A kind of preparation method of micro flow porous metal material

A porous metal, micro-flow technology, applied in the field of porous material preparation, can solve problems such as difficulty in meeting and low dimensional accuracy control, and achieve the effects of good processing performance, safe operation, and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

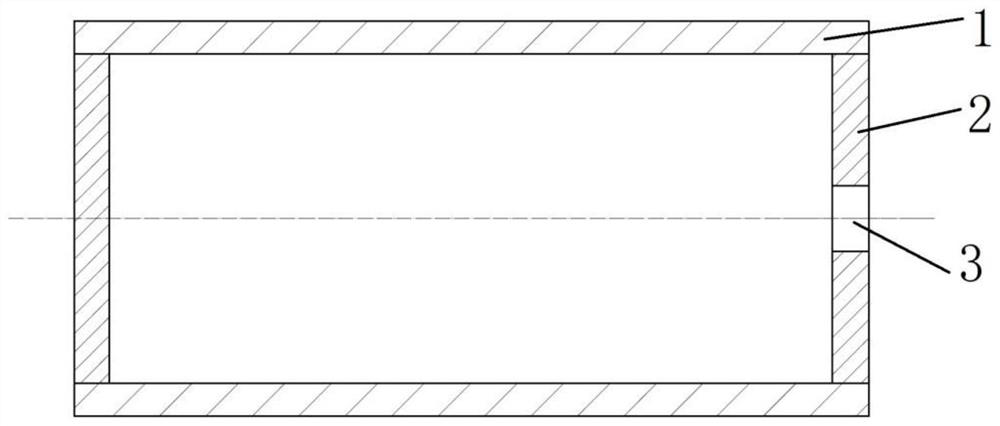

[0034] Step 1: Load the -500 mesh titanium powder into the mold, and press the cold isostatic pressing method at 100 MPa to obtain a porous tube blank. The heating rate is increased to 1050°C for 2 hours to obtain a porous titanium tube body; the pore diameter of the porous titanium tube body is not more than 10 μm;

[0035] Step 2: According to the size of the target product micro-flow porous titanium material, the surface of the porous metal tube body obtained in the step 1 is machined, the rotational speed used for machining is 280 rpm, and the feed rate is 0.5 mm to obtain the length of It is a porous titanium base tube with an outer diameter of 45mm±1mm and an outer diameter of 47.5mm;

[0036] Step 3: Process the dense titanium material to a size matching the porous titanium base tube obtained in the second step to obtain a dense titanium end cap, and select the dense titanium end cap to punch holes to a diameter of...

Embodiment 2

[0039] This embodiment includes the following steps:

[0040] Step 1. Put -500 mesh titanium powder into the mold, and press the cold isostatic pressing method at 120 MPa to obtain a porous tube blank. The heating rate is increased to 1100°C for 2 hours to obtain a porous titanium tube body; the pore diameter of the porous titanium tube body is not more than 10 μm;

[0041] Step 2: According to the size of the target product micro-flow porous titanium material, the surface of the porous metal tube body obtained in the step 1 is machined, the rotational speed used for machining is 280 rpm, and the feed rate is 0.5 mm to obtain the length of Porous titanium base tube with an outer diameter of 50mm±1mm and an outer diameter of 45mm;

[0042] Step 3: Process the dense titanium material to a size matching the porous titanium base tube obtained in the second step to obtain a dense titanium end cap, and select the dense titanium end cap to punch holes to a diameter of 10 mm to obtai...

Embodiment 3

[0045] This embodiment includes the following steps:

[0046] Step 1: Load the -500 mesh titanium powder into the mold, and press the cold isostatic pressing method at 150 MPa to obtain a porous tube blank. The heating rate is increased to 900°C for 1 hour to obtain a porous titanium tube body; the pore diameter of the porous titanium tube body is not more than 10 μm;

[0047] Step 2: According to the size of the target product micro-flow porous metal material, the surface of the porous metal tube body obtained in the step 1 is machined, and the rotational speed used for machining is 280 rpm, and the feed rate is 0.5 mm to obtain a length of It is a porous titanium base tube with an outer diameter of 45mm±1mm and an outer diameter of 44.5mm;

[0048] Step 3: Process the dense titanium material to a size matching the porous titanium base tube obtained in the second step to obtain a dense titanium end cap, and select the dense titanium end cap to punch holes to a diameter of 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com