Tamping assist device for concrete pouring and manufacture method thereof

A production method and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of high integrity requirements of the basic structure, difficulty in ensuring the quality of the structure, and inconvenient pouring methods, so as to ensure the quality of the concrete structure, Reduce operating procedures and labor intensity, and facilitate vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A tamping aid for concrete pouring of densely reinforced frame columns and joints

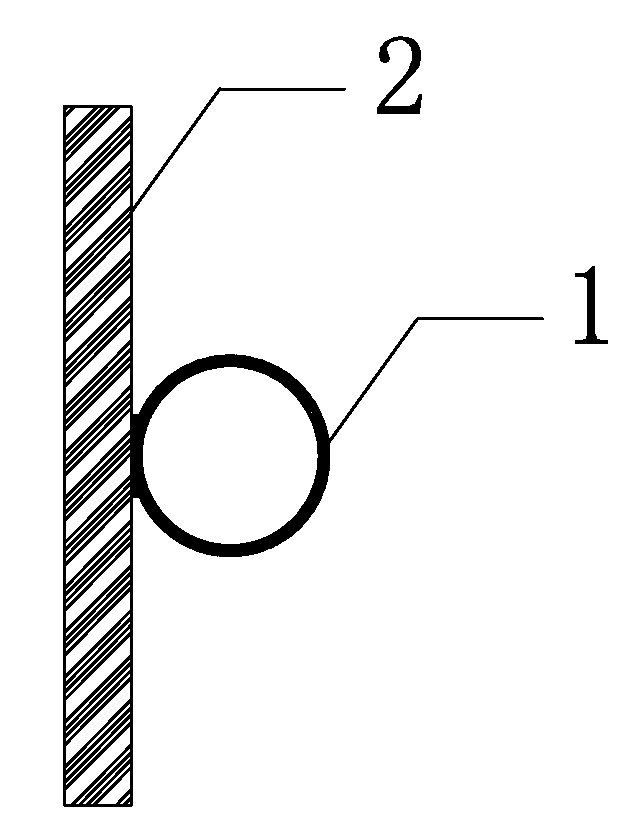

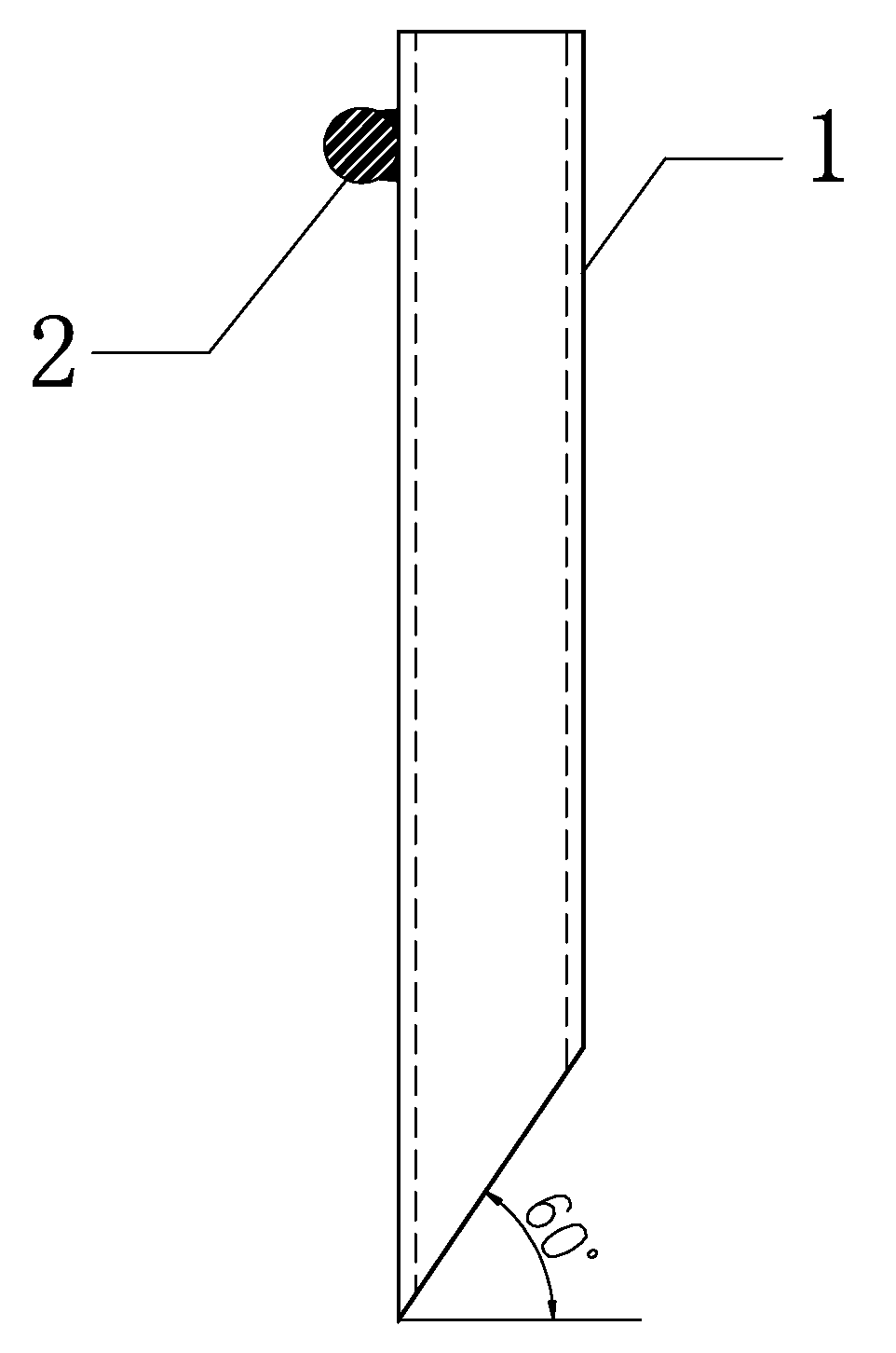

[0032] figure 1 It is a top view of an embodiment of the present invention, figure 2 for figure 1 side view. As shown in the figure, described auxiliary pounding tube 1 is a steel pipe larger than the diameter of the vibrating rod by 20mm, with a diameter of 60mm and a wall thickness of 3.6mm, and the length is the thickness of the platform to be poured plus 200mm; Flat mouth, with a 30-degree oblique tip at the lower end;

[0033] Described handle 2 is a steel bar, long 360mm, diameter 20mm, and the middle of described handle 2 is welded and fixed with the top of described auxiliary pounding cylinder 1, makes handle 2 become the handle of auxiliary pounding cylinder 1, makes it easy to carry, Installation; the distance between the welding point of the handle 2 and the pounding-aiding barrel 1 is 50mm from the upper flat mouth of the pounding-aiding barrel.

Embodiment 2

[0035] A method for manufacturing a tamping aid for concrete pouring of densely reinforced frame columns and joints, which is characterized in that it includes the following steps:

[0036] a. Making auxiliary pounding cylinder 1

[0037] Choose a steel pipe with a diameter greater than 20mm larger than the vibrating rod, with a diameter of 60mm, a wall thickness of 3.6mm, and a length equal to the thickness of the platform to be poured plus 200mm; Cut into a 30-degree oblique tip; the upper port of the tamper-assisting cylinder (1) is flat, round and free of burrs; the oblique tip of the tamper-assisting cylinder (1) is sharp and burr-free.

[0038] B, choose a diameter 20mm, the steel rod of long 360mm is made handle, welds with its length to the upper part of the auxiliary pound cylinder, and the welding point of the handle 2 and the auxiliary pound cylinder 1 is away from the upper end of the auxiliary pound cylinder. The distance is 50mm.

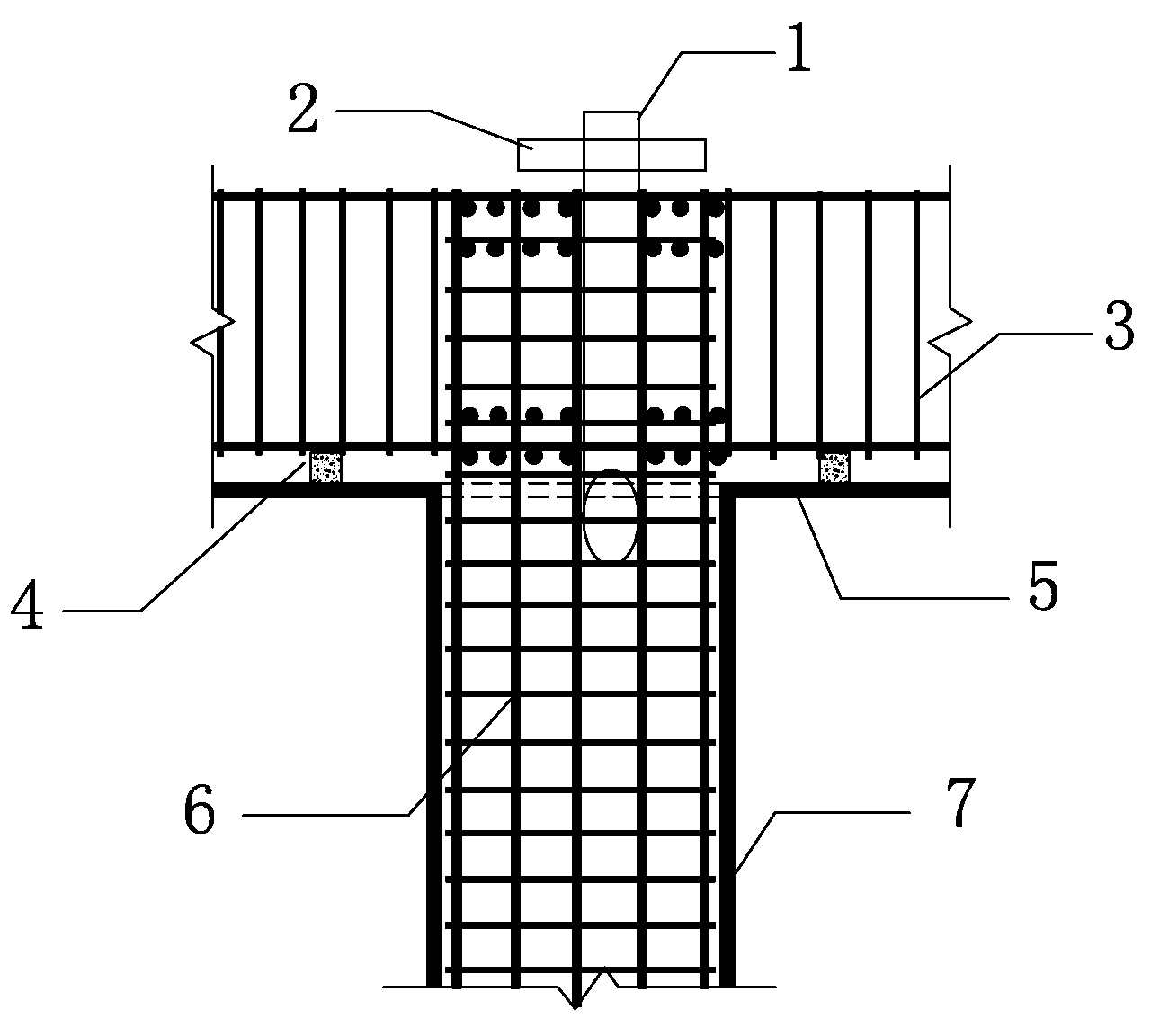

[0039] image 3 It is a sche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com