Prestressing force pipe pile precast pile tip and its production process

A technology for prestressed pipe piles and prefabricated pile tips, which is applied in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of increasing production costs of enterprises, large amount of steel at the tip of the pile, and poor vibration, so as to improve durability. performance and shock resistance, ensuring product quality, and saving labor and labor.

Inactive Publication Date: 2008-11-19

DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

View PDF0 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the whole pile production process, the above-mentioned steel pile tips have poor bonding performance with concrete, low strength, cracks, etc., which affect the durability, so that the pile tip, impact resistance and penetration force are reduced, and it is difficult to meet the pile tip rock-socketing depth of 0.5. m-1D pile diameter and depth requirements

Piles are offset and unstable, which is extremely unfavorable for seismic fortification, and at present, the amount of steel at the pile tip is large, which increases the production cost of the enterprise and reduces the economic benefit of the enterprise

In addition, the processing method of the pile tip is complicated, and the concrete is poured from the side. When pouring, the concrete is not easy to enter the steel cage, and the vibration is not solid. Sharp quality, increasing construction difficulty

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

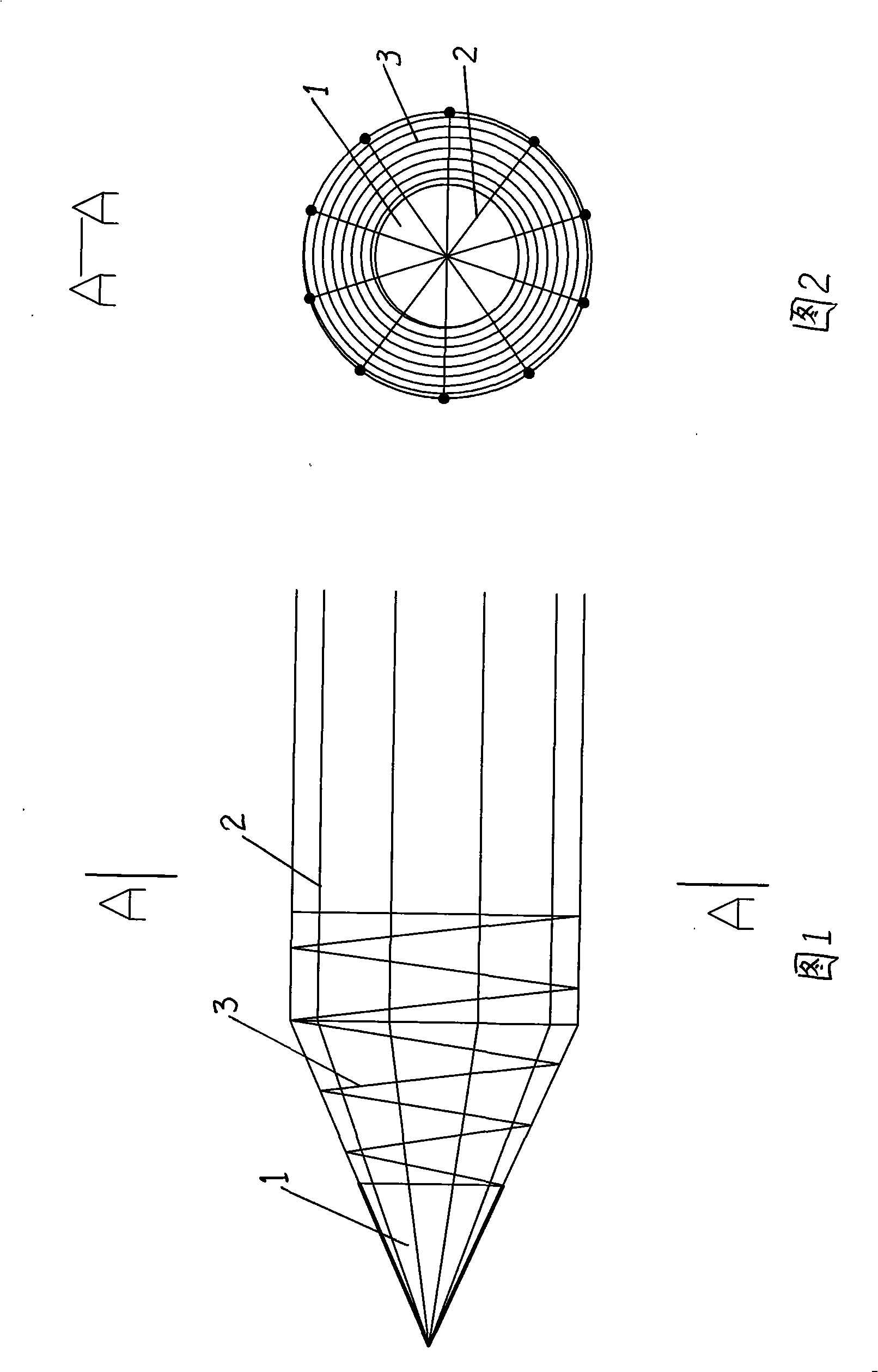

The invention relates to the architecture field and relates to a preformed pile point for a prestressed tubular pile, wherein, anchor bars are welded continuously on the inner circumference of the steel point; the outer layers of the anchor bars are bound and fastened by annular spirally reinforced columns; and prestressing tendon hole sites are preserved on a placing concrete body. The preformed pile point for the prestressed tubular pile is a unique preformed pile point with the prestress performance; the pile point is integrated into a whole with a square pile; the bearing capacity of a pile point part is improved; and the pile point is difficult to break and maintains the same service life with the pile. The method for producing the pile point guarantees the product quality, saves the labor and a great number of steel products, is safe and reliable, improves the durability and the earthquake resistance, and meets the demand of architectural pile foundation engineering.

Description

Prefabricated pile tip of prestressed pipe pile and its production method 1. Technical field The invention relates to the field of building construction pile foundations, in particular to a prefabricated pile tip processing method. 2. Background technology In the low cap pile foundation engineering of industrial and civil buildings, the pile tip of the ordinary prestressed concrete whole pipe pile is caused by the technical conditions. There are three types of steel pile tips: open type, cross type and conical type. Rock-socketed piles end-supporting hard rock formations and weathered metamorphic rock bearing layers. During the whole pile production process, the above-mentioned steel pile tips have poor bonding performance with concrete, low strength, cracks, etc., which affect the durability, so that the pile tip, impact resistance and penetration force are reduced, and it is difficult to meet the pile tip rock-socketing depth of 0.5. m-1D Pile diameter and depth require...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E02D5/30E02D5/58E02D5/72

Inventor 徐世大

Owner DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com