Patents

Literature

64results about How to "Reduce mechanical force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

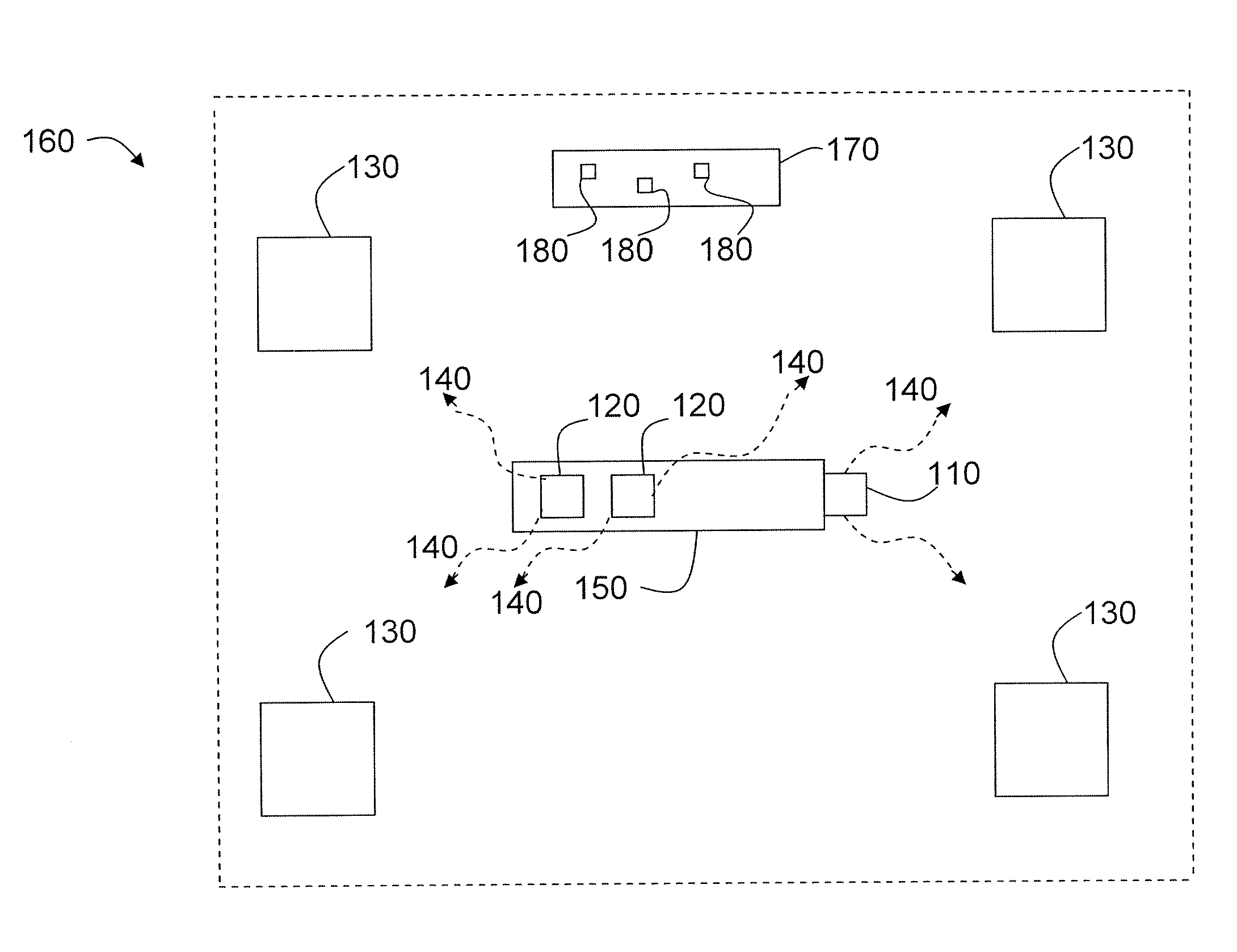

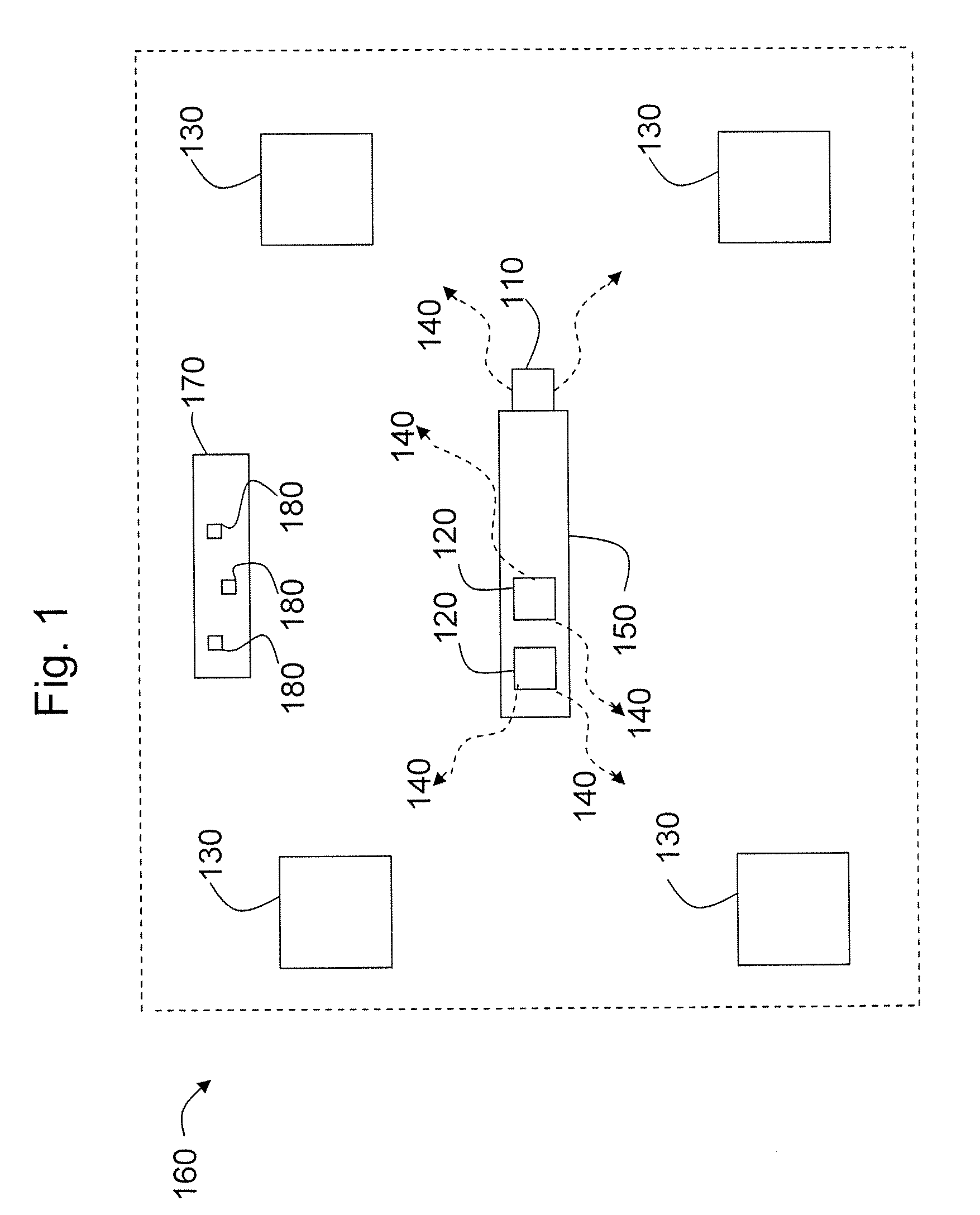

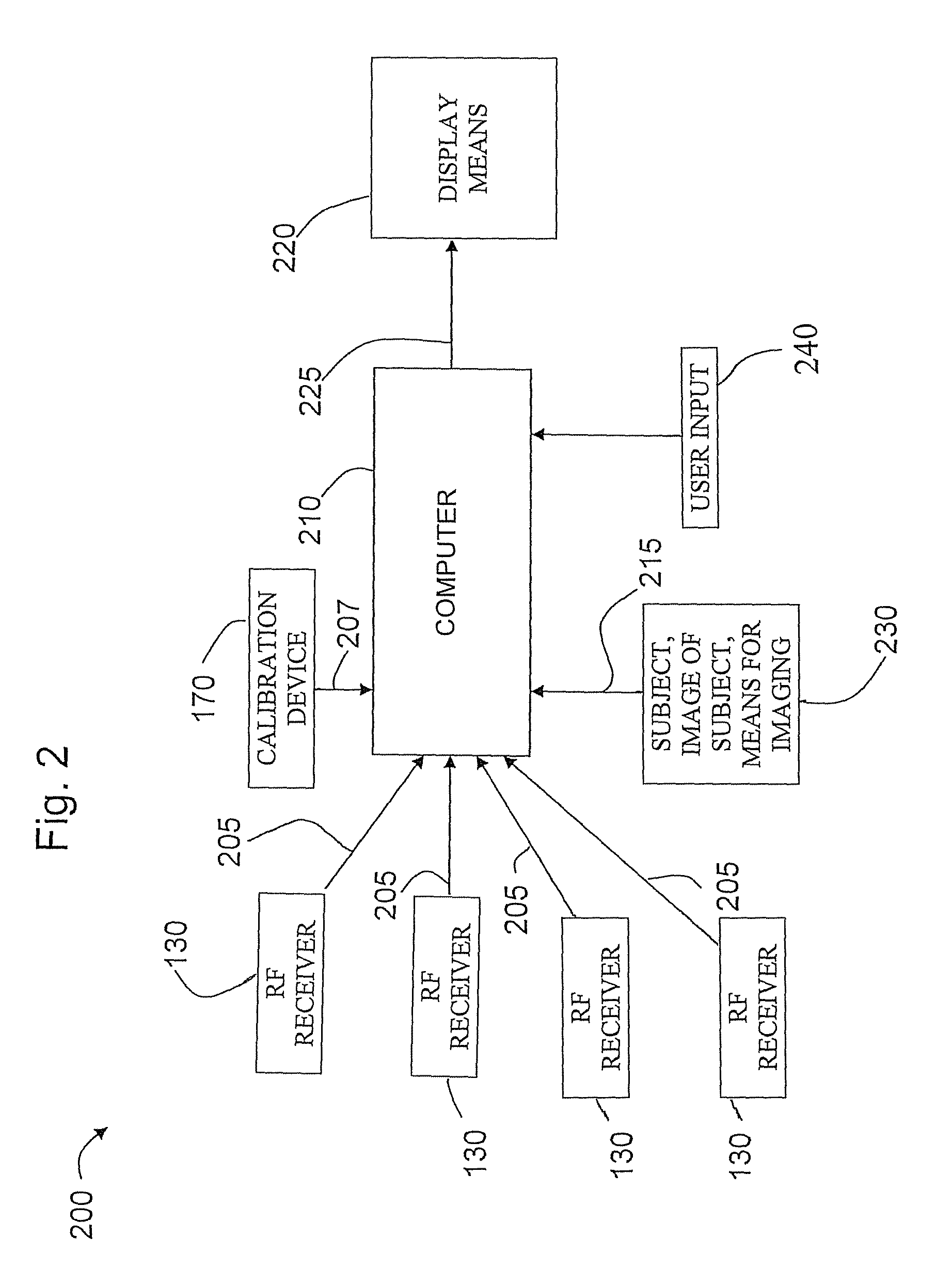

System utilizing radio frequency signals for tracking and improving navigation of slender instruments during insertion in the body

ActiveUS20070238985A1Easy to navigateShorten the timeSurgical needlesSurgical navigation systemsSignal onRobotic arm

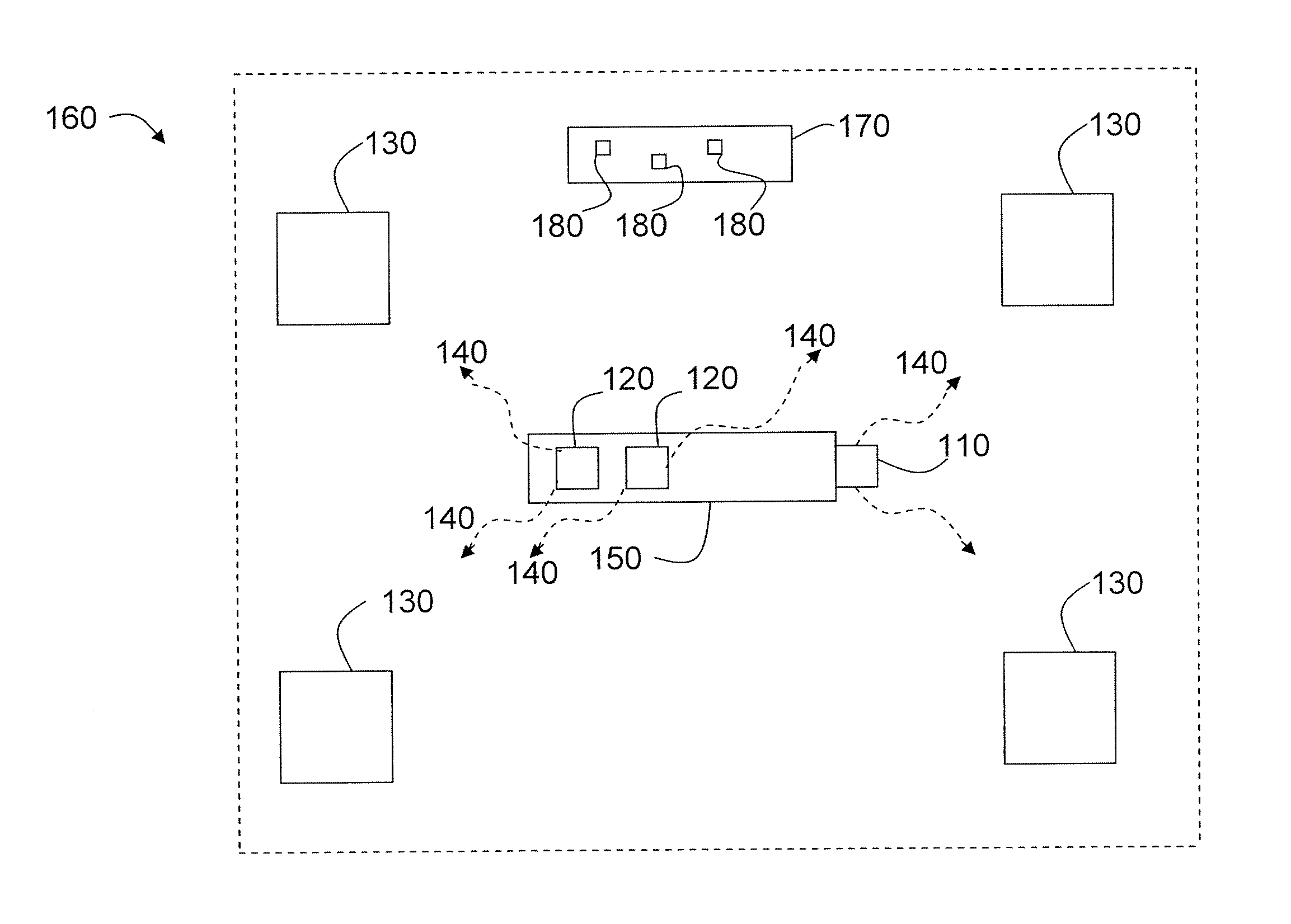

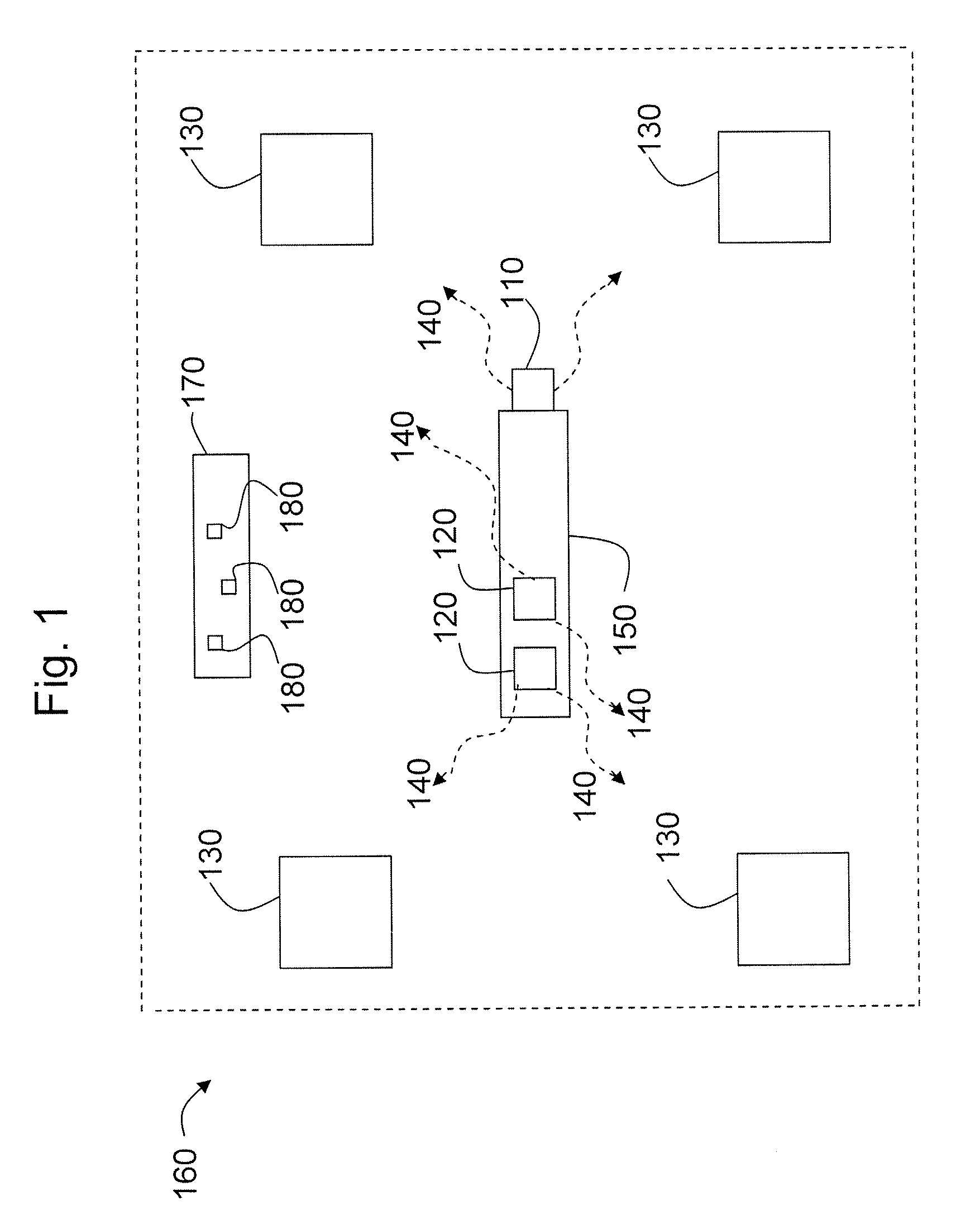

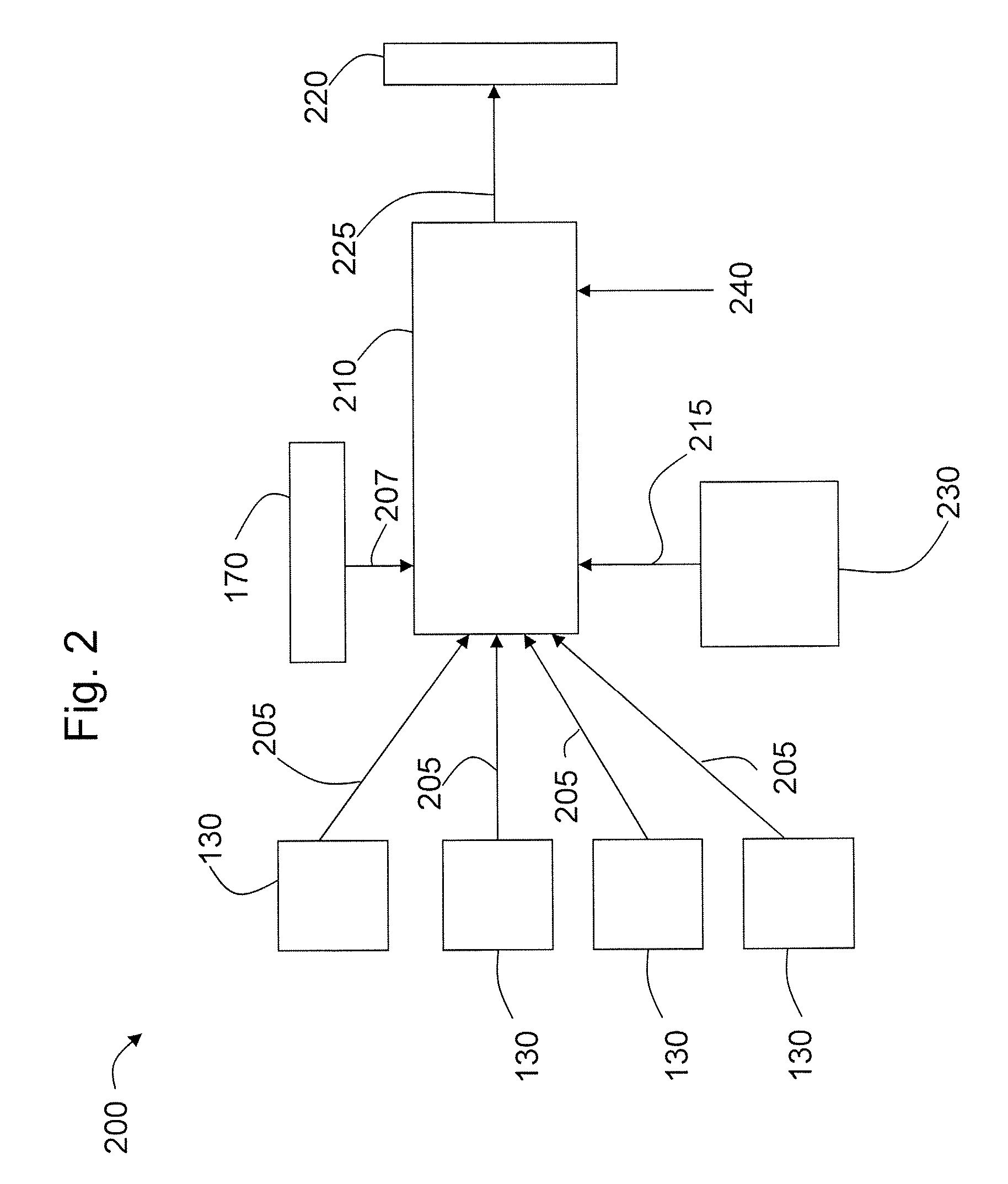

The present invention concerns a system for utilizing radio frequency signals to dynamically determine the location of a medical device throughout a procedure and to improve navigation of the medical device. For these purposes, a plurality of RF receivers are mounted at operative locations in the operating room and operate on the same clock signal. The system also utilizes a diagnostic medical image such as an MRI, and overlays the position feedback signal on the image. This allows, for example, a surgeon to pick a desired spot on the diagnostic image, and then cause a robotic arm driven device to be moved to that particular spot inside the human body.

Owner:GLOBUS MEDICAL INC +2

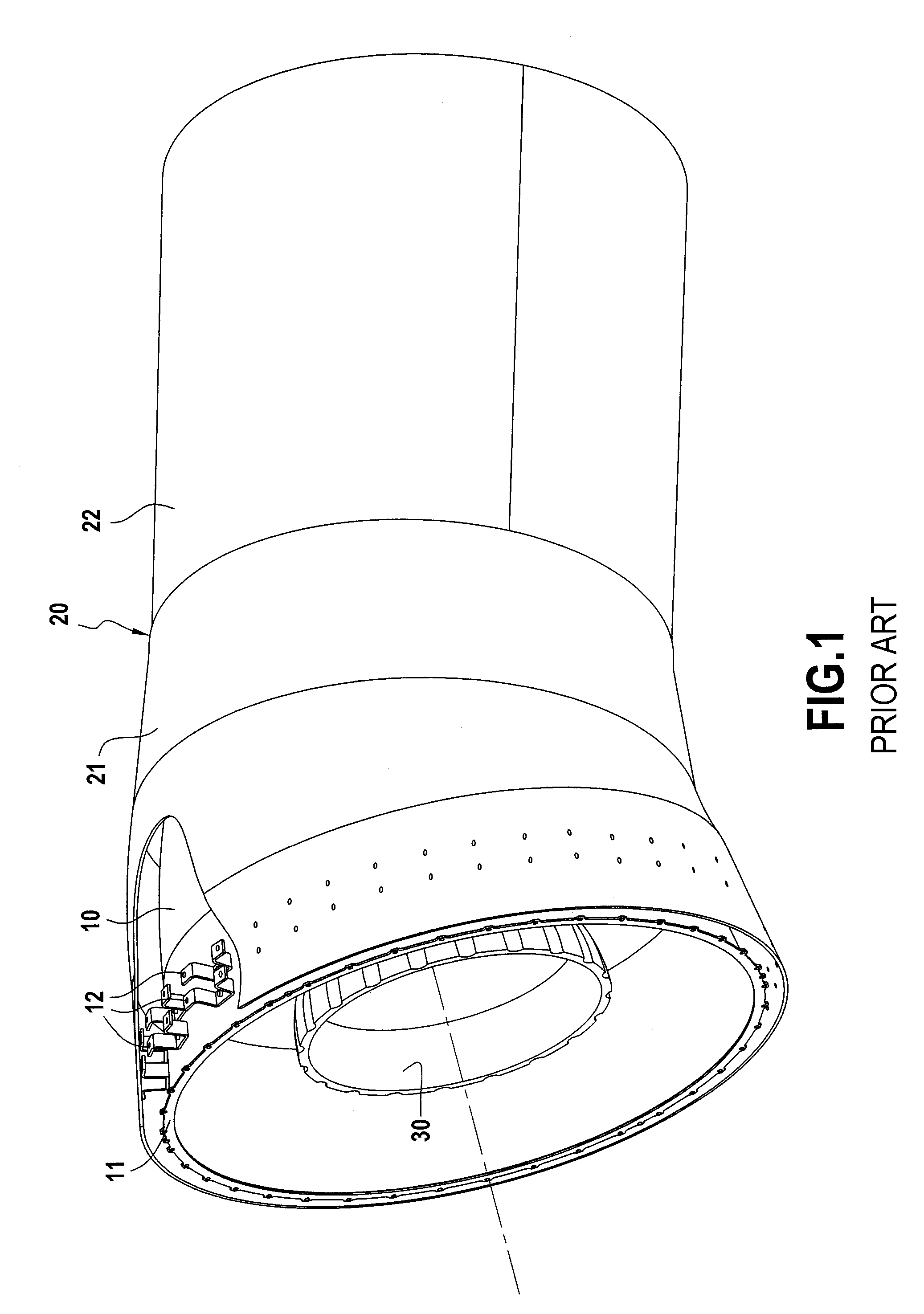

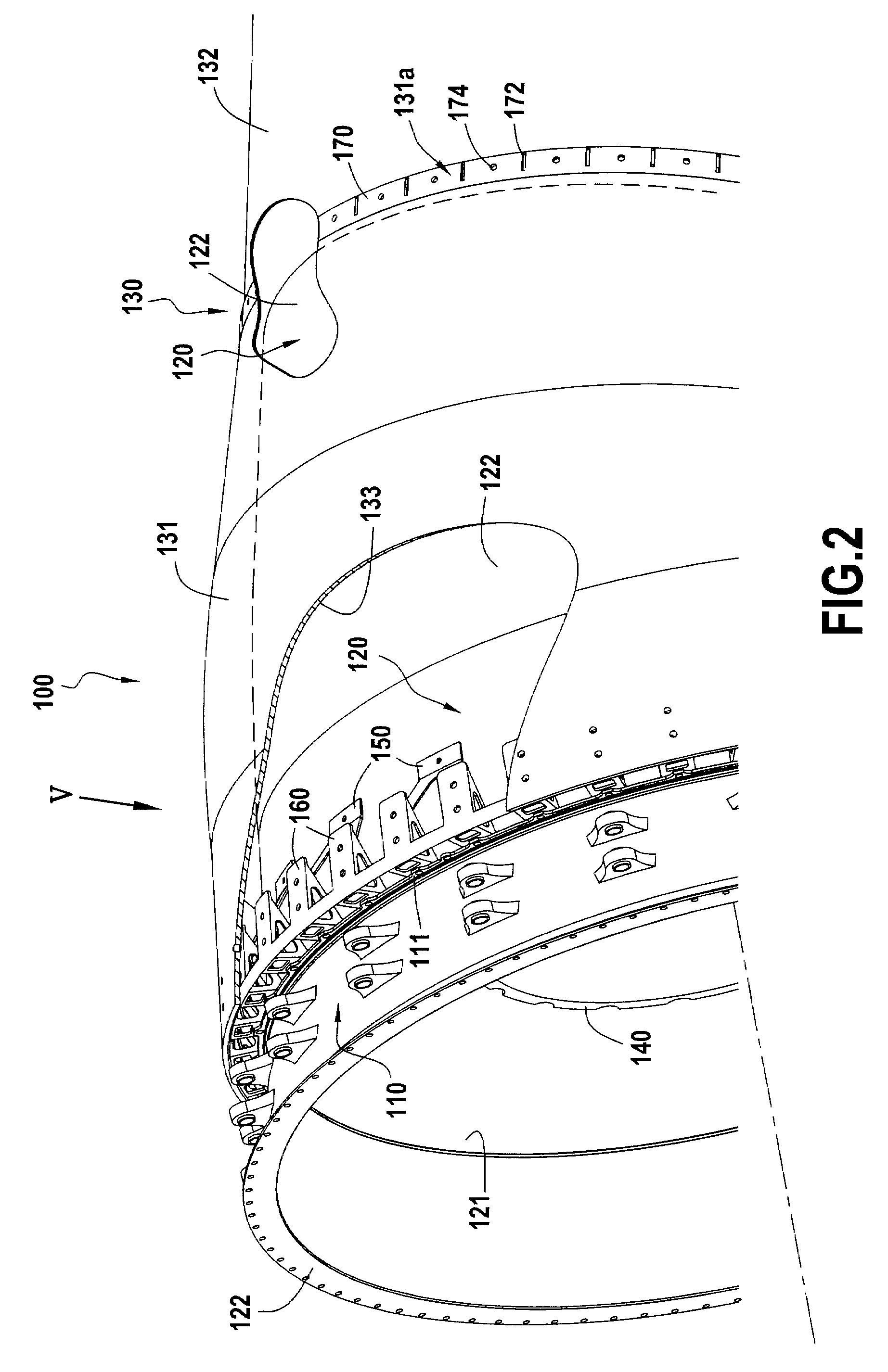

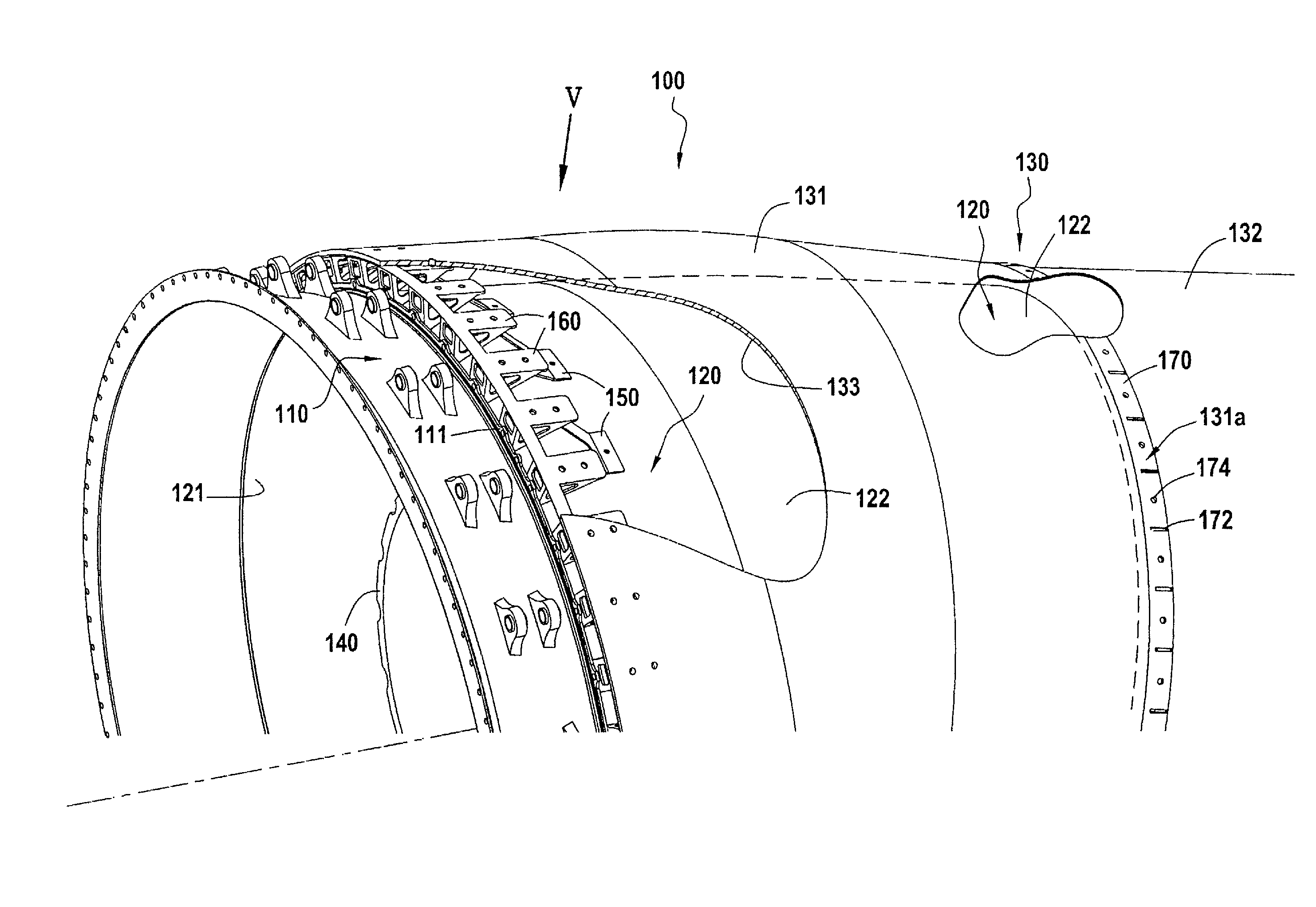

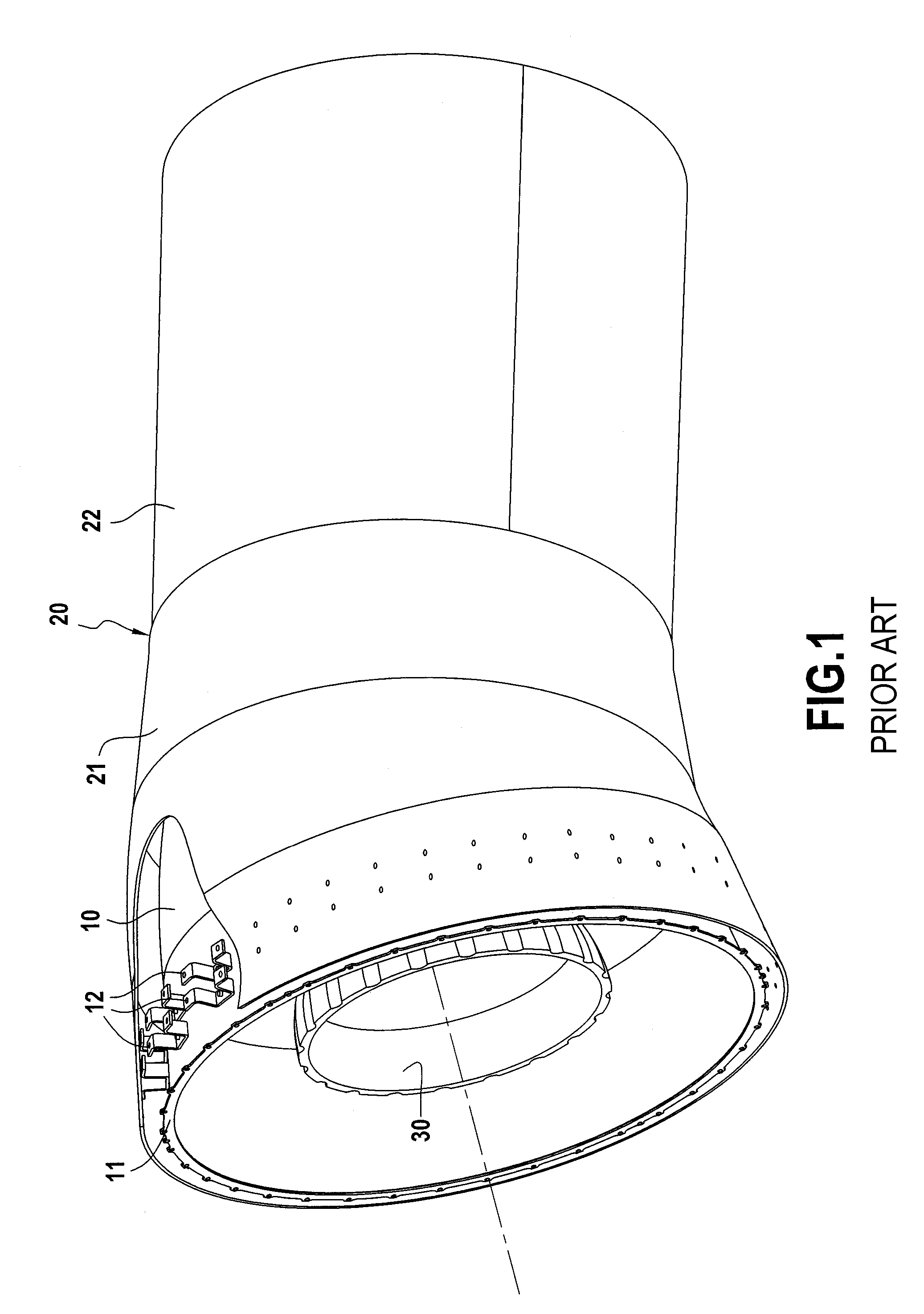

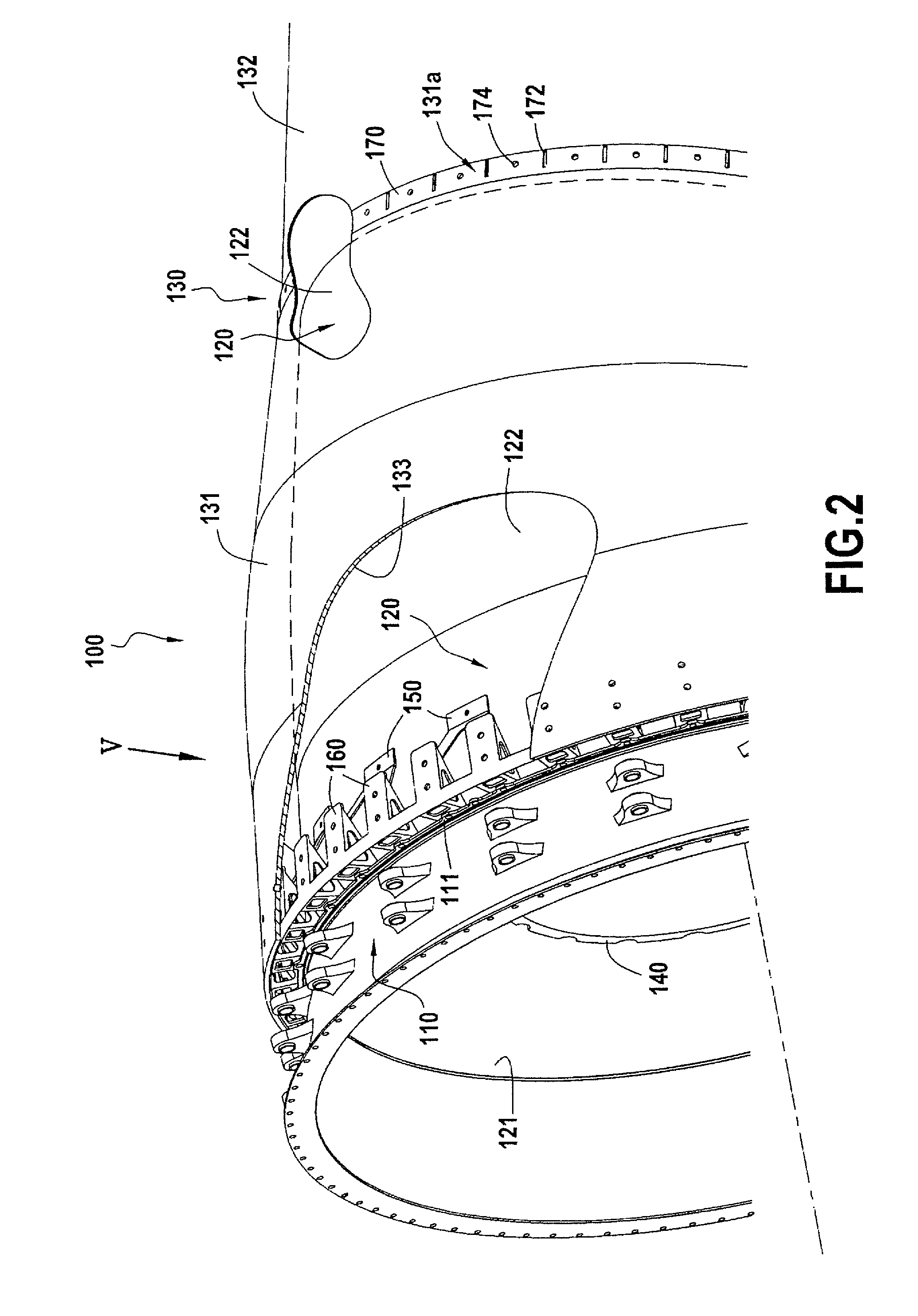

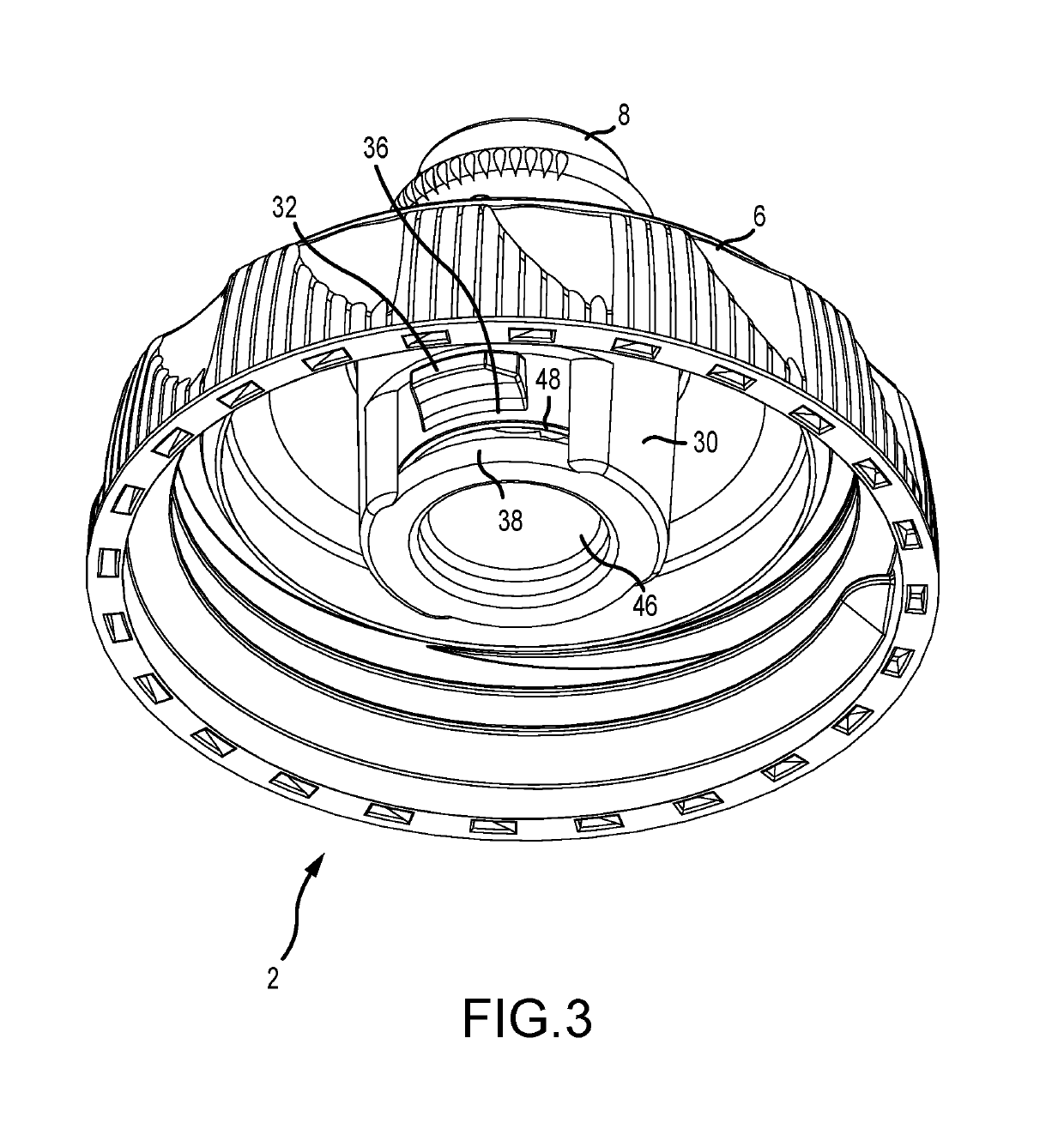

Exhaust system for gas turbine

InactiveUS20100205930A1Dampen mechanical loadReduce intensityEngine fuctionsSpraying apparatusGas turbinesAirflow

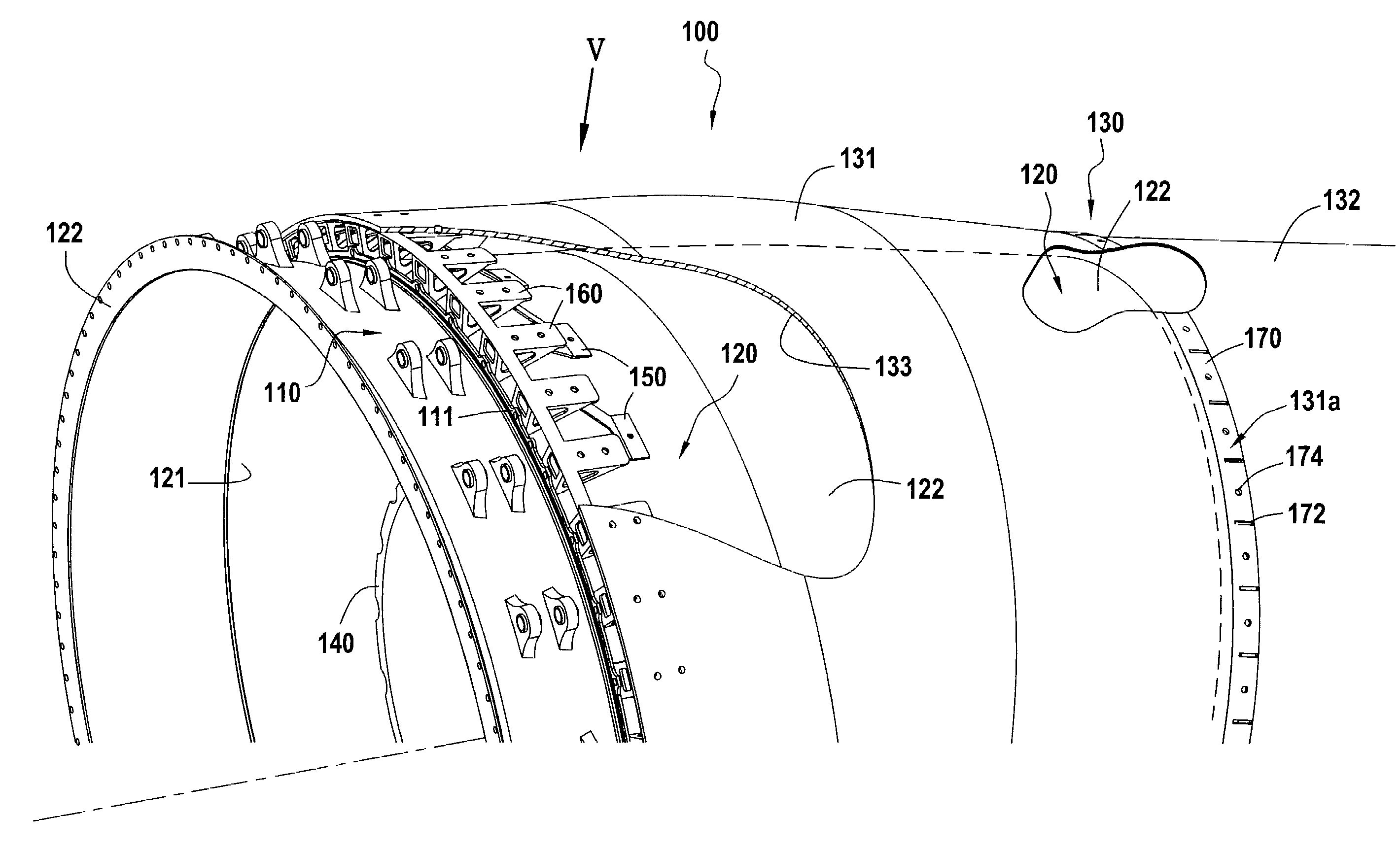

The invention relates to an exhaust system (100) for channeling the streams from a by-pass gas turbine, the system comprising a stream channeling nozzle and an exhaust casing (110) for connecting the channeling nozzle to the outlet of the gas turbine, said channeling nozzle comprising a primary nozzle (120) fastened to the exhaust casing (110) and a secondary nozzle (130) placed around the primary nozzle. The exhaust system further comprises means for fastening the secondary nozzle (130) directly to the exhaust casing (110), said secondary nozzle being supported by the exhaust casing independently of the primary nozzle (120).

Owner:SAFRAN NACELLES

System utilizing radio frequency signals for tracking and improving navigation of slender instruments during insertion in the body

ActiveUS8010181B2Easy to navigateShorten the timeSurgical needlesSurgical navigation systemsRobotic armOperating theatres

The present invention concerns a system for utilizing radio frequency signals to dynamically determine the location of a medical device throughout a procedure and to improve navigation of the medical device. For these purposes, a plurality of RF receivers are mounted at operative locations in the operating room and operate on the same clock signal. The system also utilizes a diagnostic medical image such as an MRI, and overlays the position feedback signal on the image. This allows, for example, a surgeon to pick a desired spot on the diagnostic image, and then cause a robotic arm driven device to be moved to that particular spot inside the human body.

Owner:GLOBUS MEDICAL INC +2

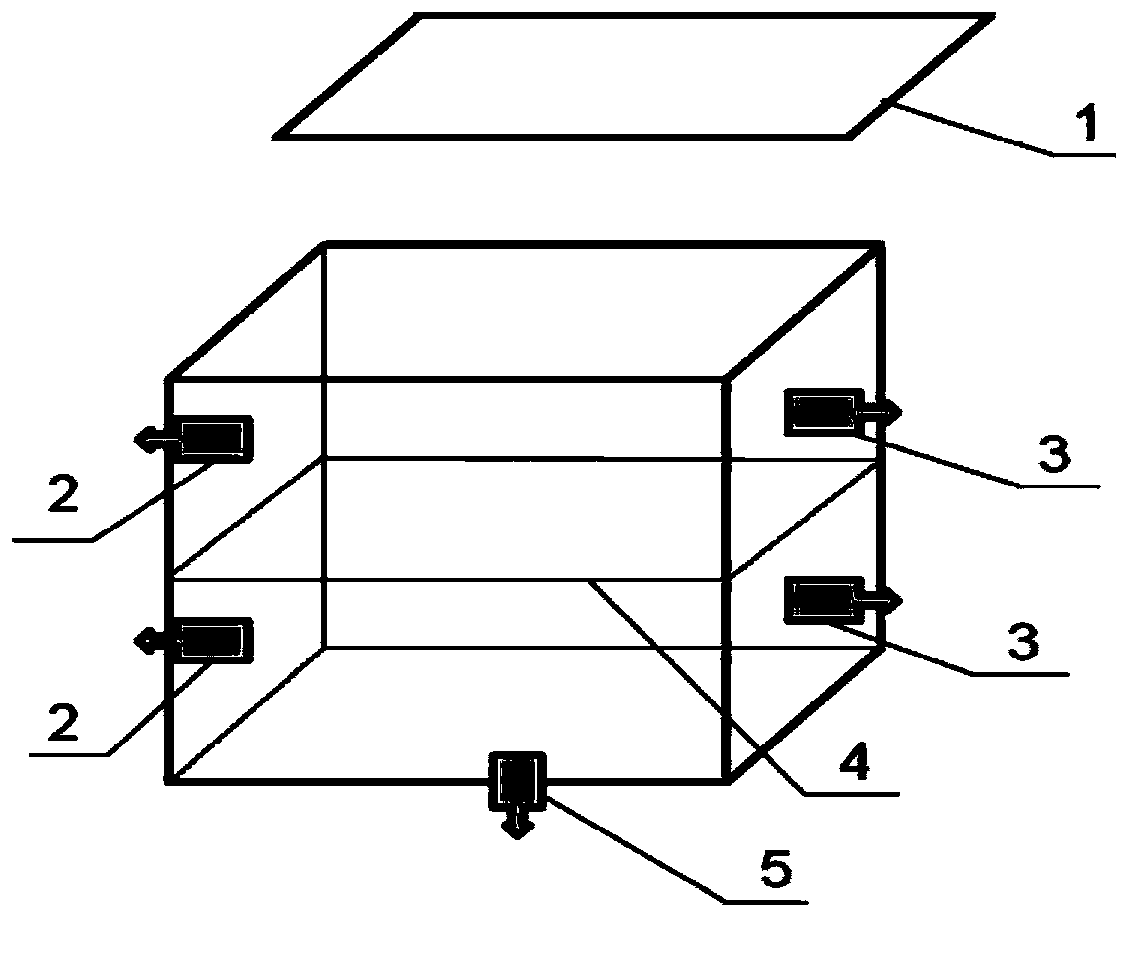

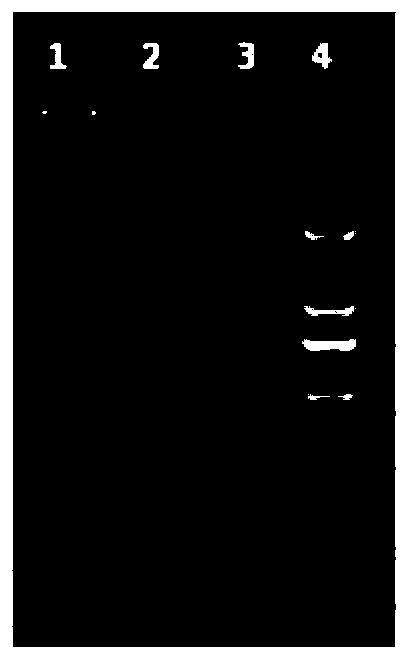

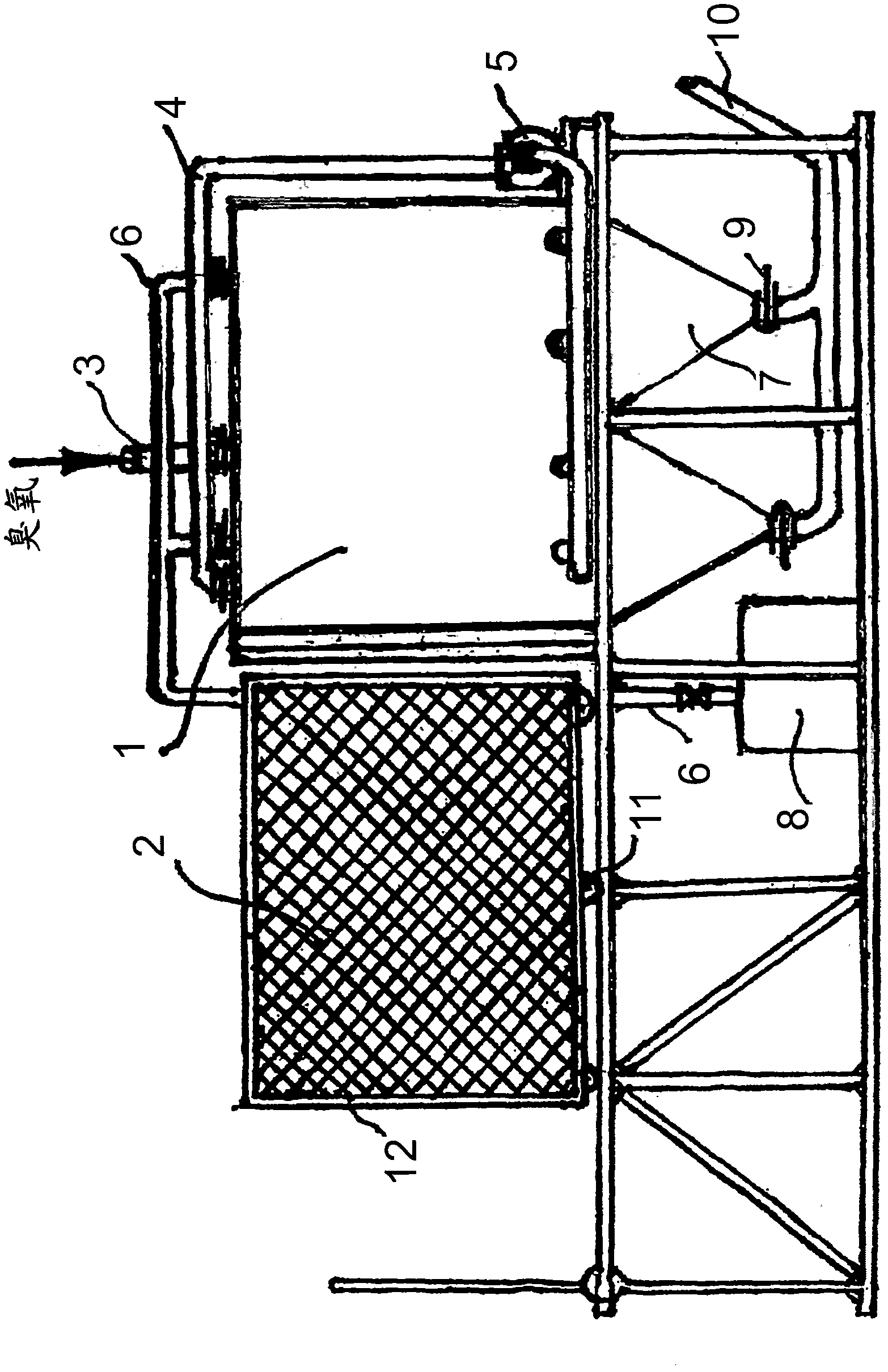

Acellular biological patch, preparation method and apparatus thereof

The invention relates to an acellular biological patch, a preparation method and an apparatus thereof. In the invention, small intestines of pigs are taken as raw materials, which are subjected to a series of decellularization treatment by means of an acid, hydrogen peroxide, a mixed solution of high salt and alkali so as to obtain the acellular biological patch. According to the preparation method, after treatment by the hydrogen peroxide, the mixed solution of high salt and alkali can be employed to conduct twice recycling treatment, thus reaching the effects of thorough decellularization and antigen removal. The employment of a transverse and longitudinal alternating laying way maintains uniformity of the patch's mechanical properties, the tensile strength, suture tear force, tear strength and other mechanical indexes can well meet clinical demands, thus facilitating surgical suture operation. The employed drying mode has no need of any adhesive and suture line for fixation, so that a natural three-dimensional support structure of the product is maintained, and after implantation into the human body, no strong inflammatory response and immunological rejection response can occur. The patch has no toxicity on cells, so that infection and adhesion cannot occur in a repair process. The acellular biological patch provided in the invention is suitable for repair of body tissue defects and soft tissue injuries, and also can be used in the bioengineering field to serve as the tissue for reinforcing repair of membranous defects and infected wounds and serve as a biological scaffold material, etc.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

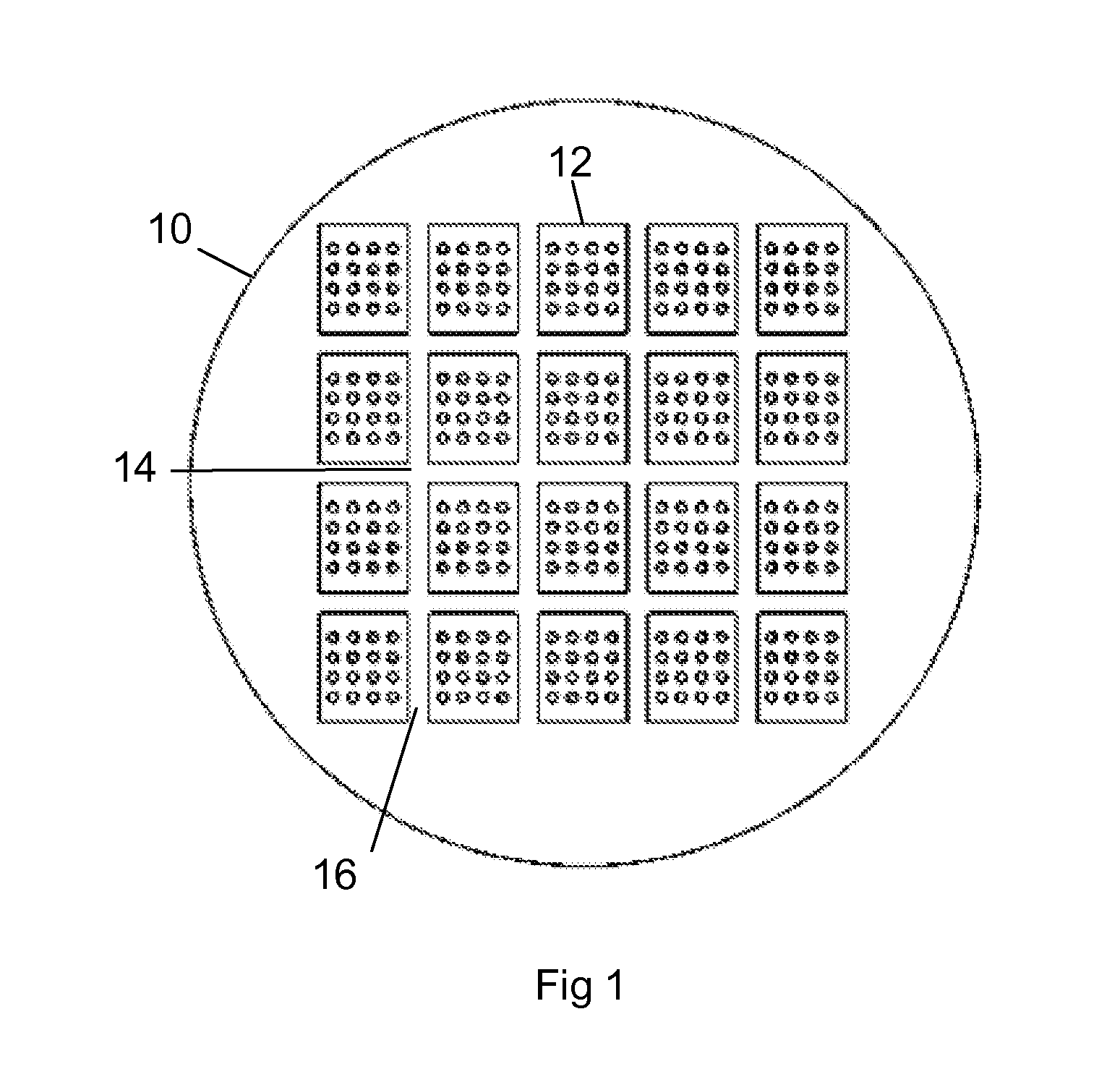

Method and apparatus for improved singulation of light emitting devices

InactiveUS20120175652A1Reduce the amount requiredAvoid thermal damageSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesPicosecond laserLaser processing

The present invention is a system and method for laser-assisted singulation of light emitting electronic devices manufactured on a substrate, having a processing surface and a depth extending from the processing surface. It includes providing a laser processing system having a picosecond laser having controllable parameters; controlling the laser parameters to form light pulses from the picosecond laser, to form a modified region having a depth which spans about 50% of the depth and substantially including the processing surface of the substrate and having a width less than about 5% of the region depth; and, singulating the substrate by applying mechanical stress to the substrate thereby cleaving the substrate into said light emitting electronic devices having sidewalls formed at least partially in cooperation with the linear modified regions.

Owner:ELECTRO SCI IND INC

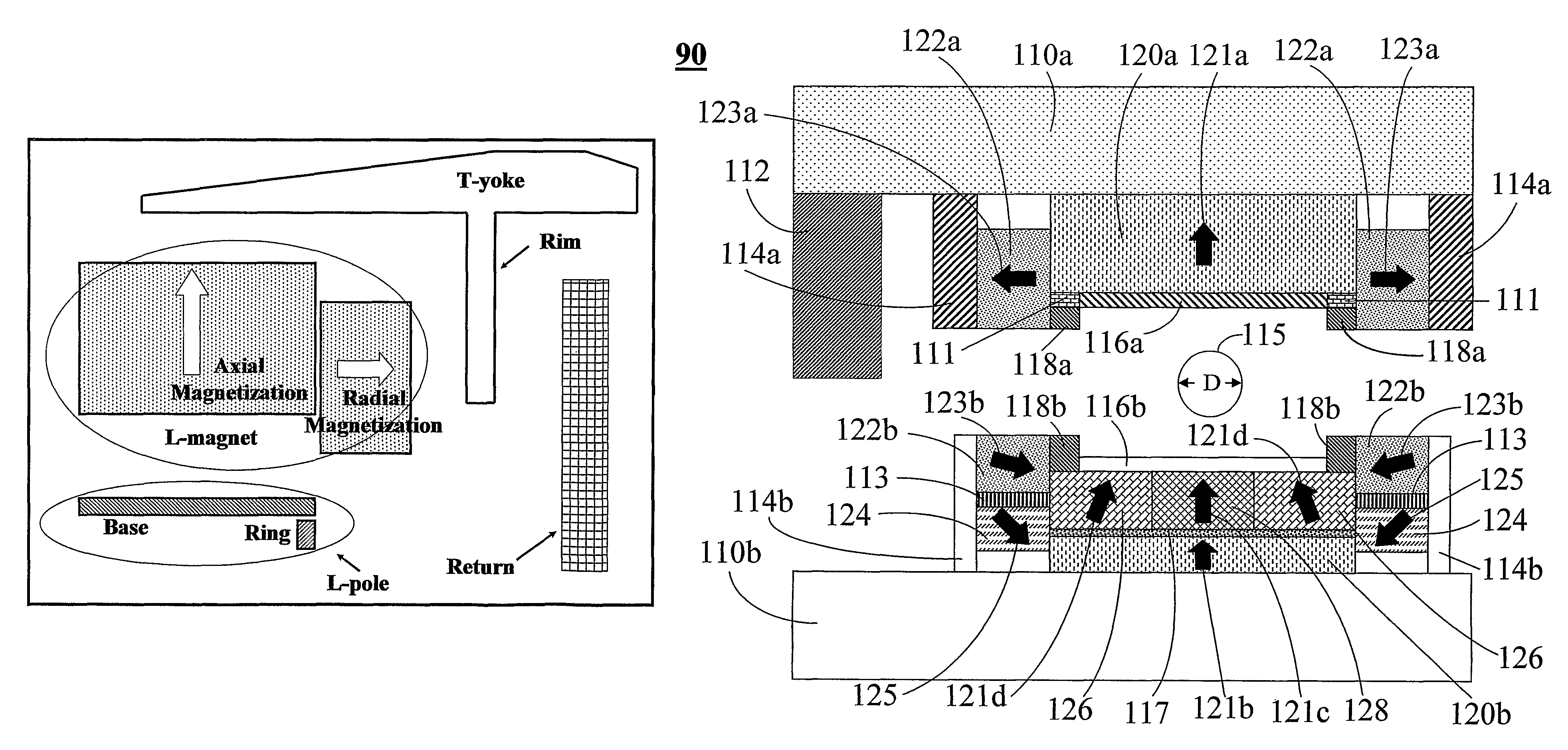

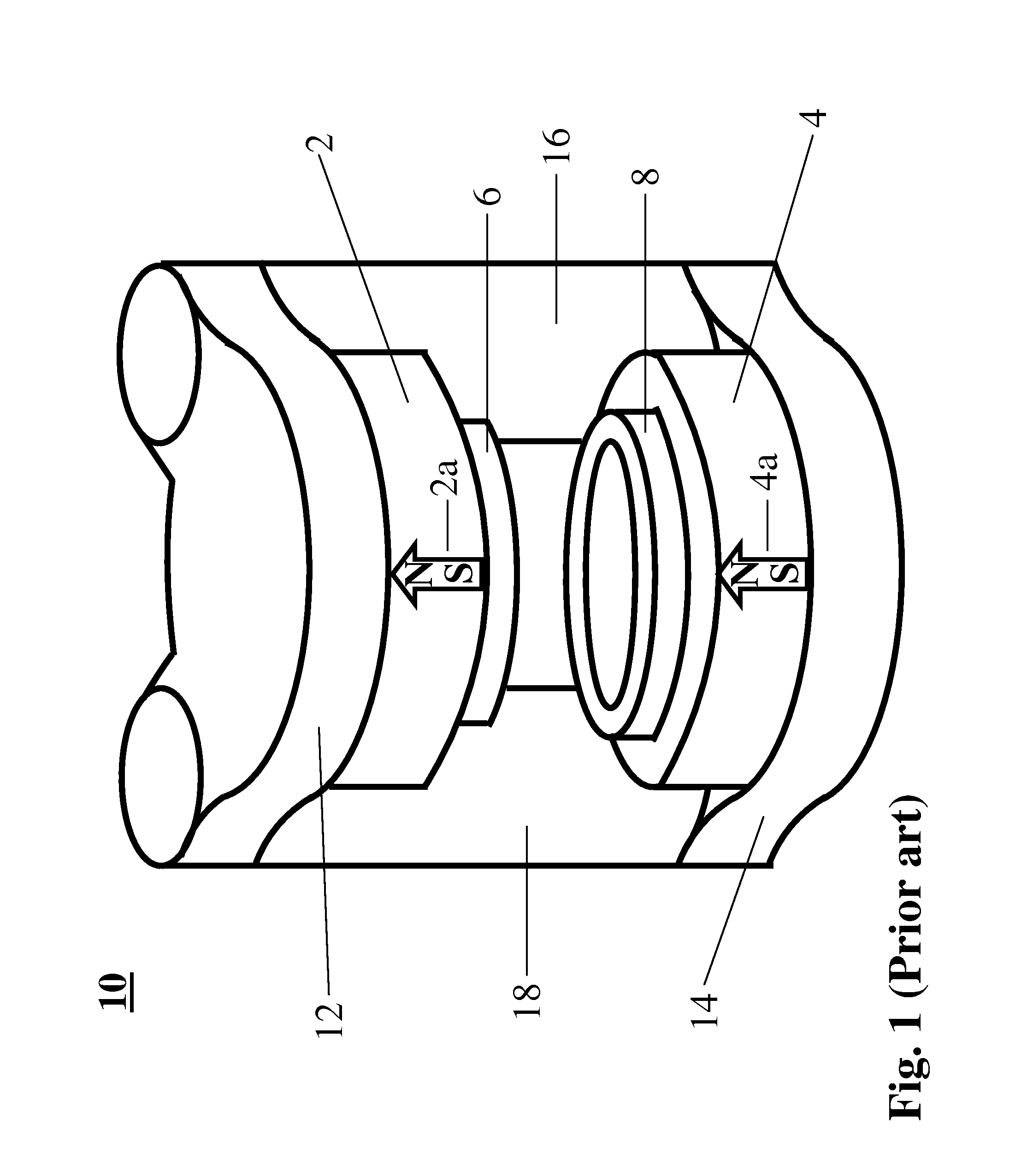

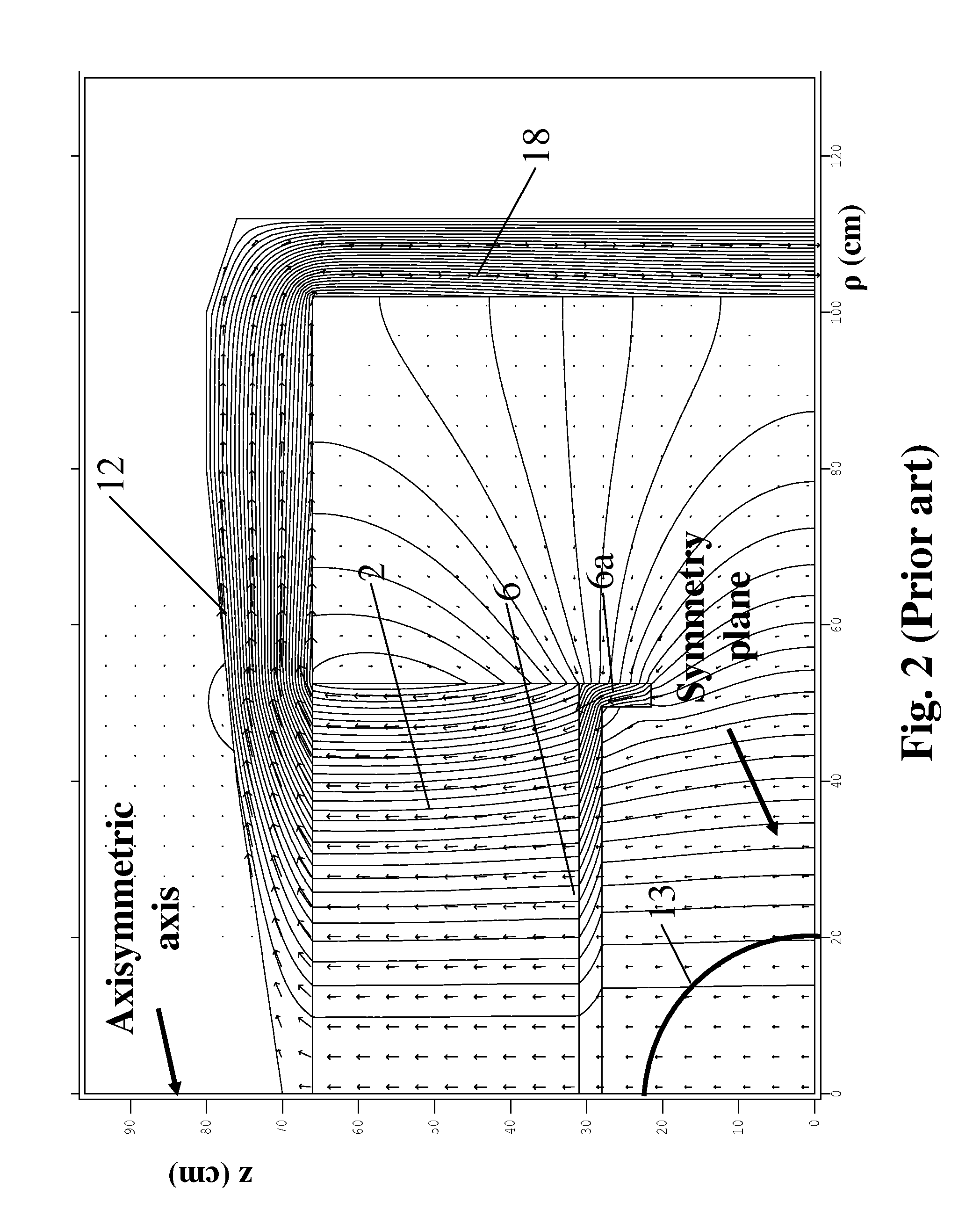

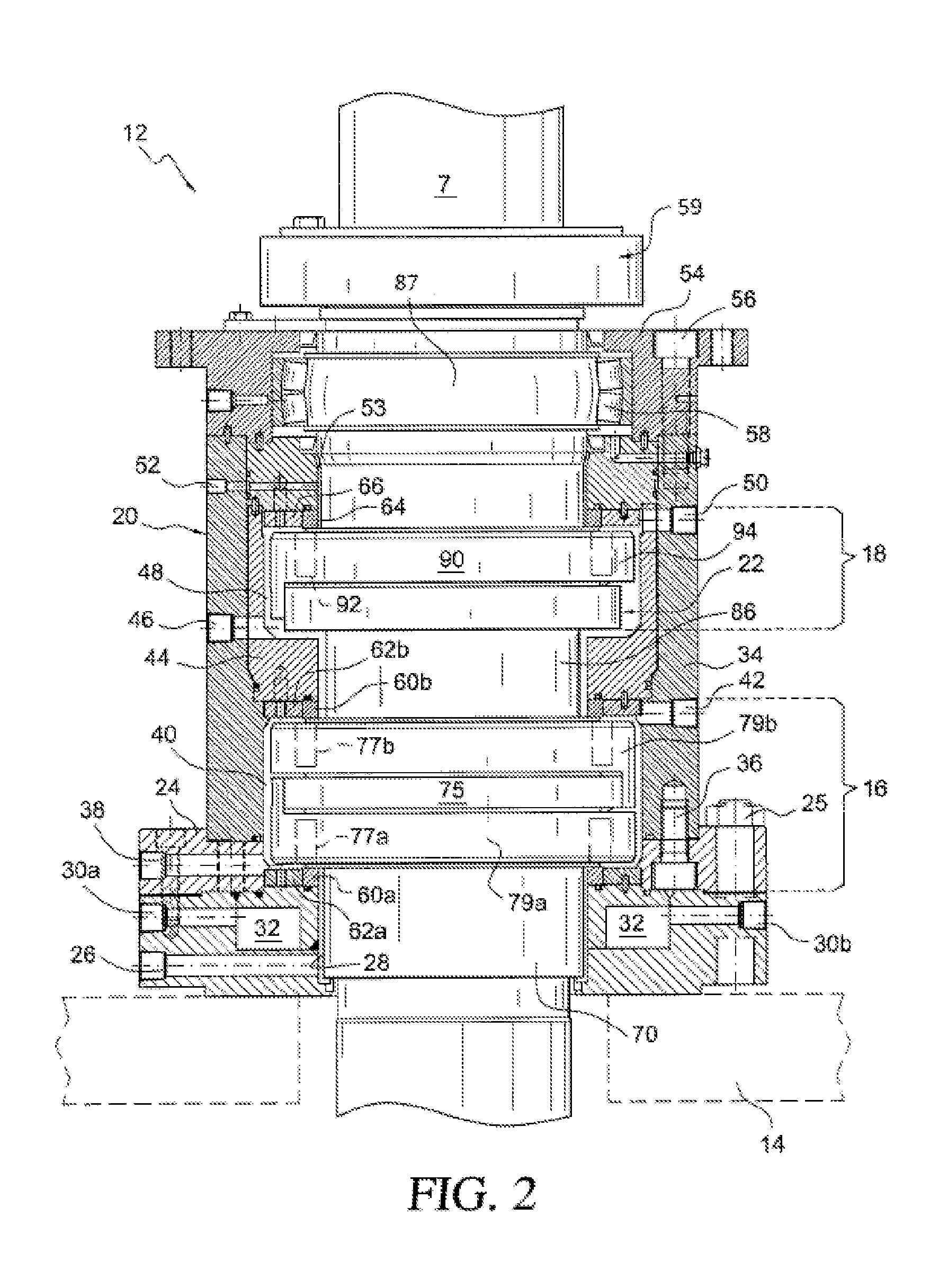

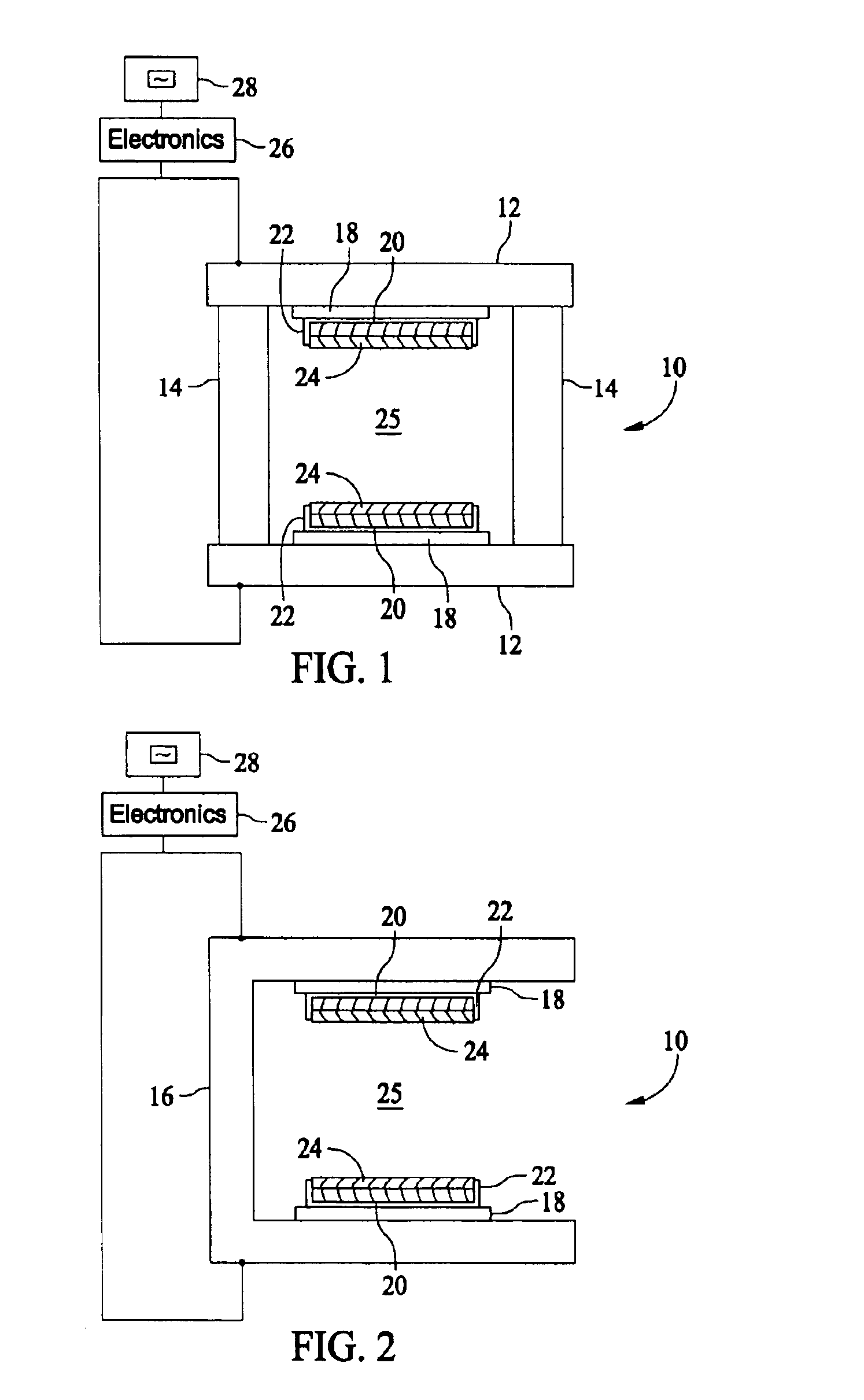

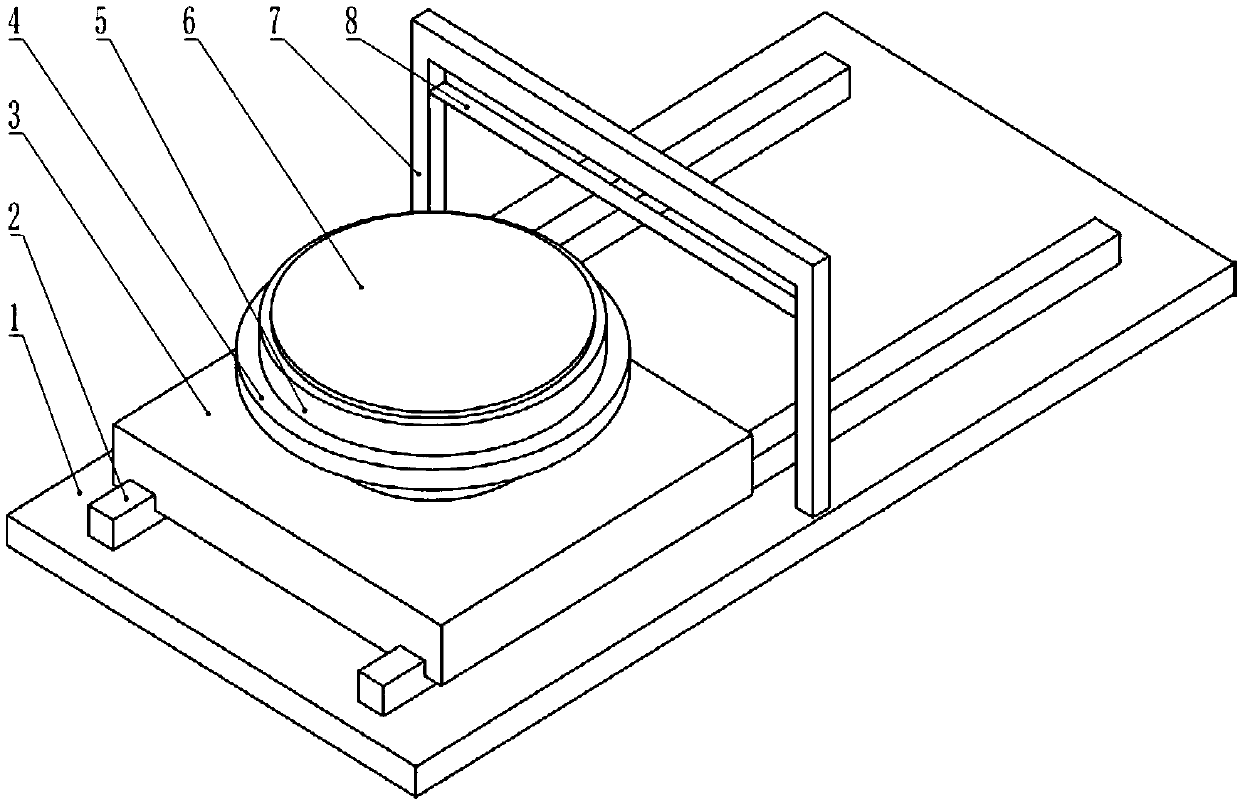

Open MRI magnetic field generator

ActiveUS8077002B2Reduce leakageImprove efficiencyMagnetic measurementsPermanent magnetsWhole bodyFlux distribution

A magnet primarily for use in MRI applications comprises a pair of poles oriented about a plane of symmetry parallel to each therebetween defining an air gap region, magnetic field sources secured on the surfaces of the poles opposite the air gap that have yokes disposed on them, the yokes connected to each other by returns so that the entire magnet assembly can form a closed magnetic flux circuit to substantially confine the magnetic fields generated by the apparatus in the air gap where an imaging region is formed to place subjects for the purposes of examination. The main assembly being cylindrical in geometry has permanent magnets for magnetic field sources that are composed of two regions, a central disk-like portion magnetized substantially along the axial direction and an outer ring-like region magnetized substantially along the radial direction extending axially to form part of the pole together producing a very efficient and even flux distribution throughout the entire magnet assembly with minimal flux leakage. A further means of reducing flux leakage is incorporated in the yokes which have two sections, a disk-like region and an ring-like section to enclose the permanent magnets. The poles are made of multiple sections with a central disk-like region and an outer ring-like region that is a combination of permanent magnets and high permeability materials. This magnet assembly can achieve 1.0 Tesla or greater magnetic fields for whole-body scanning without saturating the magnet pole and other structures.

Owner:LIAN JIANYU +2

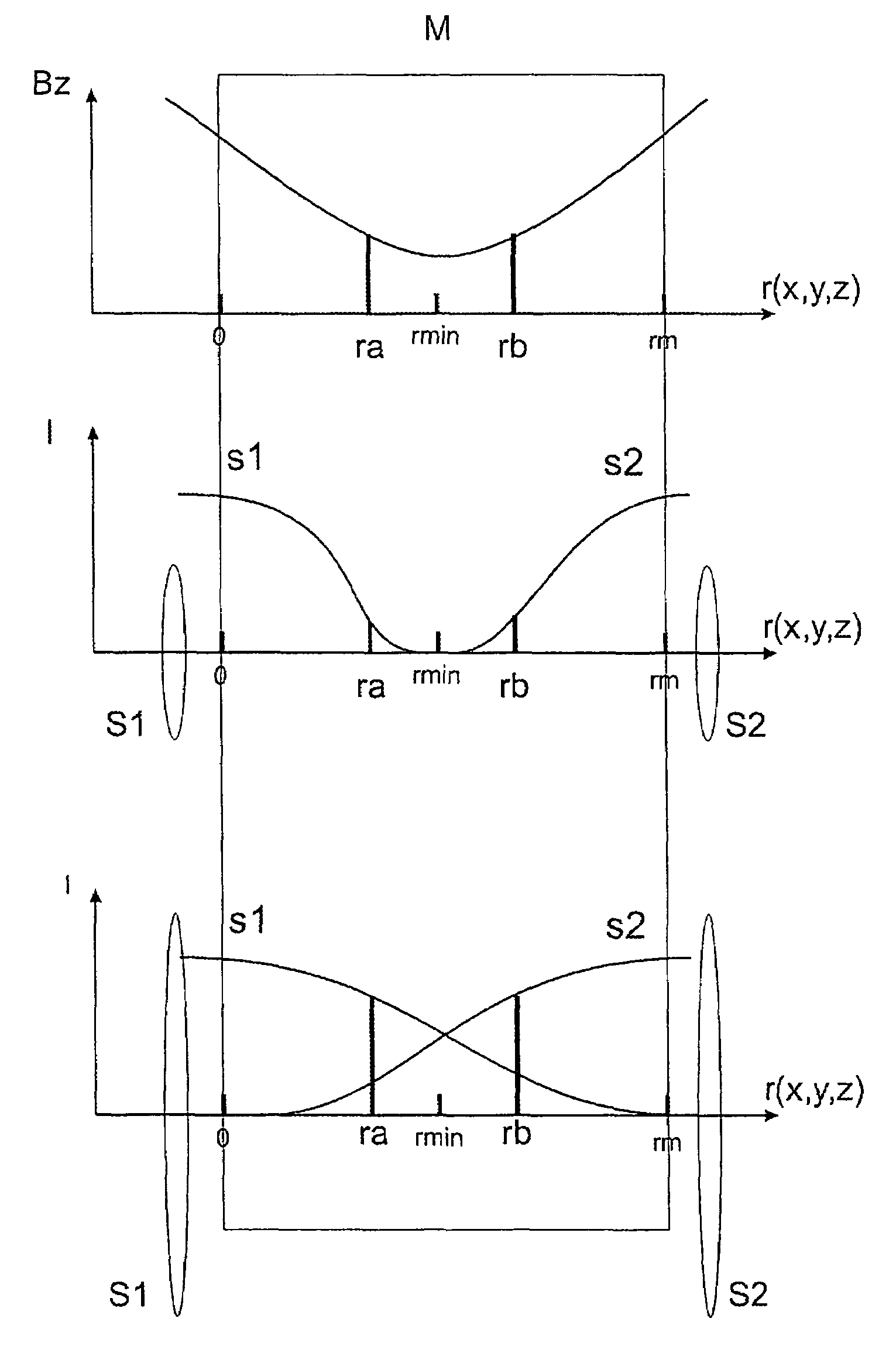

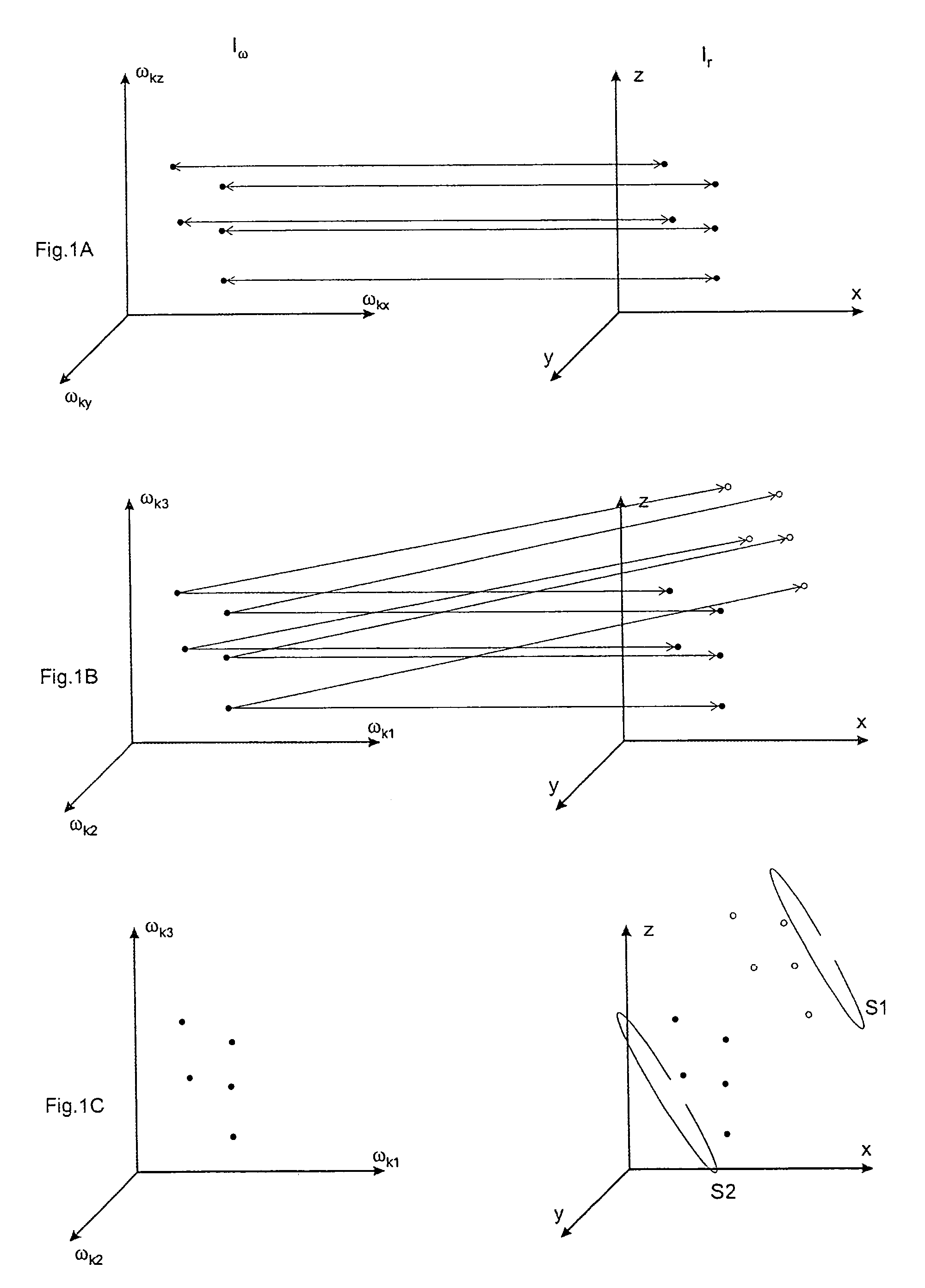

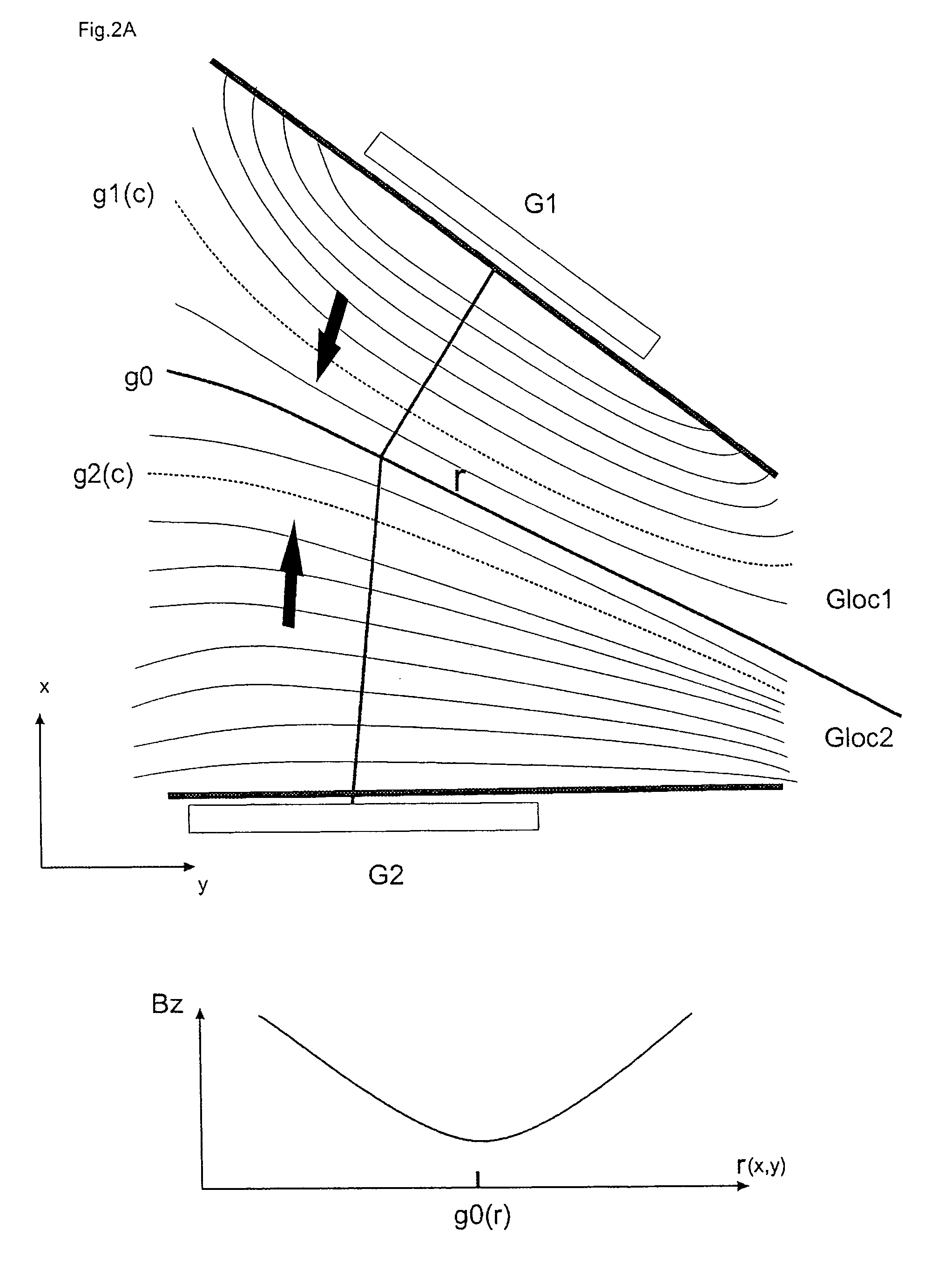

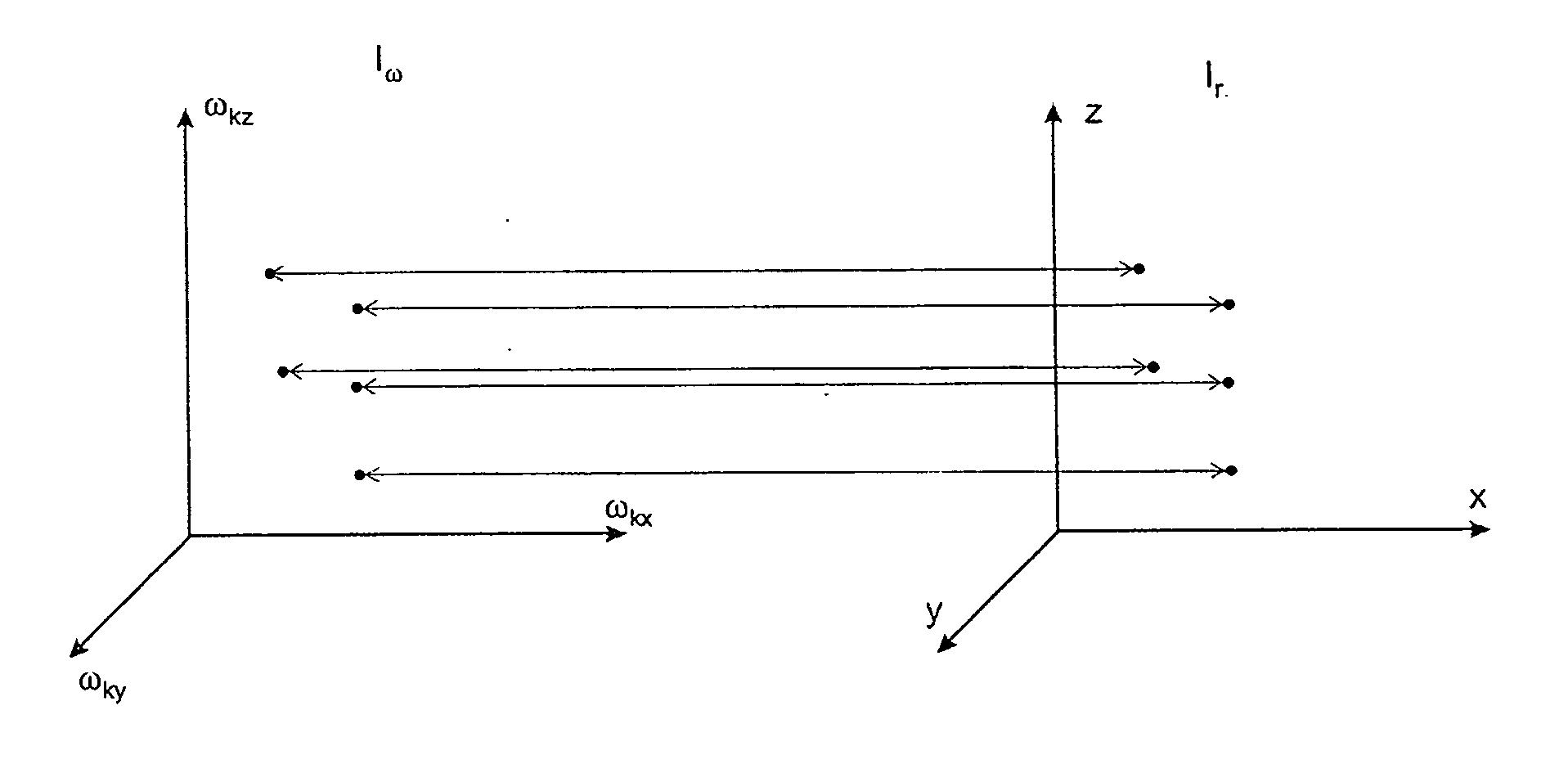

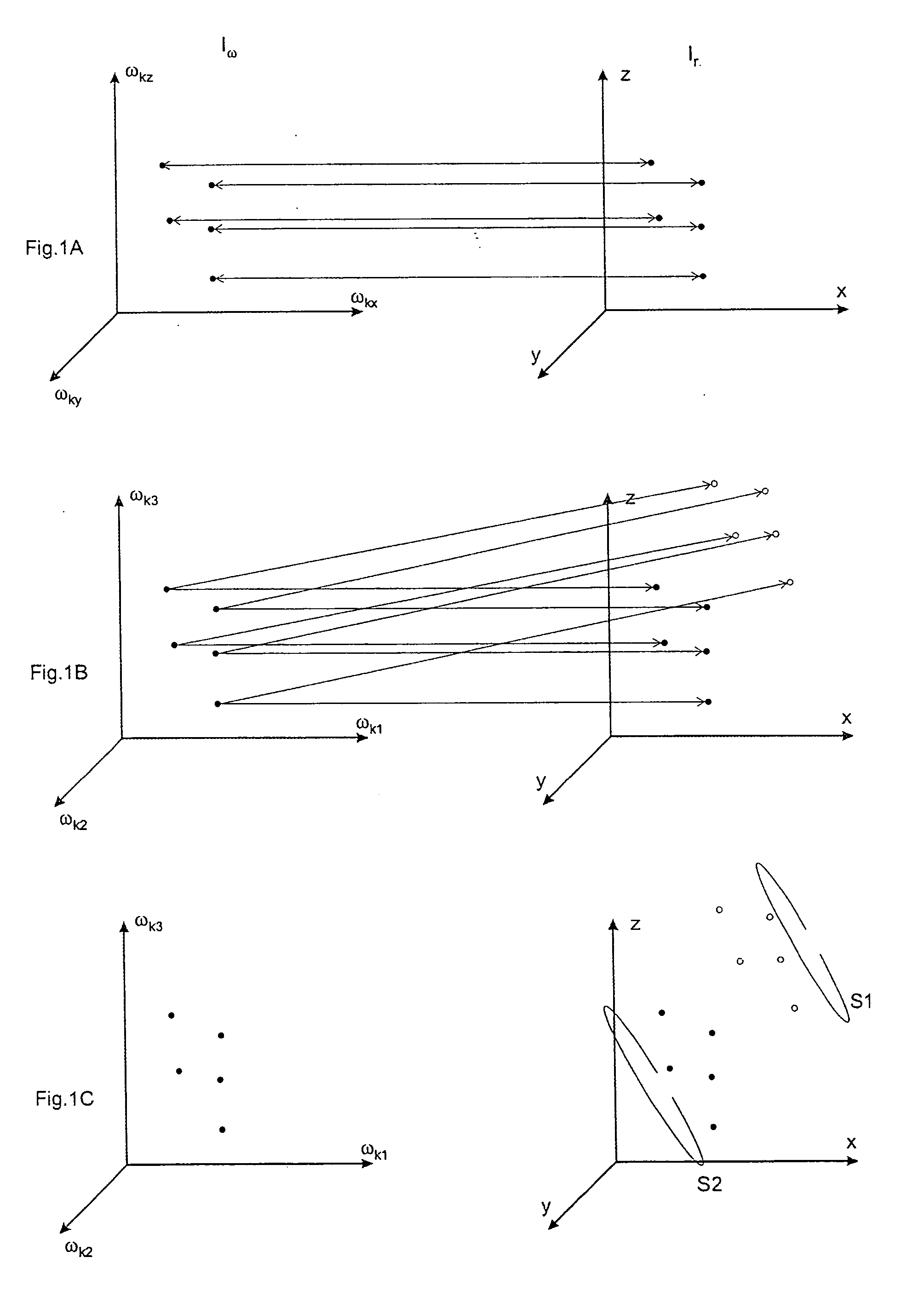

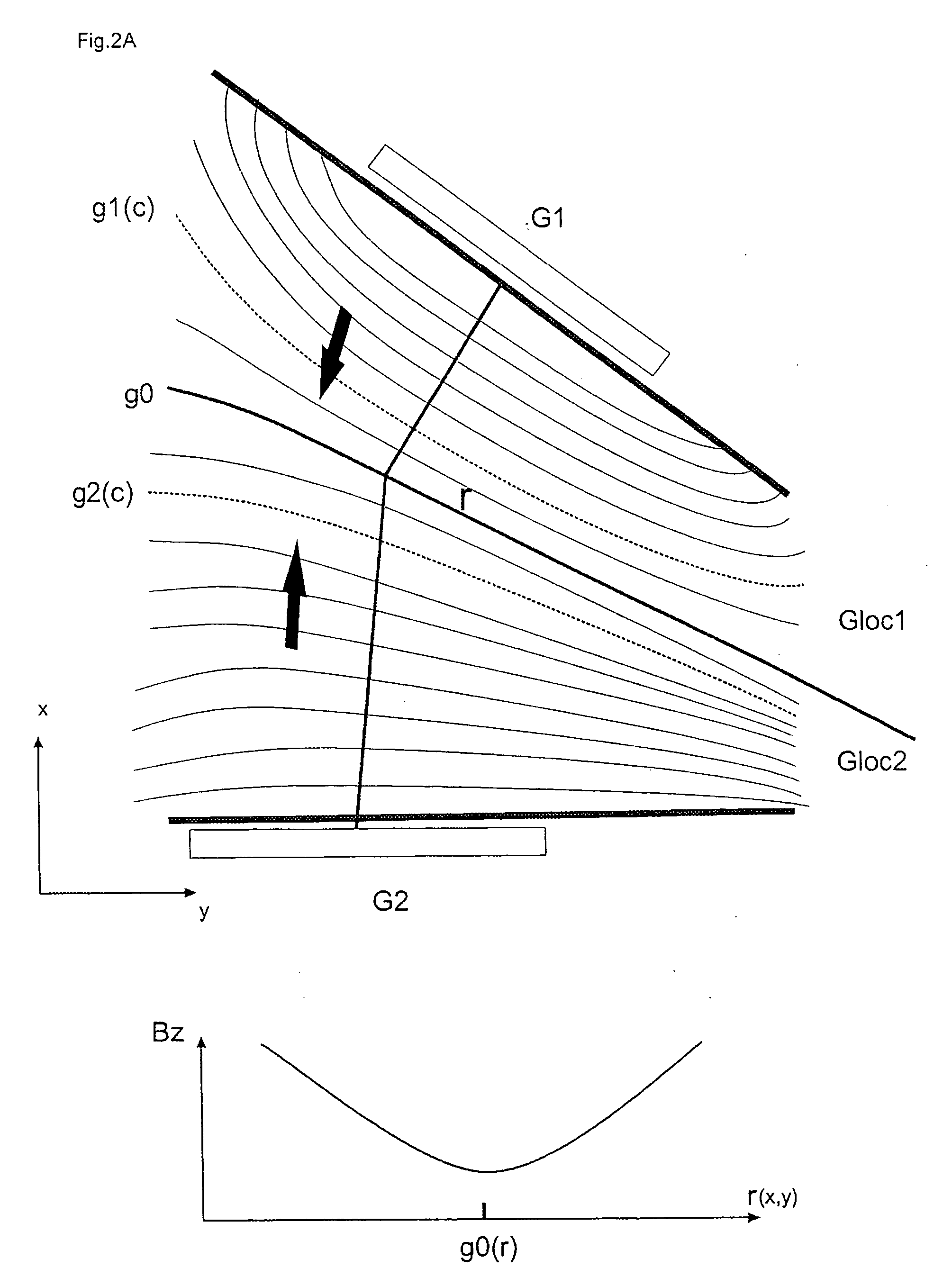

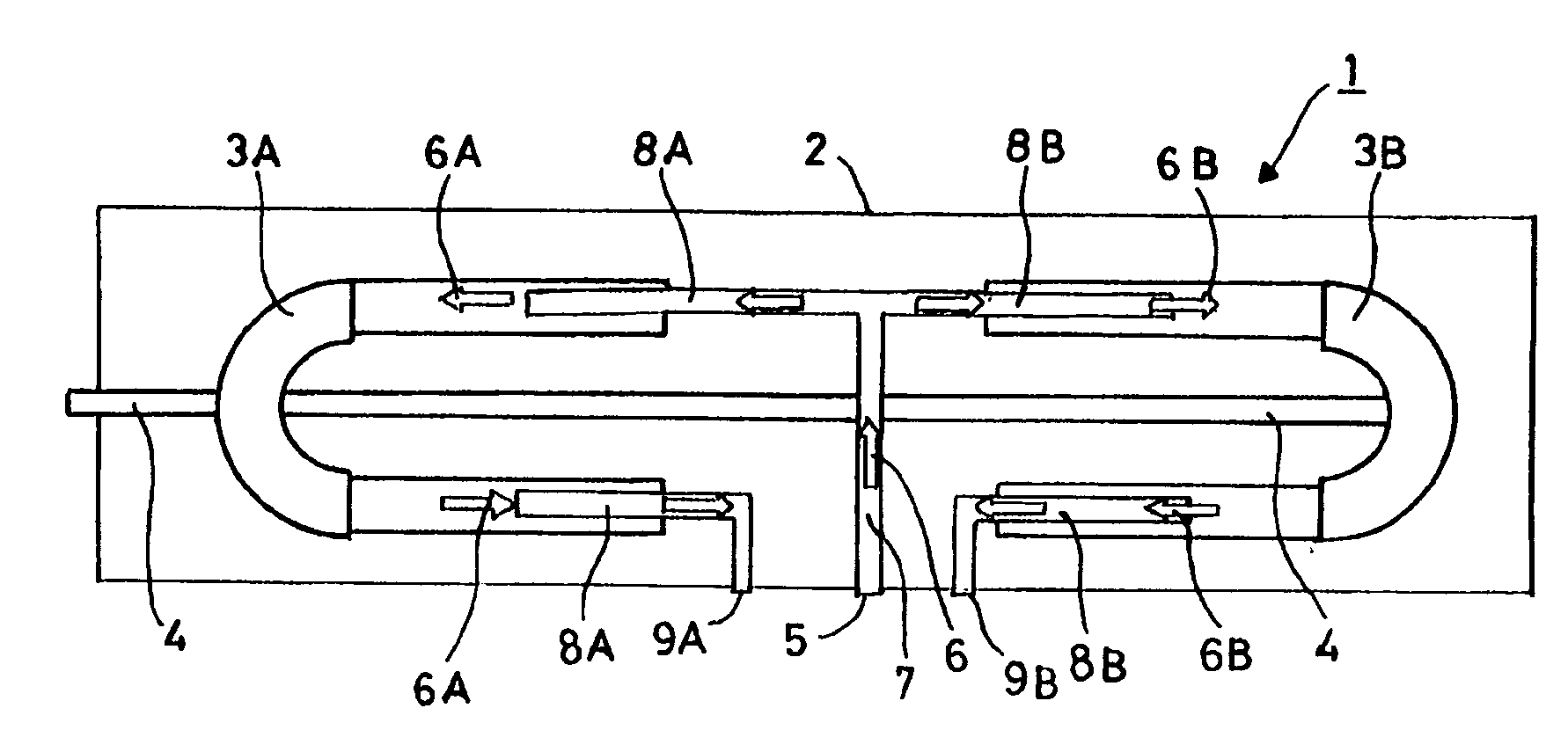

Apparatus and method for NMR tomography acquisition with local magnetic field gradients in connection with local receiver coils

ActiveUS7411395B2Small magnetic field differenceFast switching timeMagnetic measurementsElectric/magnetic detectionMagnetic field gradientResonance

A magnetic resonance tomography apparatus, includes a gradient system that can generate at least one spatially varying and optionally time-varying magnetic field for at least one-dimensional local encoding of measuring signals in an area of a test sample to be imaged. The gradient system contains at least one subsystem which can generate a non-bijective spatially varying magnetic (NBSEM) field for local encoding, such that the function of the field strength of such an NBSEM within the area to be imaged has at least one local extreme value (maximum or minimum), such that the area to be imaged is divided along the hyper surface formed by the entirety of all local extreme values of the at least one NBSEM. The apparatus can produce images of the same quality with smaller magnetic field differences and permits easy realization.

Owner:UNIVERSITATSKLINIKUM FREIBURG

Apparatus and method for NMR tomography acquisition with local magnetic field gradients in connection with local receiver coils

ActiveUS20070090838A1Fast switching timeSmall differenceMagnetic measurementsElectric/magnetic detectionMagnetic field gradientResonance

A magnetic resonance tomography apparatus, comprising a gradient system that can generate at least one spatially varying and optionally time-varying magnetic field for at least one-dimensional local encoding of measuring signals in an area of a test sample to be imaged, is characterized in that the gradient system contains at least one subsystem which can generate a non-bijective spatially varying magnetic field (=NBSEM or ambivalent / non-bijective spacially encoding magnetic field) for local encoding, such that the function of the field strength of such an NBSEM within the area to be imaged has at least one local extreme value (maximum or minimum), such that the area to be imaged is divided along the hyper surface formed by the entirety of all local extreme values of the at least one NBSEM into ng partial areas, with ng≧2, that the magnetic field profile has a non-unidirectional distribution within and / or over these partial areas, and that least ng receiver coils are provided which have a differing sensitivity in these partial areas. The apparatus can produce images of the same quality with smaller magnetic field differences and permits easy realization.

Owner:UNIVERSITATSKLINIKUM FREIBURG

Exhaust system for gas turbine

InactiveUS8424312B2Reduce intensityControl loadPower plant exhaust arrangementsEngine fuctionsGas turbinesAirflow

The invention relates to an exhaust system (100) for channeling the streams from a by-pass gas turbine, the system comprising a stream channeling nozzle and an exhaust casing (110) for connecting the channeling nozzle to the outlet of the gas turbine, said channeling nozzle comprising a primary nozzle (120) fastened to the exhaust casing (110) and a secondary nozzle (130) placed around the primary nozzle. The exhaust system further comprises means for fastening the secondary nozzle (130) directly to the exhaust casing (110), said secondary nozzle being supported by the exhaust casing independently of the primary nozzle (120).

Owner:SAFRAN NACELLES

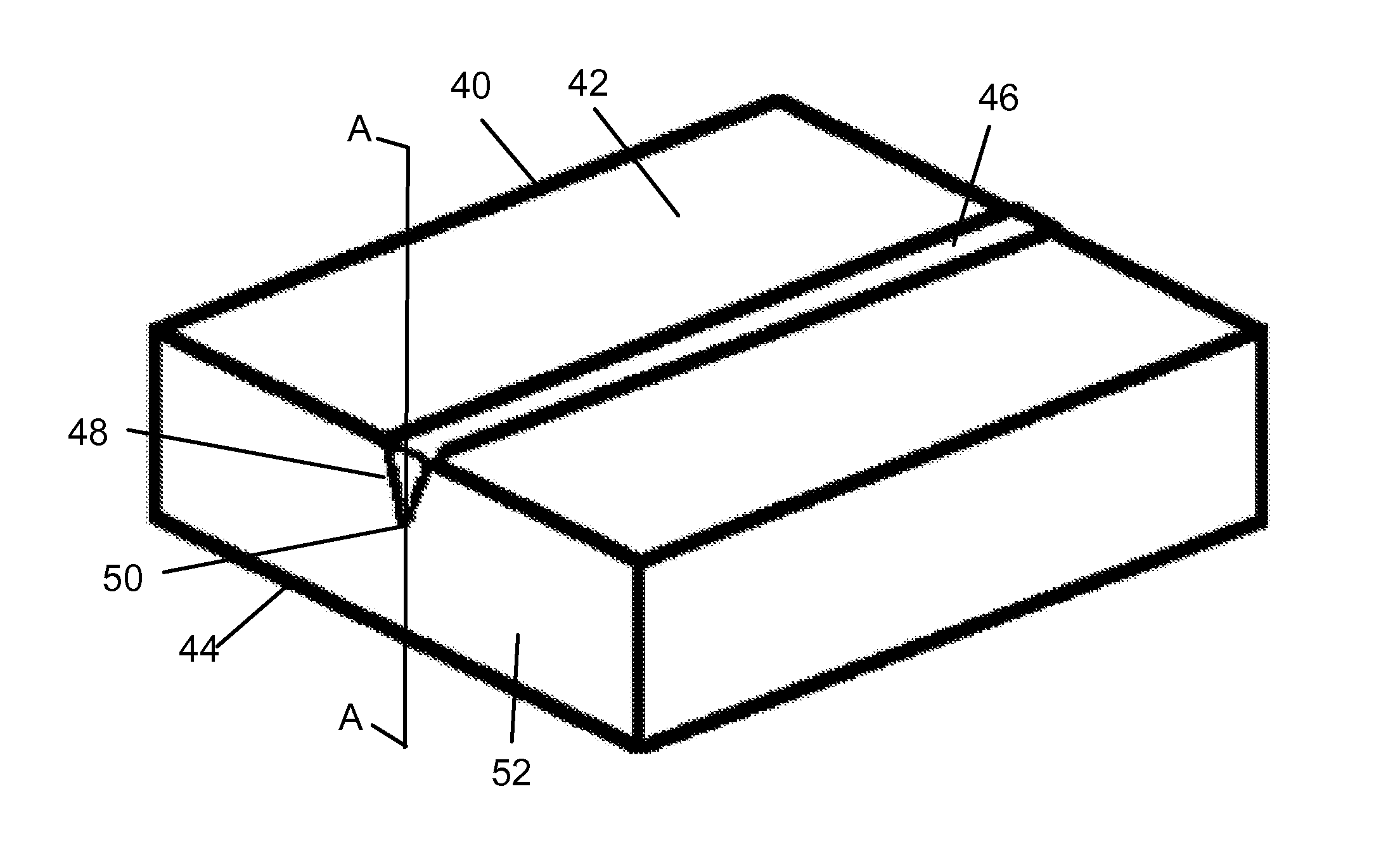

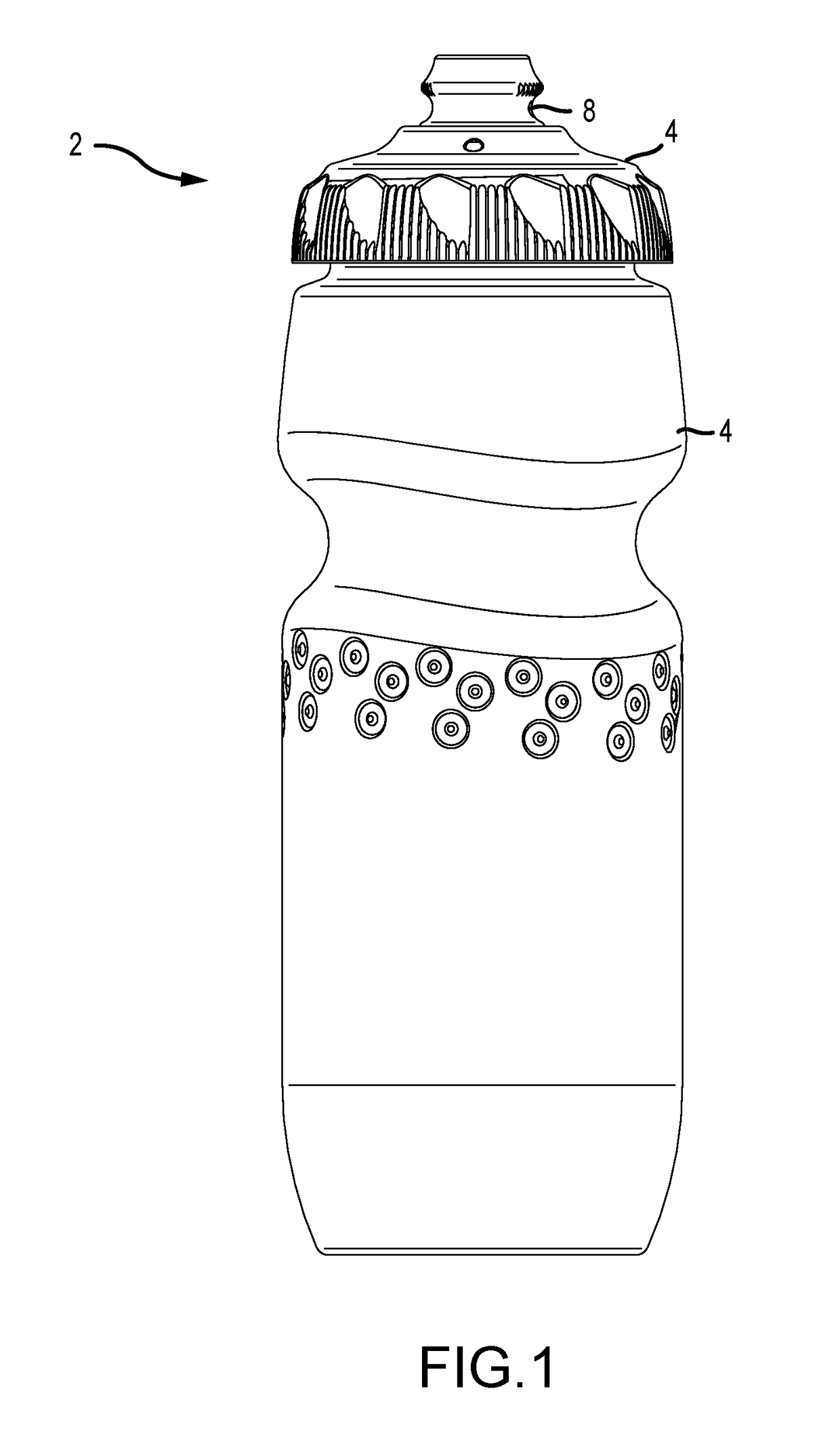

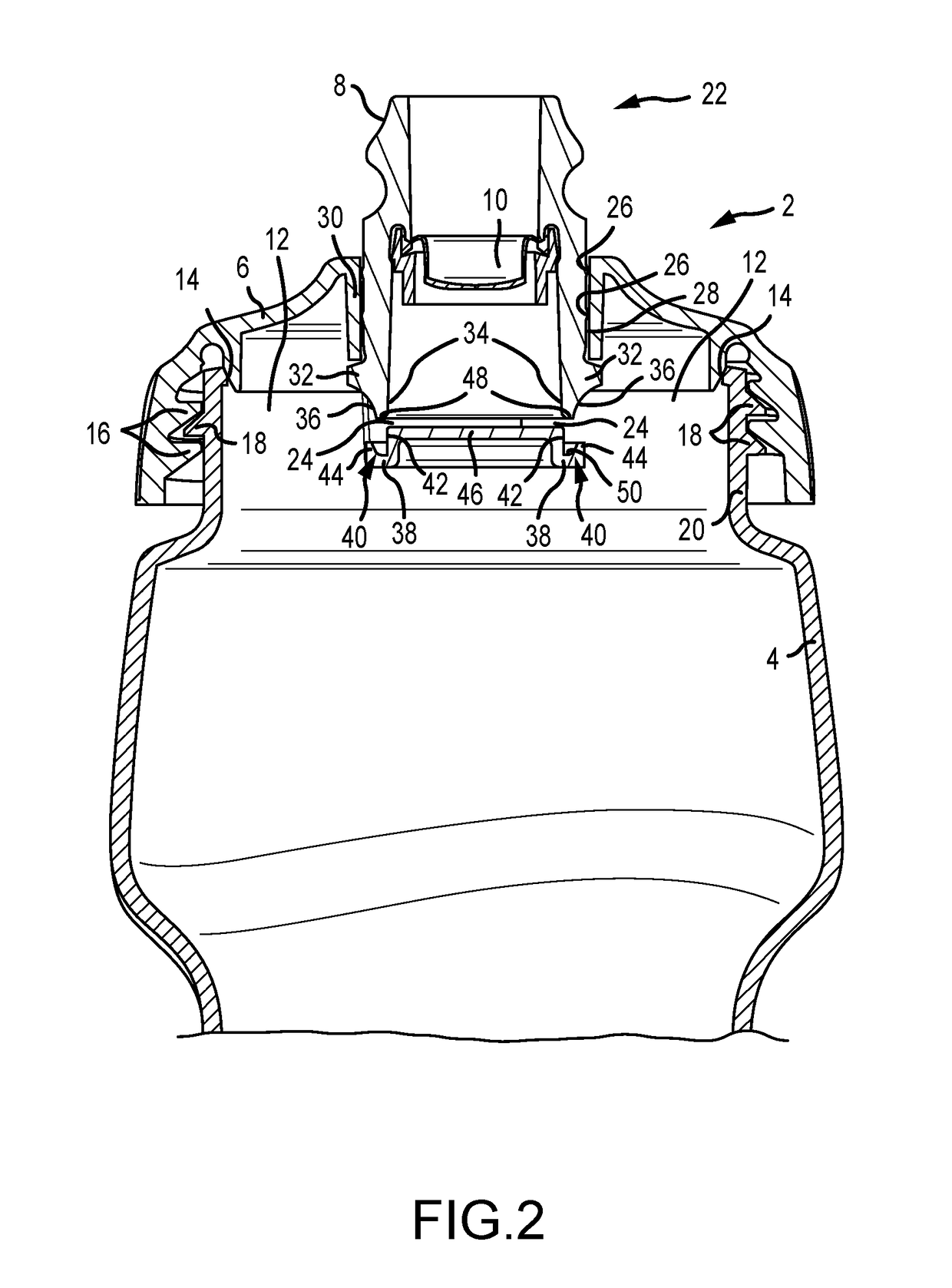

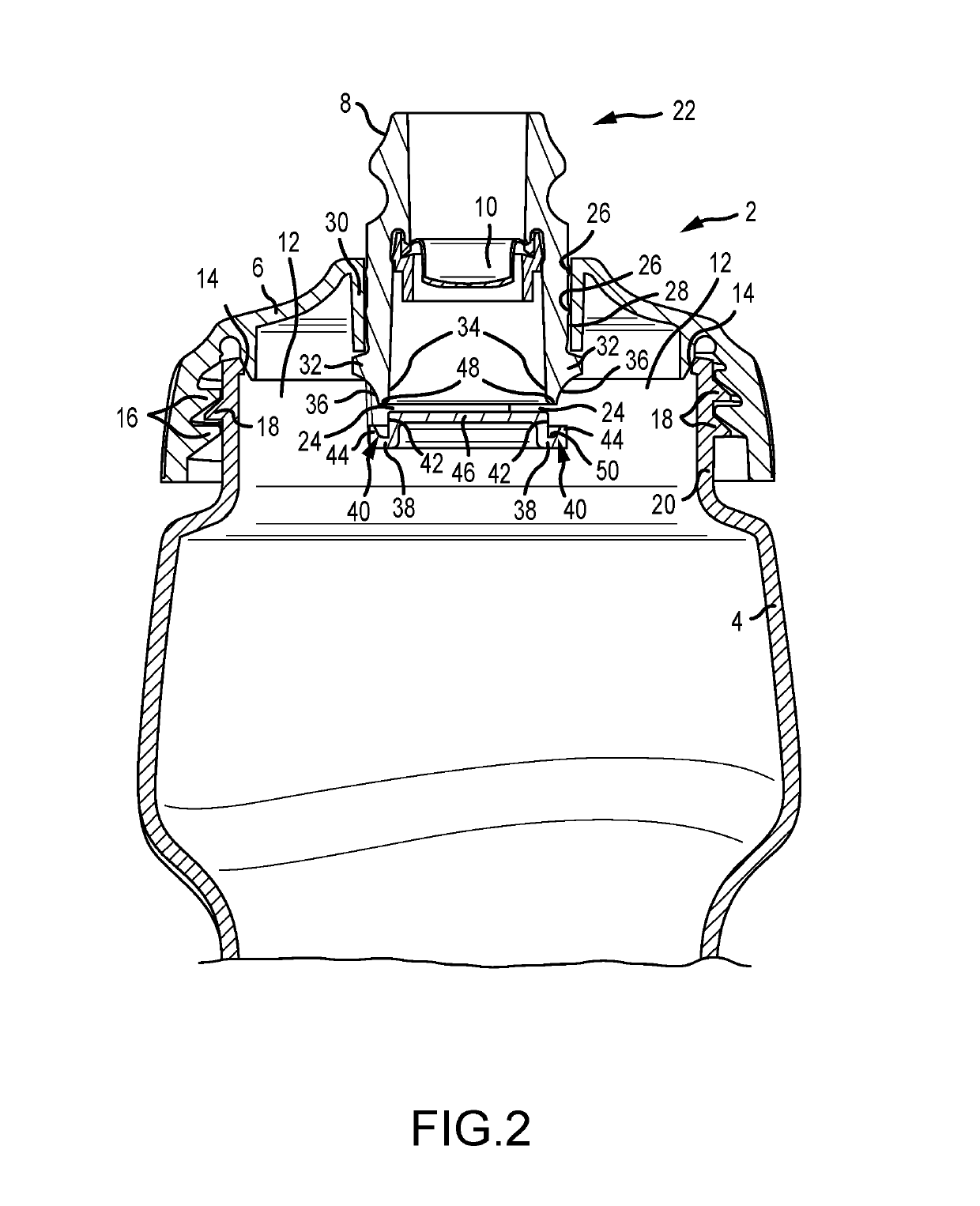

Sports bottle cap

A fluid container is disclosed with a cap body made of rigid or semi rigid material and a valve body disposed within the cap body and movable between and open and closed position. The valve body is made of a semi flexible semi rigid material that has a coefficient of thermal linear expansion that is smaller than that of the cap body. The cap body and nozzle valve are configured with three different hermetic seals to counteract the effects of exposure to heat and cold over time and thereby extend the useful life of the cap and valve.

Owner:HYDRAPAK LLC

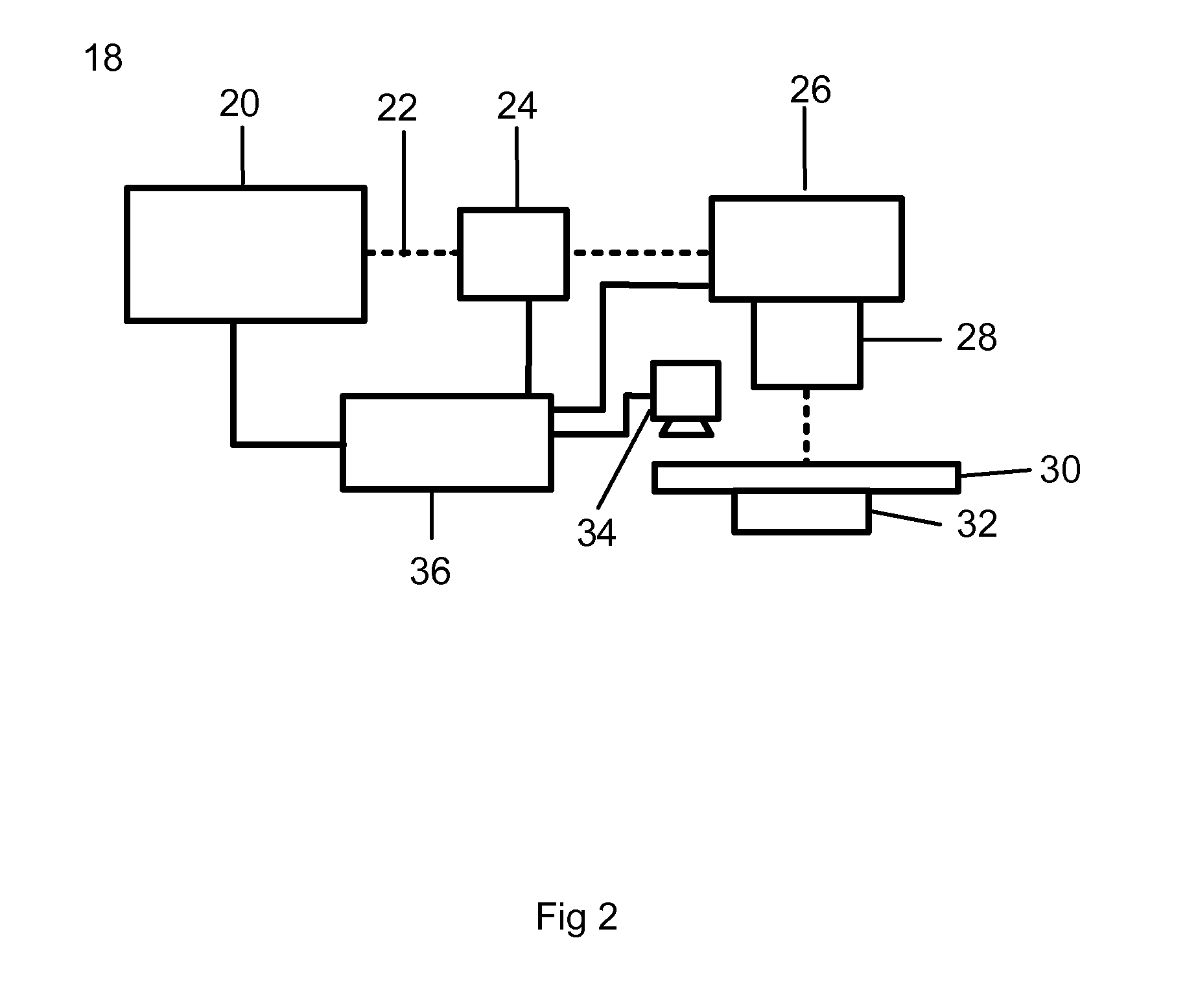

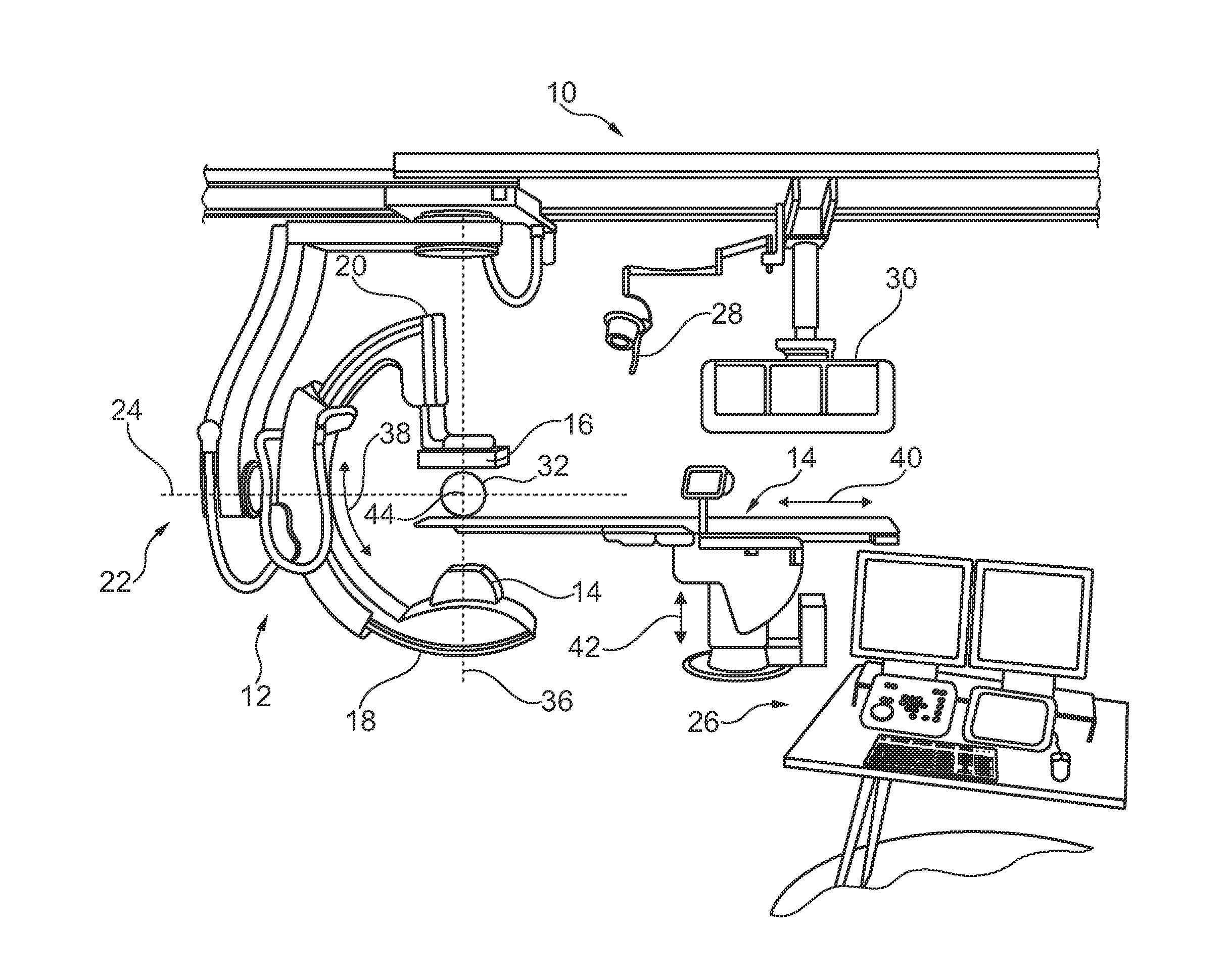

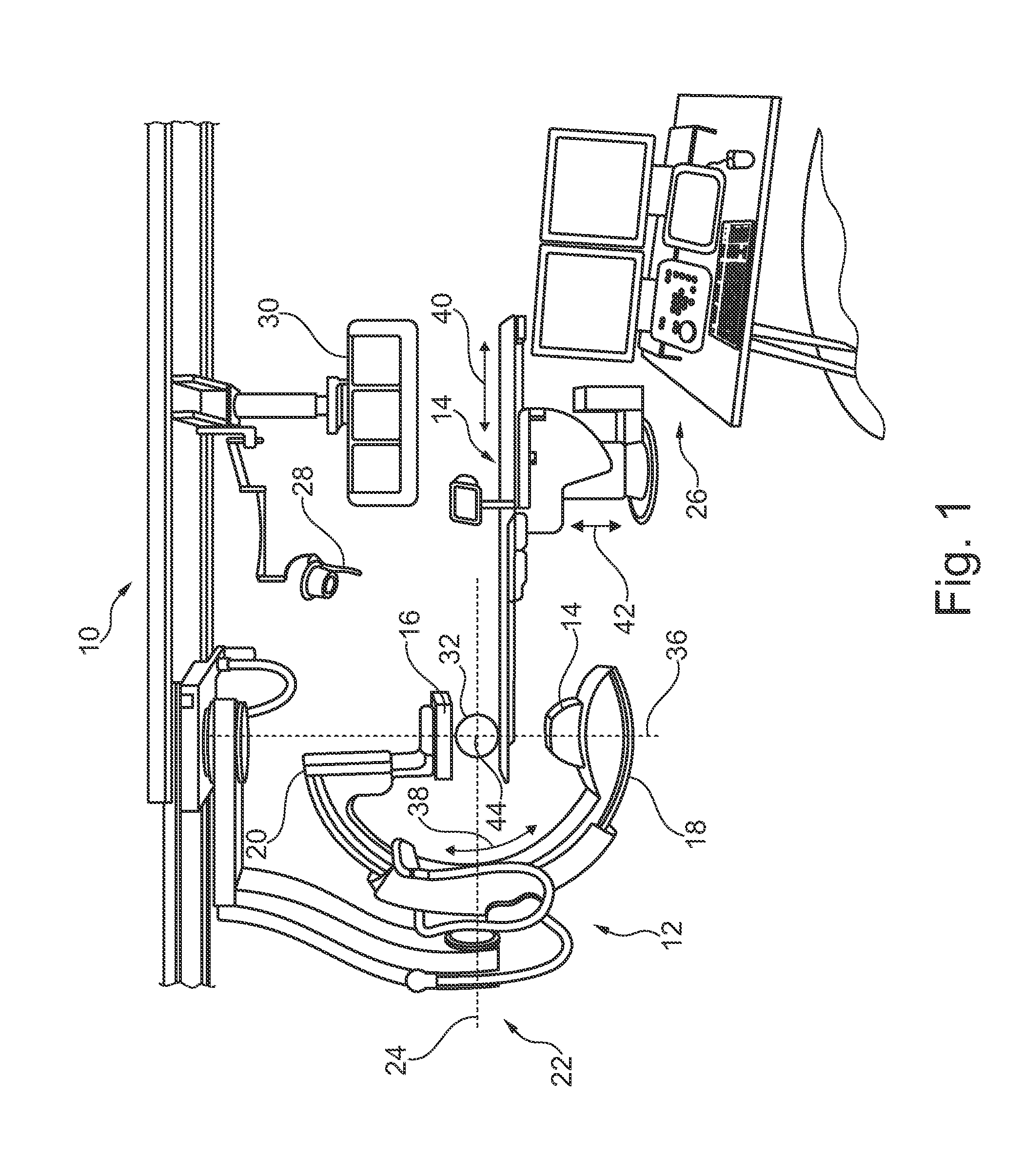

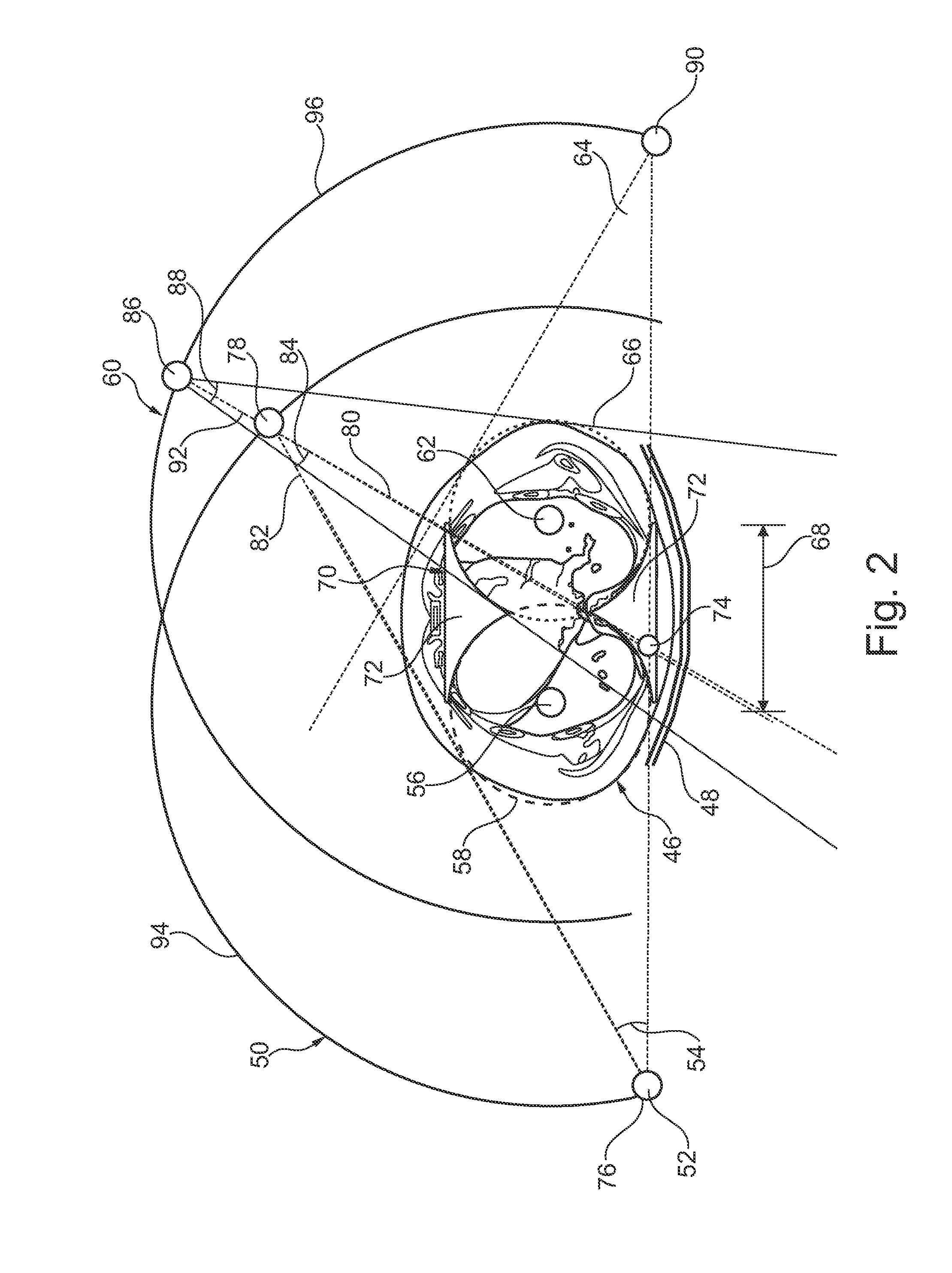

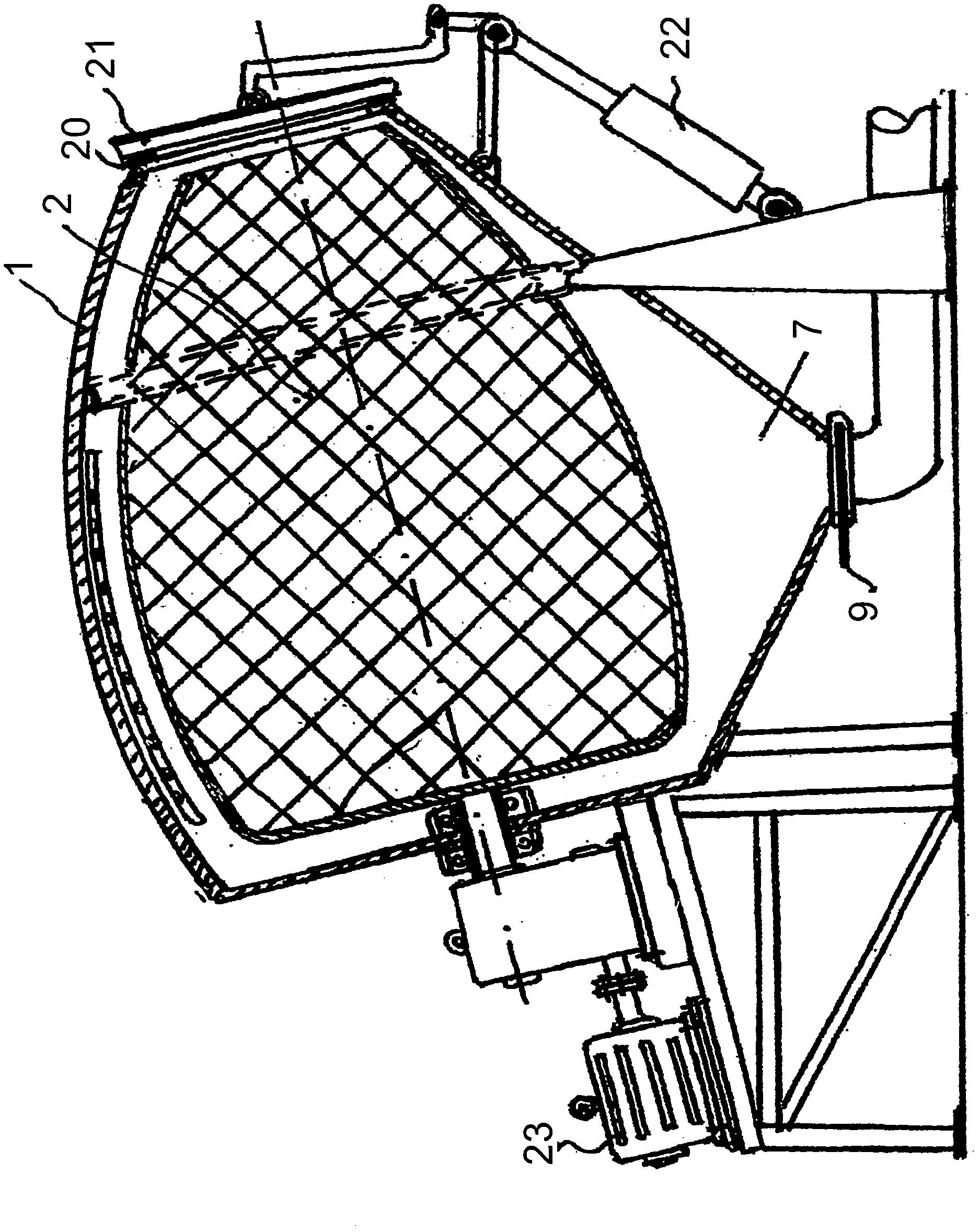

C-arm system with extended field of view

ActiveUS20140321612A1Reduce mechanical forceExpand field of viewX-ray/infra-red processesSterographic imagingCentre of rotationX ray image

The present invention relates to a C-arm X-ray imaging system. In order to provide C-arm systems with an extended three-dimensional field of view, a C-arm X-ray imaging system (10), provided to acquire extended three-dimensional images of an object, is provided, comprising a C-arm structure (12) with an X-ray source (14) and an X-ray detector (16) mounted across from the X-ray source, a motorized drive (22) for a rotational movement of the C-arm structure, and a control unit (26). The C-arm structure is provided to perform a rotational scan around an axis of rotation and around an ISO-centre acquiring a number of X- ray projections in order to generate image data for a reconstructed three-dimensional field of view. The control unit is configured to control the motorized drive, and to cause the rotational movement of the C-arm structure to perform a first rotational X-ray scan (50) around a first ISO-centre (56) with a first axis of rotation for a first field of view, and to perform at least a second rotational X-ray scan (60) around a second ISO-centre (62) with a second axis of rotation for a second field of view. The first and the second centre of rotation are displaced in relation to each other such that a connection line between the first and the second ISO-centre is arranged transverse to the first and the second axis of rotation.

Owner:KONINKLJIJKE PHILIPS NV

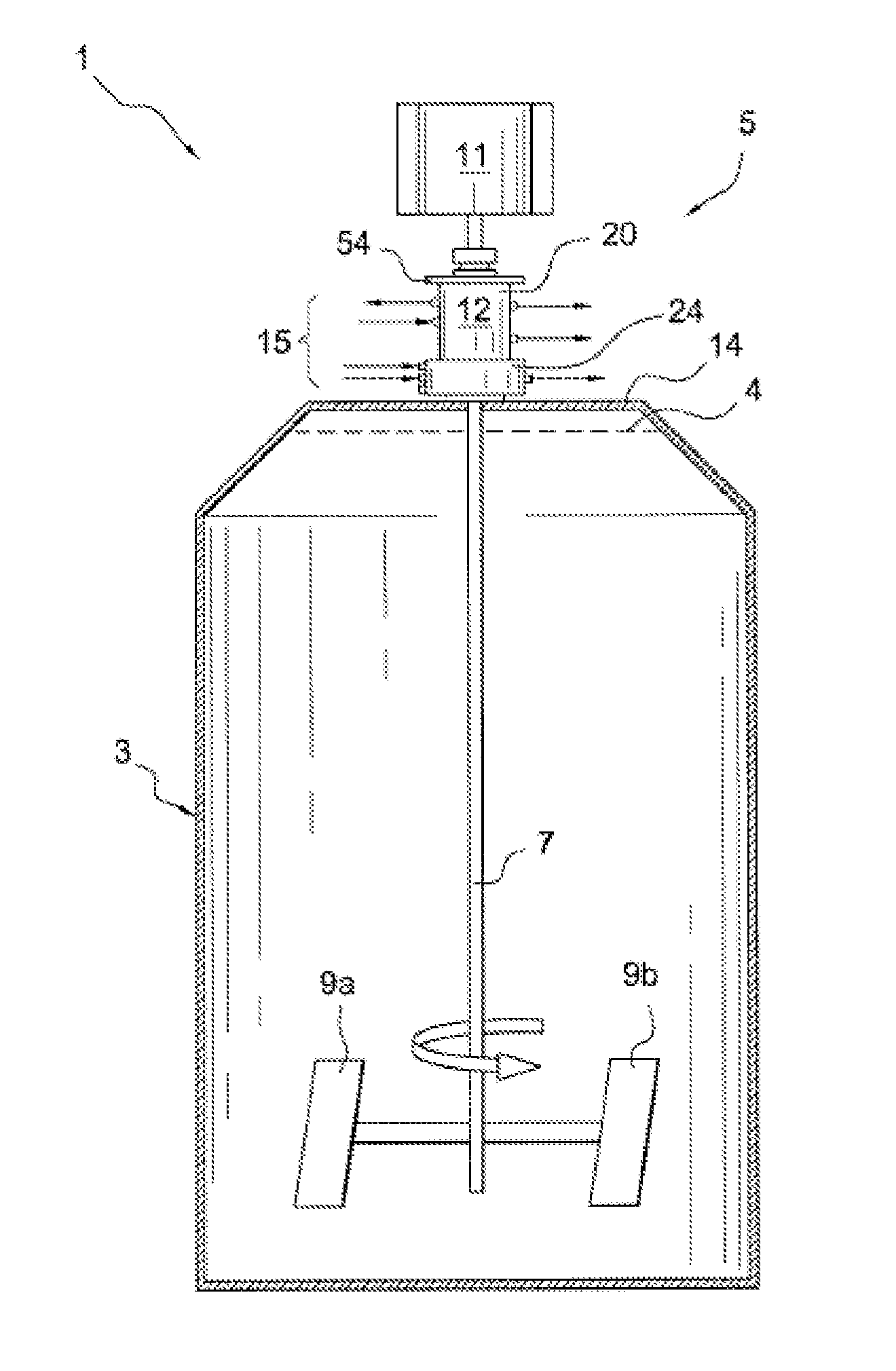

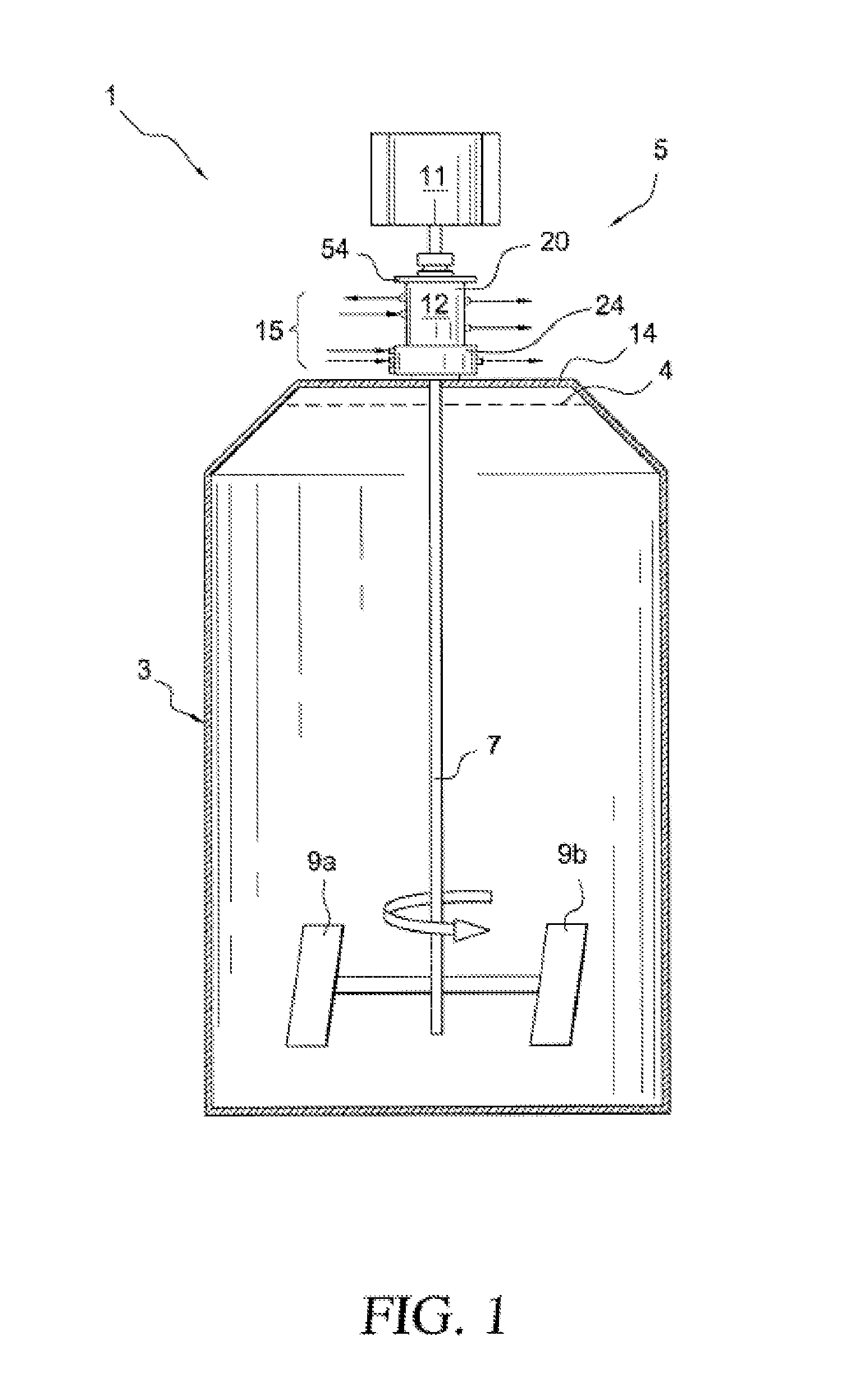

Polymerization reactor and related process

InactiveUS8735517B2Reduce mechanical forceConvenient thermal protectionProductsEngine sealsDifferential pressureClosed loop

Provided is a stirred tank polymerization reactor system having a reactor tank, a stirring assembly including a rotatable shaft that extends through a wall of the tank, and a triple barrier mechanical seal. The mechanical seal includes an outer cylinder mounted in the wall of the tank, an inner cylinder that is rotatable relative to the outer cylinder and connected to the shaft, and first, second, and third fluid barrier seals mounted between the outer and inner cylinders at different positions along the axis of rotation of the inner cylinder. First and second sources of pressurized barrier fluid are connected between the first and second pressure fluid barrier seals and the second and third barrier seals, respectively. The three barrier seals advantageously “step down” the differential pressure experienced by the uppermost barrier seals, substantially reducing mechanical stresses experienced by the annular sealing rings and seats. The mechanical seal can further include a closed loop cooling channel in its outer cylinder that is connected to a circulating source of cooling fluid.

Owner:EXXONMOBIL CHEM PAT INC

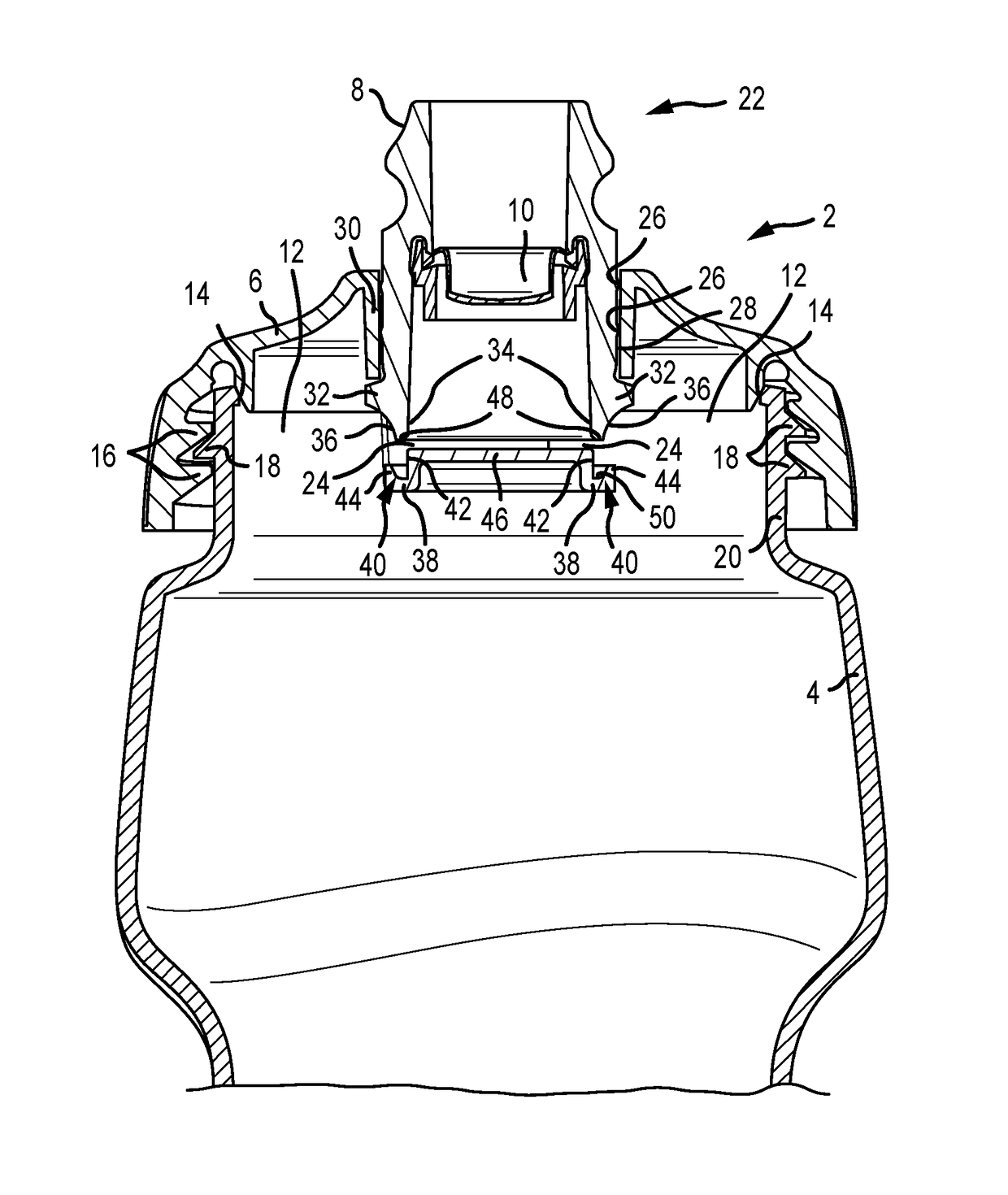

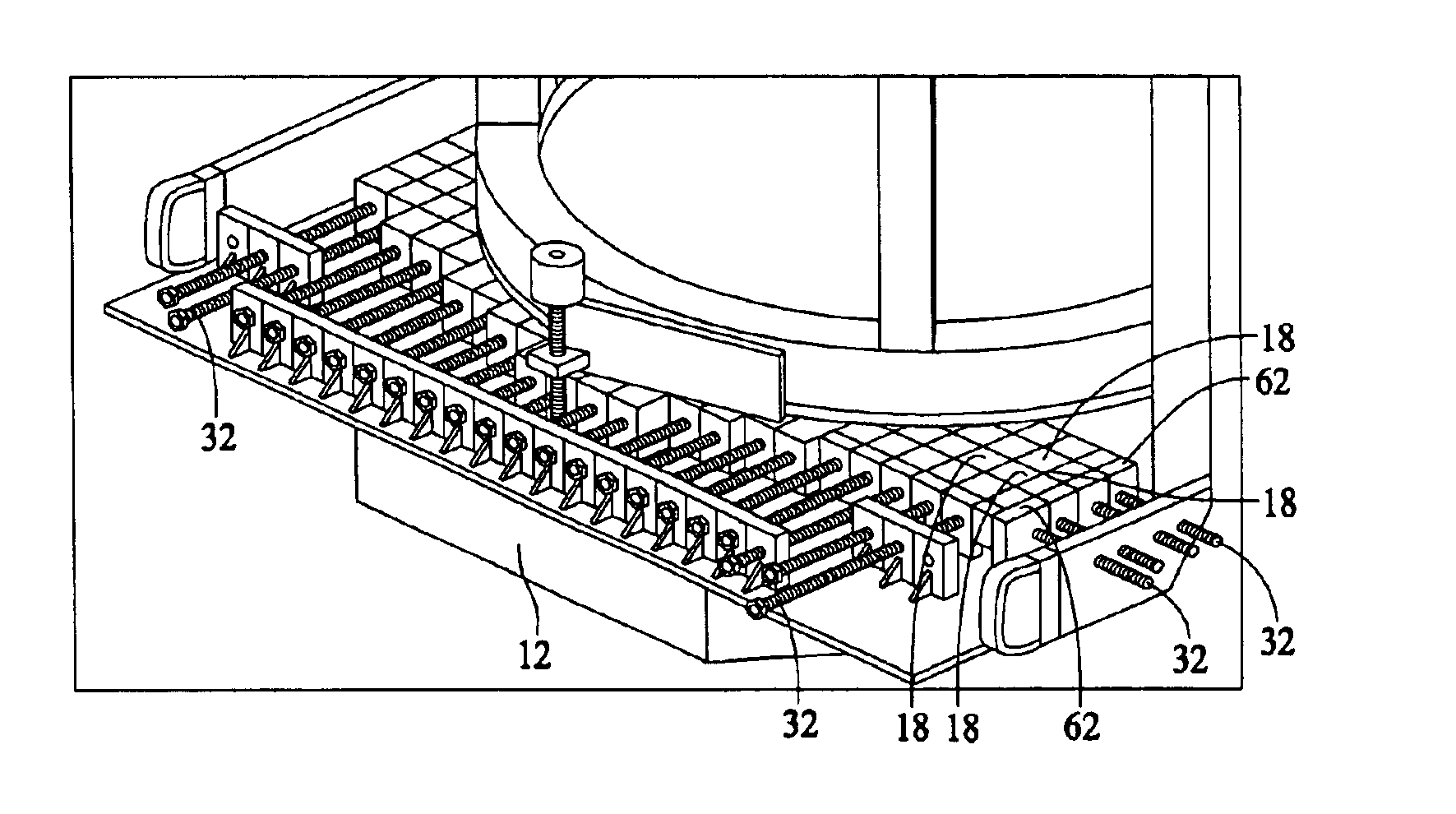

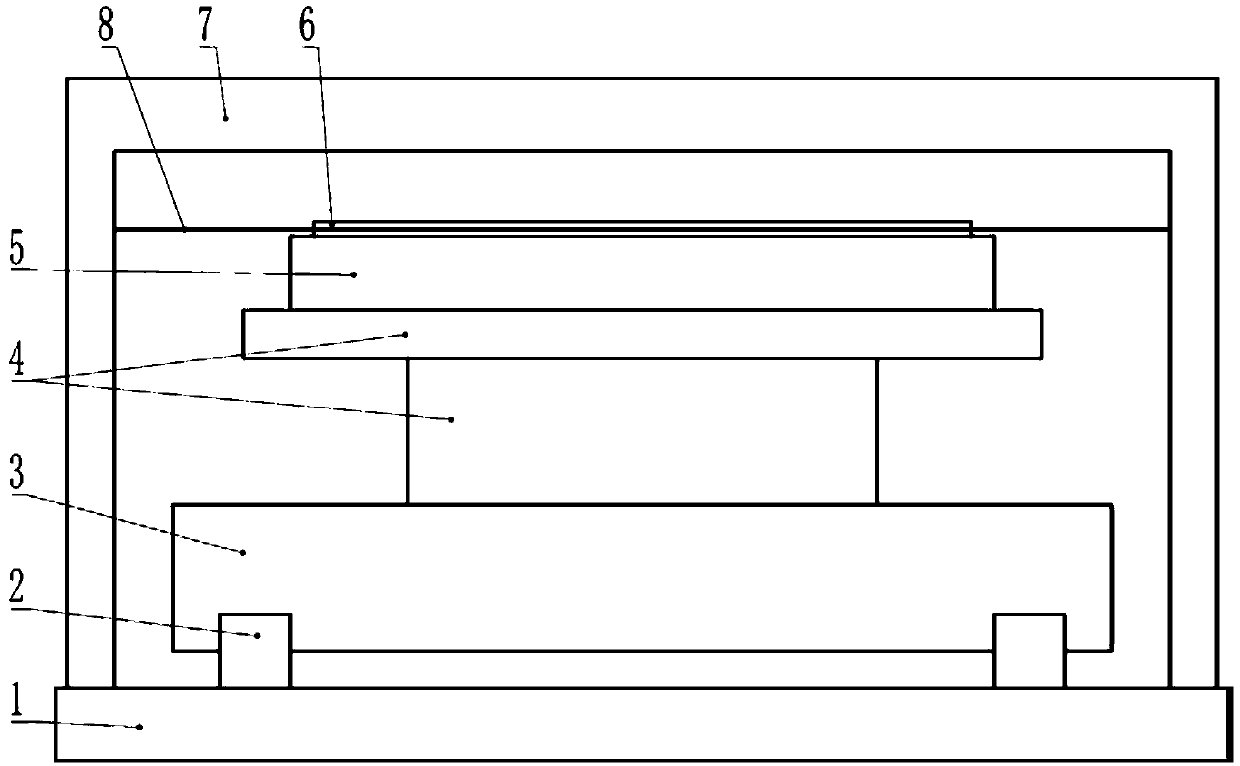

Methods and apparatus for positioning permanent magnetic blocks

InactiveUS6859123B2Reduce mechanical forcePermanent magnetsDiagnostic recording/measuringEngineeringMechanical engineering

A method for positioning permanent magnetic blocks includes providing a plurality of magnetized blocks, positioning the magnetized blocks on a yoke in a row by applying a mechanical force at a first end of the row with a first clamping member and at a second end of the row with a second clamping member, and repositioning the blocks by reducing the mechanical force at the first end by moving the first clamping member away from the first end, and moving the second clamping member toward the second end.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

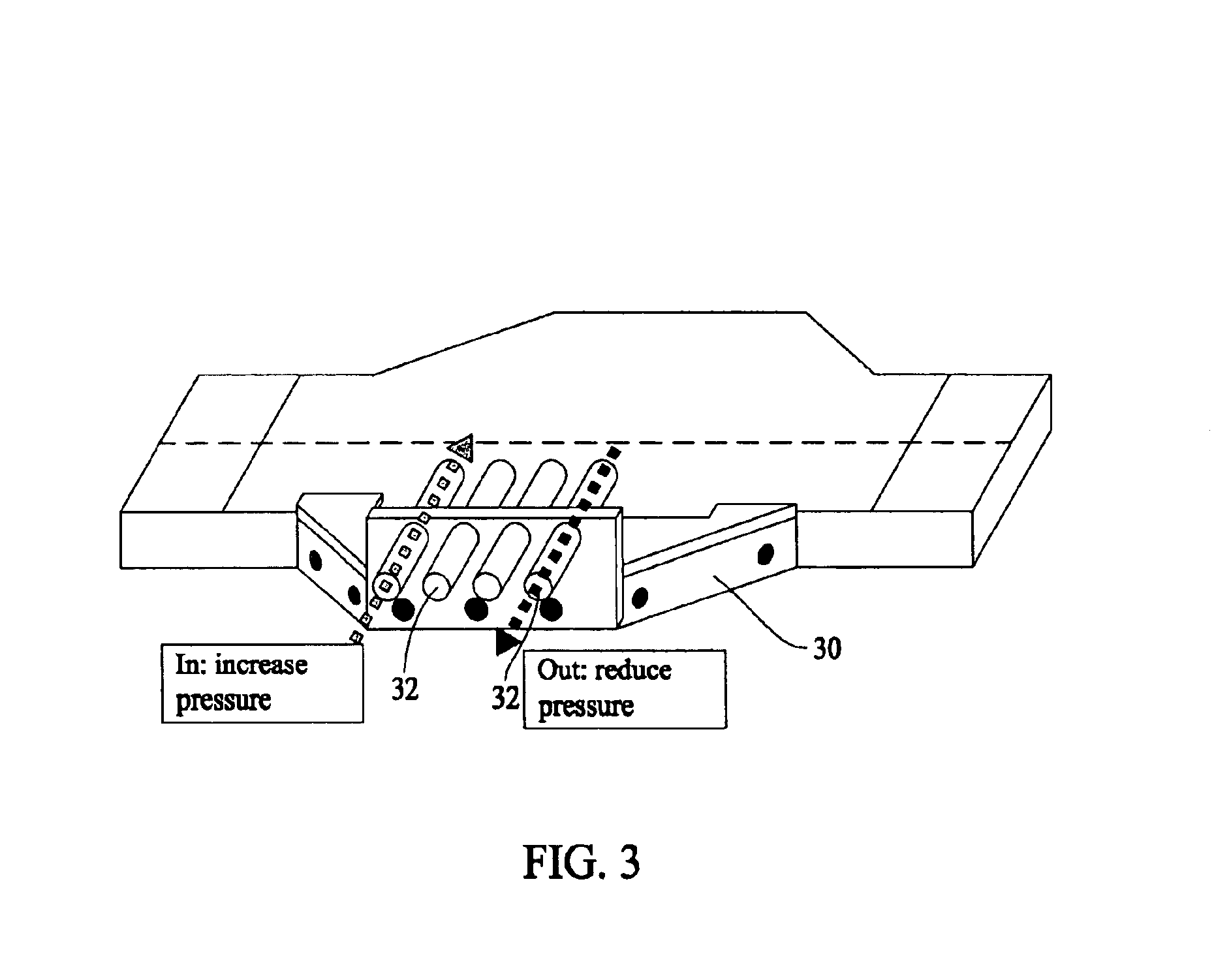

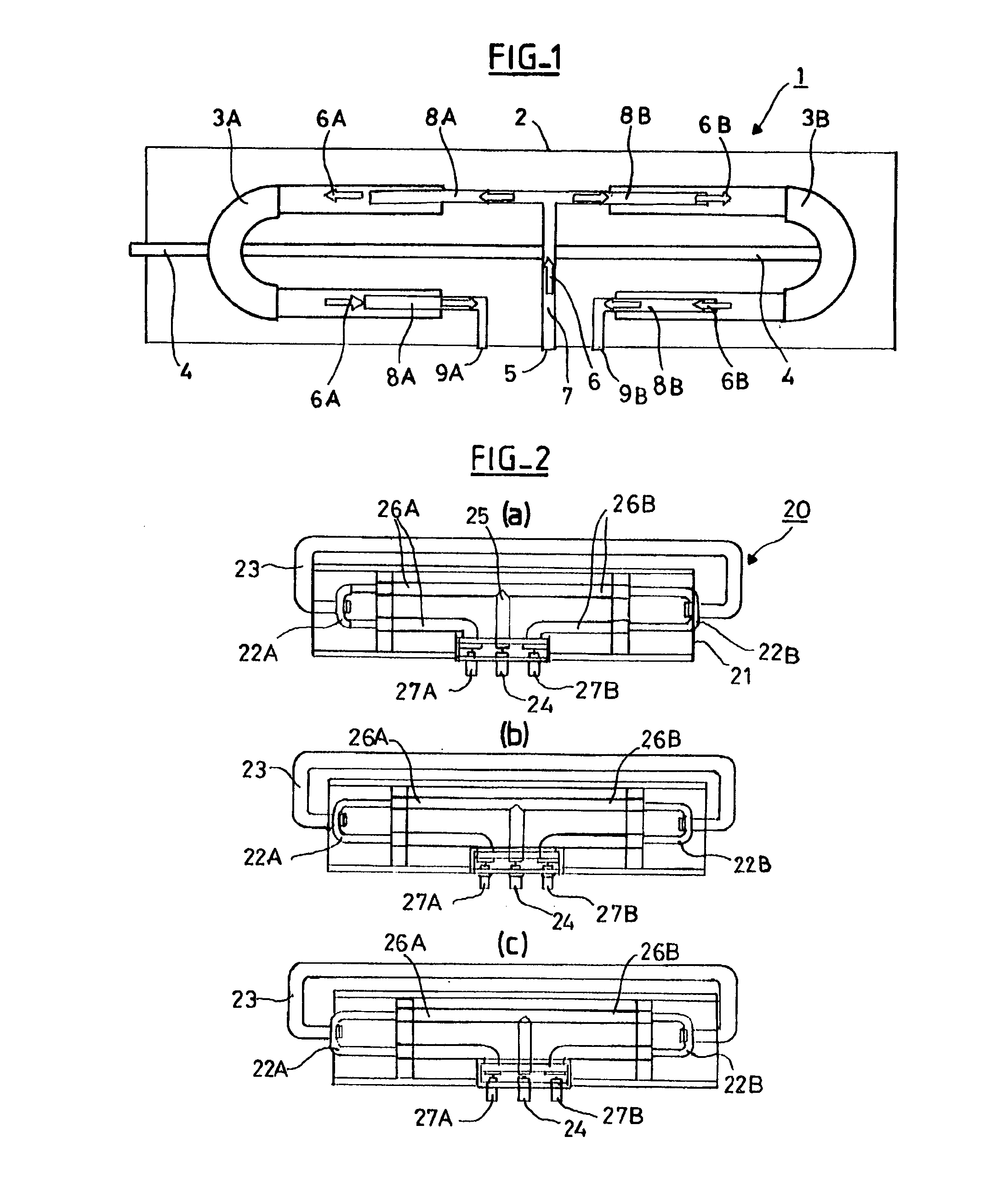

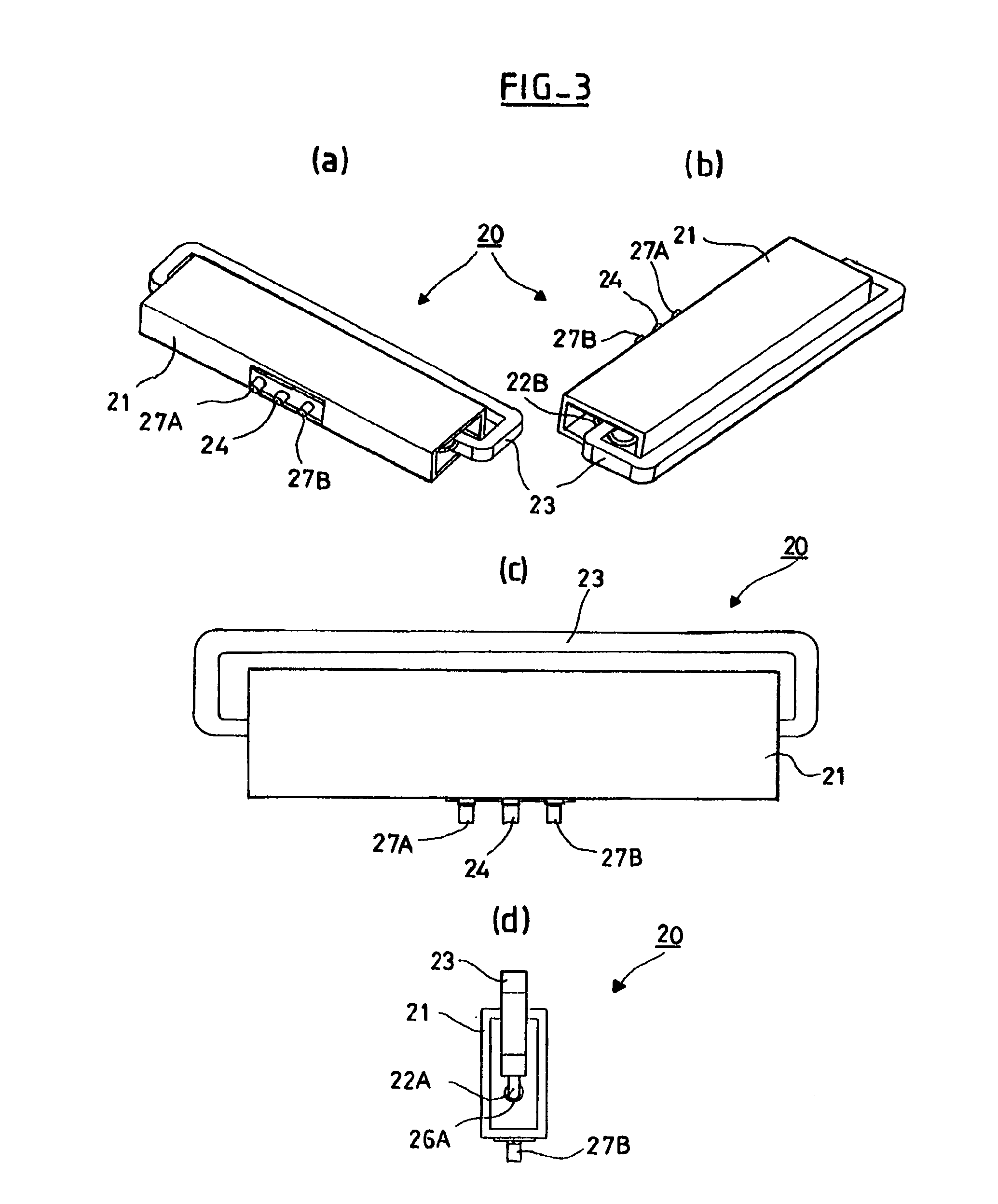

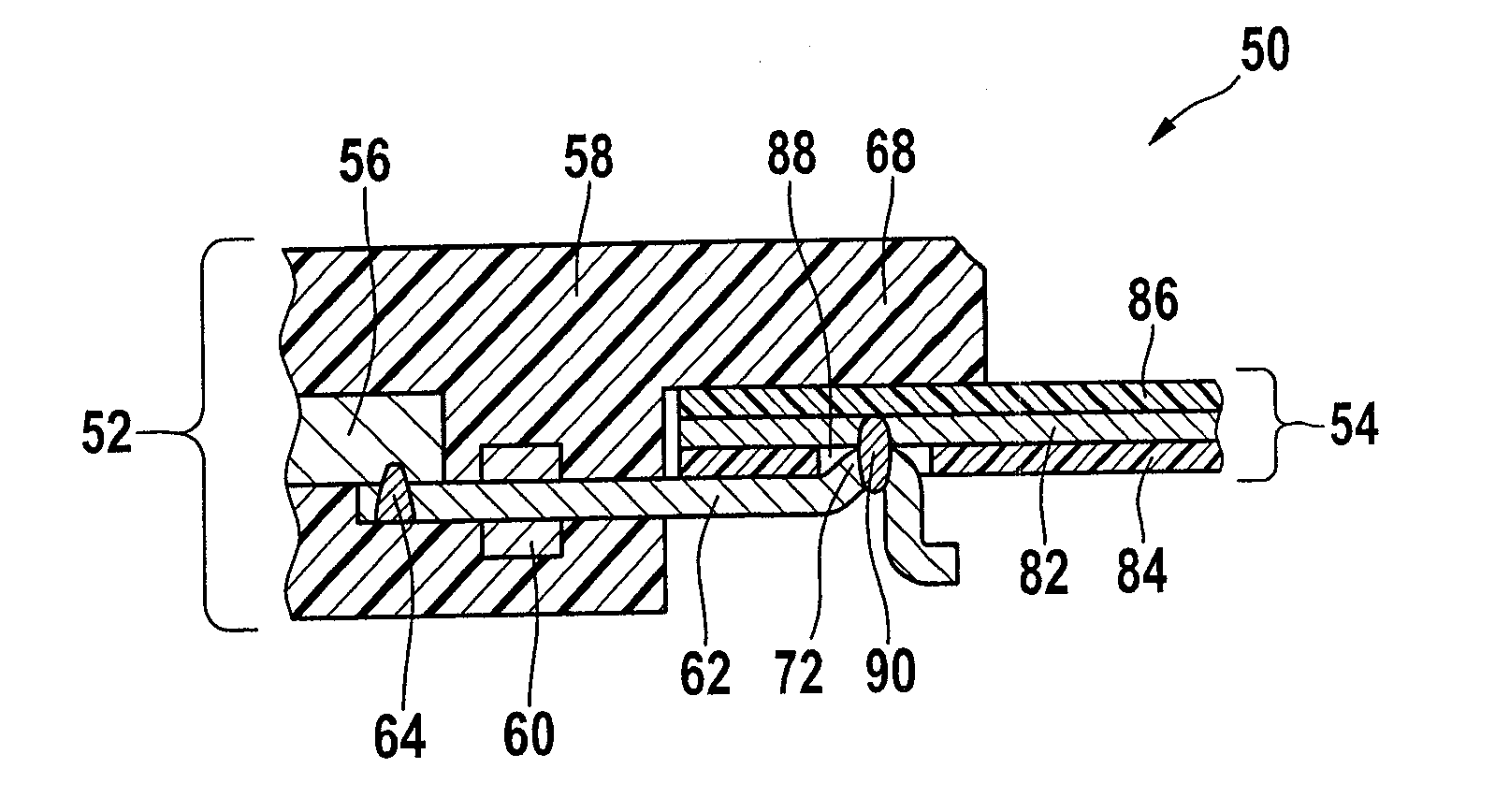

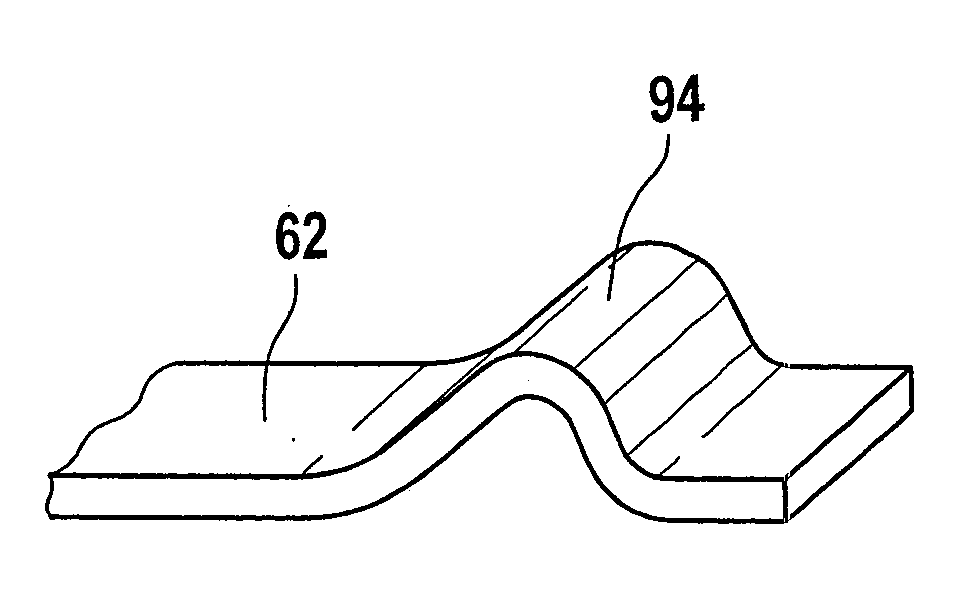

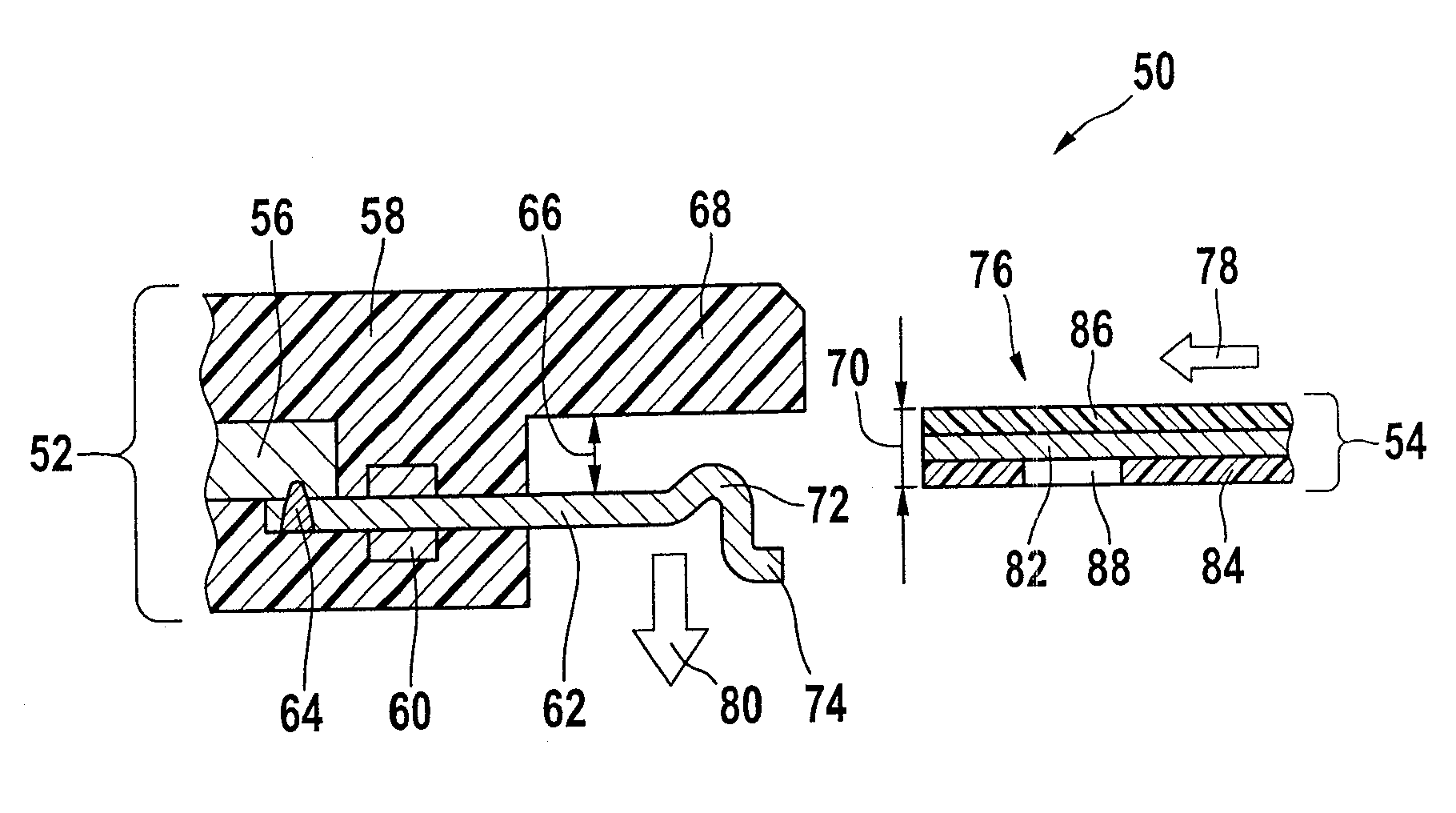

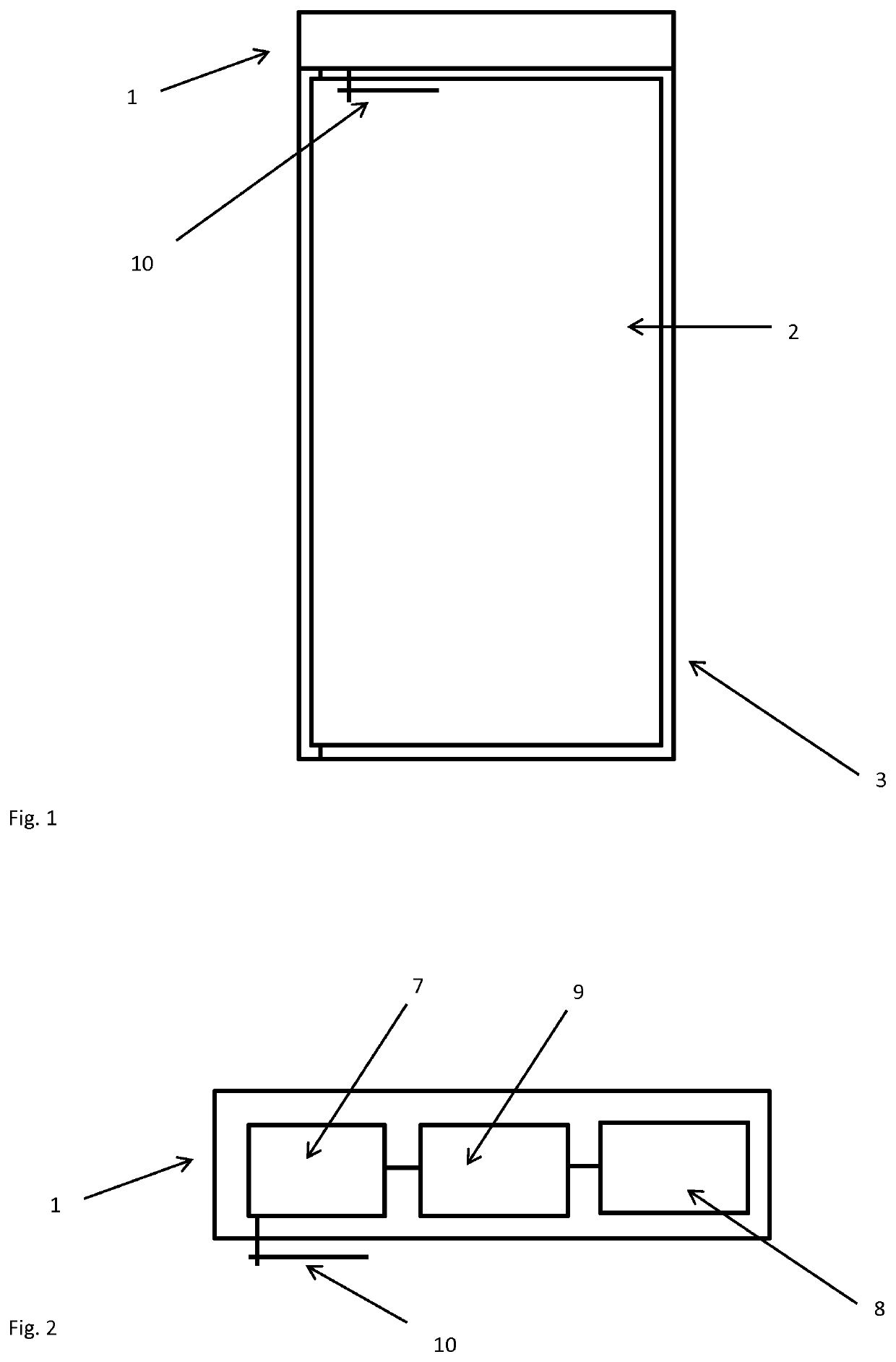

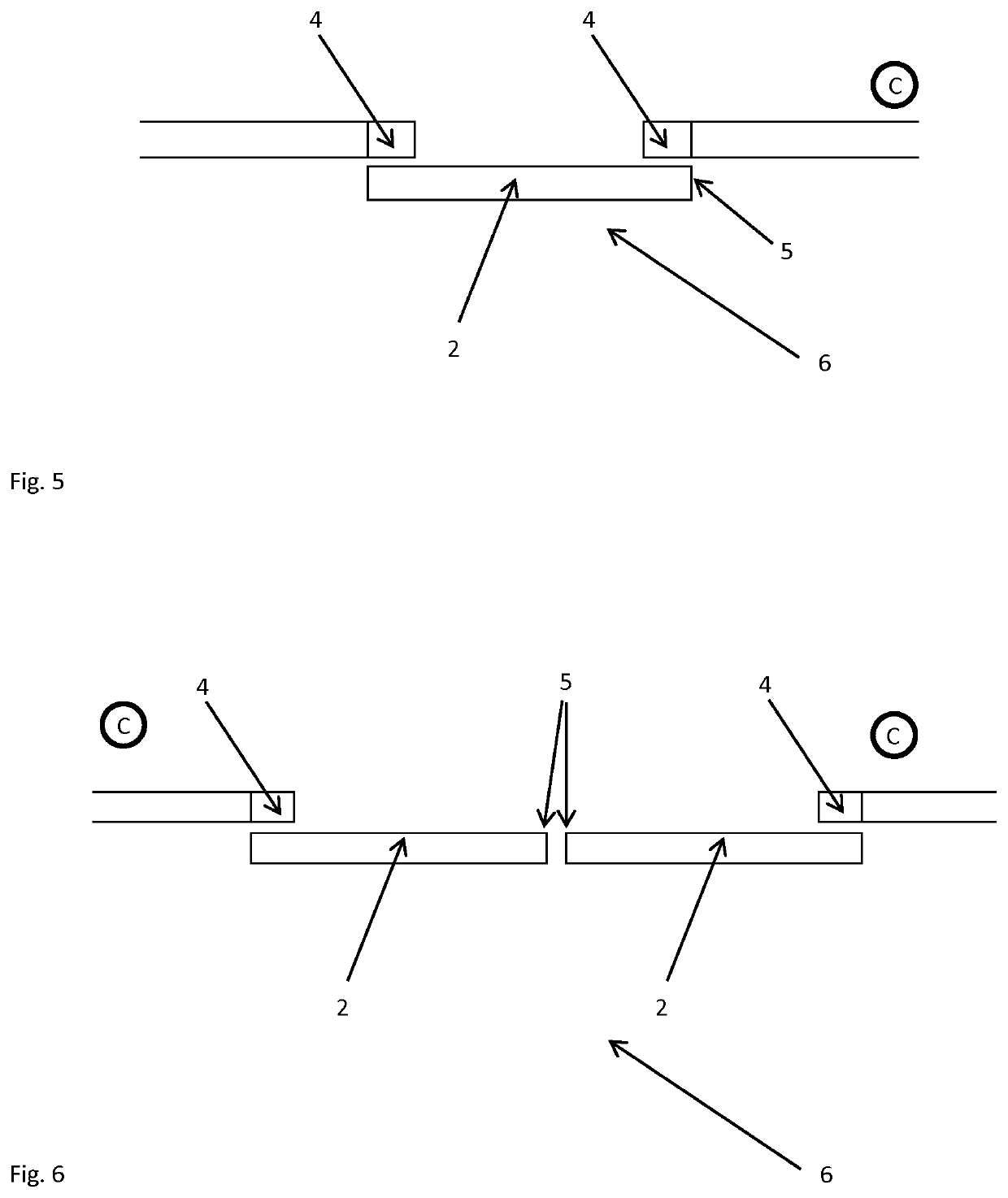

Phase-shifter and power splitter

InactiveUS20140218130A1Low costReduce mechanical forceDelay linesCoupling devicesElectrical conductorEngineering

An integrated device comprises at least one input connector (62) linked to an internal conductive line (64) and at least two output connectors (70A,70B) each respectively linked to an conductive branch (69A, 69B), wherein a single moving part (65), simultaneously serving the functions of a phase-shifter and a power-distributor, which comprises a shared segment (67) divided into two conductive arms (68A, 68B), the shared segment (67) linking the internal conductive line (64) to each of the conductive branches (69A, 69B) respectively, so as to vary, by an equal but opposite quantity, the length of the electric path between the input connector (62) and each of the output conductors (70A,70B) when the moving part (65) moves. The moving part (65) can be actuated from outside the housing, preferentially by means of a transmission bar (66).

Owner:ALCATEL LUCENT SAS

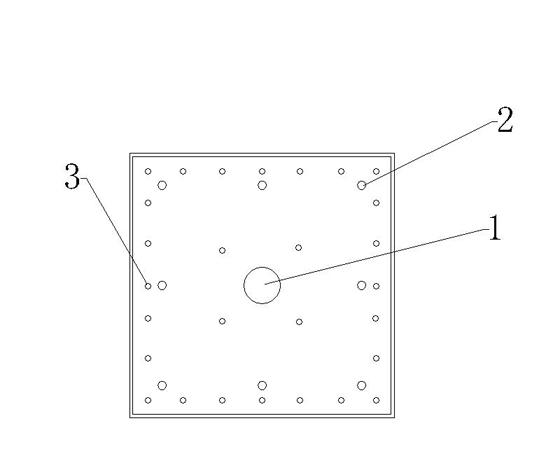

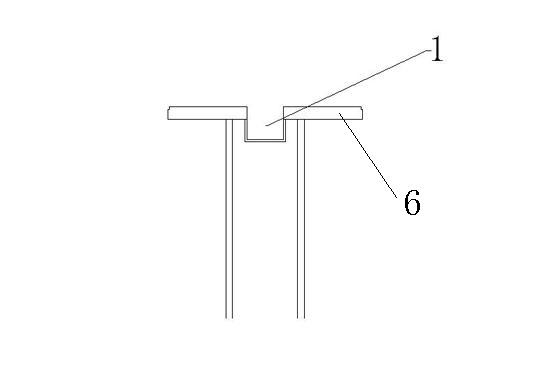

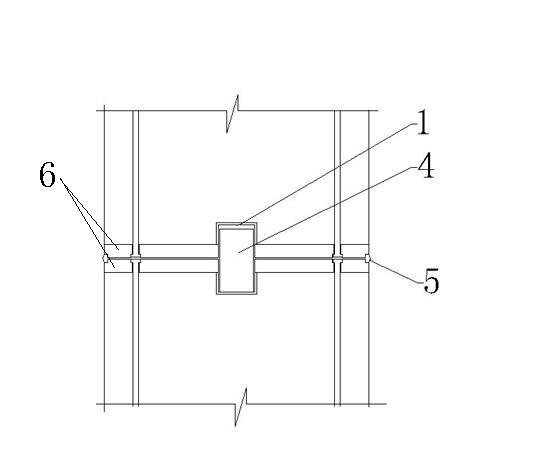

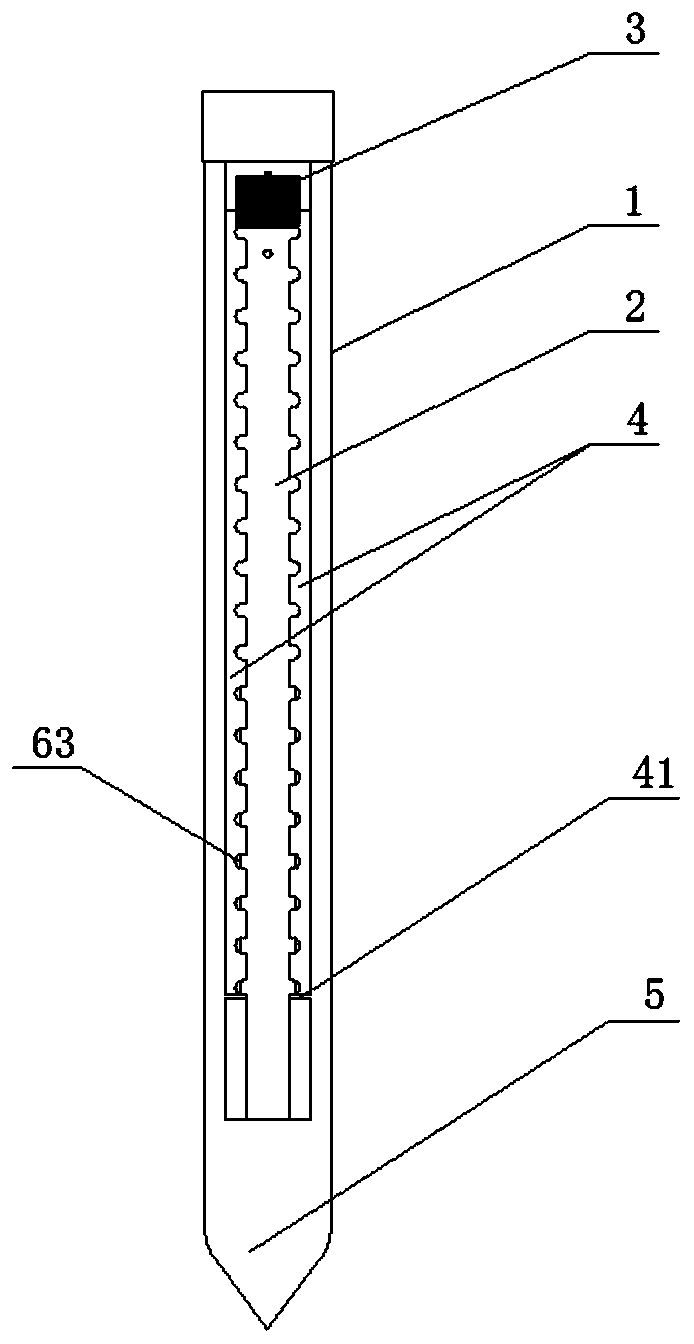

Joint with anti-seismic slots for precast concrete piles

The invention discloses a joint with anti-seismic slots for precast concrete piles, belonging to the building field. Two precast pile jointing faces of the joint with anti-seismic slots for precast concrete piles (which can be square or circular and solid or hollow) are both provided with end plates, at least one anti-seismic slot is arranged on the end plate of each precast pile jointing face, and the anti-seismic slots on the two precast pile jointing faces correspond to each other. When two precast piles are connected, connecting steel bolts are arranged in the anti-seismic slots. When the joint with anti-seismic slots for precast concrete piles is in use, after the connecting steel bolts are installed in the anti-seismic slots arranged on the jointing faces, staggered displacement between an upper precast pile and a lower precast pile and pile falling which are generated under the situations of seism and the like can be solved, pile breaking and pile falling can be avoided after a welded junction on the precast pile jointing faces is broken, the upper pile and the lower pile are concentrically stressed, and the main building can be protected from being damaged due to foundation disturbance. Meanwhile, by applying the precast pile joint, the traditional precast pile joint connection mode is changed, steel is saved, and the pile jointing process is also simplified.

Owner:DALIAN GREAT GOLDEN HORSE INFRASTRUCTURE

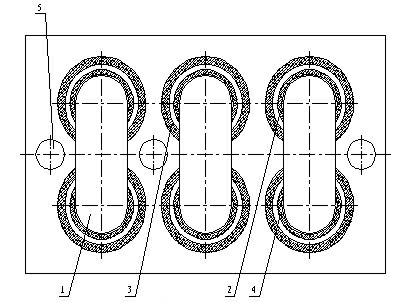

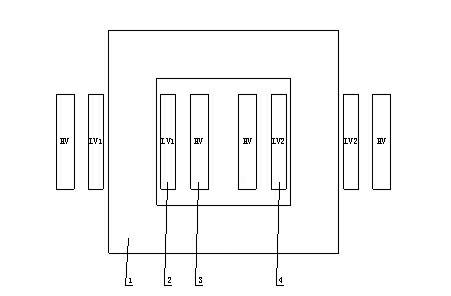

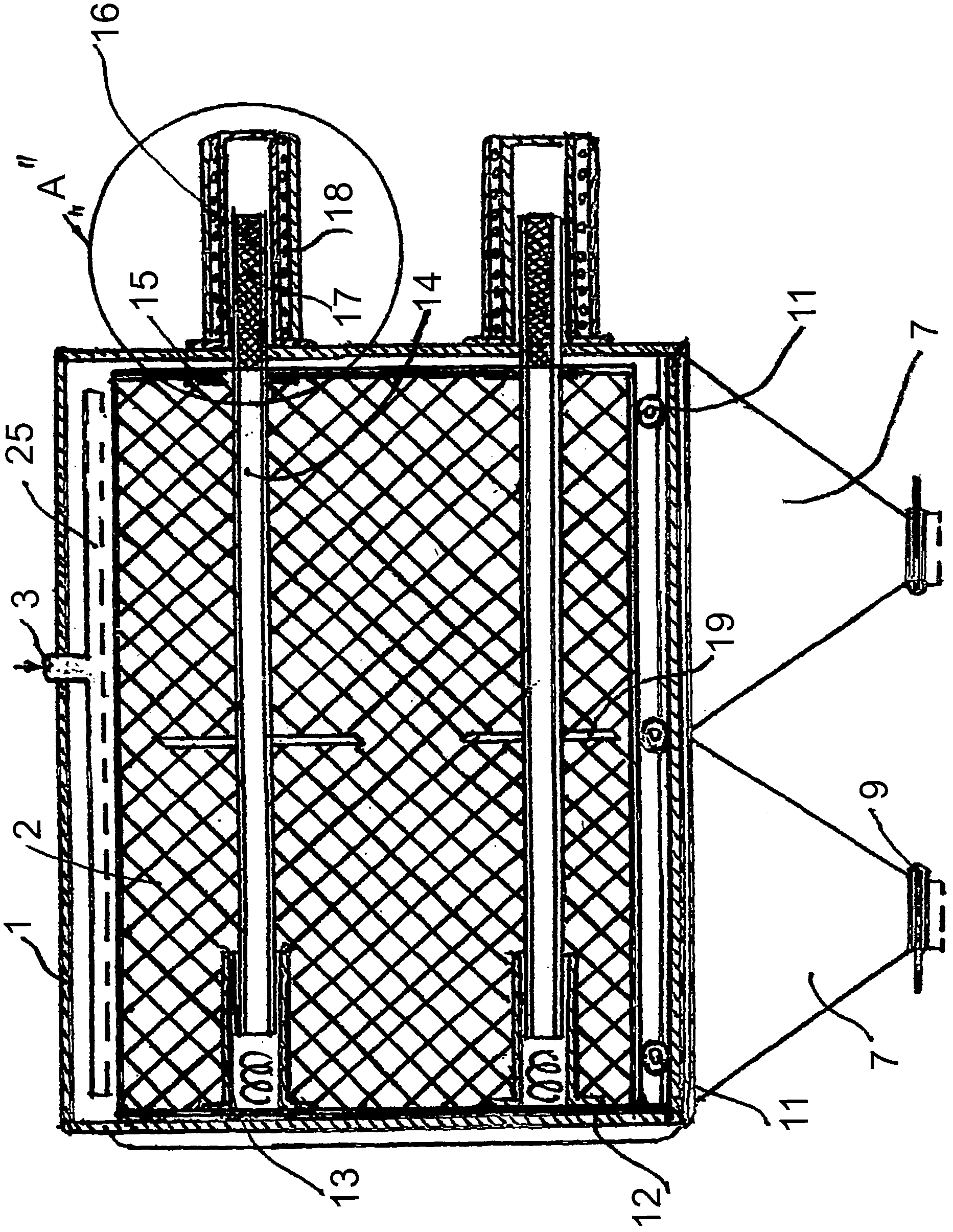

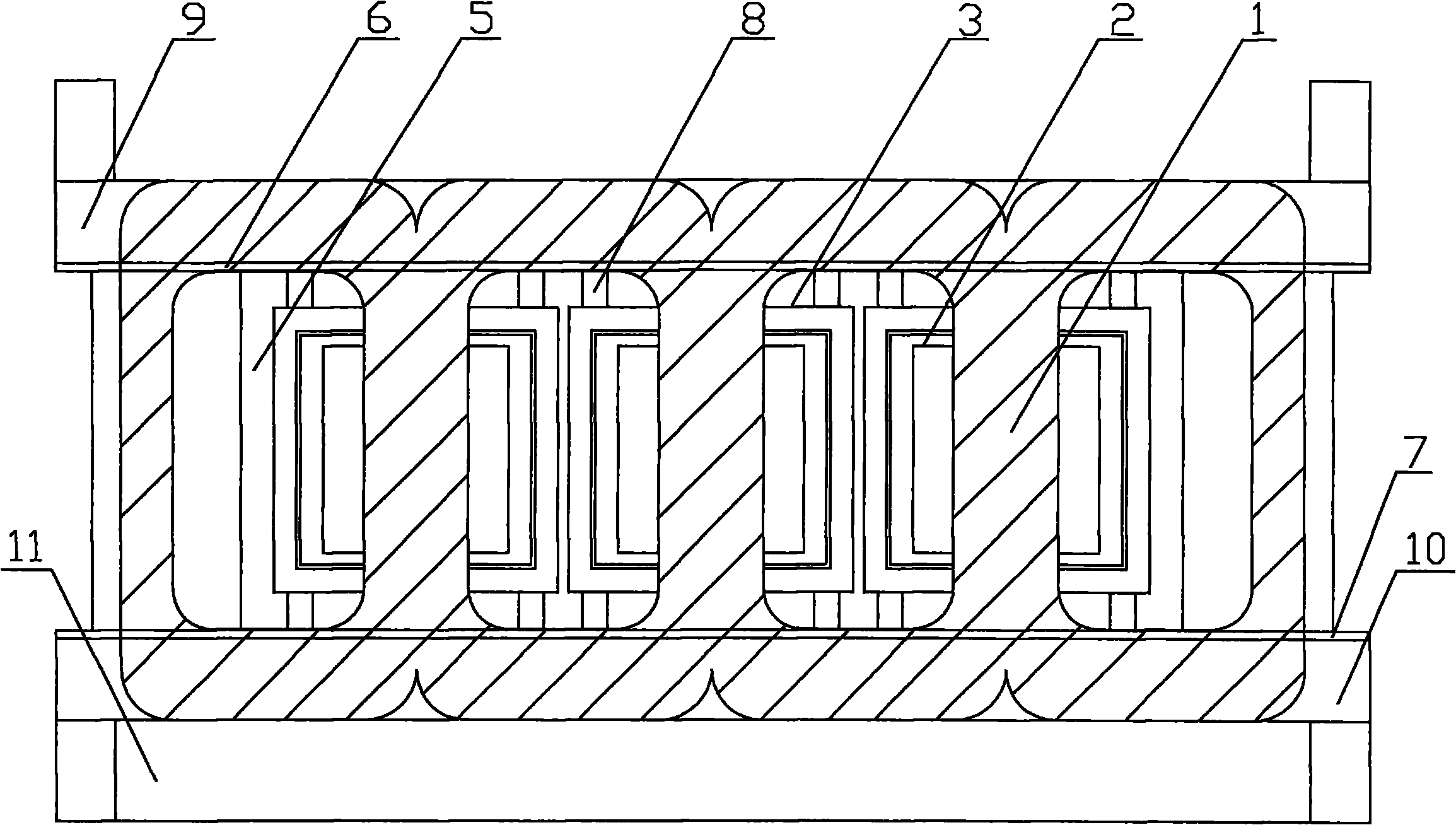

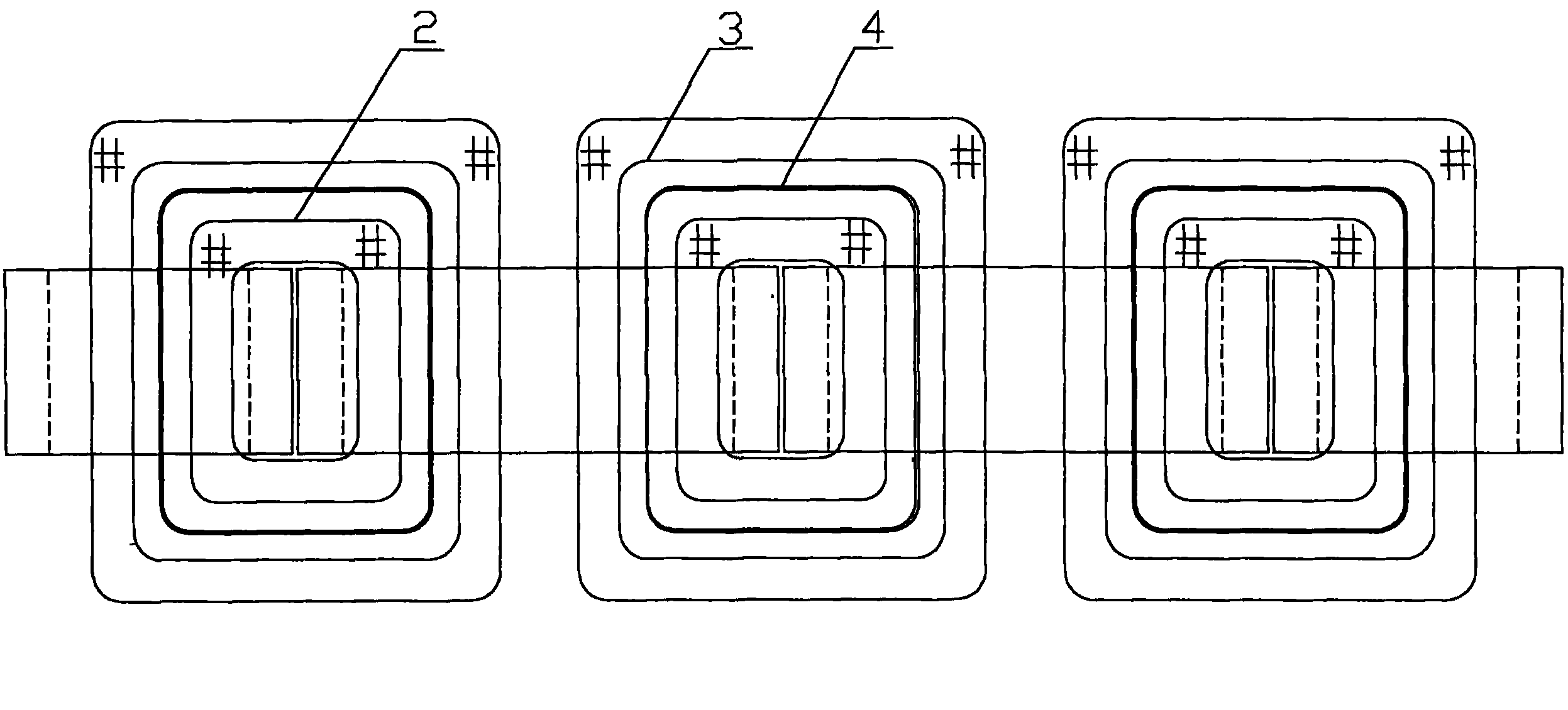

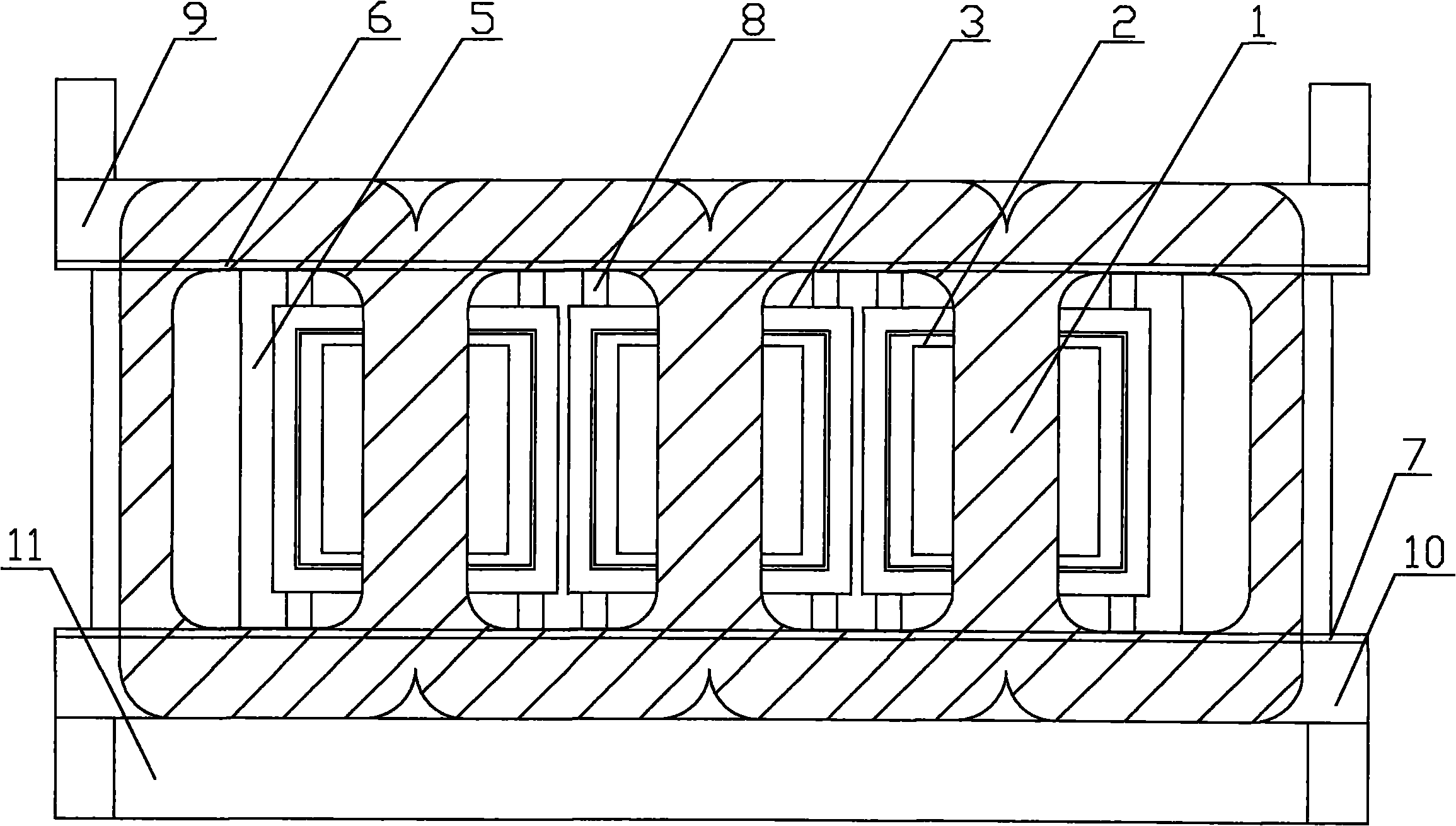

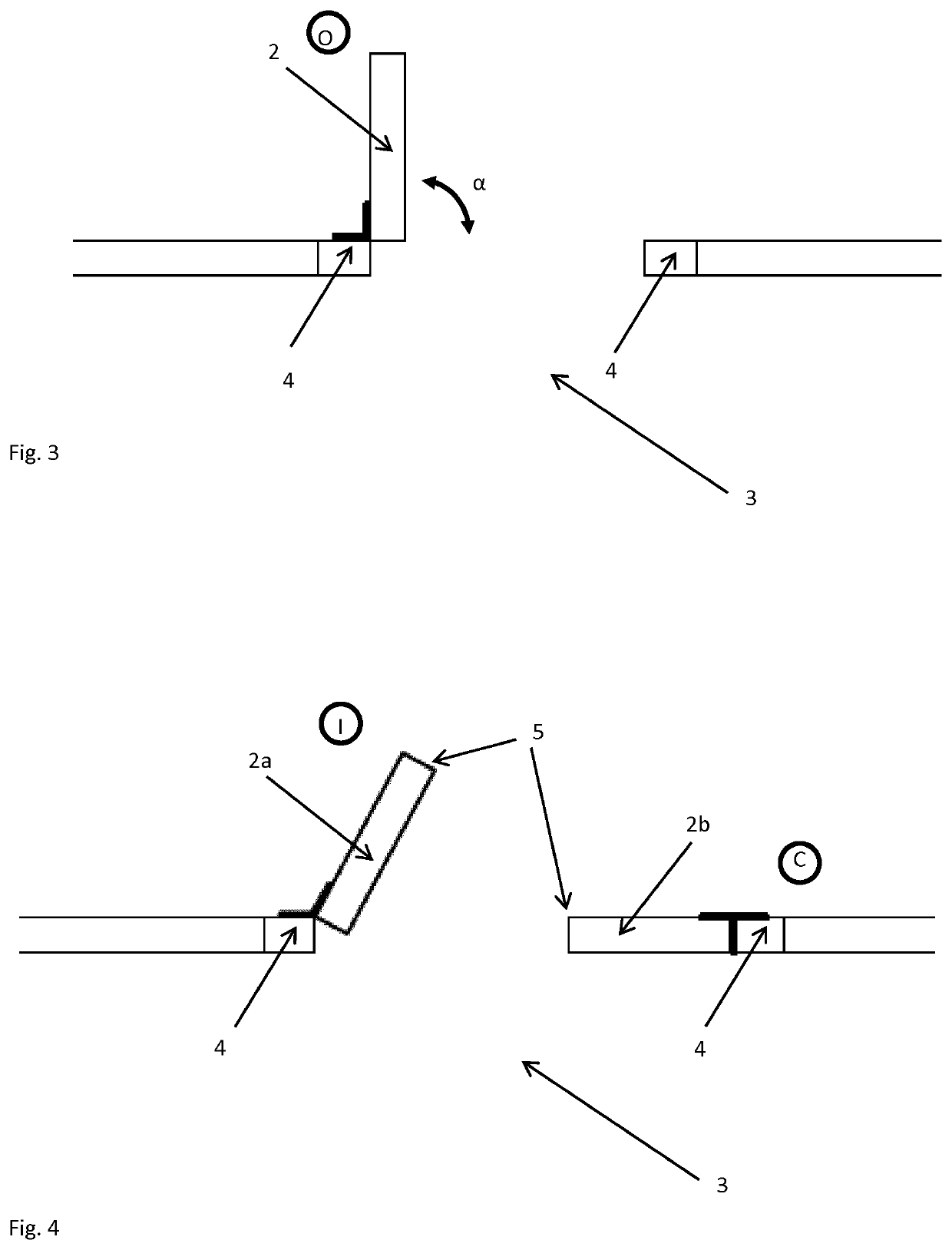

High-capacity three-body split winding type transformer

InactiveCN102436920AReduce footprintReduce in quantityTransformers/inductances coils/windings/connectionsFixed transformersLow voltageFuel tank

The invention relates to a high-capacity three-body split winding type transformer and belongs to the technical field of transformers. The technical scheme is that: three transformer bodies are arranged in a transformer oil tank, and each body is a phase; each body is provided with a square iron core (1), and each square iron core is provided with two iron core columns; each iron core column is provided with a low-voltage winding and a high-voltage winding from the inner side to the outer outside; the high voltage end of the transformer is used for no-load voltage regulation, and the low voltage end is split into two windings; the low-voltage windings of the two iron core columns on each body are led out respectively, and the two three-phase low-voltage windings (2, 4) form two angular connections; and the high-voltage windings (3) of the two iron core columns on each body are led out in parallel, and the three-phase high-voltage windings form a star-shaped connection. The high-capacity three-body split winding type transformer is a three-phase transformer of which the high voltage end is used for the no-load voltage regulation, and the low voltage end is in a double-splitting structure, the occupied area of the transformer is reduced, the mechanical force of the high-capacity split winding type transformer is effectively reduced during sudden short circuit, and the safety and reliability of the operation of products are improved.

Owner:BAODING TIANWEI GRP CO LTD

Electrical connection assembly for contacting electronic module

InactiveCN102437444AReduce mechanical forceElectrically conductive connectionsFixed connectionsComputer moduleElectrical connection

An electrical connecting device is provided to contact electronic component modules with a flexible flat line with strip conductors which are expanded between upper and lower cover films. An electronic component module comprises one or more touch panels. The touch panels are conductively connected to a circuit board using at least one connection point. An electrical line is inserted between a touch panel and a housing protrusion. At least one touch panel is deformed to form electrically conductive connection.

Owner:ROBERT BOSCH GMBH

Sports bottle cap

ActiveUS10322855B2Facilitates up and down travelReduce impactCapsClosure capsHermetic sealBottle cap

A fluid container is disclosed with a cap body made of rigid or semi rigid material and a valve body disposed within the cap body and movable between and open and closed position. The valve body is made of a semi flexible semi rigid material that has a coefficient of thermal linear expansion that is smaller than that of the cap body. The cap body and nozzle valve are configured with three different hermetic seals to counteract the effects of exposure to heat and cold over time and thereby extend the useful life of the cap and valve.

Owner:HYDRAPAK LLC

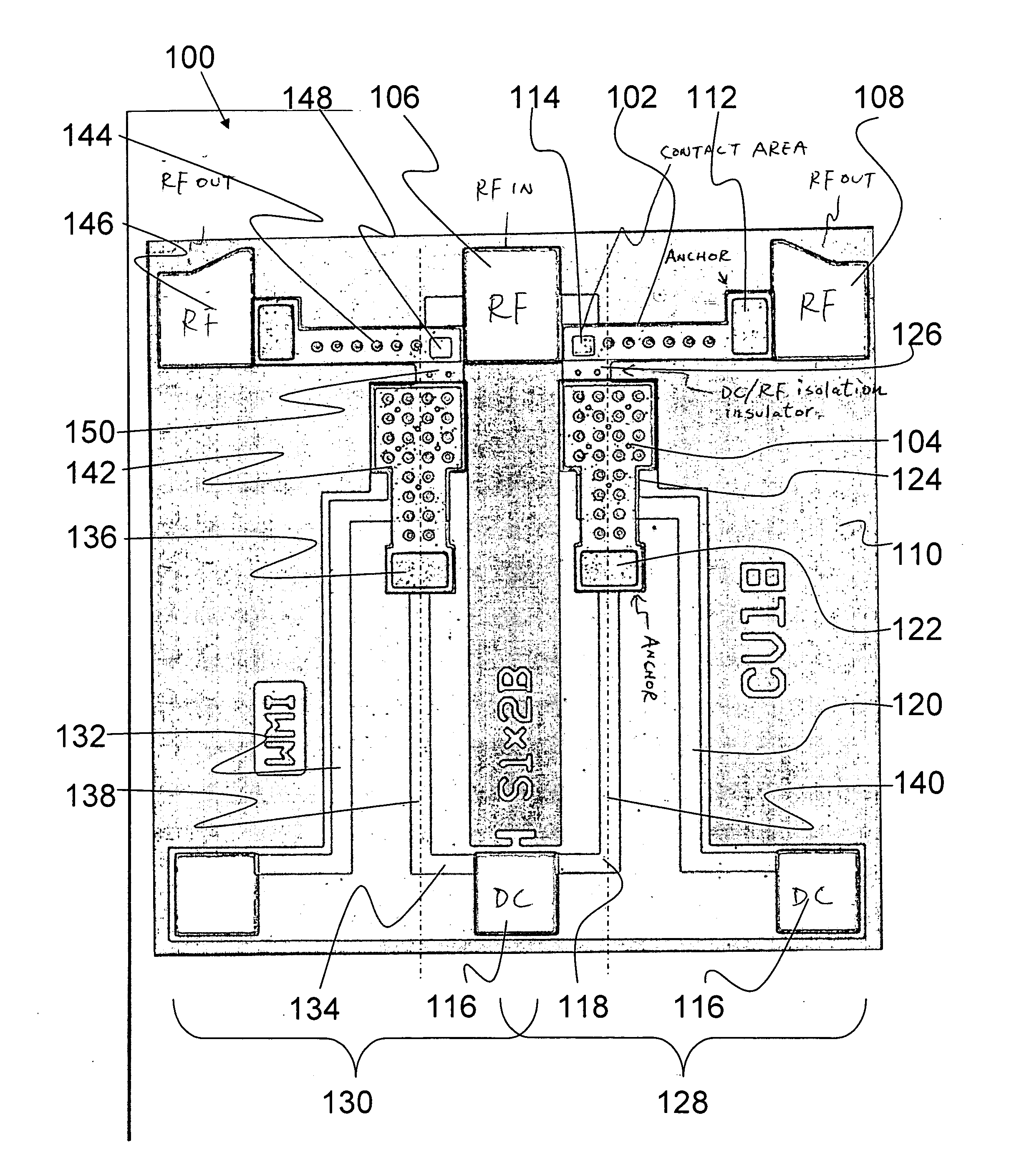

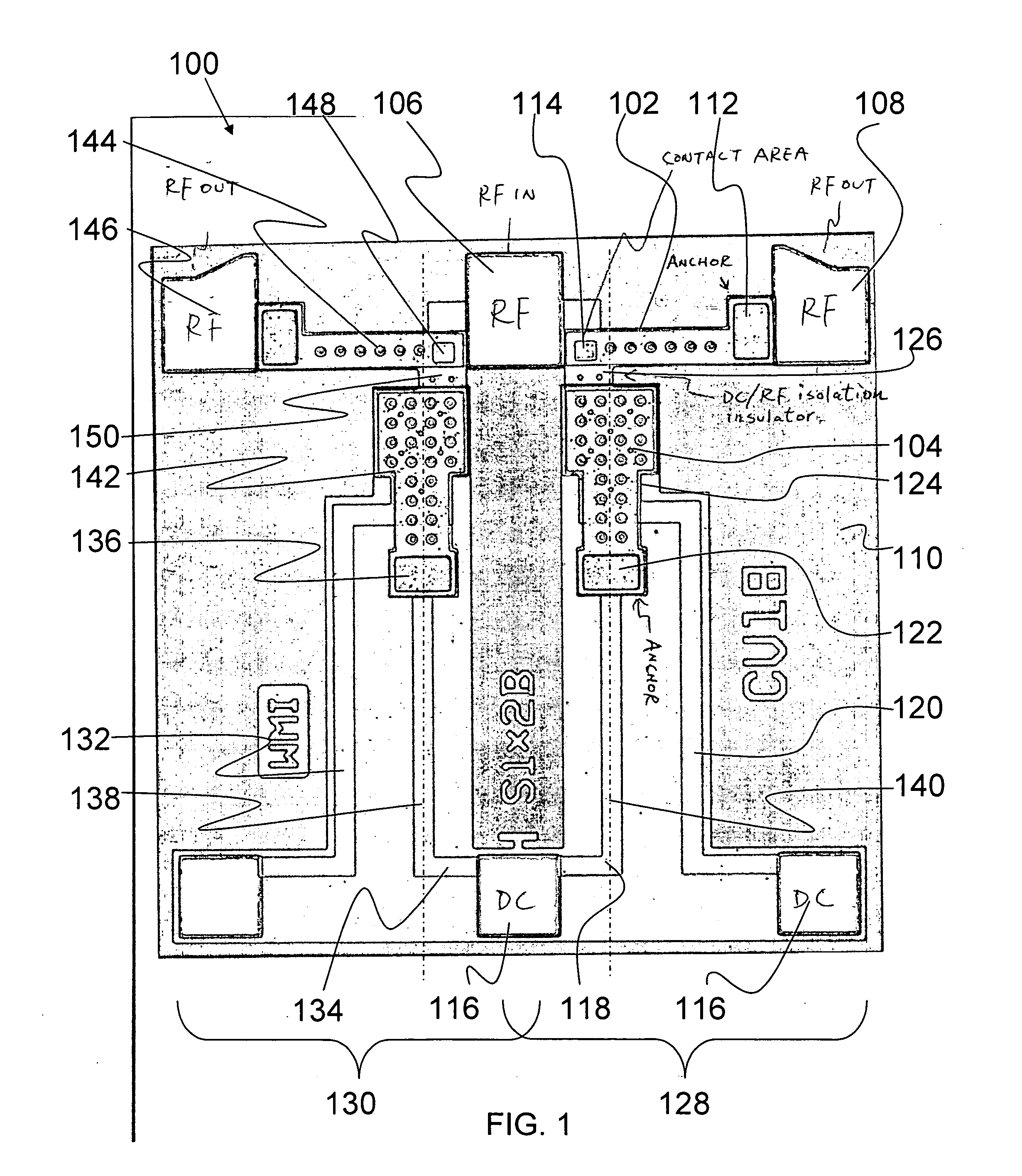

Balanced MEMS switch for next generation communication systems

InactiveUS20070030104A1Reduce probabilityReduce mechanical forceElectrostatic/electro-adhesion relaysElectrostrictive/piezoelectric relaysCommunications systemEngineering

A micro-electro-mechanical system (MEMS) switch is described. The MEMS switch includes both RF-input and output transmission lines formed on a substrate. An RF armature is anchored to the substrate and is electrically connected with the RF-output transmission line. A contact is electrically connected with the RF-input transmission line. Both bias-input and output signal lines are formed on the substrate. A bias armature is anchored to the substrate and is electrically connected with the bias-input signal line. A DC / RF isolation insulator connects the bias armature with the RF armature. When a charge is introduced to the bias-input signal line, the bias armature is forced toward the bias-output signal line, thereby forcing the RF armature to connect with the contact and form an electrical circuit between the RF-input transmission line and the RF-output transmission line.

Owner:WIRELESS MEMS

Modular implant delivery and positioning system

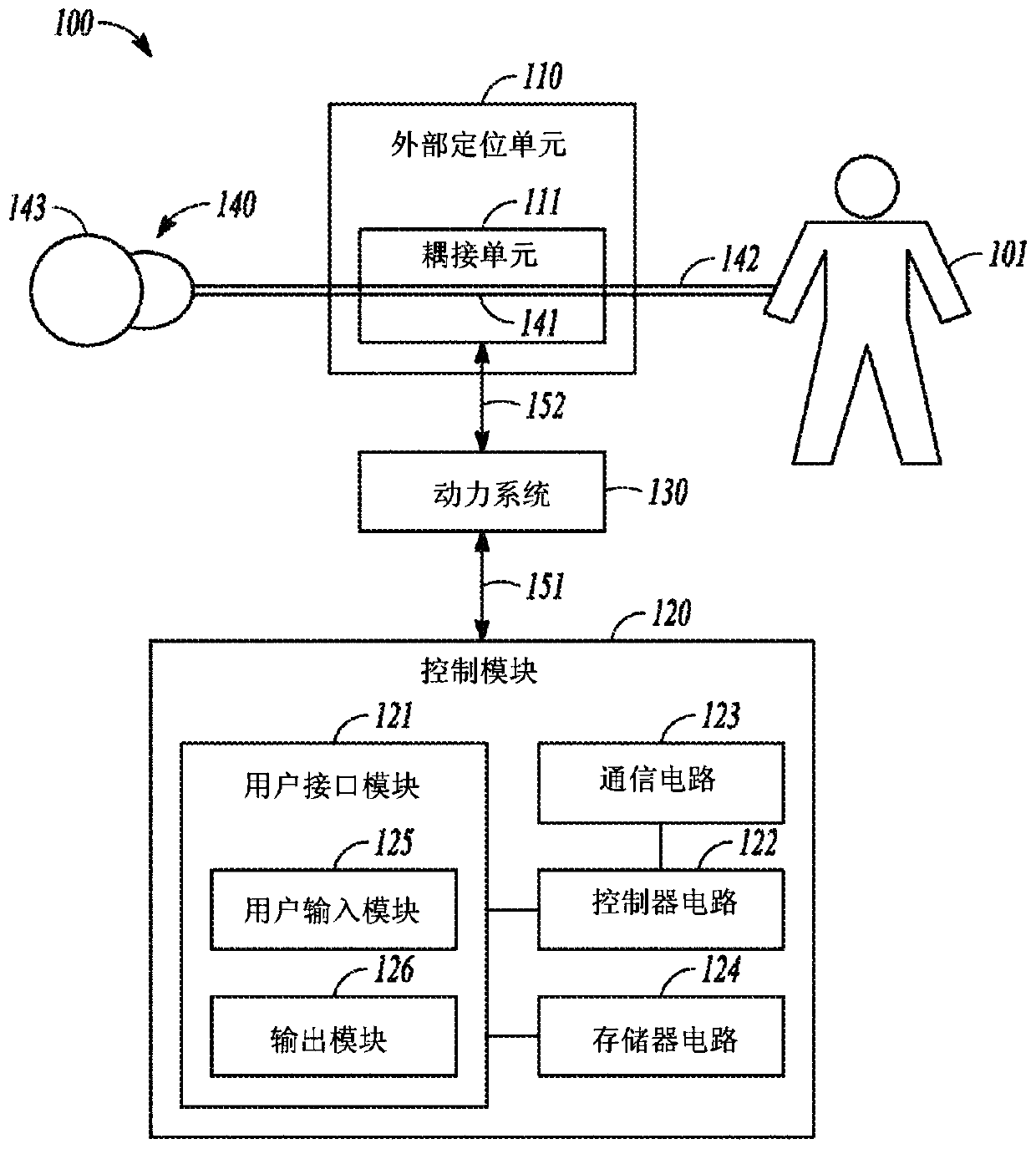

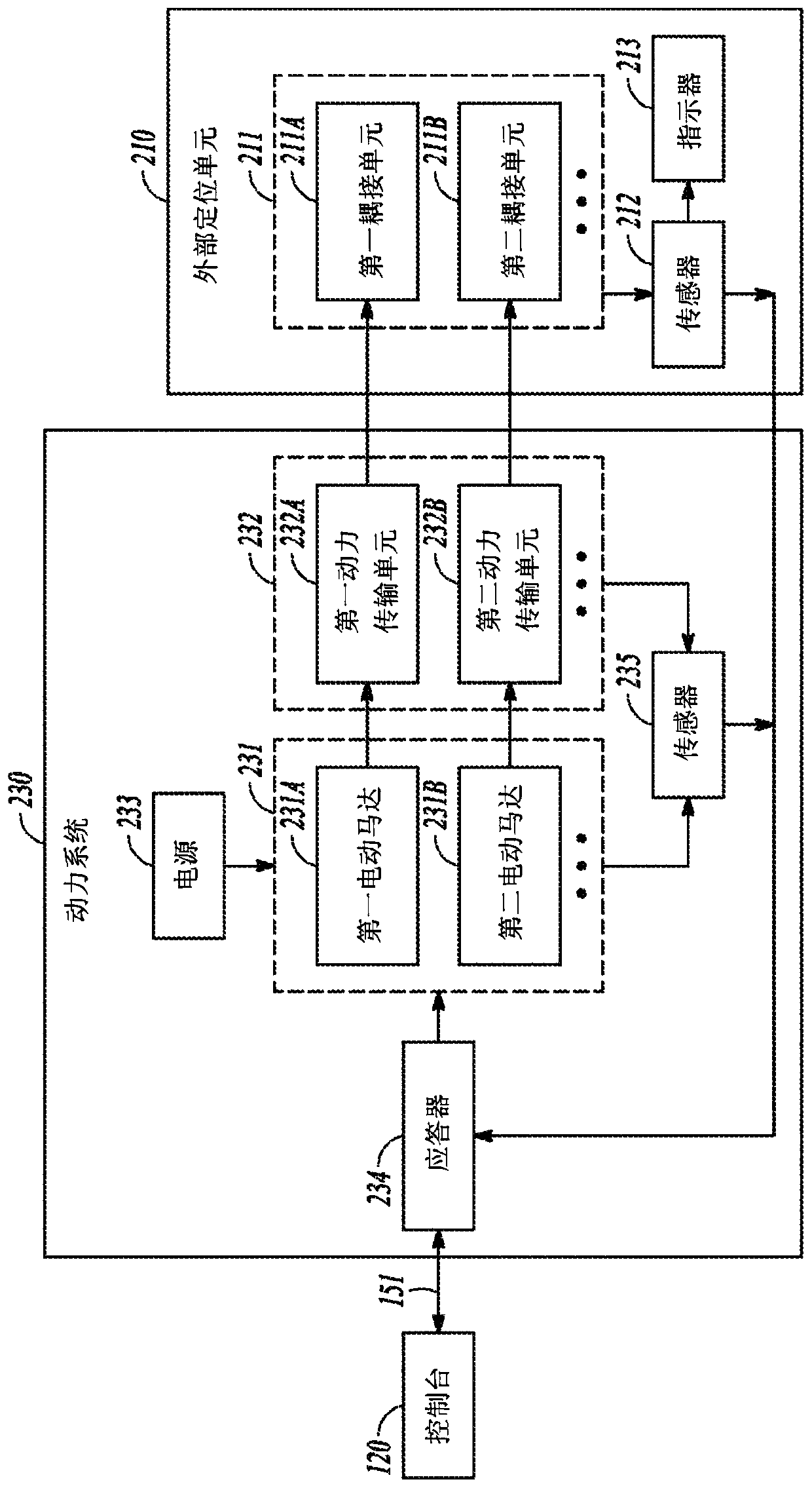

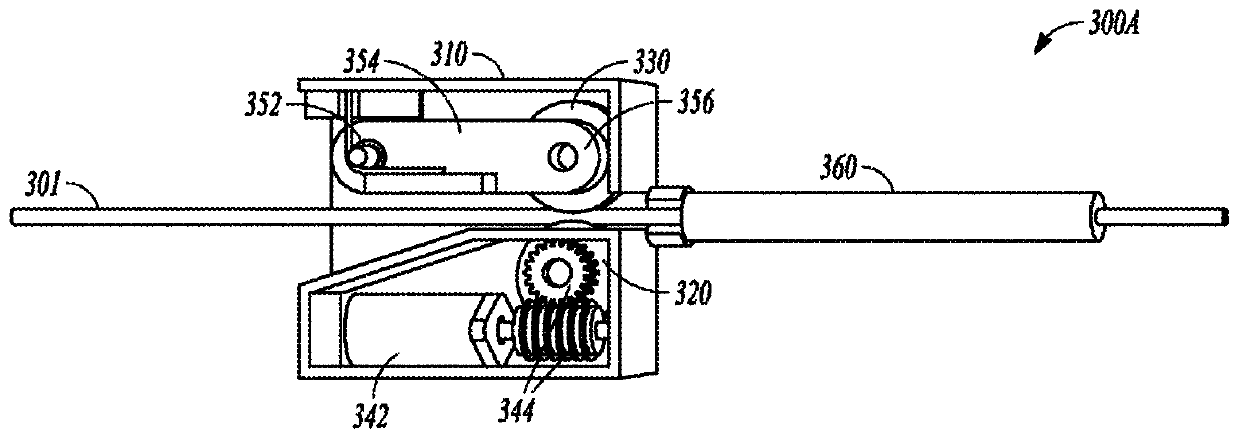

ActiveCN110430918APreserve natural hearingReduce mechanical forceHead electrodesStrain gaugePhysical medicine and rehabilitationCochlear implant surgery

A document discusses, among other things, systems and methods for robotically assisted implantation of an implant in a patient. A system includes an external positioning unit configured to engage an elongate member of the implant, and a control console communicatively coupled to the external positioning unit. The control console may have a user interface that enables a user to input motion controlinstructions. The control console may generate a motion control signal, according to a specific motion control instruction, to control the external positioning unit to propel the implant into a target implant site. The system may be used to robotically control the delivery and positing of a cochlear implant during a hearing-preservation cochlear implant surgery.

Owner:IOTAMOTION INC

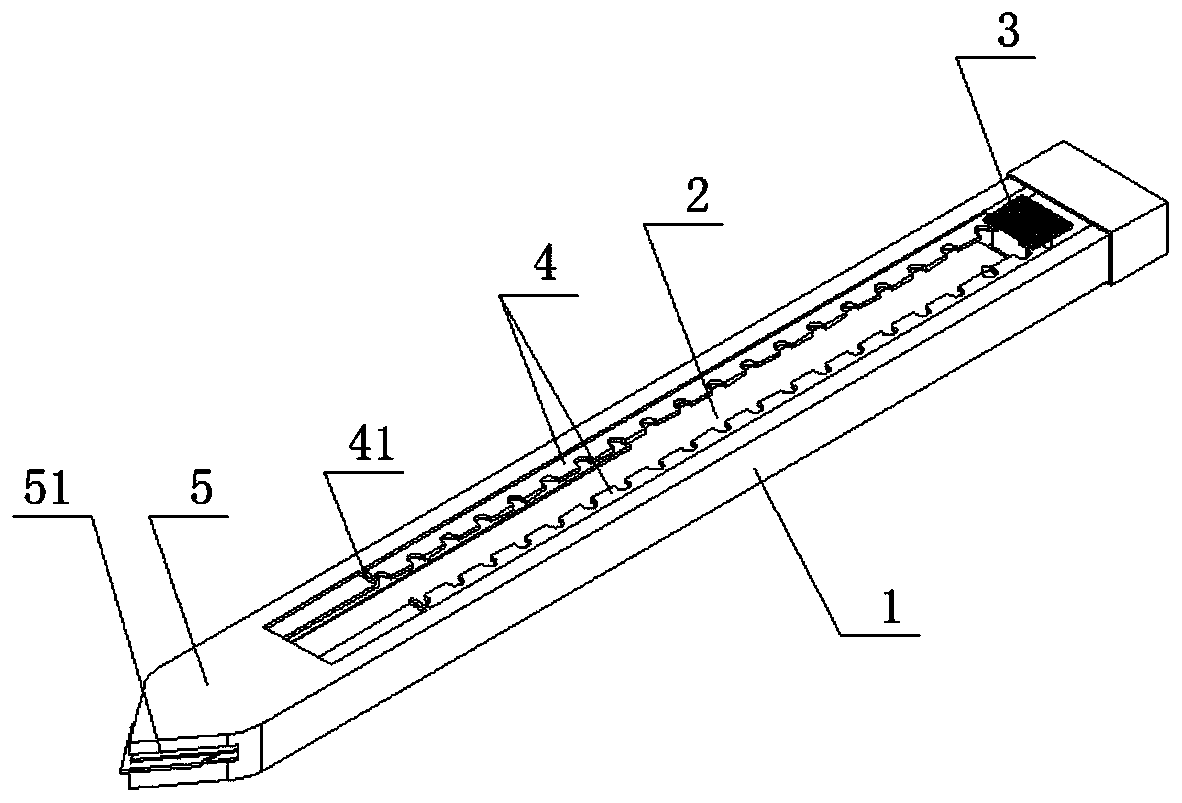

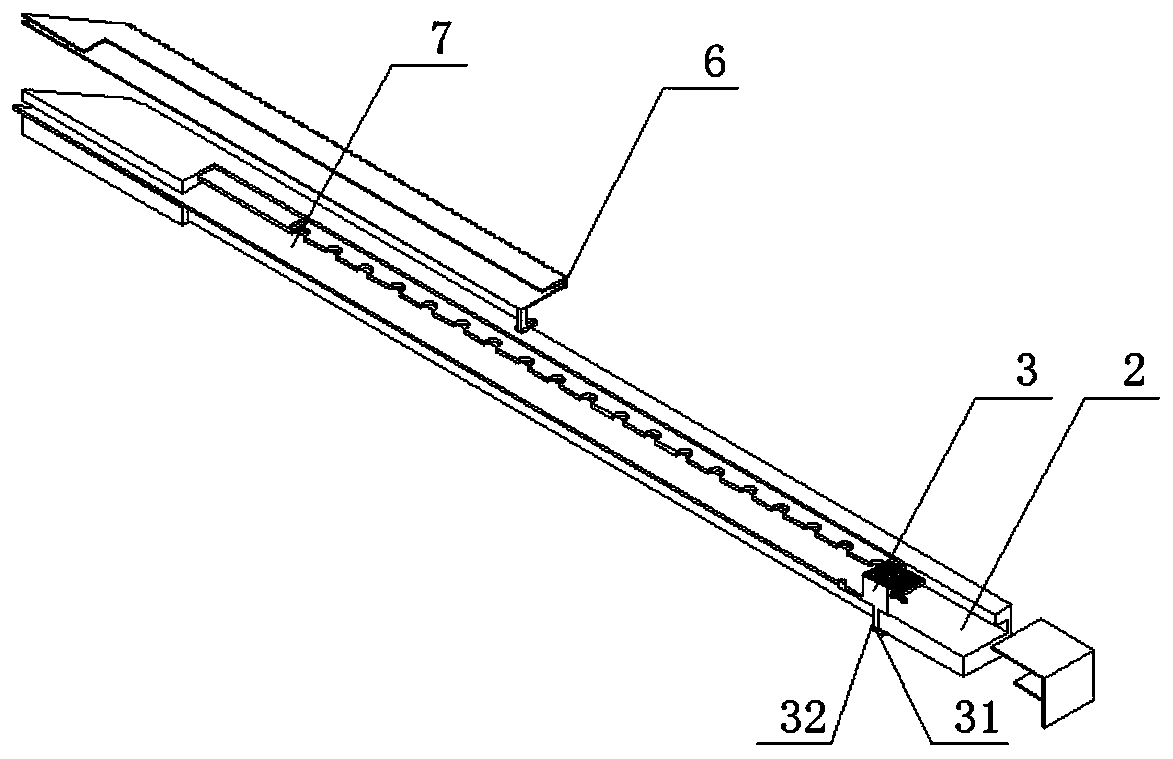

Improved art knife guide rail for preventing knife breaking

The invention discloses an improved art knife guide rail for preventing knife breaking. The improved art knife guide rail comprises a knife shell body with an upward opening, a pushing button, a knifebody and a knife body protecting assembly, wherein a guide rail body is arranged in an inner cavity of the knife shell body, the pushing button is arranged in the guide rail, the knife body is connected with the guide rail body in a sliding manner through the pushing button, and the knife body protecting assembly arranged on the periphery of the knife body in a sleeving manner. The knife body protecting assembly is formed by a first installing plate, a second installing plate and a third installing plate. According to the improved art knife guide rail for preventing knife breaking, on the premise of ensuring the use quality of the knife body, suitability between the guide rail for the art knife body and the knife body is effectively improved, then the situations that in the using process,the knife body is damaged easily, and safety accidents are caused easily can be effectively avoided, and thus the use precision of the guide rail is effectively improved. In addition, by arranging the knife body protecting assembly, the knife body can be protected, the use flexibility of the art knife body is improved conveniently, and therefore the use precision of the knife body of the arc knife is effectively ensured.

Owner:陈梦茹

Method, process and device for polymeric waste processing

InactiveCN102421578AReduce mechanical forceReduce energy consumptionProductsReagentsWaste processingEngineering

The present invention relates generally to polymeric waste processing. More particularly, the present invention relates to processing of polymeric waste which may be associated with elements such as non-polymeric material or metals. In a specific embodiment the method includes the steps of (1) loading preliminarily deformed waste into a reaction chamber, (2) applying an aggressive medium to the waste for a time sufficient to convert the one or more polymers to fragments, and separate one of more polymers from their associated elements, and (3) subjecting the products of step (2) to mechanical separation of the associated elements from the polymer fragments. The present invention is particularly useful for the processing of tyres including preliminarily deformed tyre segments or shredded tyre waste.

Owner:VR TEK PTY LTD

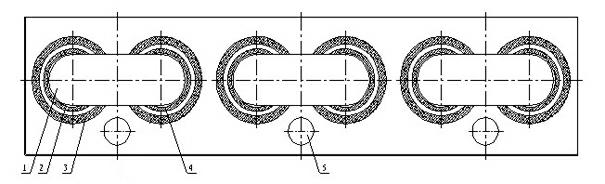

Three-phase amorphous alloy isolation transformer

InactiveCN102054573AReduce Interfering SignalsPurify the gridTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresMetal foilMechanical force

The invention relates to a three-phase amorphous alloy isolation transformer which comprises an iron core, an inner winding and an outer winding, wherein the iron core is a four-frame and five-column iron core formed by winding amorphous alloy, a metal isolating layer is arranged between the inner winding and the outer winding, the outer side of an iron yoke of the iron core is provided with a hard combined insulation member, the upper end and the lower end of the hard combined insulation member are respectively connected with an upper padding plate and a lower padding plate, cushion blocks are arranged between the windings and the upper padding plate and between the windings and the lower padding plate, the other end of the hard combined insulation member is provided with an upper clamping member, the other end of the lower padding plate is provided with a lower clamping member, and a locator is arranged on the lower end face of the lower clamping member. A metal foil is used as the metal isolating layer for isolating, thus interference signals are reduced and a power grid is purified; the amorphous alloy is used as the iron core, thus the no-load loss and the current are reduced and the energy is saved; and the hard combined insulation member ensures that a short-circuiting force does not act on the iron core when the windings are short-circuited, the clamping members and the padding plates and the like ensure that the iron core bears smaller mechanical force, thus the short-circuiting resisting capacity of a transformer is improved.

Owner:常州华迪特种变压器有限公司

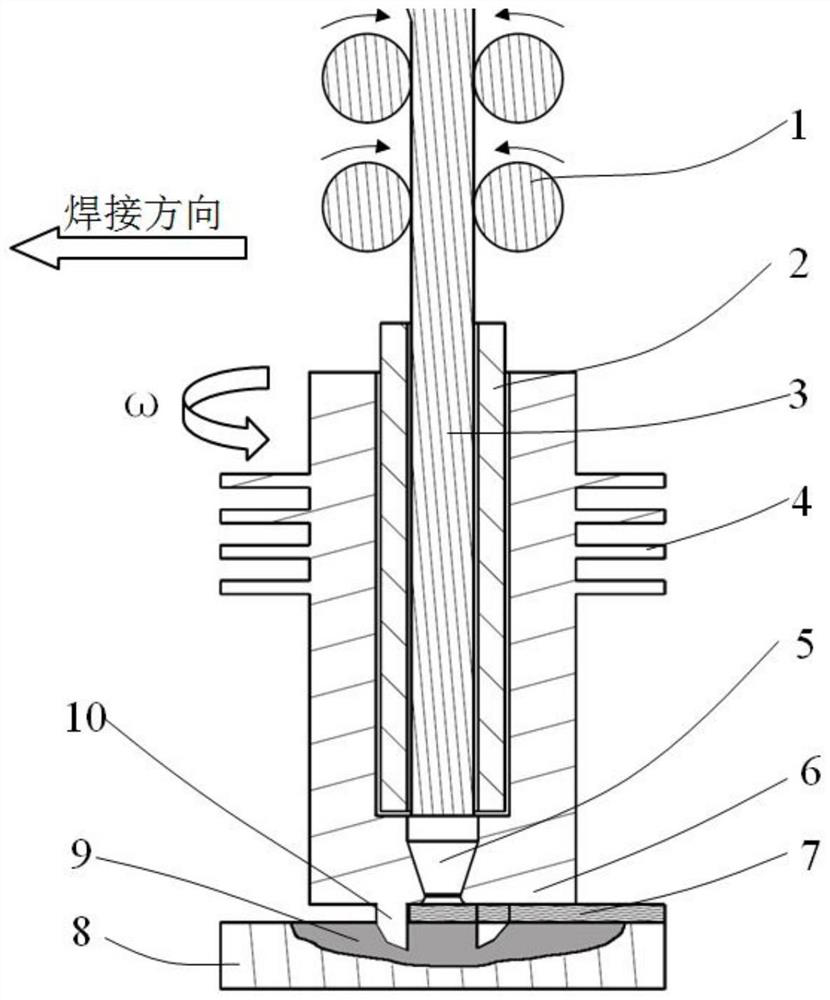

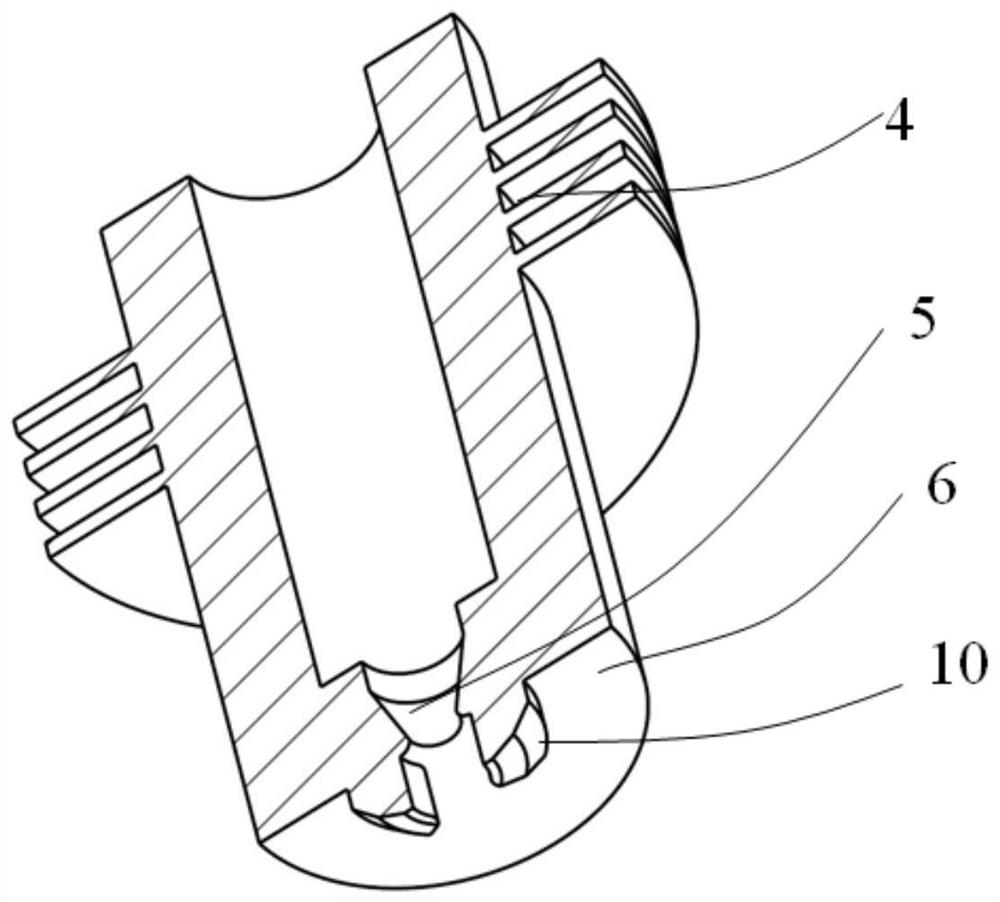

Middle wire filling type negative-pressure-in low-acting-force stirring friction welding method and device

PendingCN113927150AReduce forging effectReduce surface forgingNon-electric welding apparatusFriction weldingEngineering

The invention relates to a negative-pressure-in low-acting-force thin plate stirring friction wire filling welding method. A wire feeding mechanism, a stirring tool, a wire and a forming piece are included, the wire feeding mechanism at least comprises a feeding wheel set and a wire guide cylinder, and the stirring tool at least comprises cooling fins, a shaft shoulder, a hollow stirring needle and a friction inner neck. During welding, the stirring tool rotates at a high speed and advances in the direction of a welding seam, the stirring needle is partially inserted into a to-be-welded workpiece, a certain gap is formed between a shaft shoulder plane and the to-be-welded workpiece, a wire feeding wheel set feeds a wire along the static guide cylinder, at a friction inner neck part of the stirring tool, the wire and the stirring tool rotating at a high speed generate heat through friction under huge feeding pressure, and then the wire is plasticized, extruded along the hollow stirring needle to enter a gap between the shaft shoulder plane and the to-be-welded workpiece and fused with a plasticized material of the to-be-welded workpiece to form a welding seam. According to the middle wire filling type negative-pressure-in low-acting-force stirring friction welding method and device, the problem that traditional thin plate stirring welding is large in acting force and prone to deformation is solved, and the welding seam quality of thin-wall aluminum alloy welding and the welding process stability are improved.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

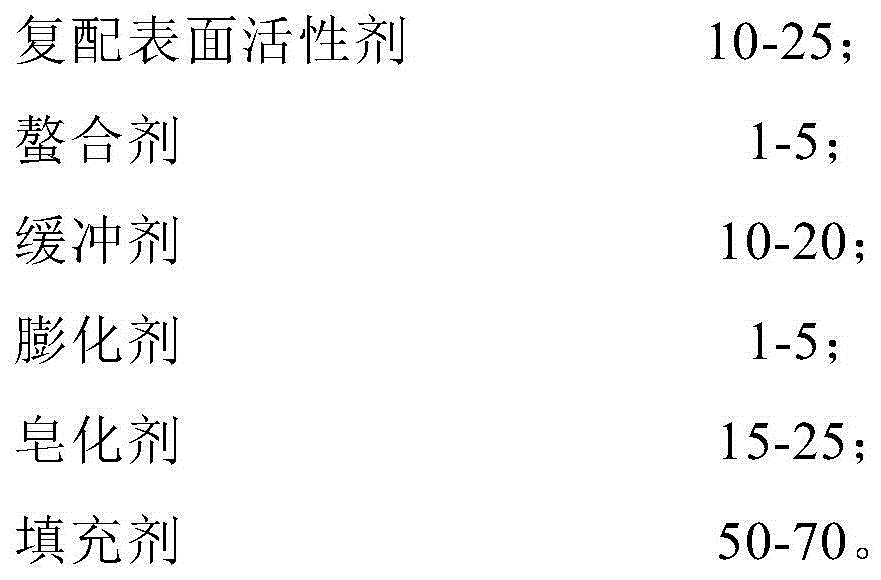

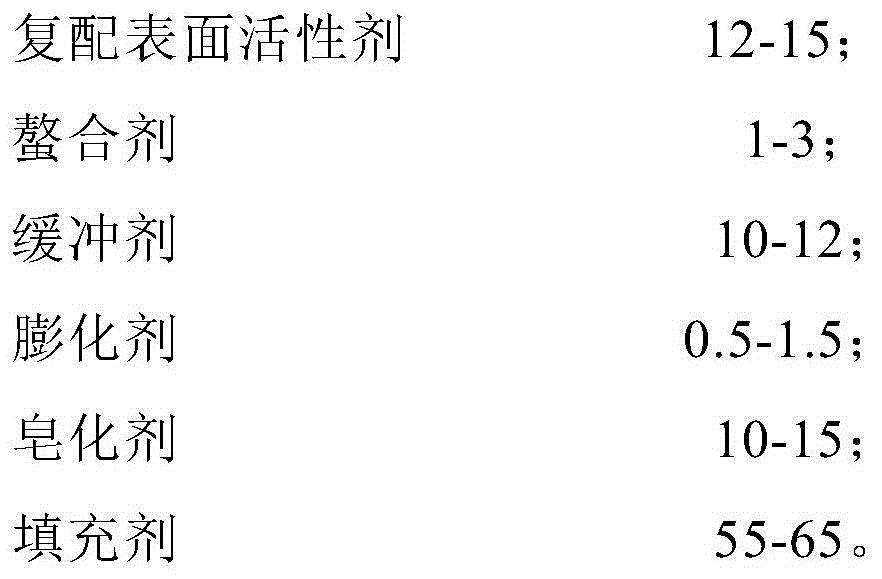

PEI bottle chip reusing treatment washing agent

InactiveCN104479900AImprove permeabilityGood emulsificationInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsFiller ExcipientDecomposition

The invention relates to a PEI bottle chip reusing treatment washing agent which is prepared by, by weight, mixing the following raw materials including a surface active agent 10-25 parts, chelating agent 1-5 parts, buffering agent 10-20 parts, swelling agent 1-5 parts, saponifying agent 15-25 parts and filling agent 50-70 parts. Compared with the prior art, the surface active agent in the washing agent is selected from a fatty alcohol polyoxyethylene-alkyl ether compound, has good emulsification and dispersion effects and remarkable hard surface washing effect and is environment-friendly and high in decomposition speed in the environment. In addition, the washing agent has foam decreasing or deforming effect, is especially suitable for mechanical washing and does not produce excessive foams when being left in a sewage treatment occasion. The washing agent has excellent permeability and can quickly permeate into the interface between the hard surface and adhered matter by utilizing the excellent permeability. Therefore, the mechanical force, temperature and time required by washing can be reduced, and the same or better washing effect can be obtained.

Owner:CITY RECYCLING

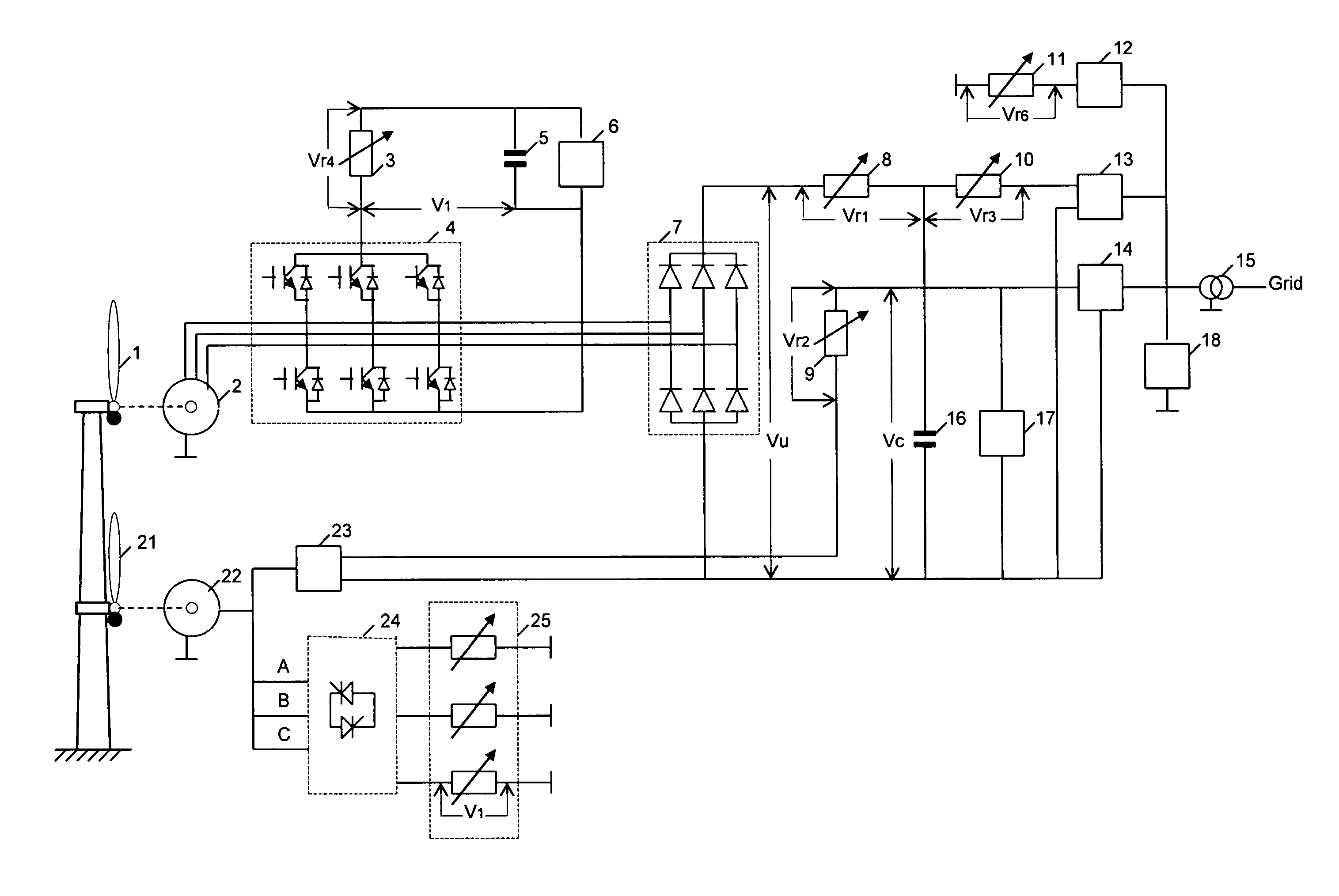

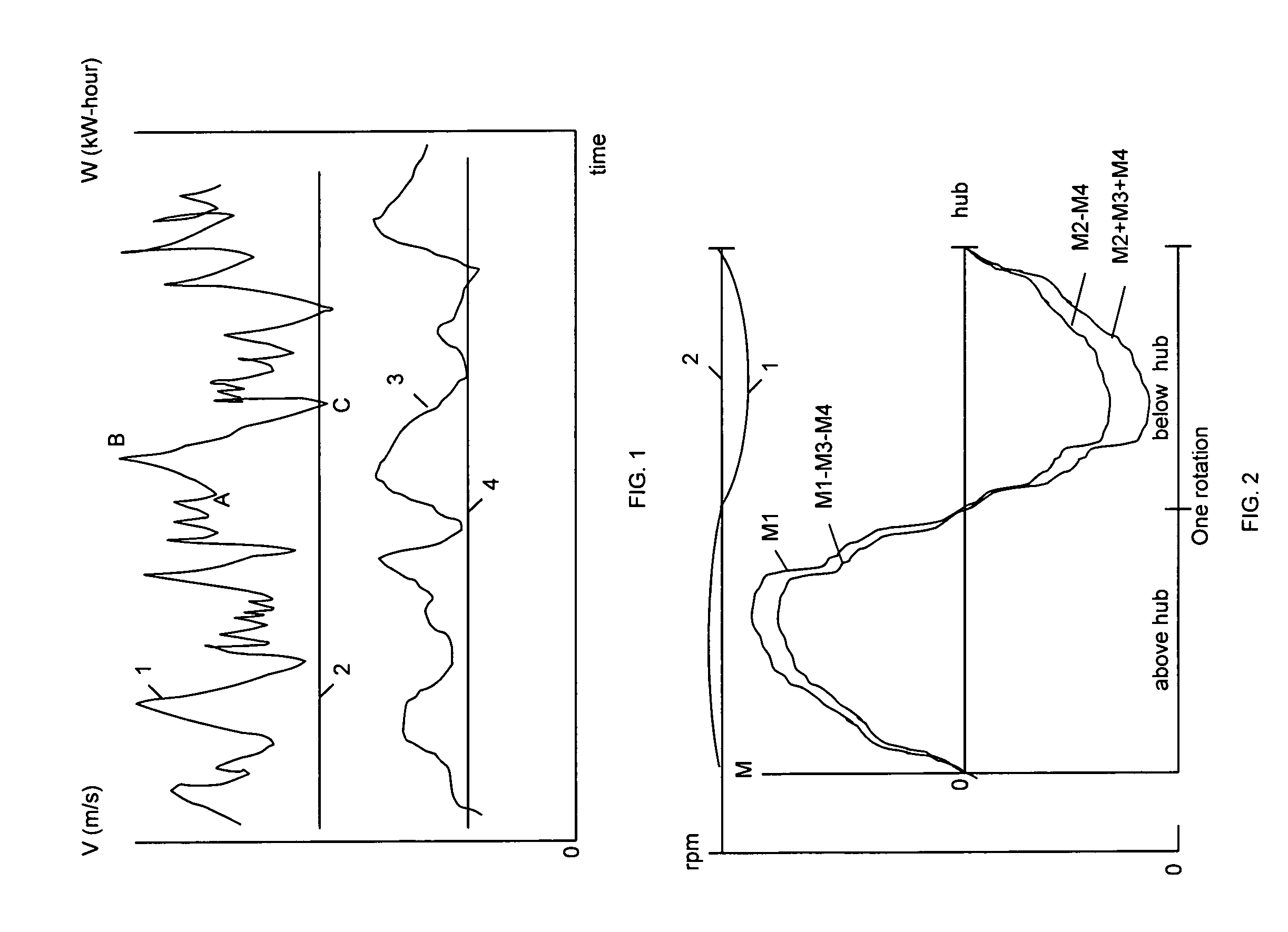

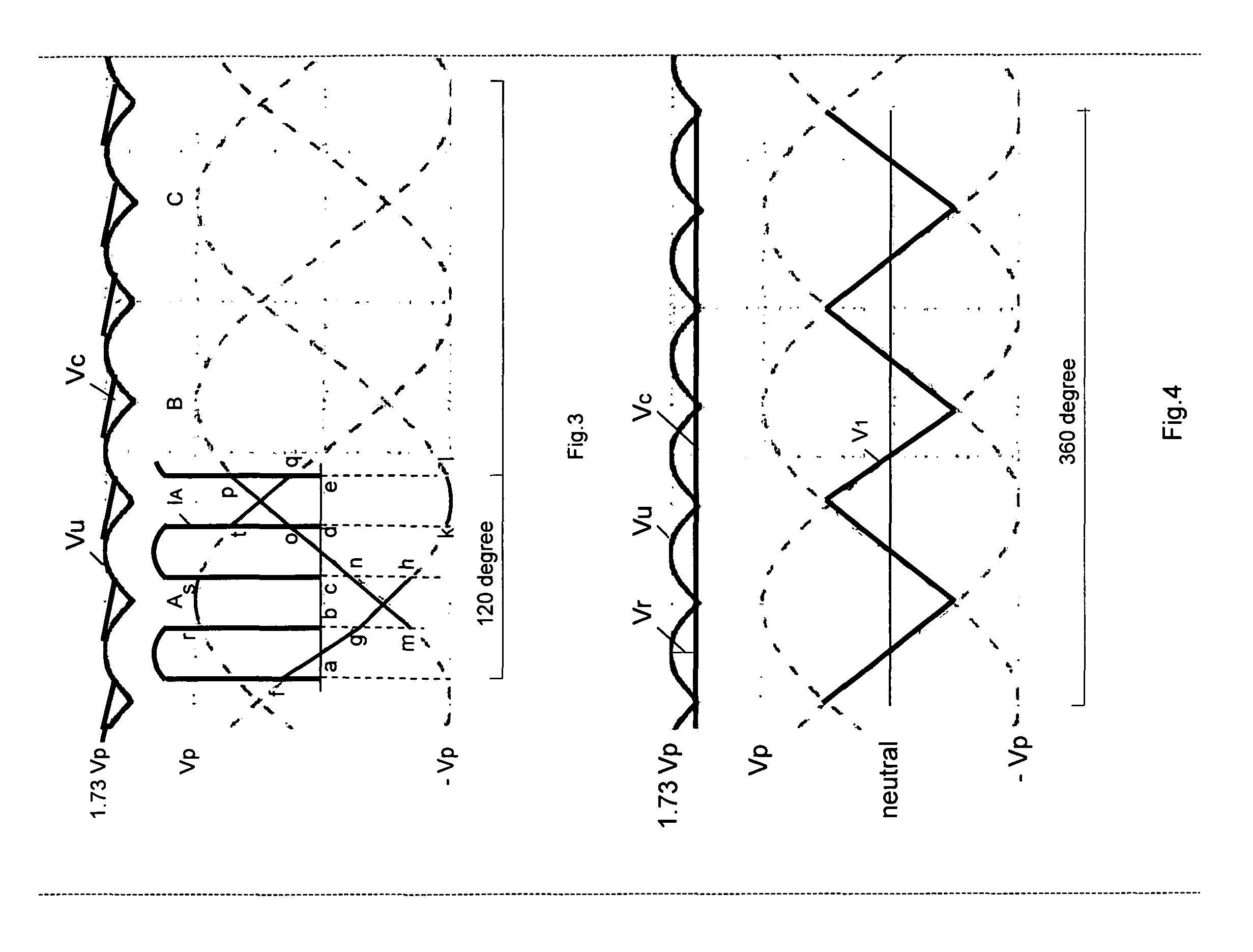

Method and system for fully utilizing wind energy in a wind energy generating system

InactiveUS8933571B2Reduce loadReduce weightAC motor controlWind motor controlEnergy systemAutomotive engineering

A wind energy system that converts fluctuating wind into electrical power, wherein part of the electrical power is converted into variable AC electrical power and fed into the grid, part is converted into DC power, and part is converted into heat.

Owner:GRINBLAT ZINOVY D

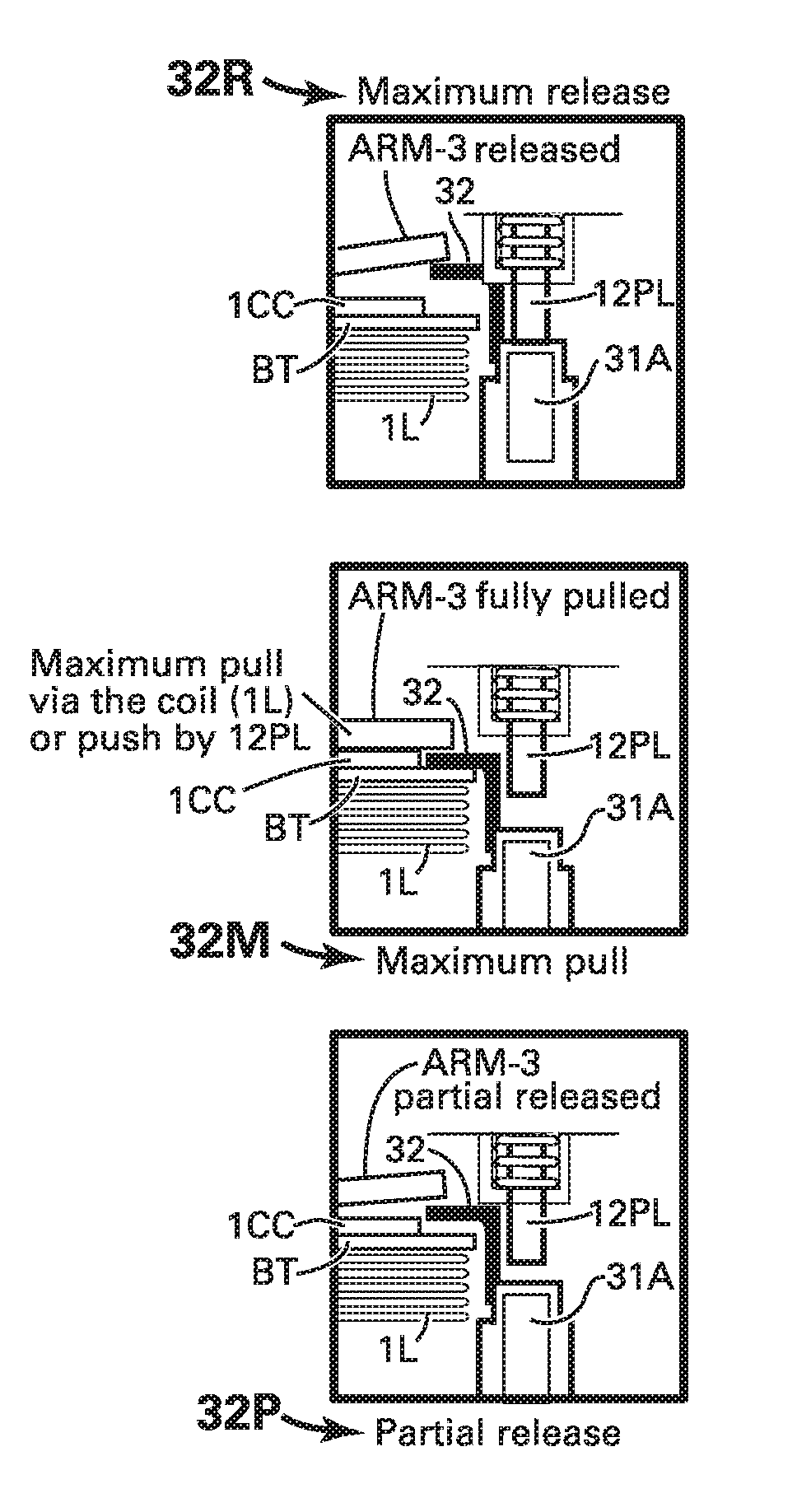

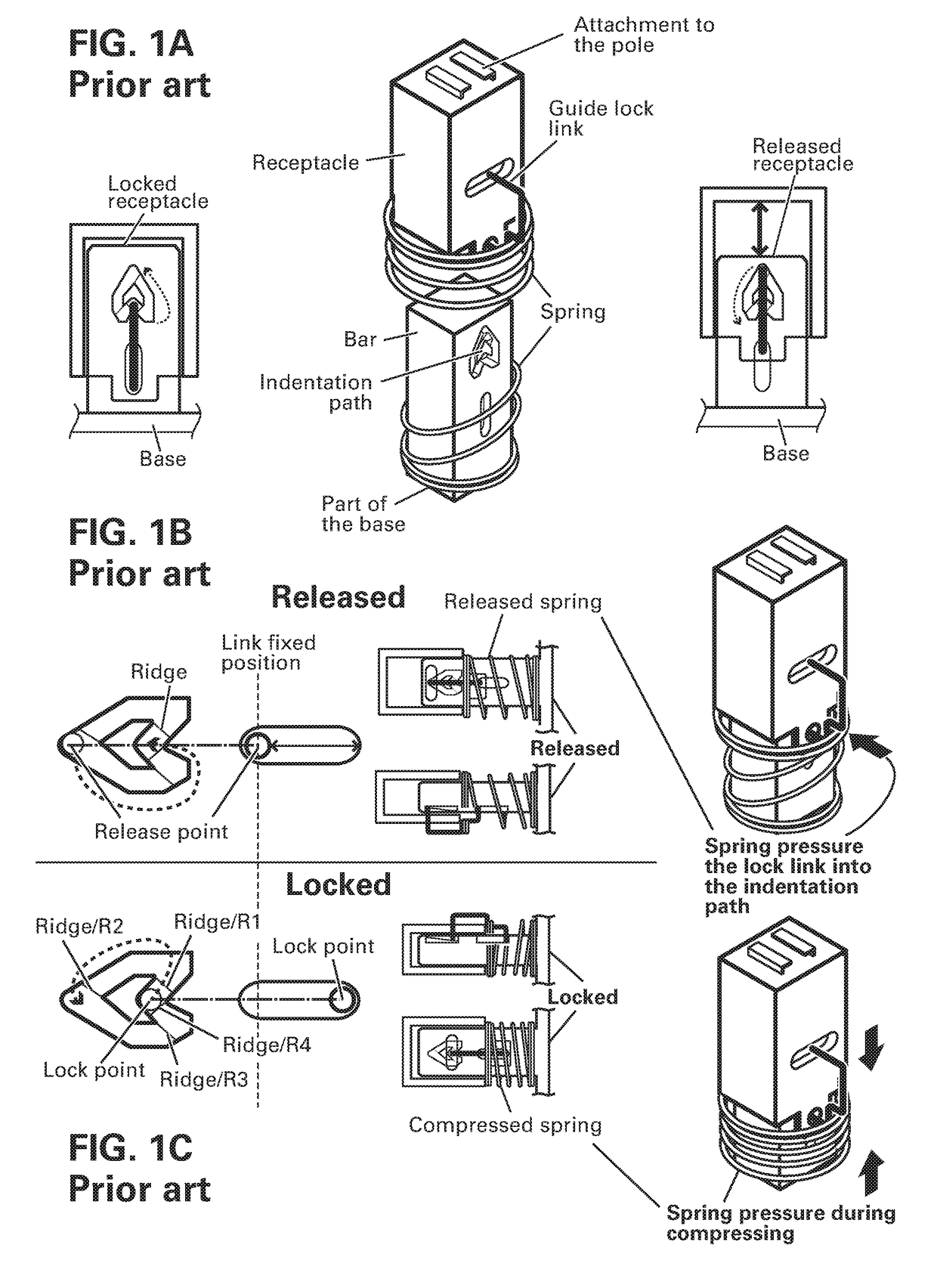

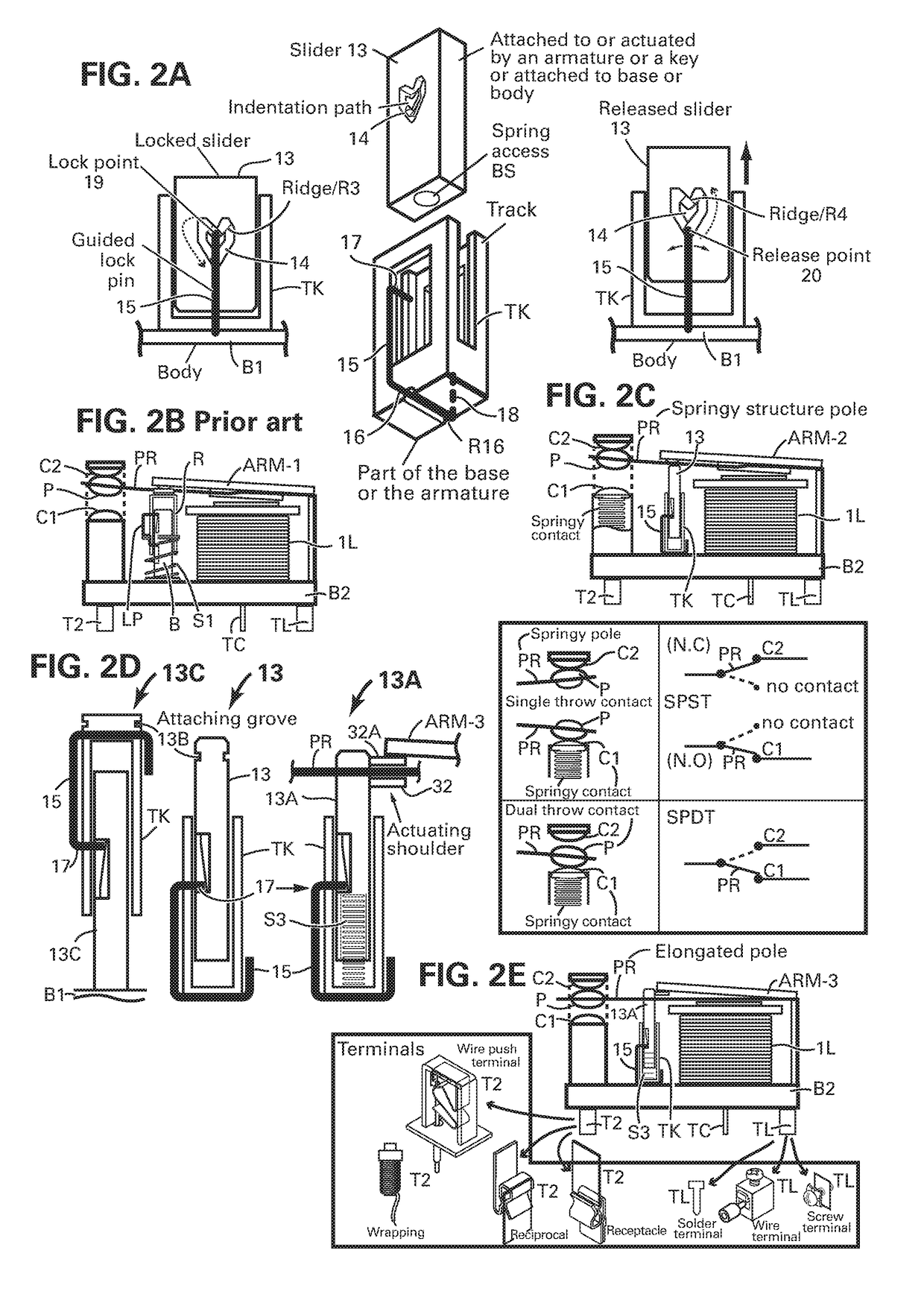

Apparatus and method for powering a coil of latching relays and hybrid switches

ActiveUS20180190461A1Small sizeImproved light controlEmergency springsElectromagnetic relay detailsEngineeringElectromagnetic coil

Apparatus and method for latching one pole contact of at least one springy pole in one of a relay and an hybrid switch for maintaining one of engaging and disengaging state of at least one first contact with said pole contact by a mechanical latching device comprising a springy lock pin exerting minute force, a slider with indentation path for guiding the lock pin and a track for the slider, the latching device extends from an armature or the springy pole to a base or a body of the relay or the hybrid switch, said springy pole is guided by said slider movement propelled by one of a pull by a voltage rated magnetic coil fed by a pulse of said rated voltage and a push by a plunger, and for operating a stronger coil for switching higher electrical current the magnetic coil is fed with combination with at least one discharge higher voltage to increase the magnetic pull power of the coil.

Owner:ELBEX VIDEO LTD

Electrostatic chuck separation device

ActiveCN110931413AReduce resistanceQuick separationSemiconductor/solid-state device manufacturingPhysicsEngineering

The invention discloses an electrostatic chuck separation device, and relates to a mechanical device for separating an electrostatic chuck, aiming to provide the electrostatic chuck separation devicecapable of nondestructively and quickly separating the electrostatic chuck from the chuck base. The electrostatic chuck separation device comprises a guide component, a rotating component and a cutting component, wherein the rotating component is mounted above the guide component and can synchronously move along with the guide component; the cutting component is fixedly mounted; the electrostaticchuck assembly is installed above the rotating component and can synchronously rotate along with the rotating component. The cutting component can generate heat when powered on and generate heat capable of melting the adhesive layer. And when the guide part drives the rotating part to synchronously move to a certain position, the cutting component can cut the bonding layer along with simultaneousmovement and rotation of the electrostatic chuck so as to realize separation of the electrostatic chuck from an element on the electrostatic chuck assembly. The electrostatic chuck separation device is simple in structure, easy to manufacture, high in separation efficiency, wide in application range and capable of achieving lossless separation.

Owner:BEIJING U PRECISION TECH

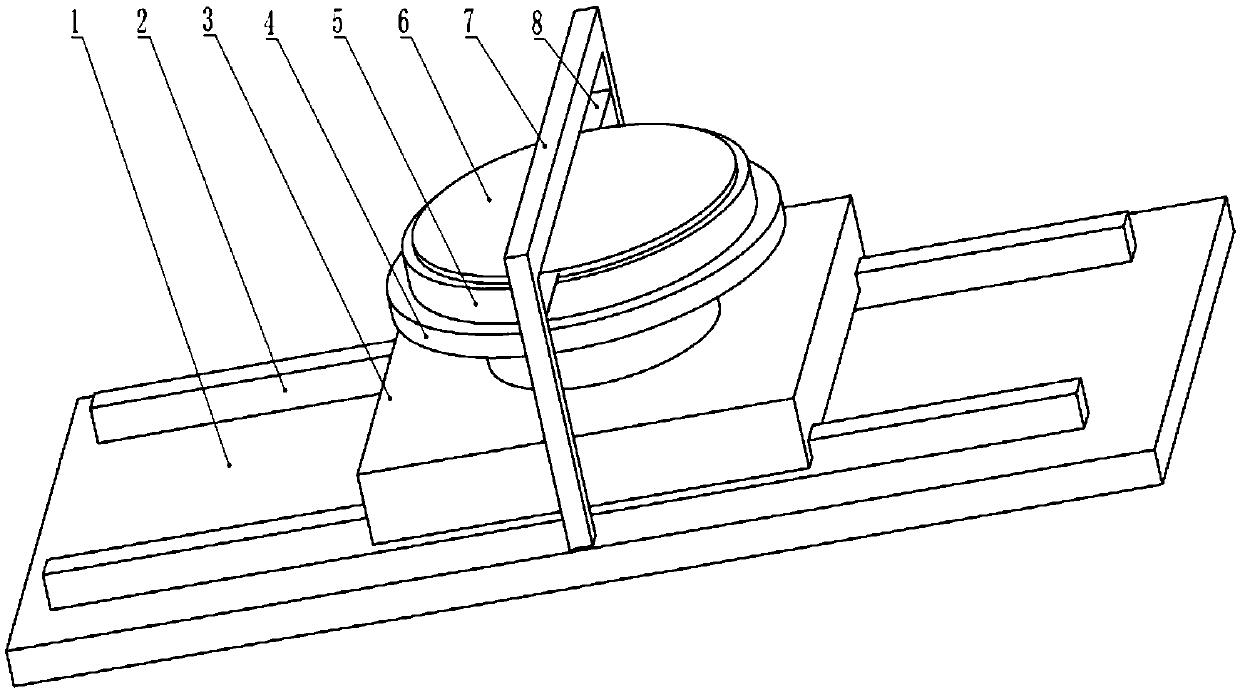

Method for set up of a door operator and a door operator

ActiveUS11085222B2Reduce mechanical wearReduce mechanical forcePower-operated mechanismCurrent controllersSimulationControl cell

The present invention relates to a door operator and a method for set up of a door operator (1) comprising a drive unit (7), a user interface (8) and a control unit (9), which control unit (9) controls the value of the current applied to the drive unit (7) such that the door operator (1) employs a first speed trajectory corresponding to the value of the current when opening and / or closing a door leaf (2) connected to the door operator (1), the method comprising the steps of: detecting a first or a second mode of set up of the control unit (9), and in the first mode, receiving a value of the time for opening and / or closing the door leaf (2) from the user interface (8), calculating a value of the current that should be applied to the drive unit (7) during acceleration and braking to obtain said value of the time for opening and / or closing the door leaf (2), and setting the calculated value of the current in the control unit (9), such that the door operator (1) employs the first speed trajectory when opening and / or closing a door leaf (2) connected to the door operator (1) corresponding to said set value of the time, in the second mode receiving a value of the current that should be applied to the drive unit (7) when opening and / or closing the door leaf (2) from the user interface (8), setting the value of the current in said control unit (9) that should be applied to the drive unit (7) during acceleration and braking such that the door operator (1) employs the first speed trajectory when opening and / or closing a door leaf (2) connected to the door operator (1) corresponding to said set value of the current.

Owner:ASSA ABLOY ENTRANCE SYST AB

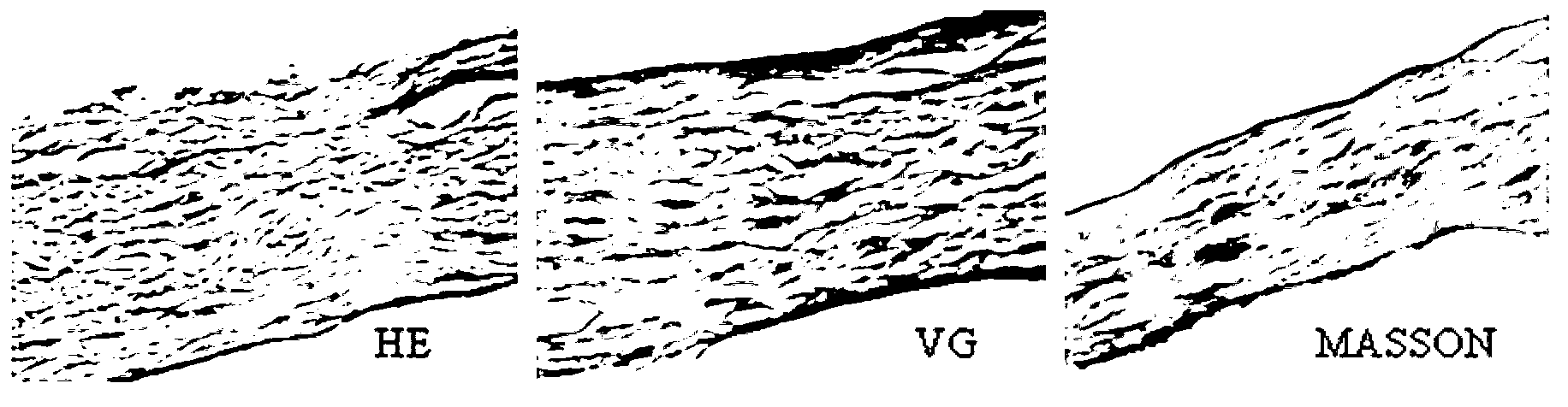

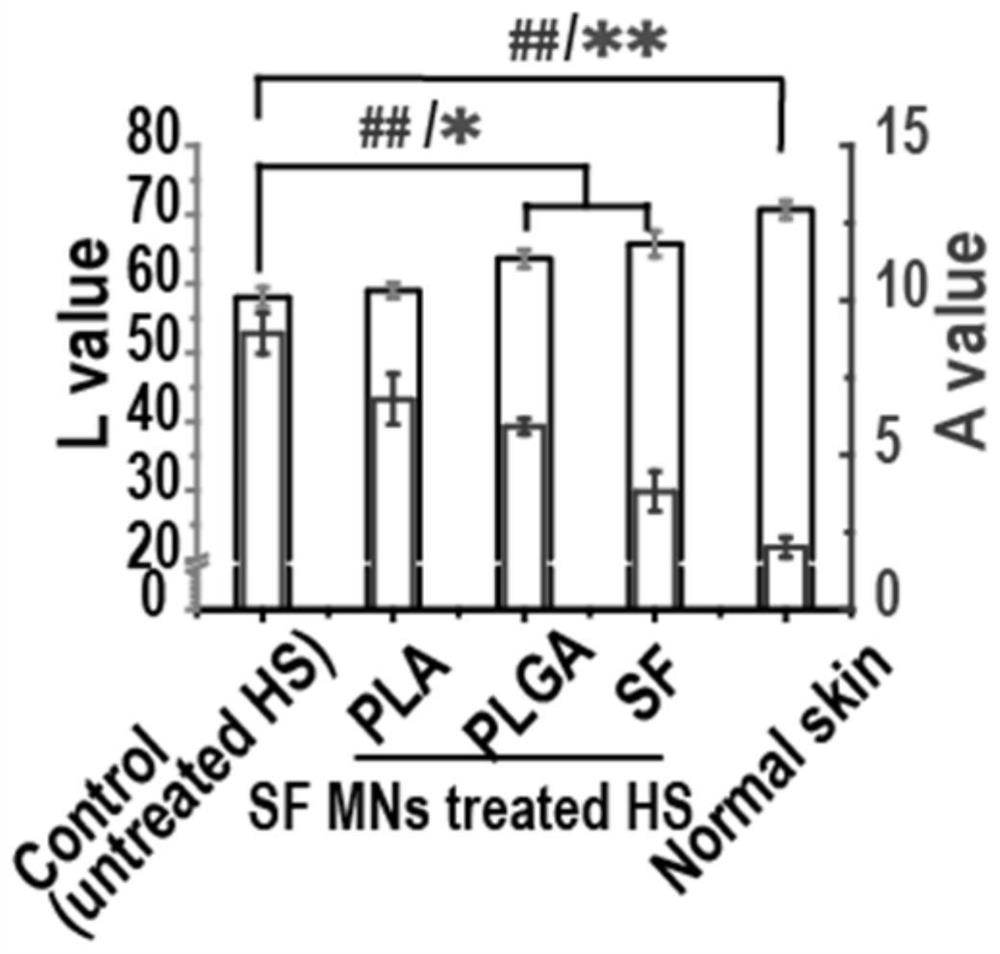

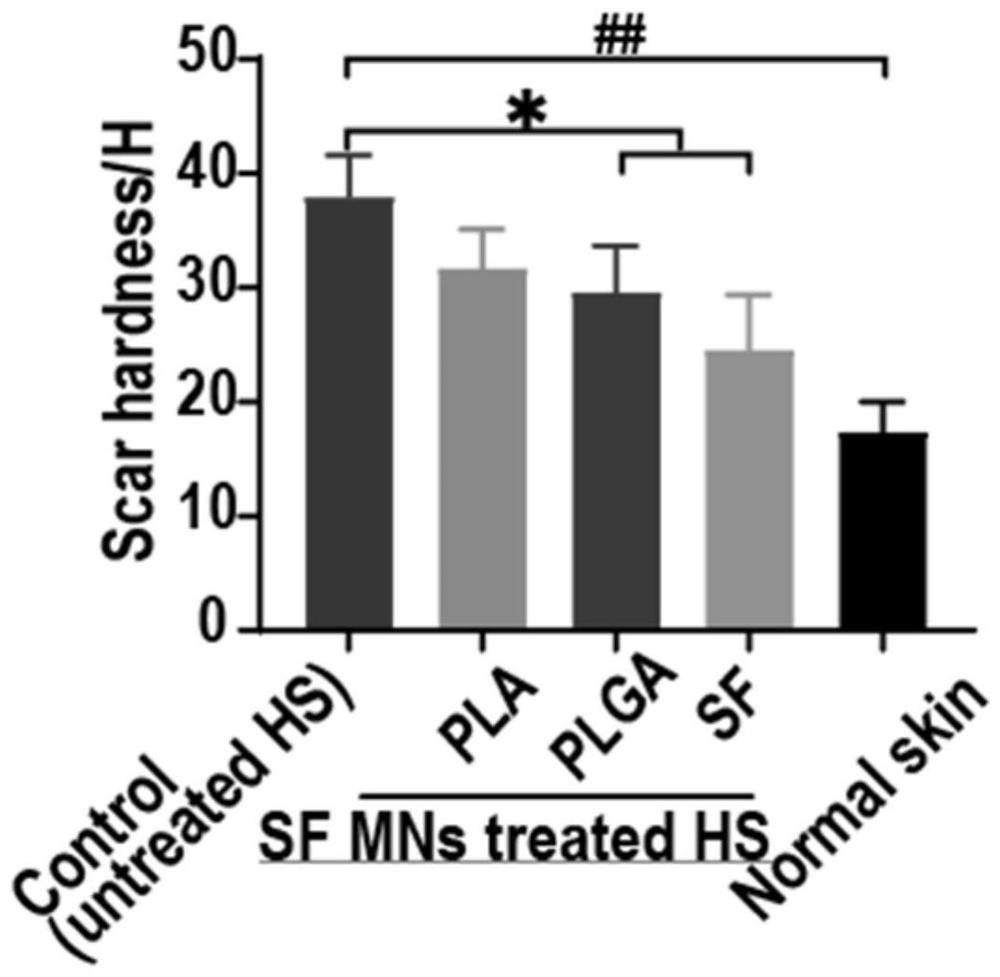

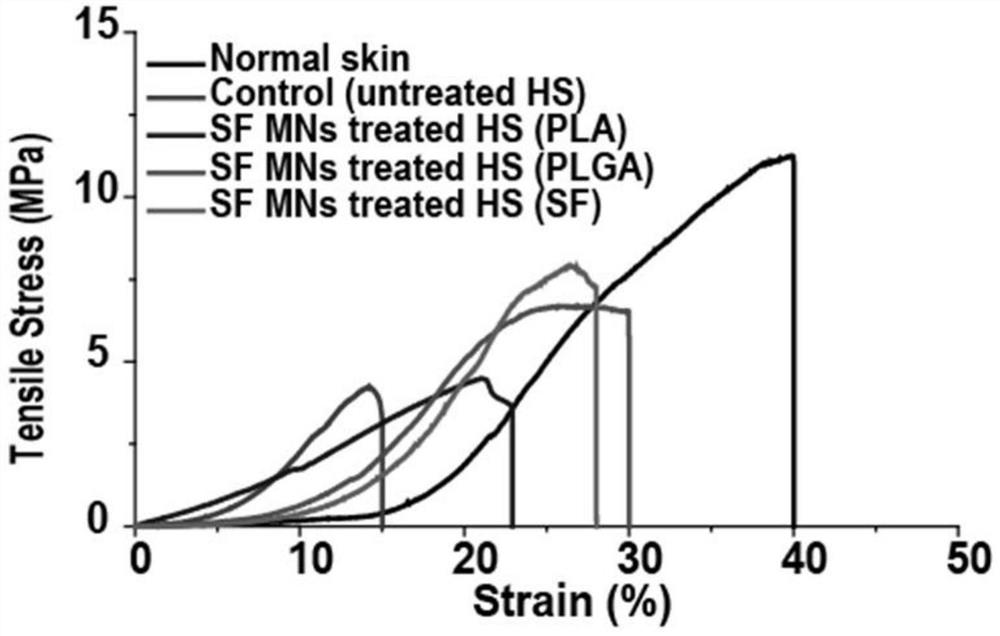

Application of microneedle patch in regulation and control of scar tissue mechanical microenvironment

PendingCN114129543AGood biocompatibilityMinimally invasive and painlessMicroneedlesMedical devicesFibrosisScar tissue

The invention relates to a scar improvement technology, in particular to application of a microneedle patch to regulation and control of a scar tissue mechanical microenvironment. The technical problem to be solved by the invention is to provide a new choice for improving scars. Research finds that the microneedle patch can regulate and control the microenvironment of fibrotic tissues, and a foundation is laid for subsequent further preparation of medical supplies for effectively improving hypertrophic scars.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com