Method for preparing lithium iron phosphate material by raw material solid phase dry grinding

A technology of lithium iron phosphate and raw materials, which is applied in the field of lithium battery material preparation, can solve the problems of uneven physical and chemical composition of products, irregular shape of precursors, wide particle size distribution, etc., and achieve excellent quality stability and consistency , the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

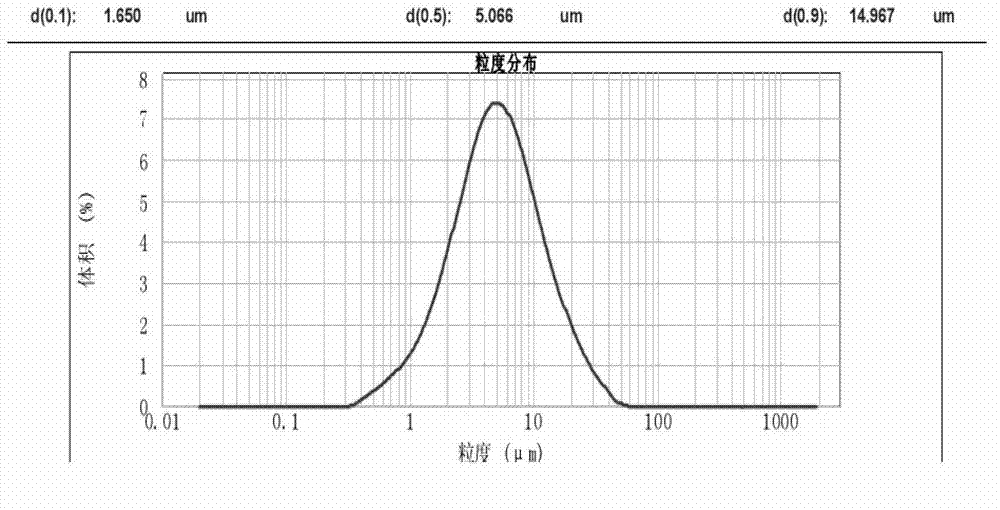

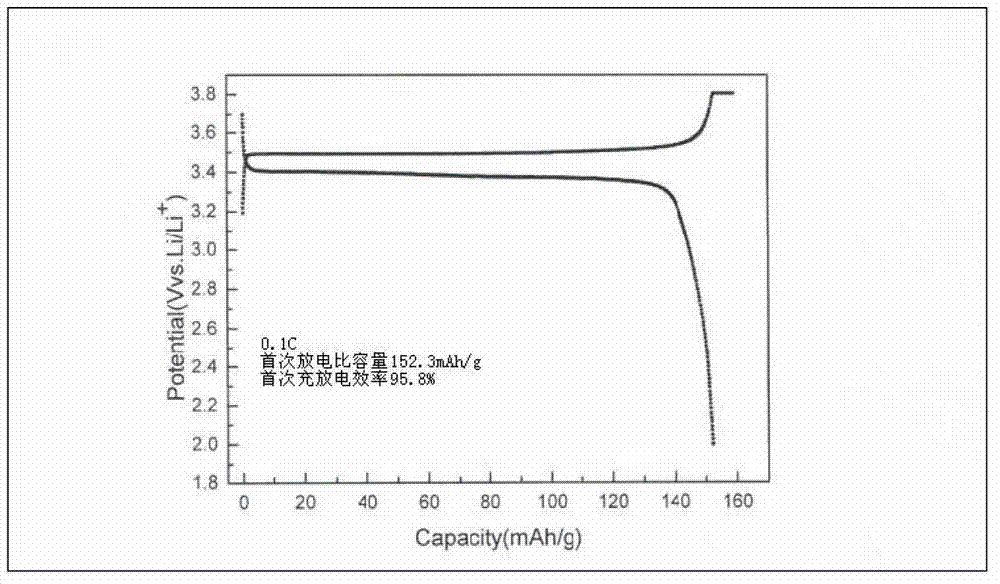

Embodiment 1

[0020] Using lithium dihydrogen phosphate and ferrous oxalate with a molar ratio of 1:1 as raw materials, the lithium dihydrogen phosphate is pulverized through disc milling and jet pulverization technology, and the pulverization pressure is adjusted to 10KG, so that the particle size and the ferrous oxalate are 10kg. The medium particle size is the same, both are less than 5um, put the two raw materials into a ball mill, the ratio of raw materials and zirconium balls is 1:5, ball mill for 2 hours, put in a tube furnace, at room temperature, pass nitrogen as a protective gas , the heating rate is 5 °C / min, the temperature is raised to 350 °C, and the temperature is kept for 10 hours. After taking it out, it is mixed with sucrose. The weight of the sucrose is 5% of the total amount of raw materials added. At room temperature, nitrogen was introduced as a protective gas, the heating rate was 5 °C / min, the temperature was raised to 850 °C, and the temperature was kept for 22 hours...

Embodiment 2

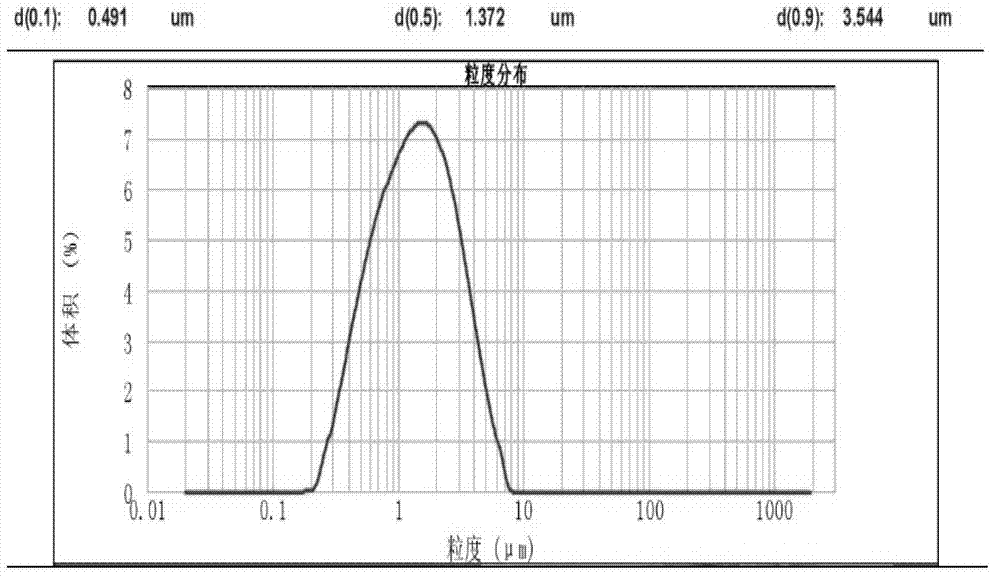

[0022] Using lithium dihydrogen phosphate and ferrous oxalate with a molar ratio of 1:1 as raw materials, the median particle size of lithium dihydrogen phosphate is 408.5um, and the median particle size of ferrous oxalate is 5um. Put it in a ball mill, the ratio of raw materials and zirconium balls is 1:5, ball milled for 2 hours, placed in a tube furnace, at room temperature, nitrogen is introduced as a protective gas, the heating rate is 5 °C / min, and the temperature is raised to 350 °C , kept for 10h, mixed with sucrose after taking out, the weight of sucrose was 5% of the total amount of raw materials added, put it in a ball mill for 2 hours, and then placed it in a tube furnace, and at room temperature, nitrogen was introduced as protective gas, The heating rate was 5 °C / min, the temperature was raised to 850 °C, and the temperature was kept for 22 hours. After taking out, the particle size was 1um, and the prepared lithium iron phosphate cathode material had an internal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Medium particle size | aaaaa | aaaaa |

| Medium particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com