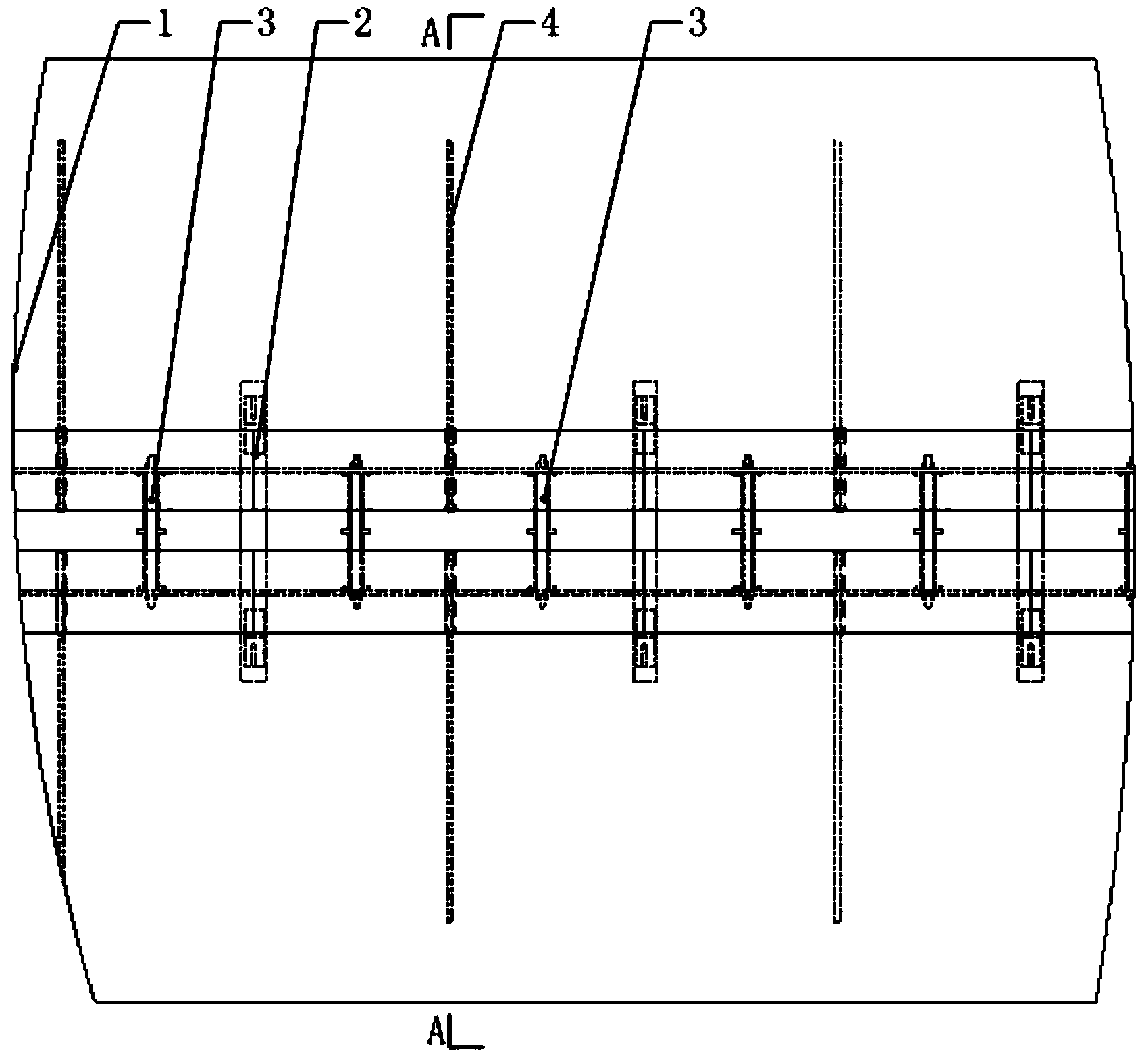

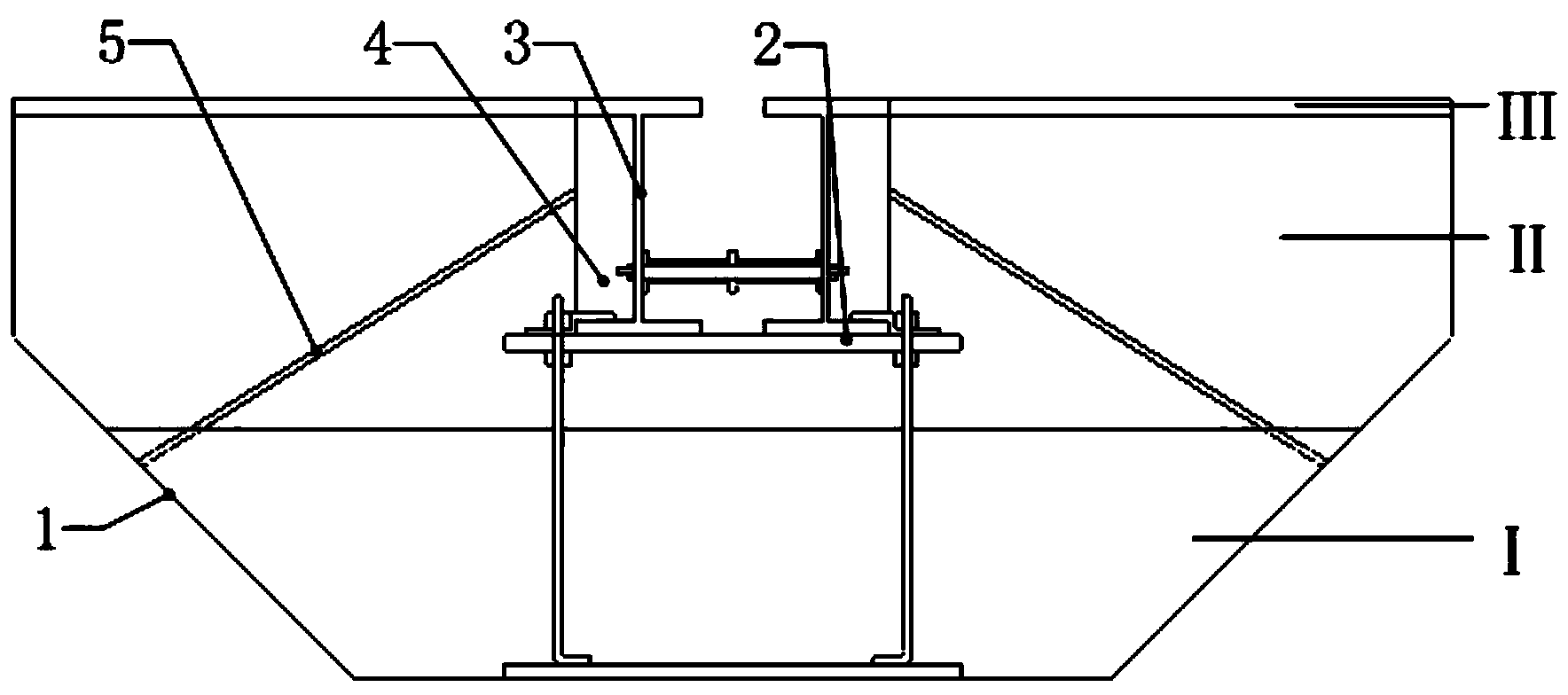

[0030] A kind of traction runway for automobile safety collision test room, its length can be set according to needs, the present embodiment is 100-200m, it comprises foundation groove 1, is installed with several groups of supporting devices interconnected in foundation groove 1, in the supporting device A concrete layer is cast between the foundation tank 1 and an asphalt layer III is laid on the upper surface of the concrete layer;

[0031] in:

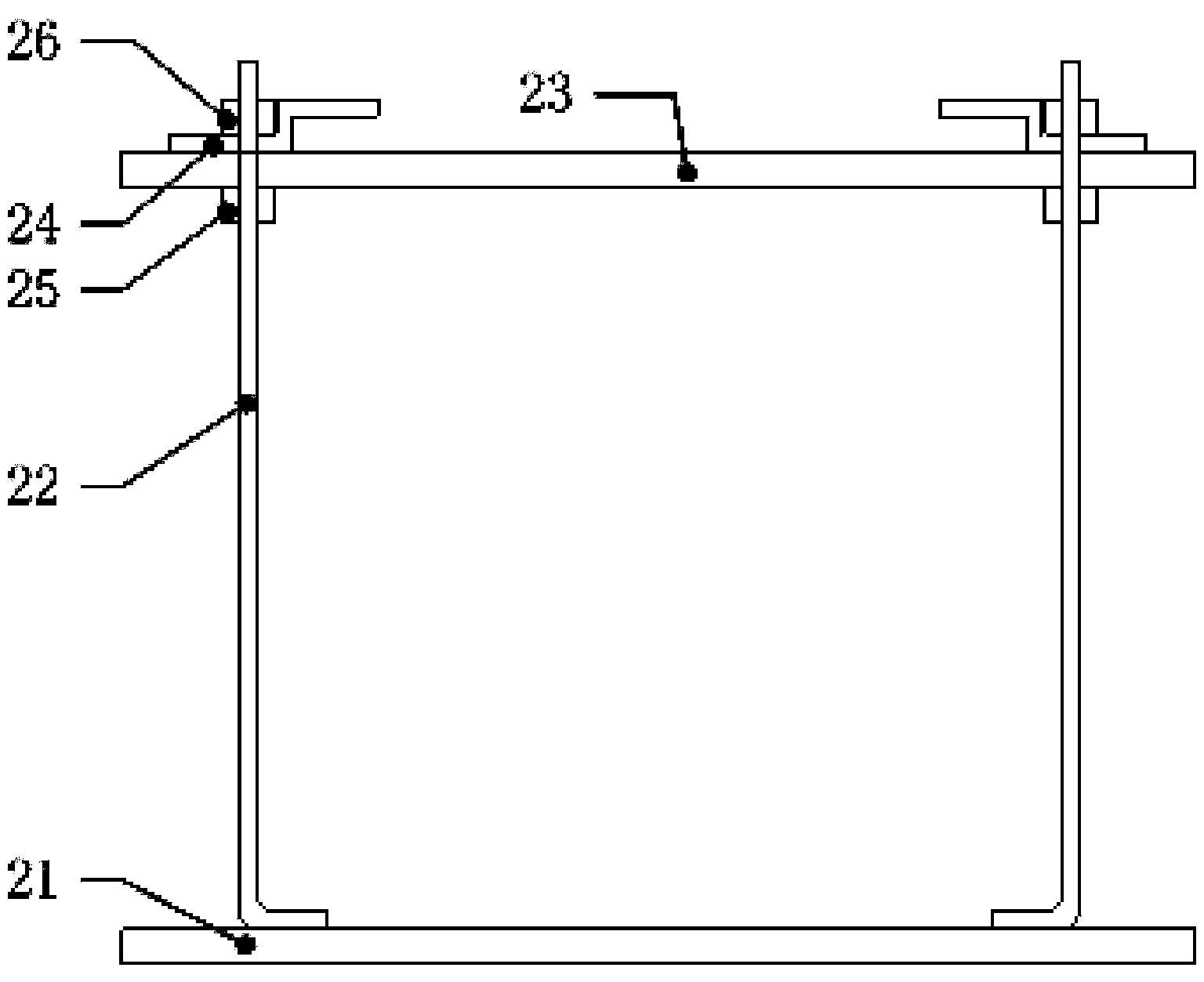

[0032] The support device includes a height adjustment bracket 2 installed on the bottom surface of the base groove 1, an H steel support mechanism 3 assembled on the top of the height adjustment bracket 2 and clamped on it, and a number of H steel reinforcement bars 4 are welded on both sides of the H steel support mechanism 3 , the H-steel reinforcing bar 4 is welded with a restraining steel bar 5, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com