Lamp head tin scolding contact qualified rate detecting device and method

A detection device and bulb head technology, which is applied in the direction of measuring devices, optical devices, and material analysis through optical means, can solve the problems of poor continuous concentration of manual detection, short duration of manual detection, and insufficient selection of defective products in time. Achieve repairs that are conducive to maintenance, save raw materials for production, and improve the overall pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

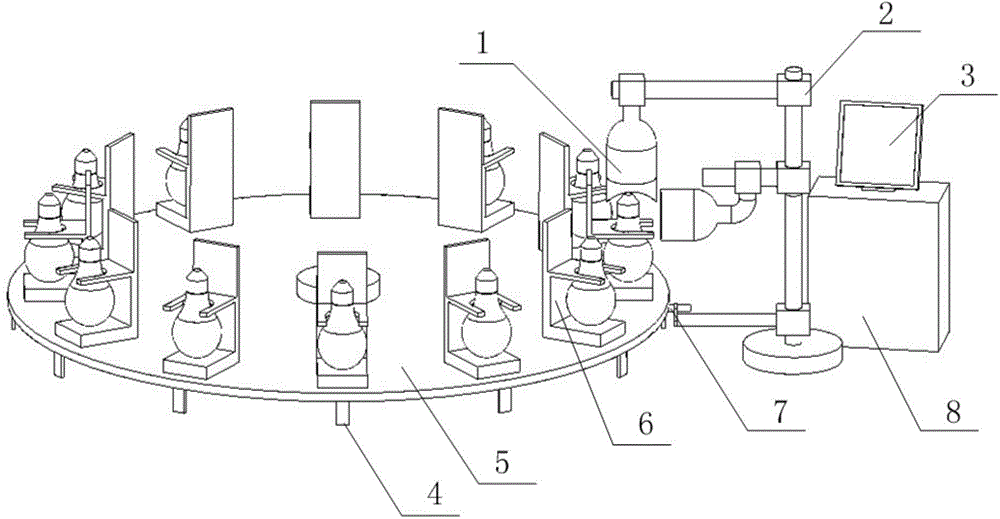

[0034] Such as figure 1 As shown, a light bulb head solder contact qualified rate detection device includes a turntable 5, a lamp position clamp 6, a turntable stop baffle position detector 7, a base bracket 2, a video image acquisition device 1, and an image processing subsystem 8 and display 3.

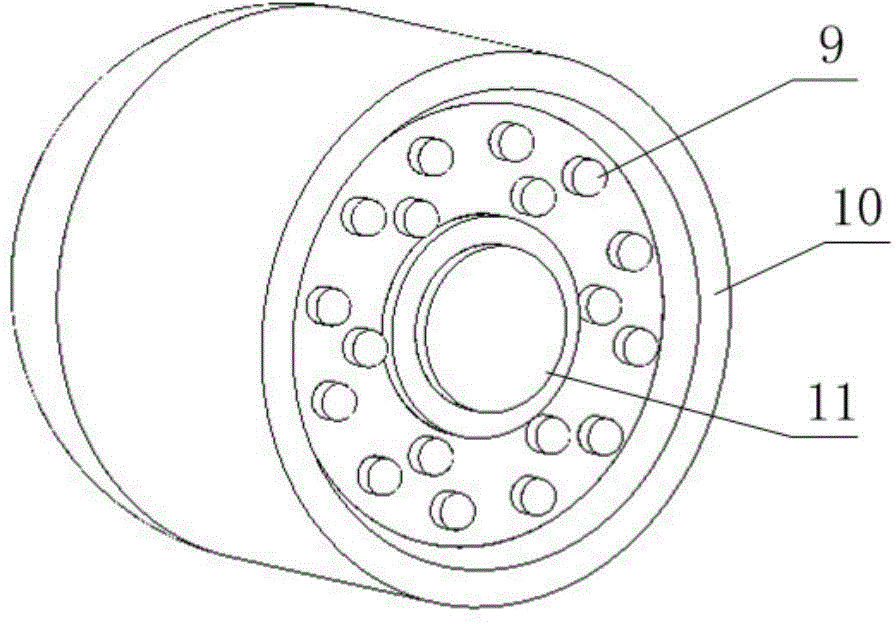

[0035] The base support 2 is a movable support, and the upper movable branch part, the middle movable branch part and the lower movable branch part are installed respectively, and can be adjusted conveniently according to the site environment, and can be locked in an ideal position. Two video image acquisition devices 1 are respectively installed on the upper part and the middle branch part of the bracket, wherein the video image acquisition device 1 includes an auxiliary light source 9, a lampshade 10 and a camera 11. In the same plane, the two cameras form a 90° right angle form of installation. The lower branch part of the base bracket 2 is equipped with a turntable stop baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com