Preparation method of multi-element metal phosphorus-doped electrocatalyst based on binary LDH derivation

An electrocatalyst, multi-metal technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of limited research, high overpotential, limited non-precious metal-based materials, etc. Excellent performance, good electrical conductivity, the effect of improving material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of CoMo-LDH-CF:

[0026] (a) Mix 20 mL of ethylene glycol and 5 mL of deionized water to obtain a mixed solvent;

[0027] (b) 40mg CoCl 2 ·6H 2 O, 20mg MoCl 2 Dissolve 120mg urea in the mixed solvent of step (a) and stir evenly to obtain solution A;

[0028] (c) Pour solution A into the reaction kettle, then add 1cm*4cm hydrophilic carbon cloth, and react in an oven at 180℃ for 15h to obtain CoMo-LDH-CF-1;

[0029] (2) Preparation of CoMo-P-CF:

[0030] Place the CoMo-LDH-CF-1 material obtained in step (1) in a tube furnace, and place a magnetic boat containing 100 mg of sodium hydrogen hypophosphite upstream of it, and set it at a temperature of 6°C / min in a nitrogen atmosphere. The temperature rise rate is to raise the reactant to 400° C. and keep it for 3 hours, and then cool to room temperature to obtain the metal phosphorus-doped electrocatalyst CoMo-P-CF-1 derived from the binary LDH containing Co and Mo bimetal.

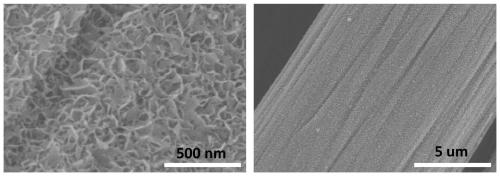

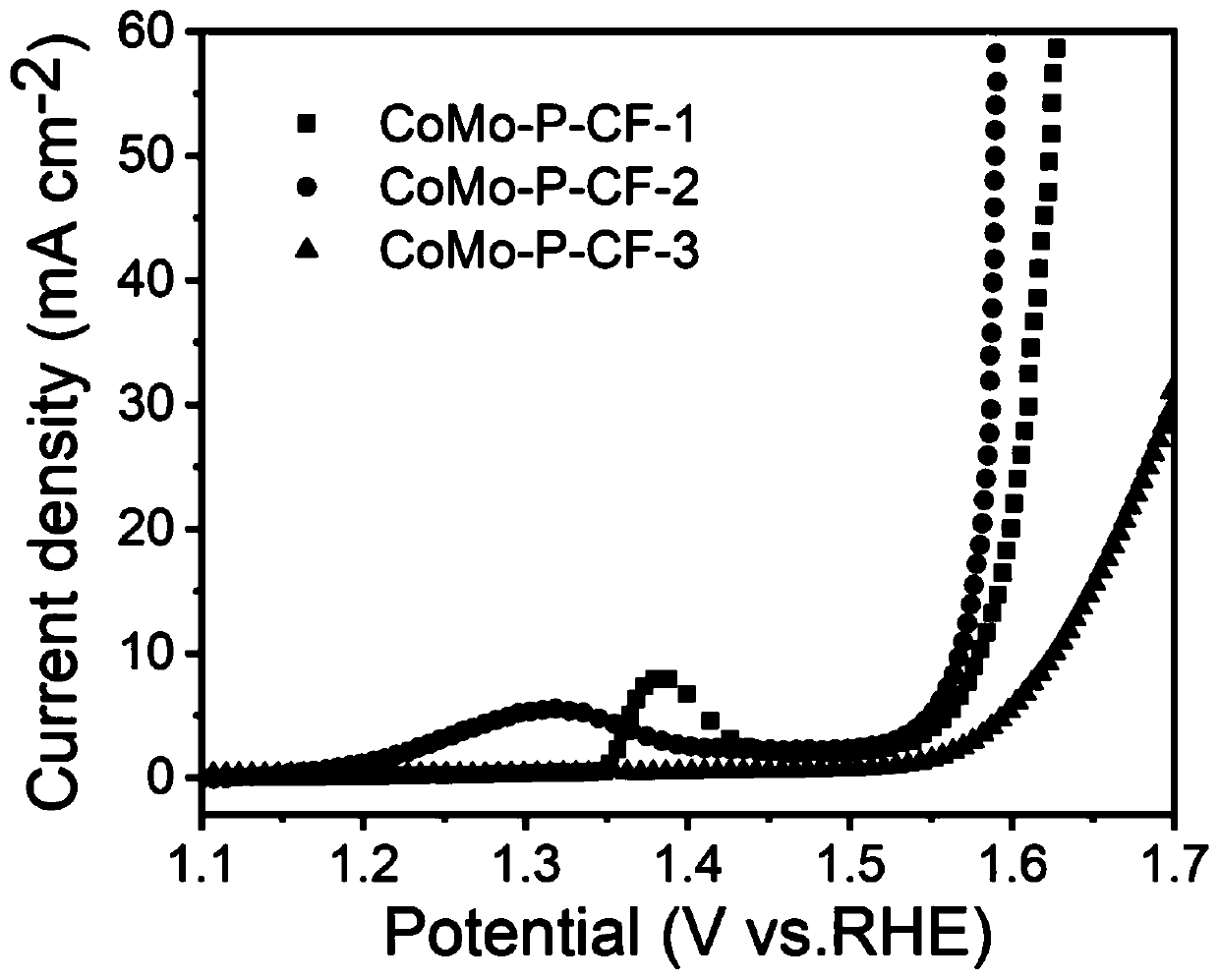

[0031] Combine figure 1 , 2 It can be seen ...

Embodiment 2

[0034] (1) Preparation of CoMo-LDH-CF:

[0035] (a) Mix 20 mL of ethylene glycol and 5 mL of deionized water to obtain a mixed solvent;

[0036] (b) Add 60mg CoCl 2 ·6H 2 O, 20mg MoCl 2 Dissolve 120mg urea in the mixed solvent of step (a) and stir evenly to obtain solution A;

[0037] (c) Pour solution A into the reaction kettle, then add 1cm*4cm hydrophilic carbon cloth, and react in an oven at 120°C for 15h to obtain CoMo-LDH-CF-2;

[0038] (2) Preparation of CoMo-P-CF:

[0039] Place the CoMo-LDH-CF-2 material obtained in step (1) in a tube furnace, and place a magnetic boat containing 100 mg of sodium hydrogen hypophosphite upstream of it, and place it in a nitrogen atmosphere at 6°C / min The temperature rise rate is to increase the temperature of the reactant to 400° C. and keep it for 3 hours, and then cool to room temperature to obtain a metal phosphorus-doped electrocatalyst CoMo-P-CF-2 derived from a binary LDH containing Co and Mo bimetal.

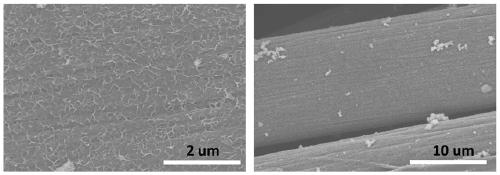

[0040] The CoMo-LDH-CF-2 material is...

Embodiment 3

[0042] (1) Preparation of CoMo-LDH-CF:

[0043] (a) Mix 20 mL of ethylene glycol and 5 mL of deionized water to obtain a mixed solvent;

[0044] (b) Add 80mg CoCl 2 ·6H 2 O, 20mg MoCl 2 Dissolve 120mg urea in the mixed solvent of step (a) and stir evenly to obtain solution A;

[0045] (c) Pour solution A into the reaction kettle, then add 1cm*4cm hydrophilic carbon cloth, and react in an oven at 180°C for 15h to obtain CoMo-LDH-CF-3;

[0046] (2) Preparation of CoMo-P-CF:

[0047] Place the CoMo-LDH-CF-3 material obtained in step (1) in a tube furnace, and place a magnetic boat containing 100 mg of sodium hydrogen hypophosphite upstream of it, and place it in a nitrogen atmosphere at 6°C / min The temperature increase rate is to increase the temperature of the reactant to 400° C. and keep it for 3 hours, and then cool to room temperature to obtain a metal phosphorus-doped electrocatalyst CoMo-P-CF-3 derived from a binary LDH containing Co and Mo bimetal.

[0048] The CoMo-LDH-CF-3 materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com