Probe grinding machine of wheel speed sensor

A wheel speed sensor and grinding machine technology, applied in grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of difficult control of product accuracy, high labor intensity of workers, and product scrapping, so as to reduce product scrapping rate, The effect of high work efficiency and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

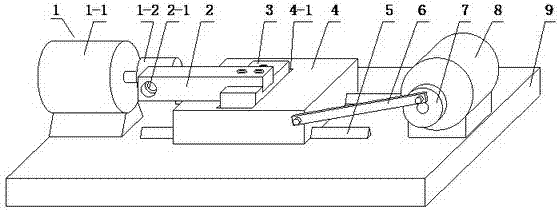

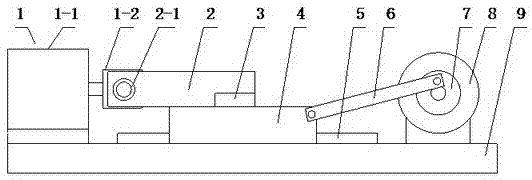

[0022] Embodiment 1: refer to Figure 1~7 . A probe grinding machine for a wheel speed sensor, the probe grinding machine includes a grinder 1, a frame 9, a transverse guide rail 5, a supporting plate 4, a probe frame, a connecting rod 6, an eccentric wheel 7 and a motor 8, and the upper end of the frame 9 is provided with a transverse guide rail 5. There is a guide groove 4-2 under the supporting plate 4, and the supporting plate 4 cooperates with the transverse guide rail 5 through the guide groove 4-2, and the supporting plate 4 can slide left and right along the transverse guide rail 5, and the grinder 1 is located on the supporting plate 4 On the left side, the motor 8 is positioned at the right side of the supporting plate 4, the power output direction of the motor 8 is perpendicular to the transverse guide rail 5, the front end of the power output shaft of the motor 8 is connected with the eccentric wheel 7, and the two ends of the connecting rod 6 are connected with th...

Embodiment 2

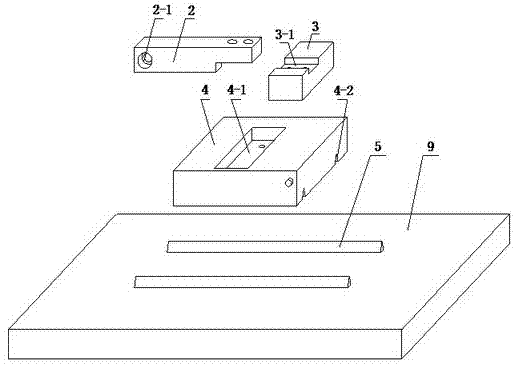

[0023] Embodiment 2: refer to figure 1 , 2 , 3, 6 and 7. The probe frame is composed of an adjustment block 3 and a probe matching block 2. The upper end of the supporting plate 4 is provided with an adjustment groove 4-1. The adjustment block 3 is located in the adjustment groove 4-1 and is fixed to each other by bolts. The right end of the probe matching block 2 is connected to the adjustment The block 3 is connected, and its left end is provided with a matching hole 2-1 for installing the sensor probe 11.

Embodiment 3

[0024] Embodiment 3: refer to Figure 4 and 5 . On the basis of Embodiment 1 and Embodiment 2, the upper end of the supporting plate 4 is provided with a longitudinal guide rail 10, the lower end of the adjustment block 3 is provided with a guide groove I3-2 and the guide groove I3-2 cooperates with the longitudinal guide rail 10, and the adjustment block 3 3. The slide can be adjusted back and forth along the longitudinal guide rail 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com