Electrostatic chuck separation device

An electrostatic chuck and separation device technology, which is applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of damage to the electrostatic chuck, time-consuming and laborious, inconvenient operation, etc., and achieves good structural rigidity and easy manufacturing. , the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

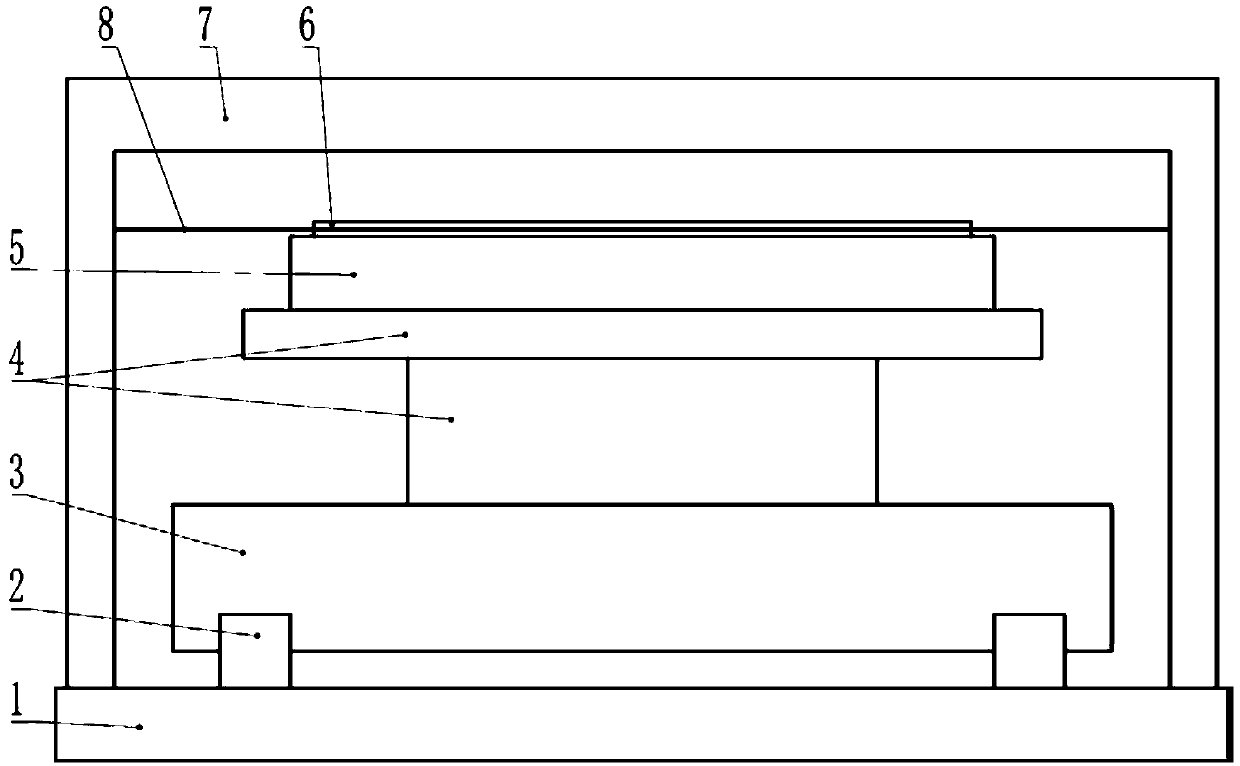

[0025] In the present invention, the "height" refers to the vertical distance between the heating sheet and the guide rail seat.

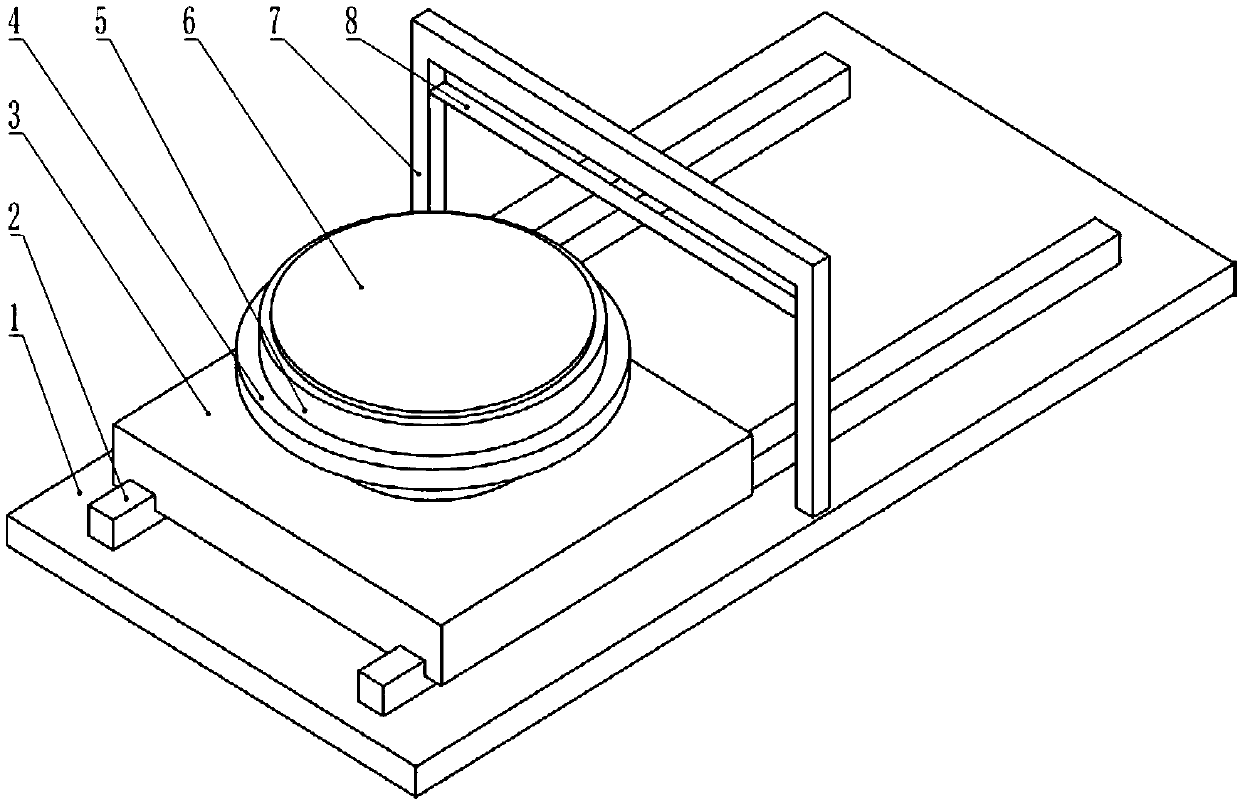

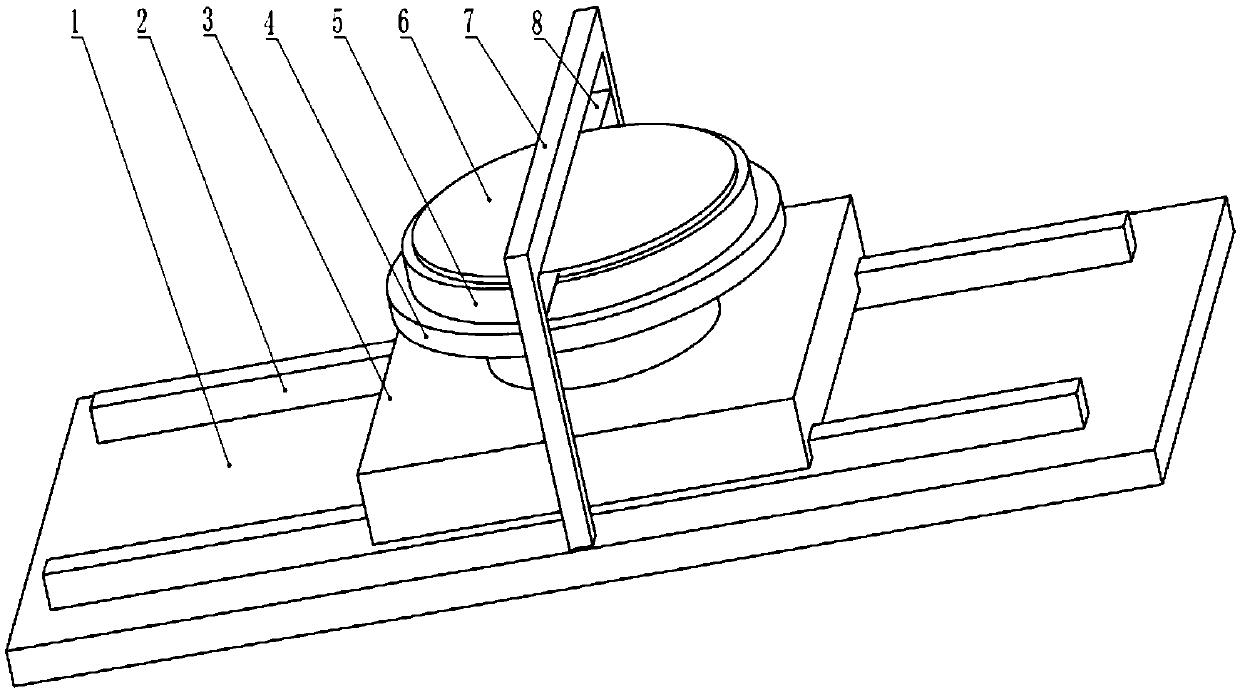

[0026] Bonding technology is widely used in semiconductor processing and manufacturing processes, such as chip packaging, wafer stacking, and the connection of various functional components of electrostatic chucks. The so-called bonding is to connect at least two components together through adhesives. In processing equipment, PVD, CVD, Etch and other process equipment are equipped with electrostatic chuck components. The electrostatic chuck component includes an electrostatic chuck 6 and a chuck base 5. The electrostatic chuck 6 is bonded to the chuck through an adhesive layer. Base 5.

[0027] During long-term use, the adsorption force of the electrostatic chuck 6 will decrease, and the electrostatic chuck 6 needs to be repaired or replaced. First, the electrostatic chuck 6 needs to be separated from the chuck base 5, and then processed , in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com