Grinding liquid for processing surface curvature radiuses of sapphires and preparation method

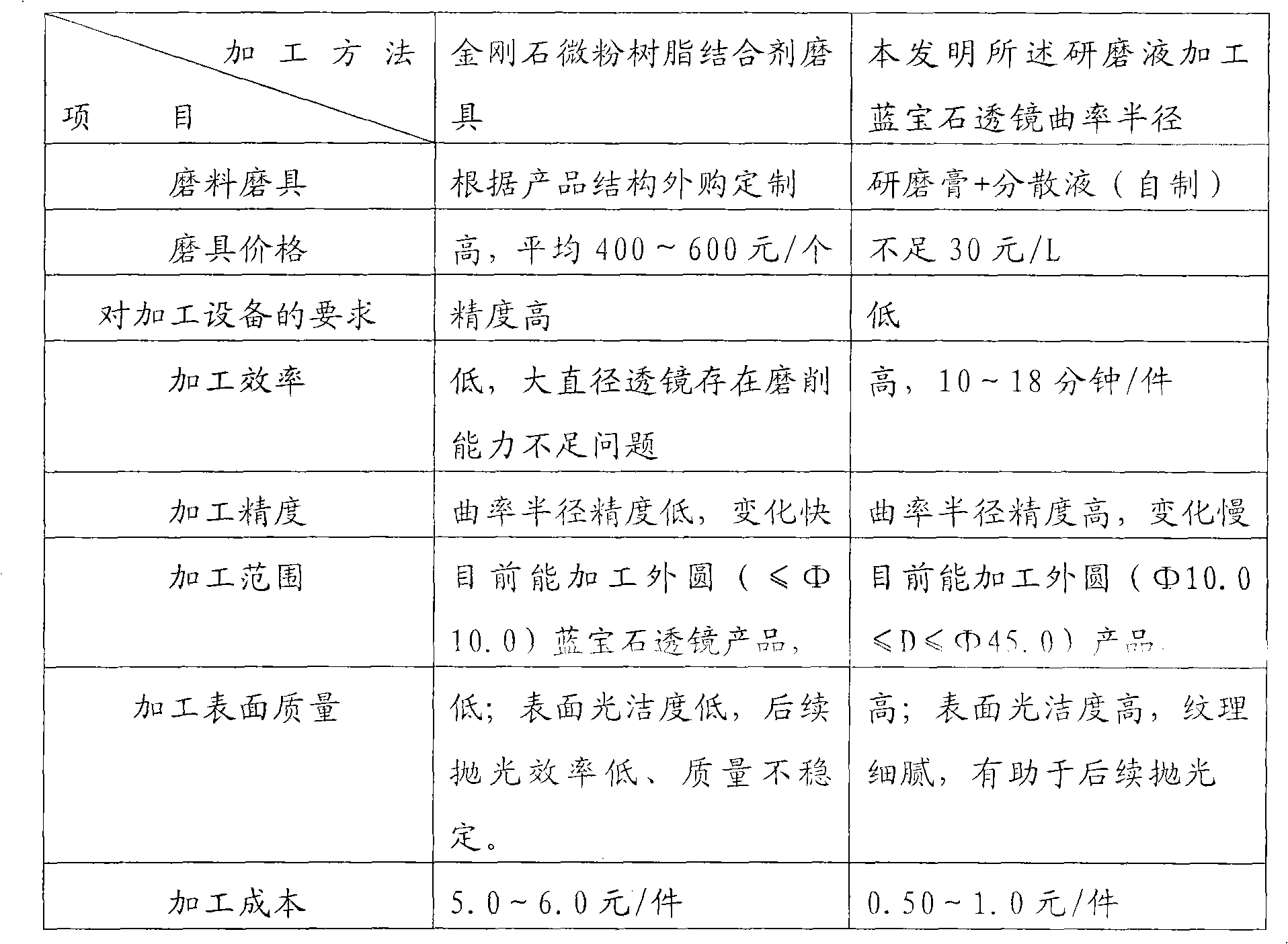

A technology of surface curvature and grinding fluid, applied in the field of grinding fluid, can solve the problems of sapphire lens curved surface profile exceeding poor, prolonging grinding time, lens center bulge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

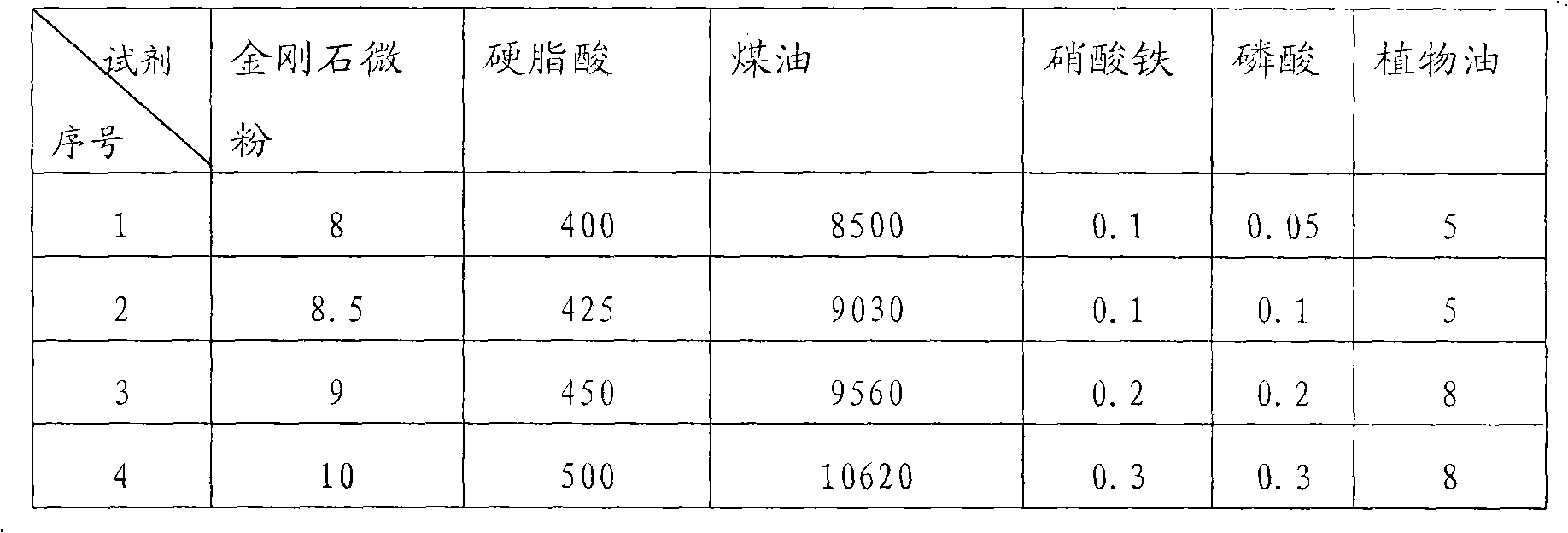

[0040] (1) Weighing: Put a layer of clean white paper on the electronic balance, take out the diamond powder with a medicine spoon and place it on the white paper, and weigh 8-10g.

[0041] (2) Baking: Put the white paper containing the diamond powder together on a heating platform, bake at a temperature of 100° C. for 120 minutes, and then take it out and cool it in the air for 30 minutes.

[0042] (3) Grinding: Grinding in a medium-sized agate mortar, grinding and dispersing the hardened diamond powder blocks, each time no more than 2 grams, and the time is no less than 30 minutes.

[0043] (4) Ultrasonic dispersion: put the ground diamond powder in a beaker, add 20-50 g of kerosene, and ultrasonically disperse for 60 minutes.

[0044] (5) Preparation of liquid: Pour 400-500 g of stearic acid into the final liquid, and stir to mix.

[0045] (6) Boiling and condensation: boil the prepared liquid on a heating platform at 100° C., put it into cold water to cool until condensed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com