Turning tool capable of achieving rapid clamping and rapid clamping method using same

A clamping and fast technology, used in clamping, positioning devices, manufacturing tools, etc., can solve the problems of insufficient strength of thin-walled parts, deformation and displacement of parts, affecting the quality of parts, etc., to break through the bottleneck of mass production and achieve mass production. Processing, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

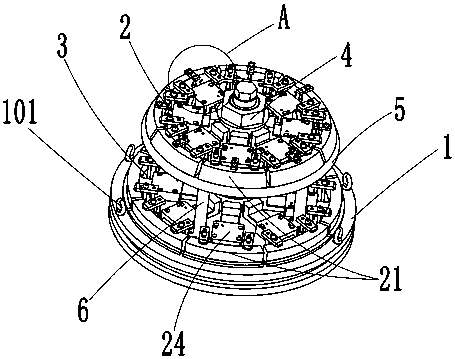

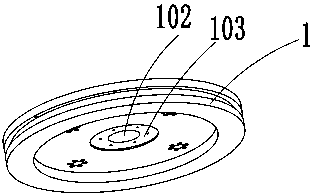

[0048]The quick clamping turning tool of the present invention comprises a base 1 with a circular structure, and a lower positioning device 3 and an upper positioning device 2 installed on the base 1 sequentially from bottom to top, and also includes a driving device 4, and the upper positioning device 2 and the lower positioning device The positioning device 3 is composed of several support blocks 21, and the support blocks 21 are arranged alternately to form a circular support for the part 7. The outer wall of each support block 21 is provided with a fitting surface 2112 matching the inner wall of the part 7, so The driving device 4 can drive the supporting block 21 in the upper positioning device 2 to move synchronously, and can drive the supporting block 21 in the lower positioning device 3 to move synchronously.

[0049] Specifically, several of the supporting blocks 21 include several first supporting blocks 211 and several second supporting blocks 212, several of the fir...

Embodiment 2

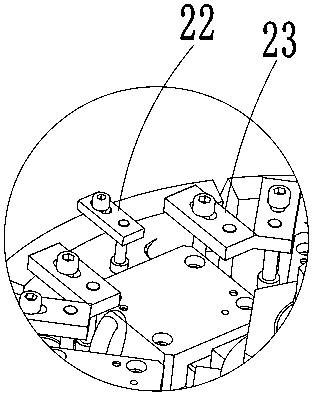

[0060] In this embodiment, the difference from Embodiment 1 is that the second pressing device 23 for pressing the support block 21 is respectively provided on the mounting plate 5 and the base 1, and the eight first pressing devices 23 are used to compress the supporting blocks 21. A support block 211 is pressed onto the mounting plate 5, and eight second support blocks 212 are pressed onto the base 1, which is conducive to processing the fitting surface 2112 of the support block 21 during the processing stage of the tooling, so that when the tooling is used The bonding surface 2112 of the support block 21 is better bonded to the inner wall of the component 7 .

Embodiment 3

[0062] The present invention also provides a method for fast clamping, using the fast clamping turning tool as described in any one of embodiment 1 or 2, the steps are as follows:

[0063] A. Install the base 1 on the processing table;

[0064] B. Adjust the compression nut 403 and the second screw rod 4041 so that the first expansion core 402 and the second expansion core 404 are in a free state;

[0065] C. Install part 7 from above the tooling;

[0066] D. Adjust the second screw 4041 so that the second expansion core 404 goes down, so that the second support block 212 tightens the inner wall of the lower section 702 of the part 7;

[0067] E. Adjust the compression nut 403 so that the first expansion core 402 goes down, so that the first support block 211 tightens the inner wall of the upper section 701 of the part 7;

[0068] F. Turn the pressing plate on the first pressing device 22 so that the height of the pressing plate matches the part 7, and then turn the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com