Movable boring device for tail wheel bracket of large towing winch

A mobile, towline technology, applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve problems such as waste of funds and resources, difficulty in moving workpieces, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

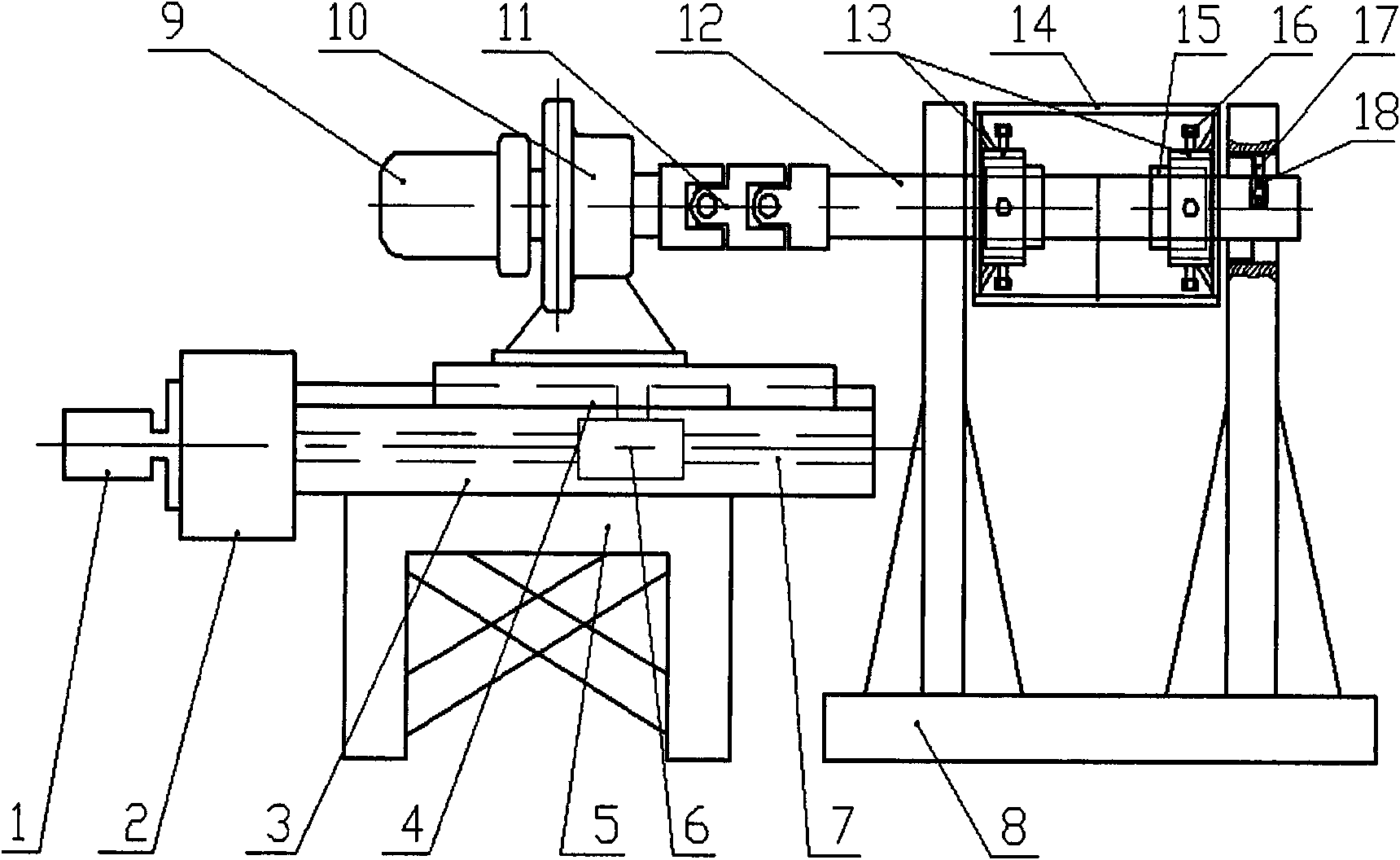

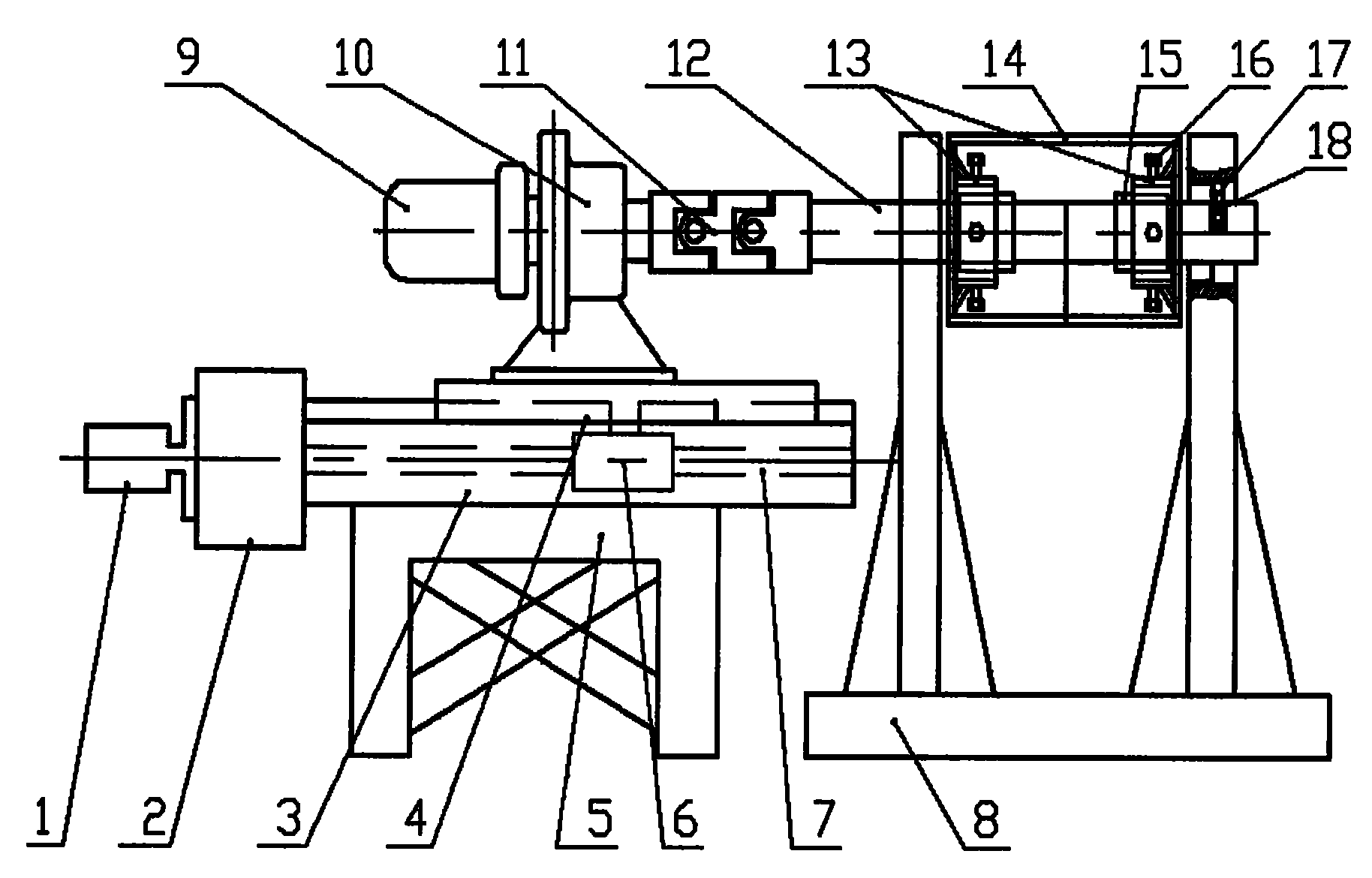

[0006] The present invention will be further described below in conjunction with the accompanying drawings.

[0007] The feeding device comprises a feeding motor (1), a feeding gearbox (2), a base (3), a slide plate (4), a moving nut (6) and a lead screw (7). The rotational speed output is changed through the feed gearbox (2), and the feed motor (1) and the feed gearbox (2) are connected by bolts. The feed gearbox (2) is driven by an epicyclic gear train, and the sliding plate (4) and the base (3) are matched by a dovetail groove, and the matching state can be adjusted by using an inlay. The leading screw (7) is connected with the feed gearbox (2) by a coupling to realize synchronous rotation. Rolling bearings are installed at both ends of the leading screw, which cooperate with the bearing base on the base (3) to make it axially fixed and able to rotate around its own axis. The moving nut (6) is connected with the slide plate (4) by the base; the moving nut (6) cooperates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com