Method for producing gradient wear resistant layer from titanium oxide to titanium nitride on surface of titanium alloy artificial joint head

An artificial joint, titanium alloy technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of low bonding strength between film and substrate, low bonding strength, rough modified surface, etc. Achieve the effect of improving biocompatibility and corrosion resistance, good biocompatibility, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

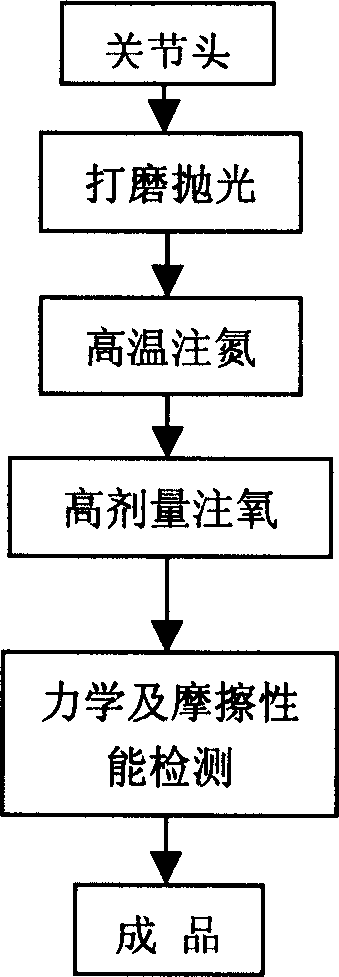

Image

Examples

Embodiment 1

[0018] The medical Ti-6Al-4V alloy was selected as the base material, and a multifunctional omnidirectional ion implanter (PII) was used to prepare the Ti-O-Ti-N gradient film. The preparation process was as follows: Step 1: Nitrogen ion implantation: The titanium alloy joint head is ground and polished to the surface roughness Ra 17 / cm 2 ;Injection target temperature: 600~700℃; Vacuum degree 5×10 -2 Pa; microwave power: 100w; pulse frequency: 400Hz; pulse width: 50μS; second step: oxygen ion implantation: re-inject oxygen ions into the sample after nitrogen injection, and the implantation process parameters are: implantation energy: 30~50Kev; implantation dose : 1~5×10 18 / cm 2 ;Injection target temperature: room temperature~100℃; vacuum degree 1.5×10 -1 Pa; microwave power: 100w; pulse frequency: 400Hz; pulse width: 50μS. Ti-O-Ti-N gradient membrane artificial joint can be obtained after two-step ion implantation.

example 2

[0020] The medical Ti-6Al-4V alloy was selected as the base material, and a multifunctional omnidirectional ion implanter (PII) was used to prepare the Ti-O-Ti-N gradient film. The preparation process was as follows: Step 1: Nitrogen ion implantation: The titanium alloy joint head is ground and polished to the surface roughness Ra 17 / cm 2 ;Injection target temperature: 600~700℃; Vacuum degree 5×10 -2 Pa; microwave power: 100w; pulse frequency: 400Hz; pulse width: 50μS; second step: oxygen ion implantation: re-inject oxygen ions into the sample after nitrogen injection, and the implantation process parameters are: implantation energy: 30~50Kev; implantation dose : 5~10×10 18 / cm 2 ;Injection target temperature: room temperature~100℃; vacuum degree 1.5×10 -1 Pa; microwave power: 100w; pulse frequency: 400Hz; pulse width: 50μS. Ti-O-Ti-N gradient membrane artificial joint can be obtained after two-step ion implantation.

example 3

[0022] The medical Ti-6Al-4V alloy was selected as the base material, and a multifunctional omnidirectional ion implanter (PII) was used to prepare the Ti-O-Ti-N gradient film. The preparation process was as follows: Step 1: Nitrogen ion implantation: The titanium alloy joint head is ground and polished to the surface roughness Ra 17 / cm 2 ;Injection target temperature: 600~700℃; Vacuum degree 5×10 -2 Pa; microwave power: 100w; pulse frequency: 400Hz; pulse width: 50μS; second step: oxygen ion implantation: re-inject oxygen ions into the sample after nitrogen injection, and the implantation process parameters are: implantation energy: 30~50Kev; implantation dose : 1~5×10 18 / cm 2 ;Injection target temperature: 200~300℃; Vacuum degree 2.5×10 -1 Pa; microwave power: 100w; pulse frequency: 400Hz; pulse width: 25μS. Ti-O-Ti-N gradient membrane artificial joint can be obtained after two-step ion implantation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com