A kind of flower basket nut processing equipment

A technology of turnbuckle nuts and processing equipment, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high labor intensity, low efficiency, and poor precision of workers, and achieve low labor intensity, high efficiency, and accurate processing dimensions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and example the present invention will be further described:

[0029] What needs to be explained here is that the orientation words mentioned in the text are up, down, left and right. figure 2 The views shown are defined by reference, and it should be understood that the use of said localizers should not limit the scope of protection claimed in this application.

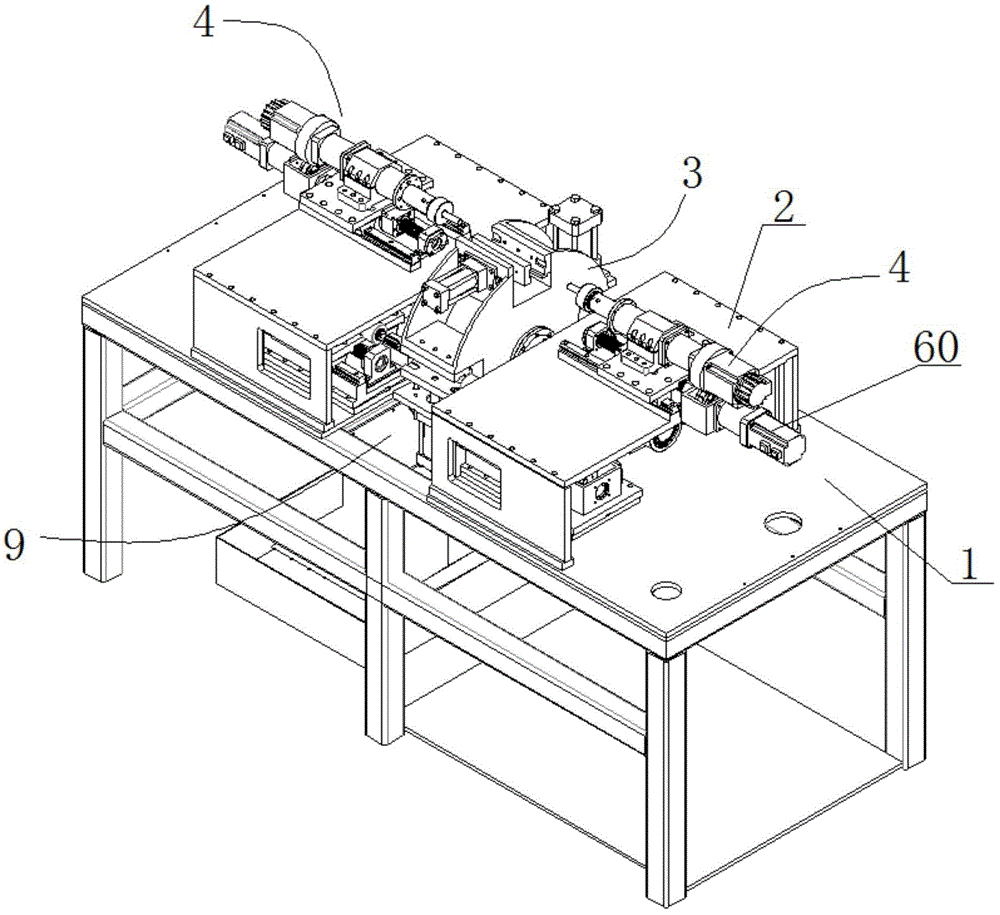

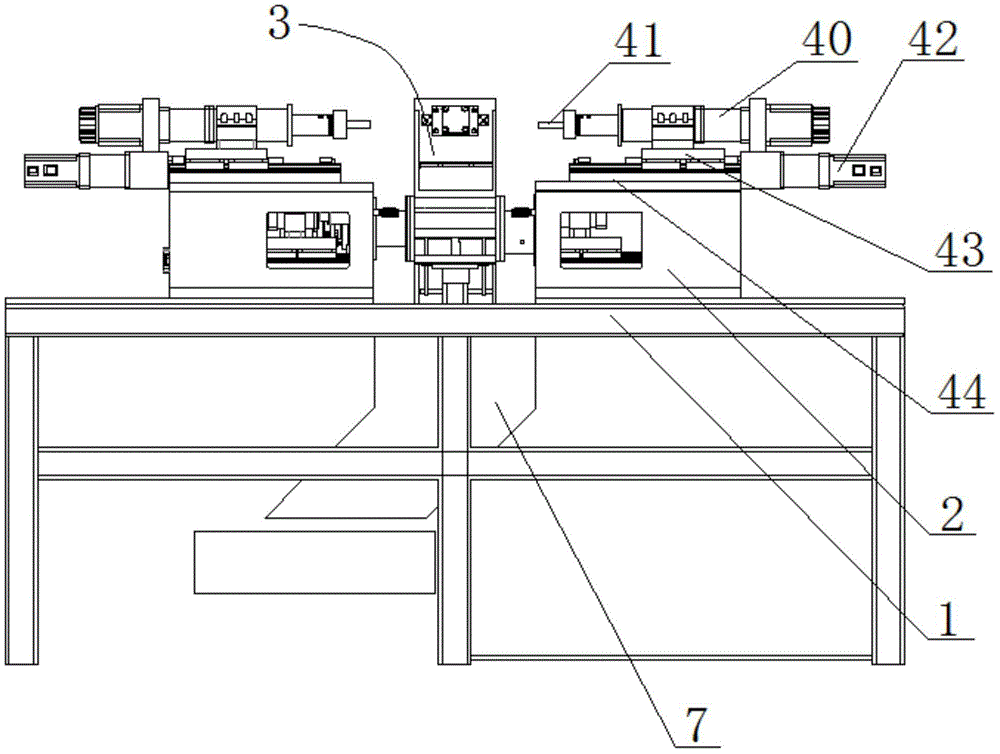

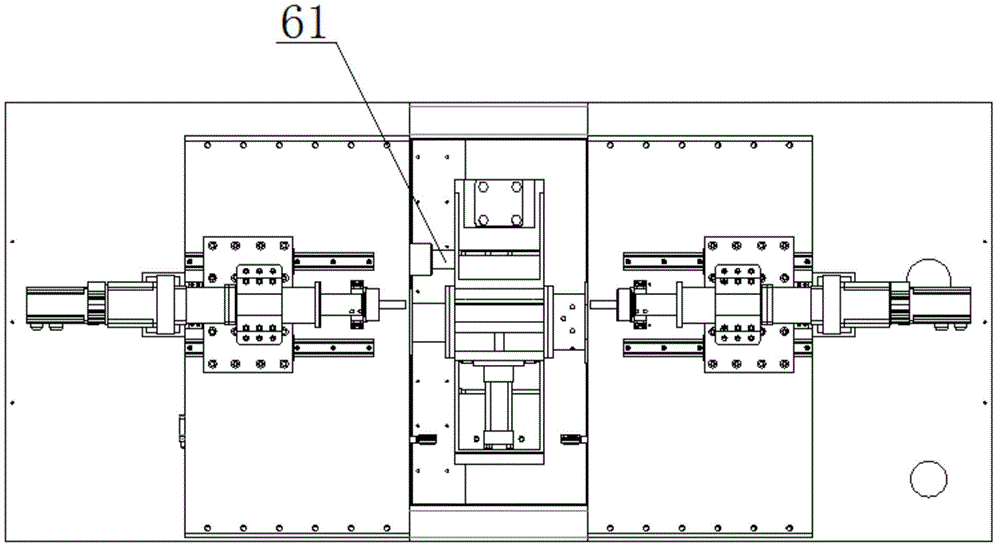

[0030] Such as Figure 1 to Figure 4 As shown, a kind of turnbuckle nut processing equipment of the present embodiment is characterized in that:

[0031] The frame 1 has a slot 9 in the middle;

[0032] The bearing platform 2 is fixedly connected to the frame 1, and the bearing platform 2 is two, which are respectively placed on the left and right sides of the slot 9;

[0033] The station conversion part 3 for fixing the workpiece and converting the station is arranged between the two carrying platforms 2;

[0034] There are two drilling parts 4 for processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com