High-capacity three-body split winding type transformer

A split transformer, large capacity technology, applied in the field of transformers, can solve the problems of large footprint, large short-circuit axial instability, poor safety performance, etc., to improve safety and reliability, reduce footprint and reduce mechanical force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

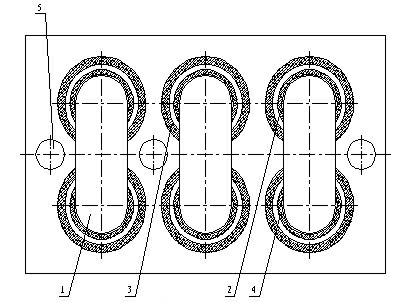

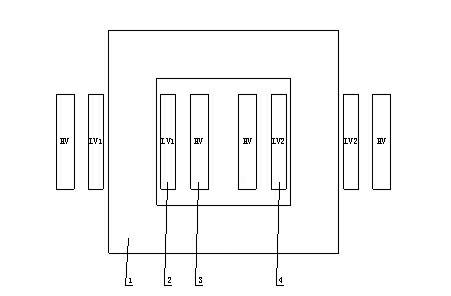

[0021] Embodiment one, with reference to the attached figure 1 . The three bodies are arranged in parallel along the short axis of the transformer. The iron core is a single-phase structure, each of which is a phase. There are two windings on each column. The order of the windings from the inside to the outside is: core—low voltage winding LV1— High-voltage winding HV, or core-low-voltage winding LV2-high-voltage winding HV. There is a single-phase no-load voltage regulating switch between the two columns of each body of the transformer, which is used for high-voltage no-load voltage regulation.

Embodiment 2

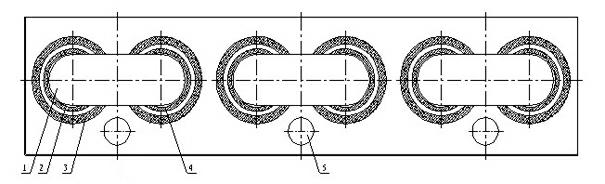

[0022] Embodiment two, referring to the attached figure 2 . The three bodies are arranged sequentially along the long axis of the transformer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com