Vertical soilless culture system pushed and pulled through single-circuit stepping motor

A technology of soilless cultivation and stepping motors, which is applied in the direction of soilless cultivation, cultivation, botany equipment and methods, etc., to achieve the effects of reducing space volume, improving stability and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

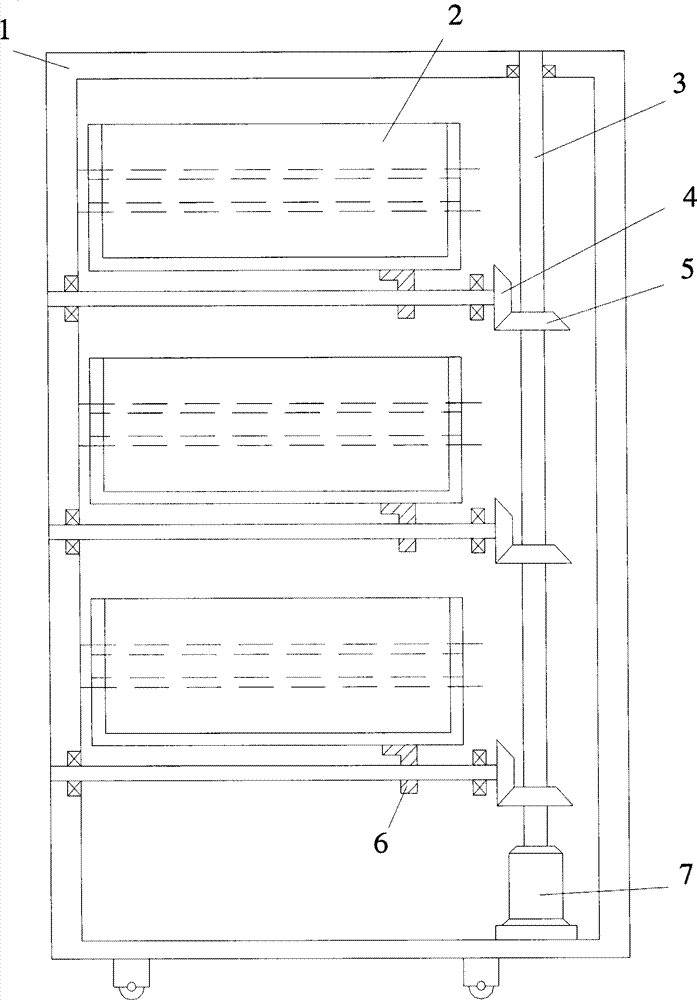

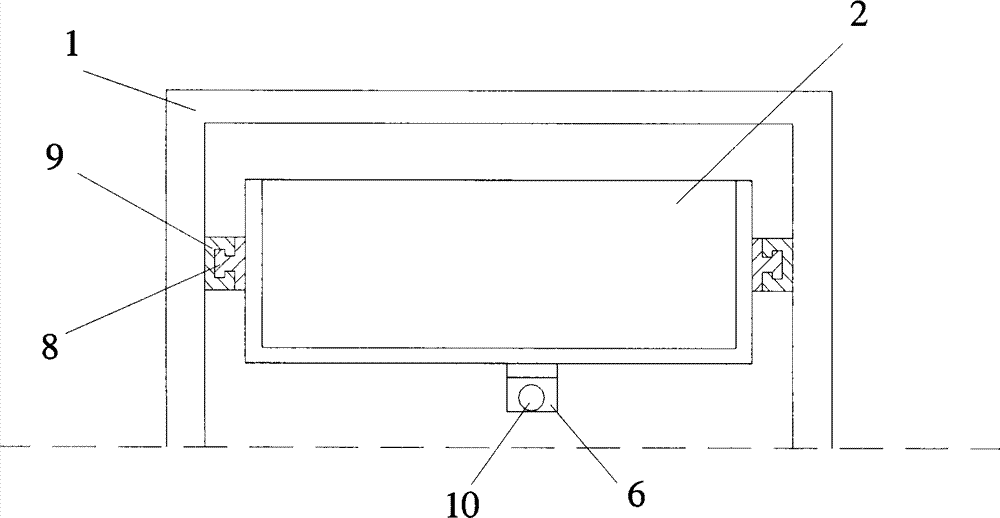

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] Such as figure 1 , 2 As shown, the soilless cultivation system of the present invention includes a vertical cabinet body 1, and a plurality of drawer-type boxes 2 for soilless cultivation are arranged in the cabinet body 1, and each drawer-type box body 2 is stacked in the cabinet body 1.

[0037] As an embodiment, each box body 2 of the present invention can be arranged in a bracket with an upper end open, the box body 2 and the bracket are in a split structure, and the box body 2 can be freely taken and placed in the bracket. The bracket and the box body 2 jointly form a soilless cultivation unit.

[0038] The soilless cultivation box 2 has a built-in grid-shaped plant cage, and the cultivated crops are respectively arranged in the grid of the cage to keep the upward and upright growth posture of the plants.

[0039] The size of the grid can be determined w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com