Method, process and device for polymeric waste processing

A polymer and waste technology, applied in the direction of grain processing, application, educts, etc., can solve the problems of reducing the quality of rubber powder, cross-contamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

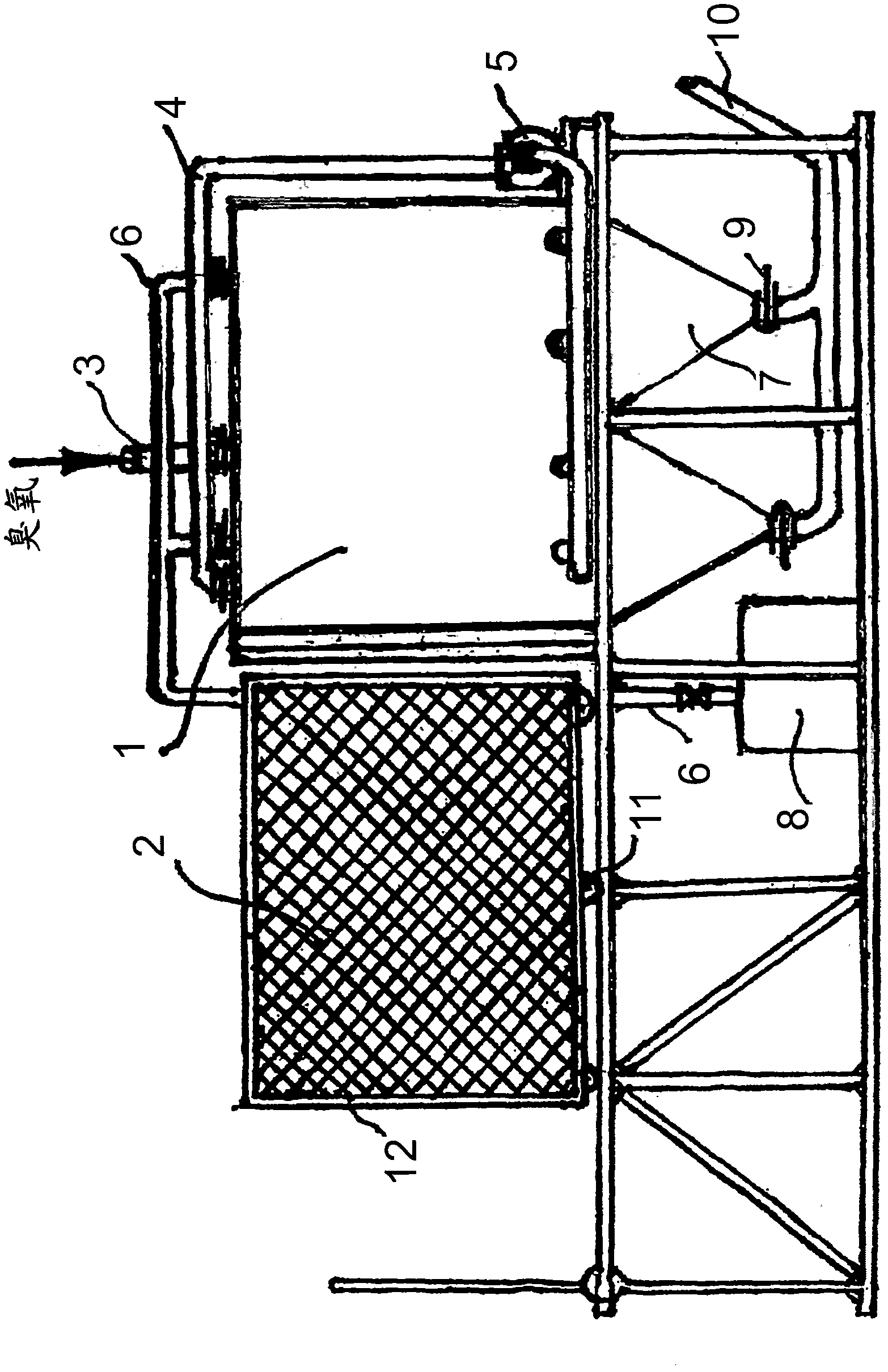

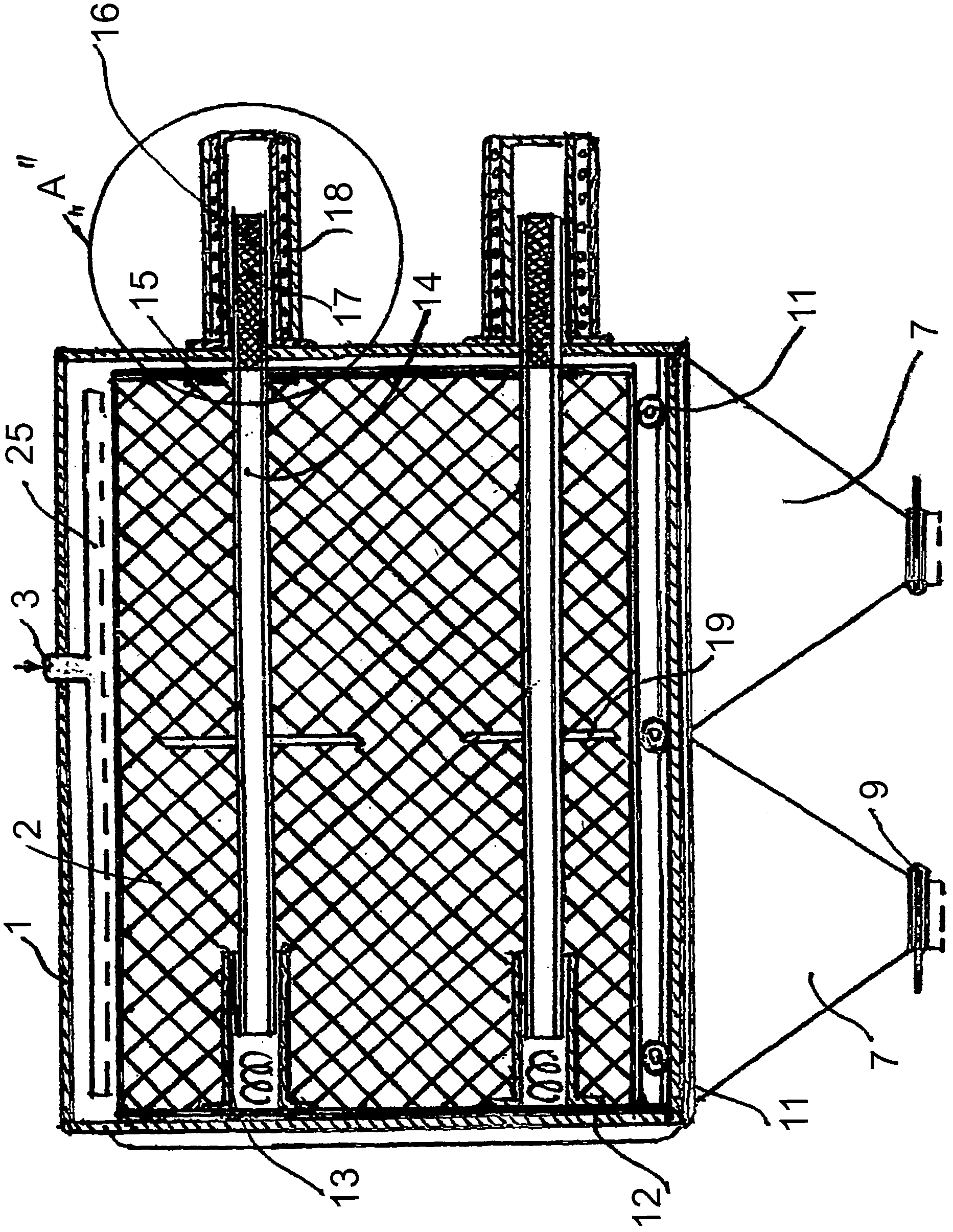

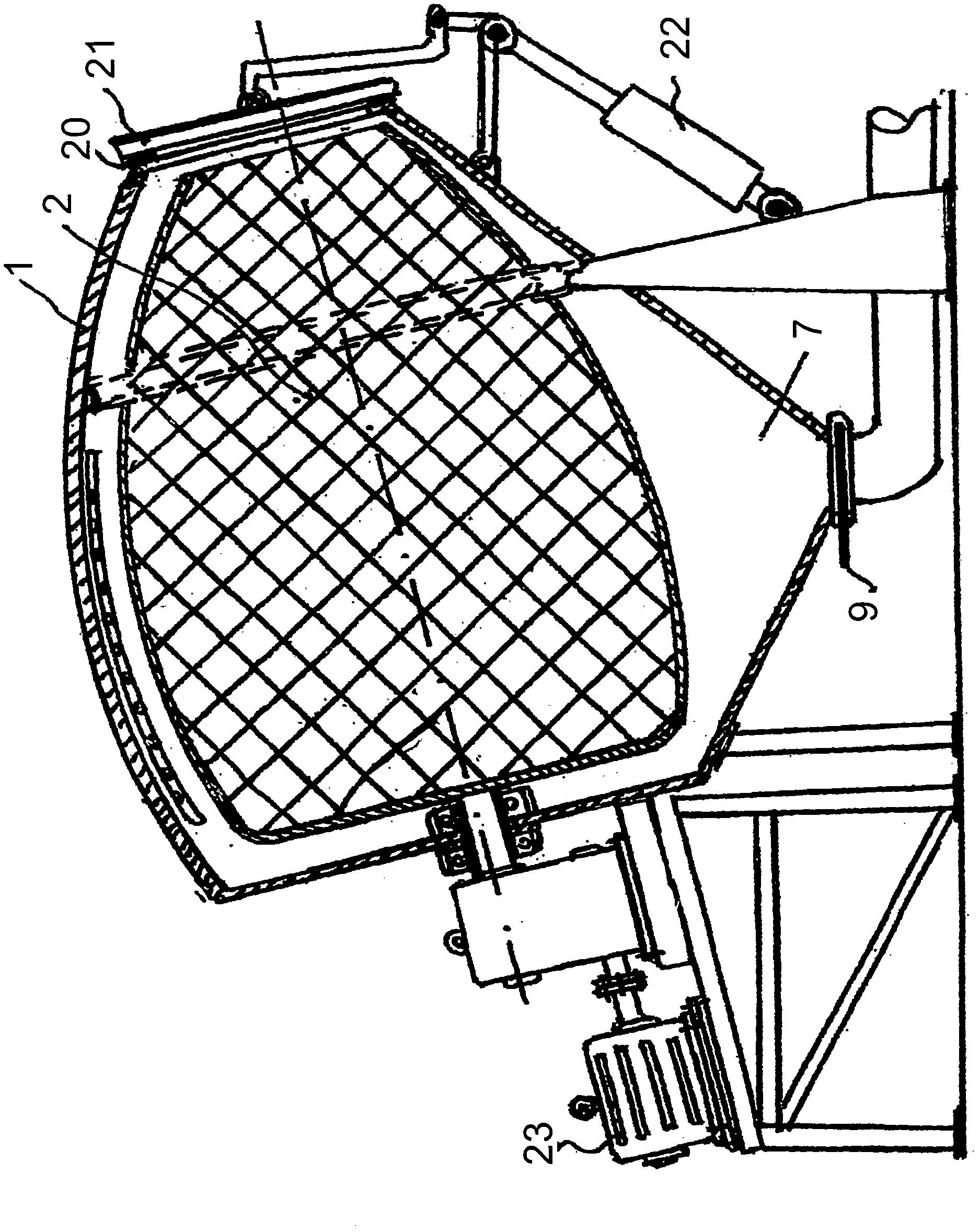

[0186] figure 1 An embodiment of a waste treatment device is illustrated having two distinct compartments made of or coated with a material resistant to the corrosive media used in the process. The reaction chamber comprises a hermetically sealable housing 1 and a screen 2 . In this embodiment the screen 2 is movable and can be moved into the hermetically sealable housing 1 . In this embodiment polymer waste is loaded into the screen 2 through an open port eg at the top of the screen 2 before the screen 2 is moved into the hermetically sealable housing 1 . The initial deformation of the polymer waste can be done outside or inside the screen 2 before the corrosive medium is applied inside the shell 1 . When loaded with initially deformed polymer waste, the screen 2 is positioned inside the housing 1, which is then hermetically sealed. The corrosive medium can then be circulated in the hermetically sealable housing 1 , wherein the corrosive medium diffuses through the screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com