Integrated microfluidic chip interface, interface mould, and interface manufacturing and using methods

A microfluidic chip, chip technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of microchannel blockage, adhesive infiltration, etc., achieve good sealing effect, and achieve the effect of batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

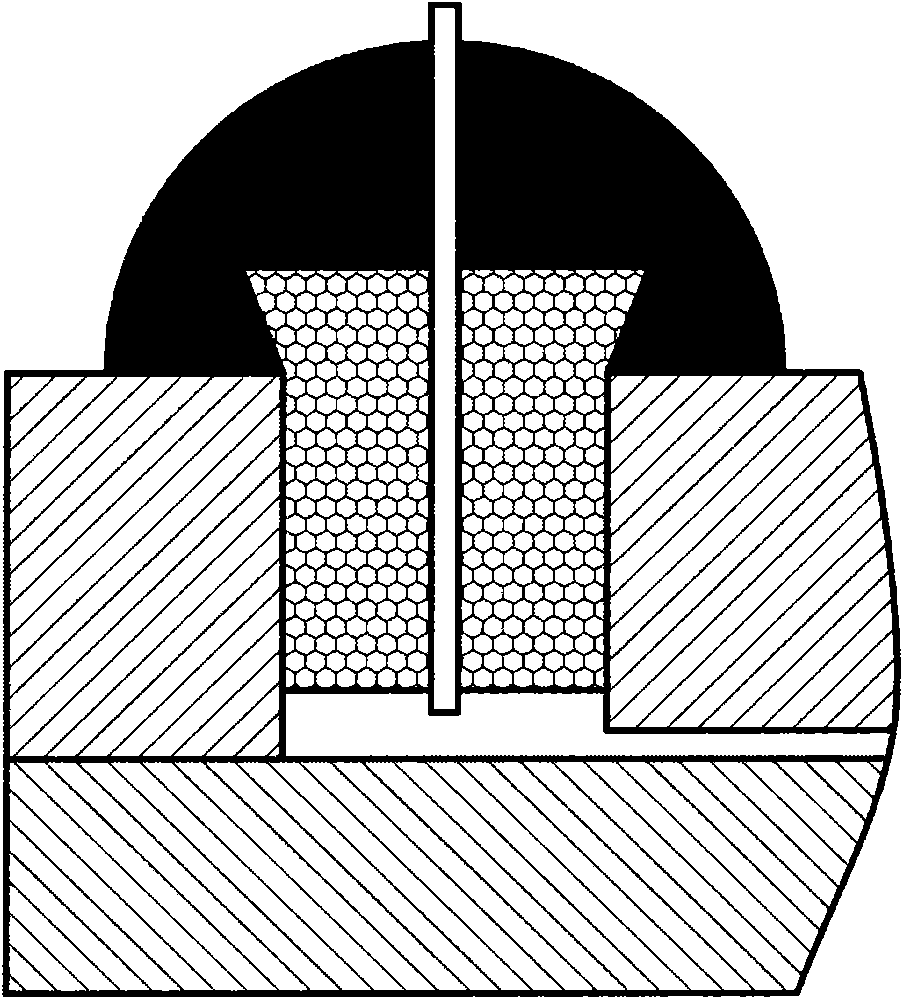

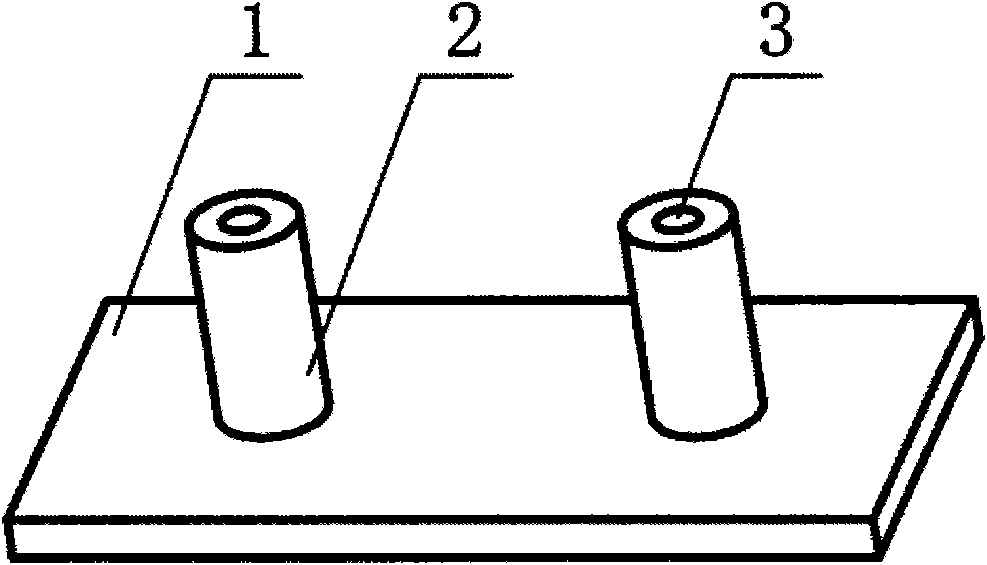

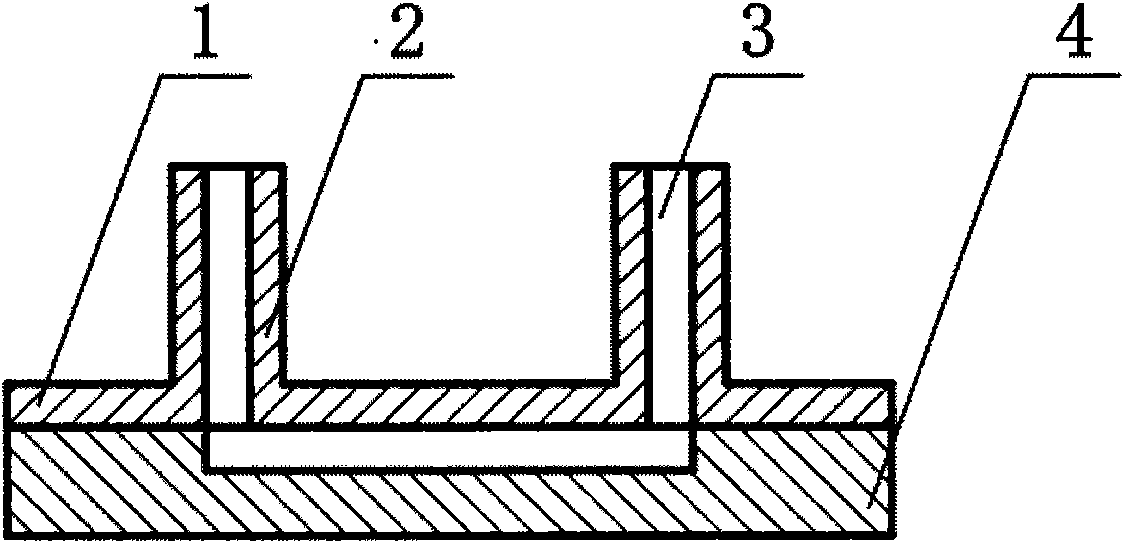

[0042] refer to figure 2 , image 3 , this embodiment provides a two-port integrated microfluidic chip interface made of PDMS, including a horizontal substrate 1 sealed on the microfluidic chip 4 and two bosses 2 on the horizontal substrate 1; There is a connecting pipe 3 inside the boss 2, and the connecting pipe 3 connects the microchannel on the microfluidic chip 4 with the outside world. Among them, the dimensions of the horizontal base 1 are: length 40mm, width 20mm, thickness 2mm; boss 2 is a round tube with an outer diameter of 5 mm and a height of 6 mm; the inner diameter of the connecting pipe 3 is 2 mm.

[0043] refer to Figure 4 , the integrated microfluidic chip interface mold material used in the present embodiment is PMMA, including the bottom plate 17 with the male mold microcolumn connecting the pipeline, the female mold orifice plate 9 of the boss and the horizontal base cofferdam 6; There is the base plate 17 of connecting pipe male mold microcolumn to b...

specific Embodiment 2

[0053] refer to Figure 7 , Figure 8 , this embodiment provides a four-port integrated microfluidic chip interface made of PDMS, including a horizontal substrate 1 sealed on the microfluidic chip 4 and four bosses 2 on the horizontal substrate 1; There is a connecting pipe 3 inside the boss 2, and the connecting pipe 3 connects the microchannel on the microfluidic chip 4 with the outside world. Among them, the size of the horizontal base 1 is: length 90mm, width 40mm, thickness 3mm; boss 2 is a round tube with an outer diameter of 6 mm and a height of 8 mm; the inner diameter of the connecting pipe 3 is 3 mm.

[0054] refer to Figure 9 , the integrated microfluidic chip interface mold material used in this embodiment is PC, which successively includes a bottom plate 13, a male die microcolumn fixed orifice plate 12 for connecting pipes, a female die orifice plate 9 for a boss, and a horizontal base cofferdam 6; The connecting pipe male mold microcolumn fixed orifice 12 is...

specific Embodiment 3

[0064] refer to Figure 12 , Figure 13 , this embodiment provides a multi-port integrated microfluidic chip interface made of PDMS, including a horizontal substrate 1 sealed on the microfluidic chip 4 and 19 bosses 2 located on the horizontal substrate 1; There is a connecting pipe 3 inside the boss 2, and the connecting pipe 3 connects the microchannel on the microfluidic chip 4 with the outside world. Wherein, the horizontal substrate 1 is a disk with a diameter of 100 mm and a thickness of 3 mm; the boss 2 is a circular tube with an outer diameter of 6 mm and a height of 6 mm; the inner diameter of the connecting pipe 3 is 4 mm.

[0065] refer to Figure 14 , the material of the integrated microfluidic chip interface mold used in this embodiment is nickel, which successively includes a bottom plate 13, a fixed orifice plate 12 for connecting pipe male mold microcolumns, a boss female mold orifice plate 9 and a horizontal base cofferdam 6; The connecting pipe male mold m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com