Middle wire filling type negative-pressure-in low-acting-force stirring friction welding method and device

A friction stir and welding method technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as large force and easy deformation, and achieve the purpose of reducing mechanical force, reducing heat input, and reducing deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

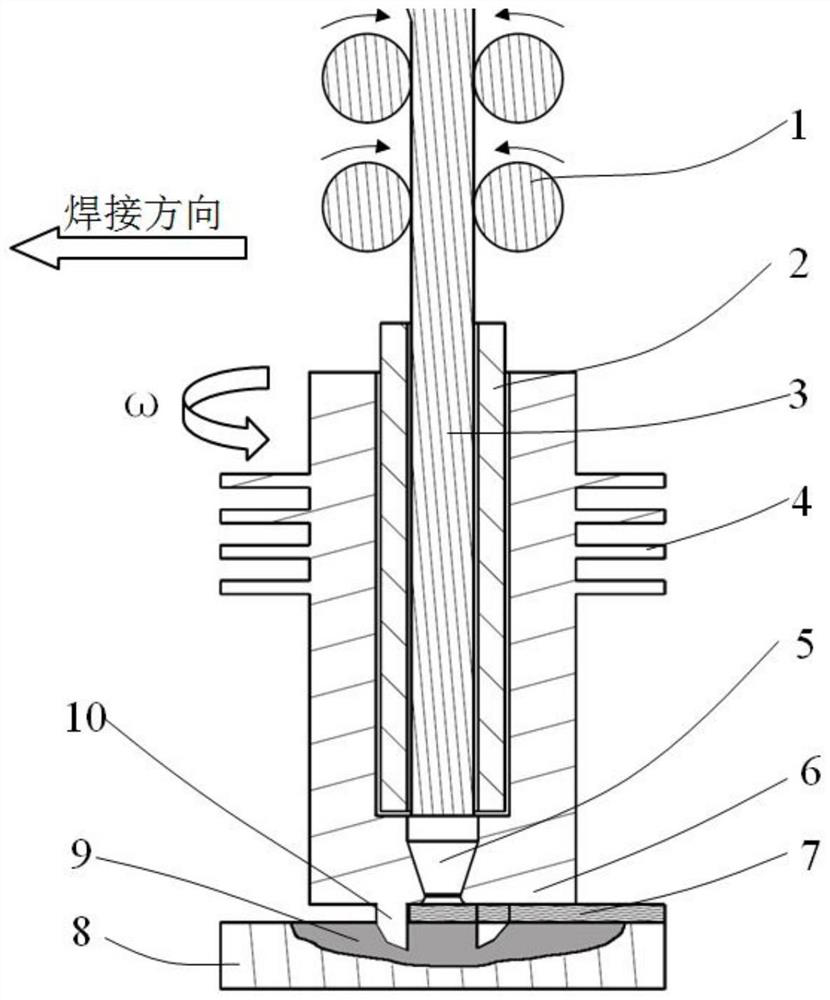

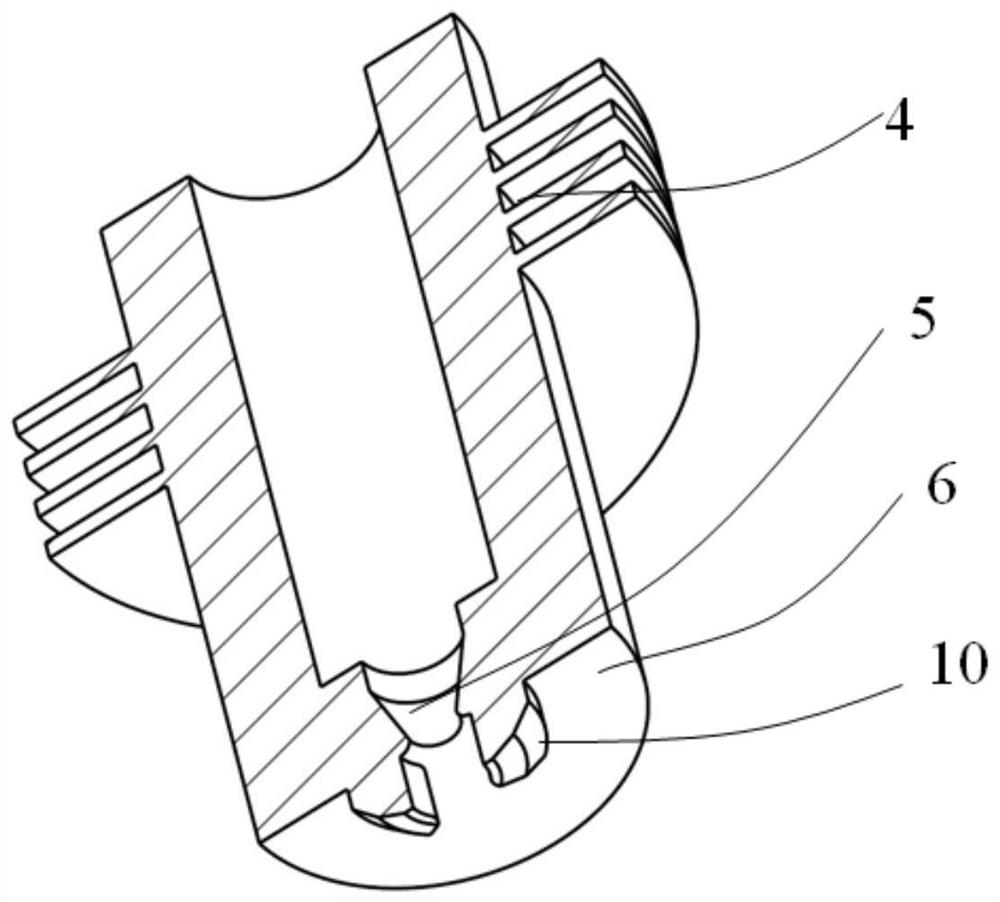

[0024] Such as figure 1 and figure 2 As shown, a negative pressure input low force friction stir wire filling welding method and its equipment include a wire feeding mechanism, a stirring tool, a wire material and a formed part, and the wire feeding mechanism at least includes a feeding wheel set 1, a wire Material guide cylinder 2, the stirring tool at least includes cooling fins 4, shaft shoulder 6, hollow stirring needle 10, friction inner neck 5. In this embodiment, the wire 3 is Φ1mm aluminum alloy, the feeding speed of the wire is 0.5mm / s, the friction inner neck 5 of the stirring tool has an inlet of Φ1mm and an outlet of Φ0.5mm, and the workpiece to be welded has a thickness of 1mm Aluminum plate, the length of the stirring pin 10 is 1mm, the depth inserted into the workpiece 8 to be welded is 0.9mm, the gap between the shoulder 6 and the upper surface of the workpiece 8 to be welded is 0.1mm, the rotation speed of the stirring tool is 10000-20000rpm, and the welding...

Embodiment 2

[0026] Such as figure 1 and figure 2 As shown, a negative pressure input low force friction stir wire filling welding method and its equipment include a wire feeding mechanism, a stirring tool, a wire material and a formed part, and the wire feeding mechanism at least includes a feeding wheel set 1, a wire Material guide cylinder 2, the stirring tool at least includes cooling fins 4, shaft shoulder 6, hollow stirring needle 10, friction inner neck 5. In this embodiment, the wire 3 is a Φ0.8mm magnesium alloy, the feeding speed of the wire is 1mm / s, the friction inner neck 5 of the stirring tool has an inlet of Φ0.8mm and an outlet of Φ0.4mm, and the workpiece to be welded It is a magnesium alloy plate with a thickness of 0.8mm, the length of the stirring pin 10 is 0.8mm, the depth inserted into the workpiece 8 to be welded is 0.7mm, the gap between the shoulder 6 and the upper surface of the workpiece 8 to be welded is 0.1mm, and the rotation speed of the stirring tool is 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com