Thermal creeping forming method for machining of titanium alloy cover of weight reduction tank

A technology of mechanical processing and weight-reducing grooves, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as uneven corrosion edges, environmental pollution, and poor fatigue stability, so as to reduce stress concentration and improve Dimensional control accuracy and effects of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A thermal creep forming method for machining a titanium alloy skin of a weight reduction groove, comprising the following steps:

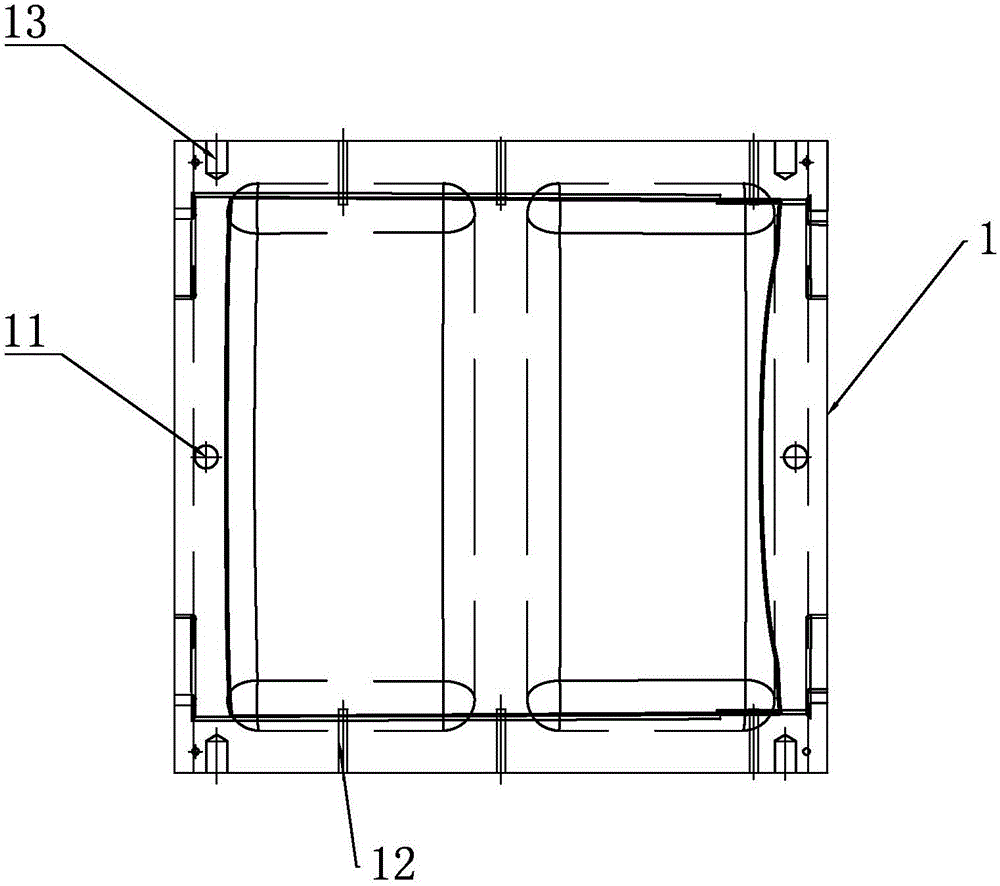

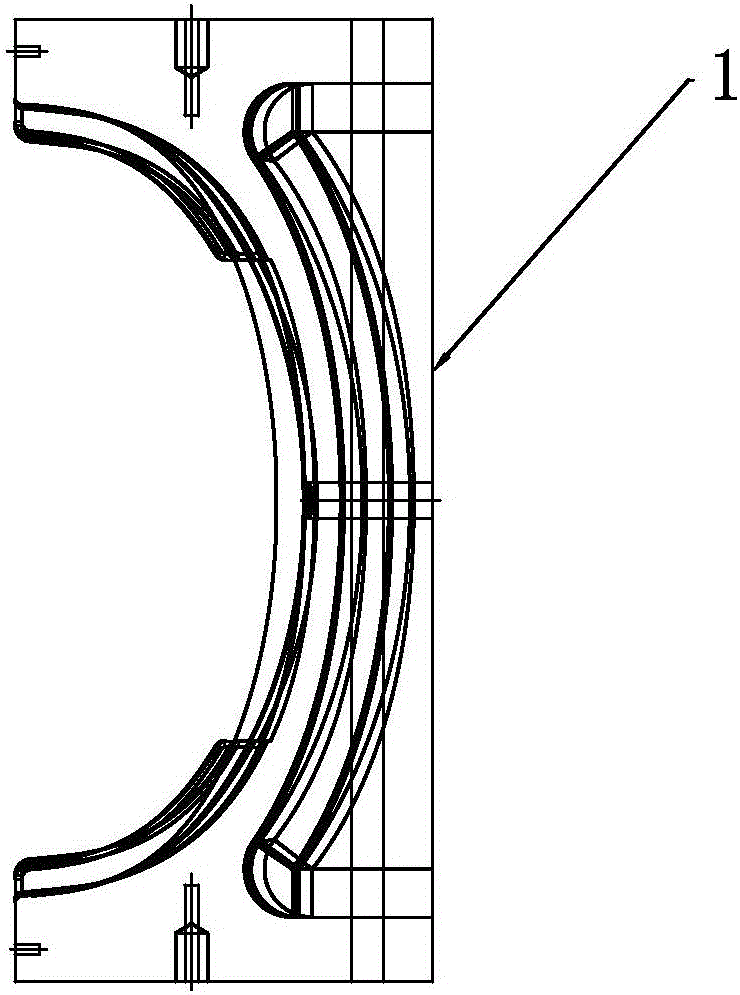

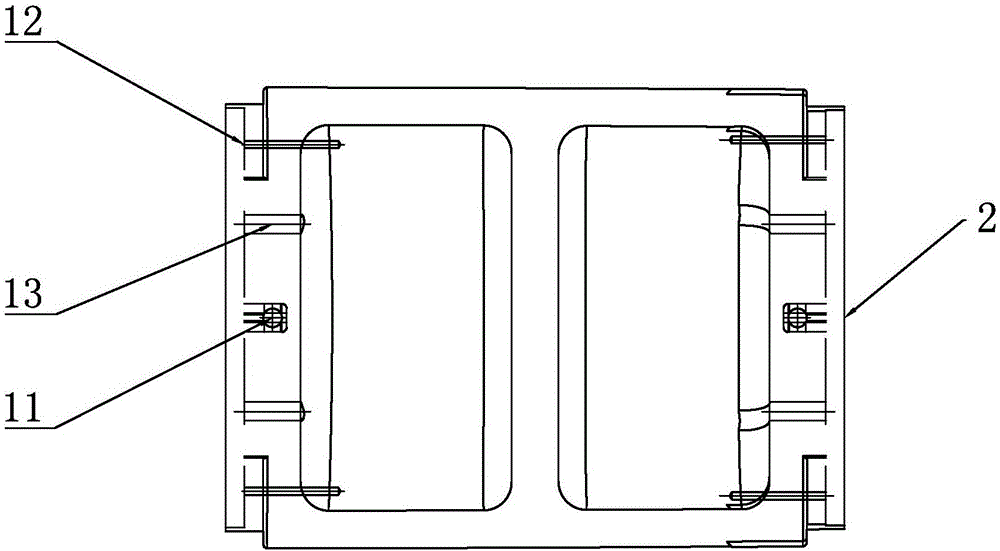

[0046] (1) Forming mold making

[0047] During thermal creep forming of titanium alloy skin, it is necessary to use a mold to control the shape of the part. The mold includes a punch and a die. The cavity surfaces of the punch and die are consistent with the appearance of the thermally creep-formed skin. Positioning holes, temperature measuring holes, and hoisting holes are processed on the die and punch respectively;

[0048] (2) Blank processing

[0049] Calculate the theoretical size of the unfolded blank according to the product size of the skin, add a 5mm process allowance, use wire cutting to process the outer contour of the blank according to the size requirements, and use a milling machine to pre-process weight-reducing grooves of corresponding sizes on the blank. The size of the billet is calculated using the theory of constant vo...

Embodiment 2

[0064] A thermal creep forming method for machining a titanium alloy skin of a weight reduction groove, comprising the following steps:

[0065] (1) Forming mold making

[0066] During thermal creep forming of titanium alloy skin, it is necessary to use a mold to control the shape of the part. The mold includes a punch and a die. The cavity surfaces of the punch and die are consistent with the appearance of the thermally creep-formed skin. Positioning holes, temperature measuring holes, and hoisting holes are processed on the die and punch respectively;

[0067] (2) Blank processing

[0068] Calculate the theoretical size of the unfolded blank according to the product size of the skin, add 8mm process allowance, process the outer contour of the blank by wire cutting according to the size requirements, and pre-process weight-reducing grooves and weight-reducing grooves of corresponding sizes on the blank by using a milling machine The size of the billet is calculated using th...

Embodiment 3

[0083] A thermal creep forming method for machining a titanium alloy skin of a weight reduction groove, comprising the following steps:

[0084] (1) Forming mold making

[0085] During thermal creep forming of titanium alloy skin, it is necessary to use a mold to control the shape of the part. The mold includes a punch and a die. The cavity surfaces of the punch and die are consistent with the appearance of the thermally creep-formed skin. Positioning holes, temperature measuring holes, and hoisting holes are processed on the die and punch respectively;

[0086] (2) Blank processing

[0087] Calculate the theoretical size of the blank after unfolding according to the product size of the skin, add 10mm of process allowance, use wire cutting to process the outer contour of the blank according to the size requirements, and use a milling machine to pre-process weight-reducing grooves and weight-reducing grooves of corresponding sizes on the blank The size of the billet is calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com