Patents

Literature

72 results about "Polymer waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

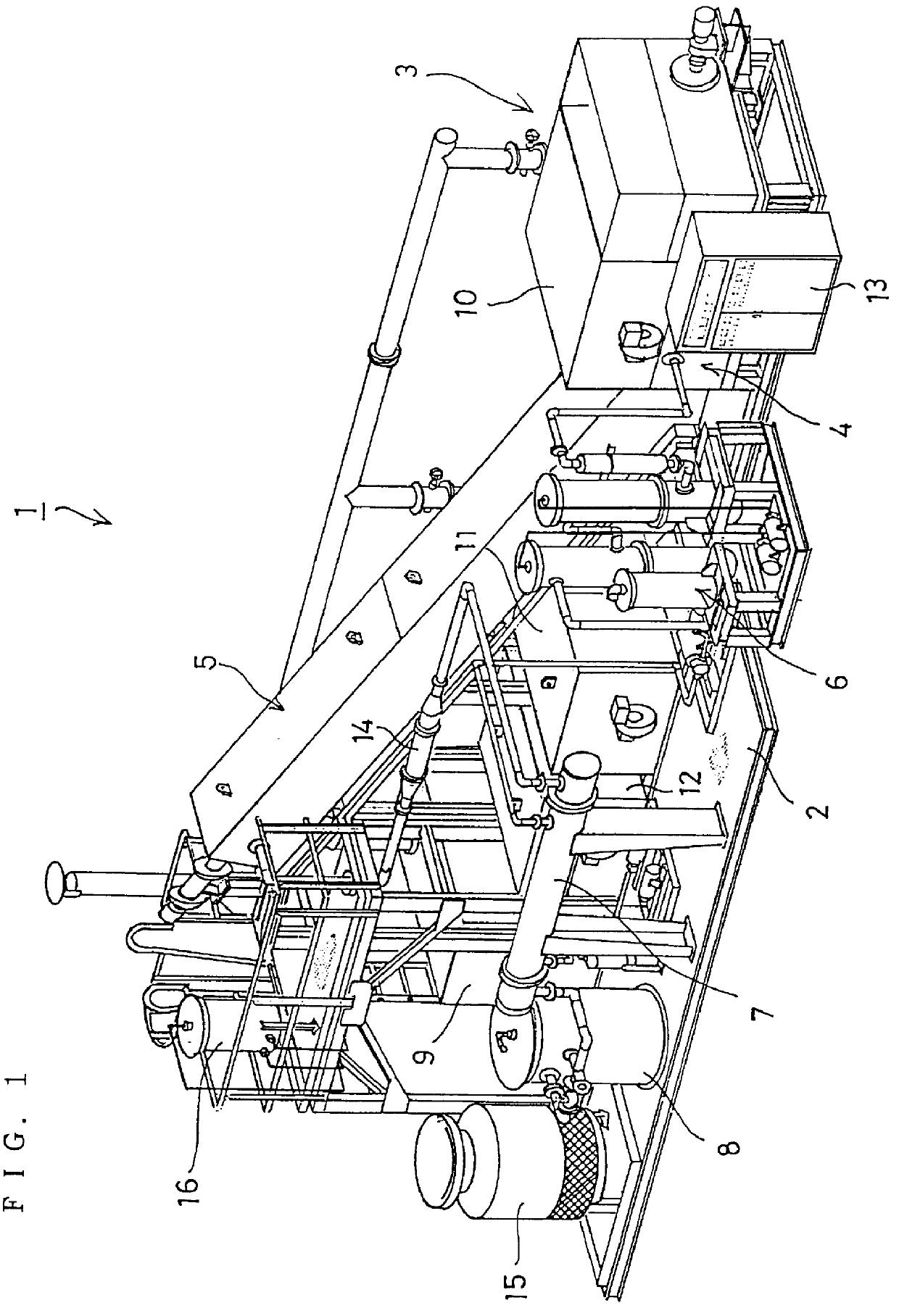

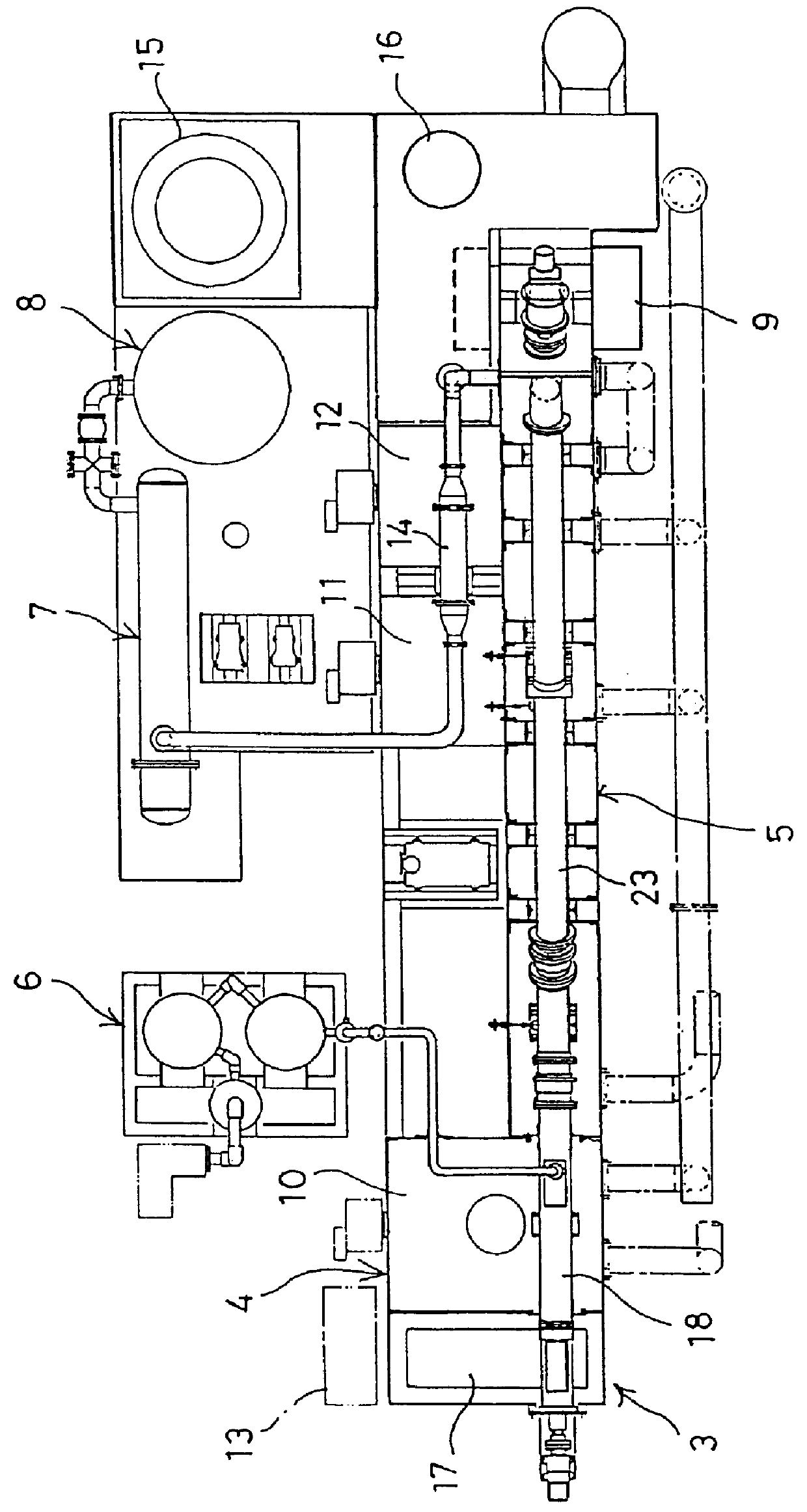

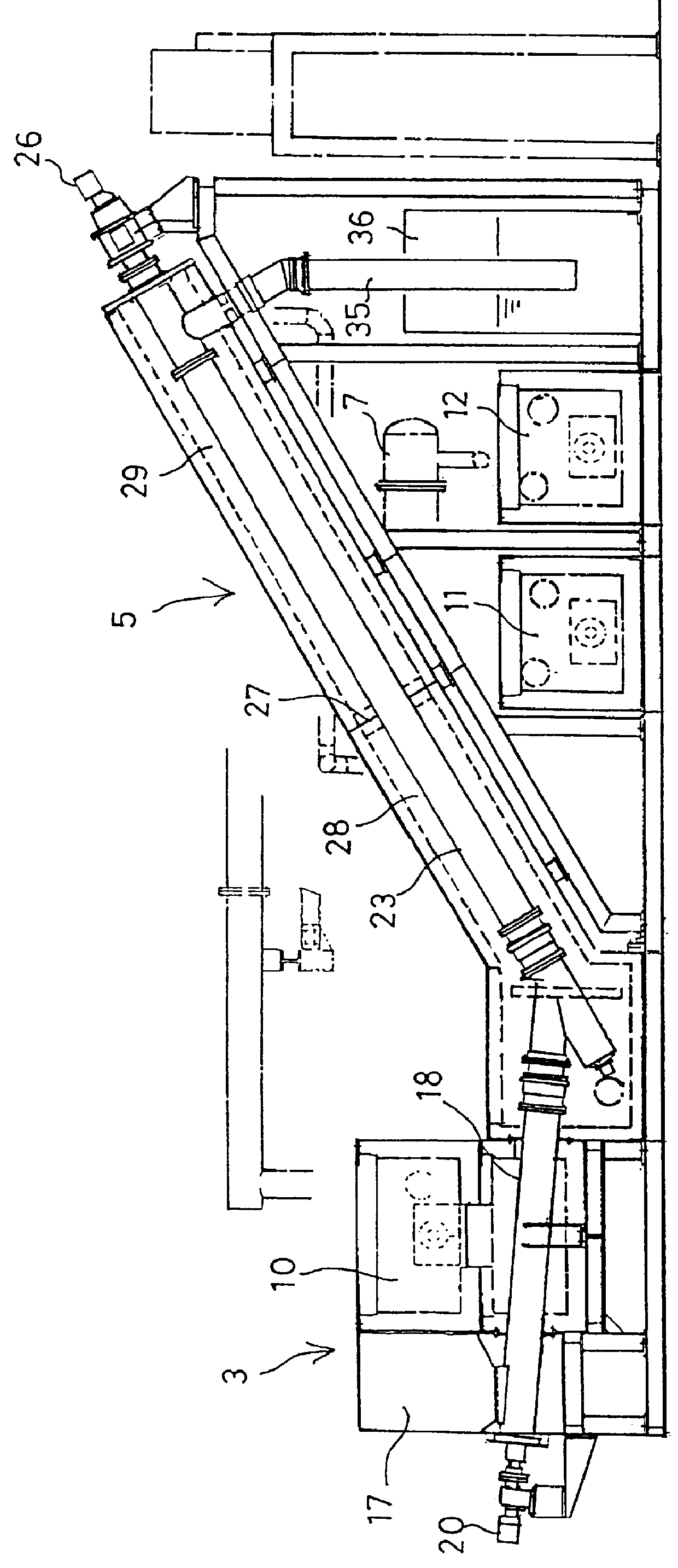

Thermal decomposition apparatus of reversed temperature gradient type for polymer waste

InactiveUS6126907ASimple structureSmall sizeSolid waste disposalDirect heating destructive distillationDecompositionSludge

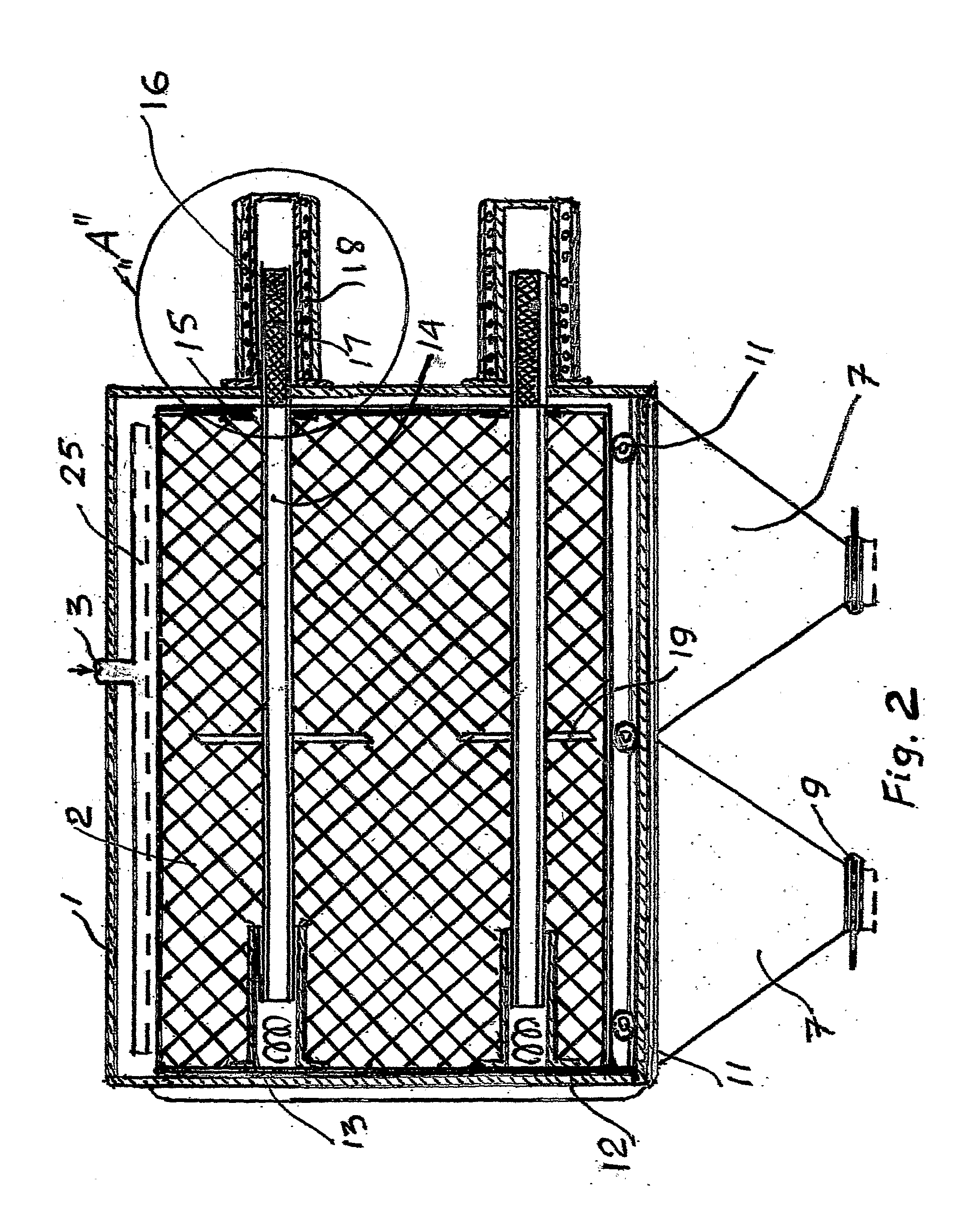

A thermal decomposition apparatus for decomposing polymer waste is provided which is simple in structure, small in size and inexpensive, and also the operating cost thereof is low. A feed pipe 18 and an inclined pipe 23 are connected in the form of the letter V at a large angle therebetween, and a feed screw 19 and an feed-up screw 25 are arranged inside the respective pipes. Polymer waste introduced into a hopper 17 is melted in the interior of the feed pipe 18 by heat from a first hot air furnace 10 and accumulated in the V-shaped portion. The polymer melt is then conveyed upward by the feed-up screw 25. In the process of conveyance, the polymer melt undergoes primary decomposition by means of heat from a second hot air furnace 11 and the cracked gas thus generated undergoes secondary decomposition by the heat from a third hot air furnace 12, the resultant gas being guided to a condenser 7. Sludge drops down through a chute pipe 35 into a water tank 36.

Owner:WADA YOUICHI

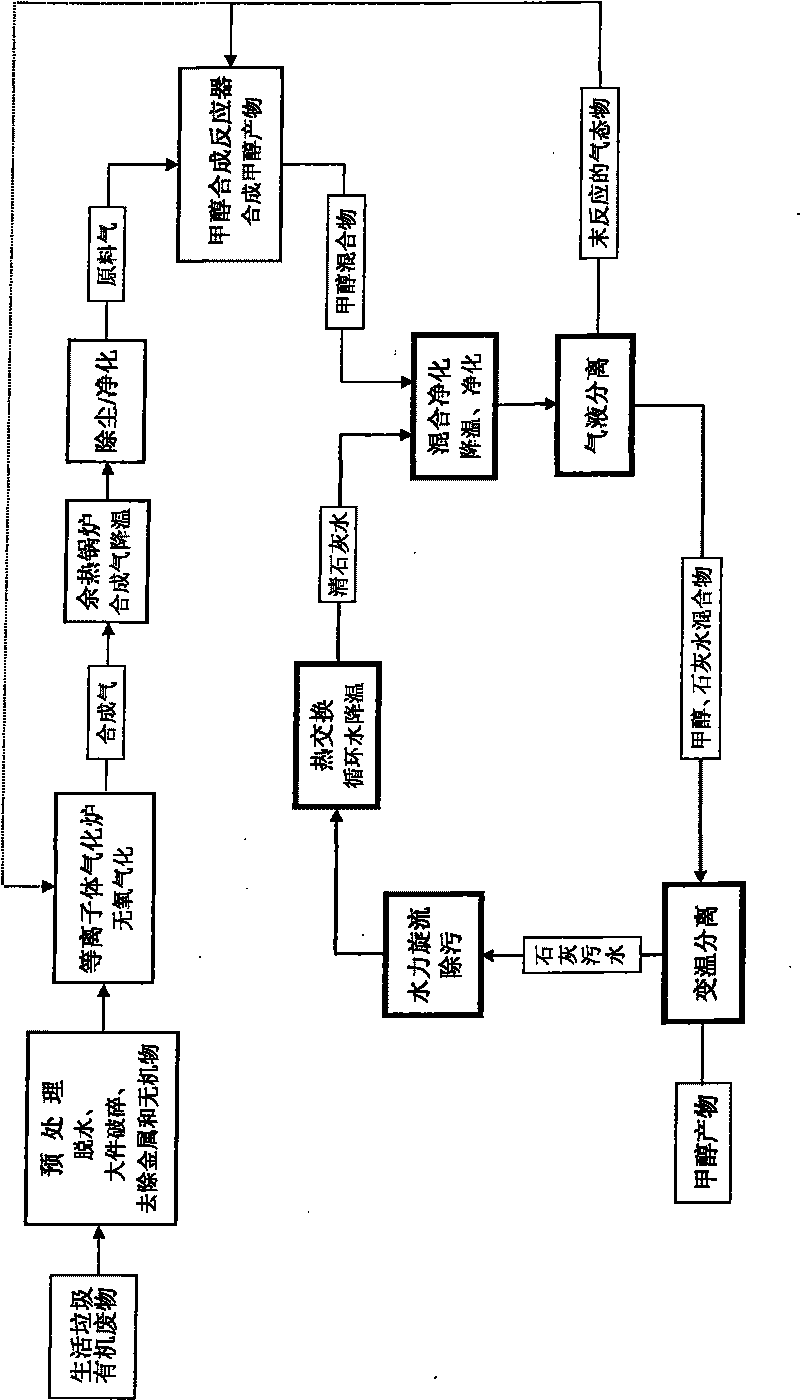

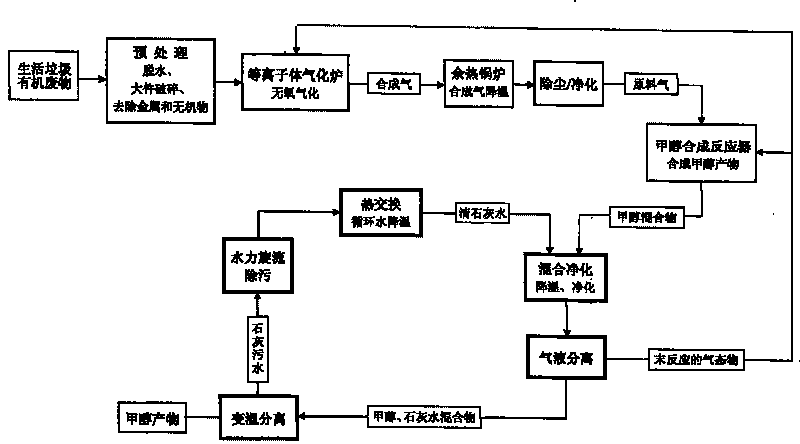

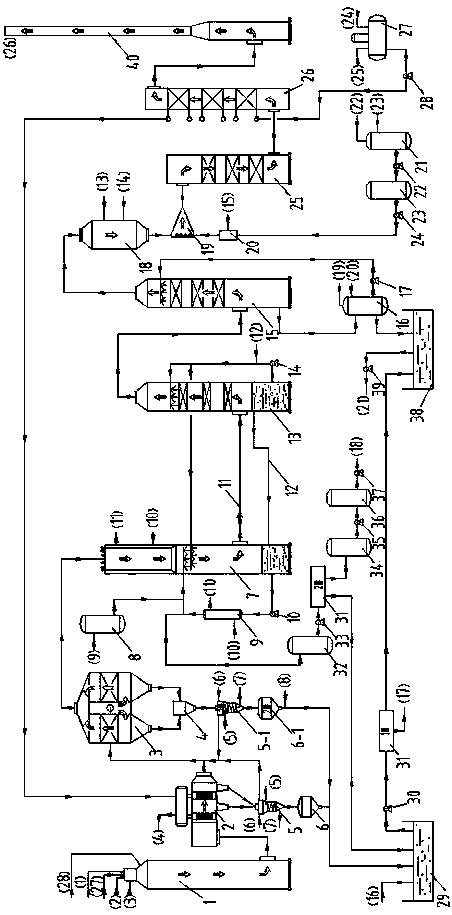

Process for gasification-liquefaction disposal of domestic garbage and organic waste

The invention discloses a process for gasification-liquefaction disposal of domestic garbage and organic waste, which relates to disposal technology of the domestic garbage and the organic waste. The process comprises the steps of: performing oxygen-free gasification on the domestic garbage or the organic waste in a plasma gasification furnace to produce hydrogen-rich syngas which does not contain oxygen and takes CO and H2 as main components, wherein the conditions of the formation of dioxin are avoided; then sending the hydrogen-rich syngas taken as feed gas into a methanol synthesis reactor to catalytically synthesize a methanol product after temperature reduction and dust removal / purification; then drawing the methanol product out of the reactor to mix with lime water for terminal purification operation; and using calcium hydroxide as an absorbent to ensure that pollutants and purities which are not eliminated in a dust removal / purification working procedure and comprise the dioxin are removed. The process almost has no the discharge of the pollutants during the whole disposal process, and is suitable for harmless disposal of municipal domestic waste, rural domestic refuse, medical waste, industrial polymer waste, agricultural and forestry waste, composting leftovers and refuse sorting field waste.

Owner:周开根

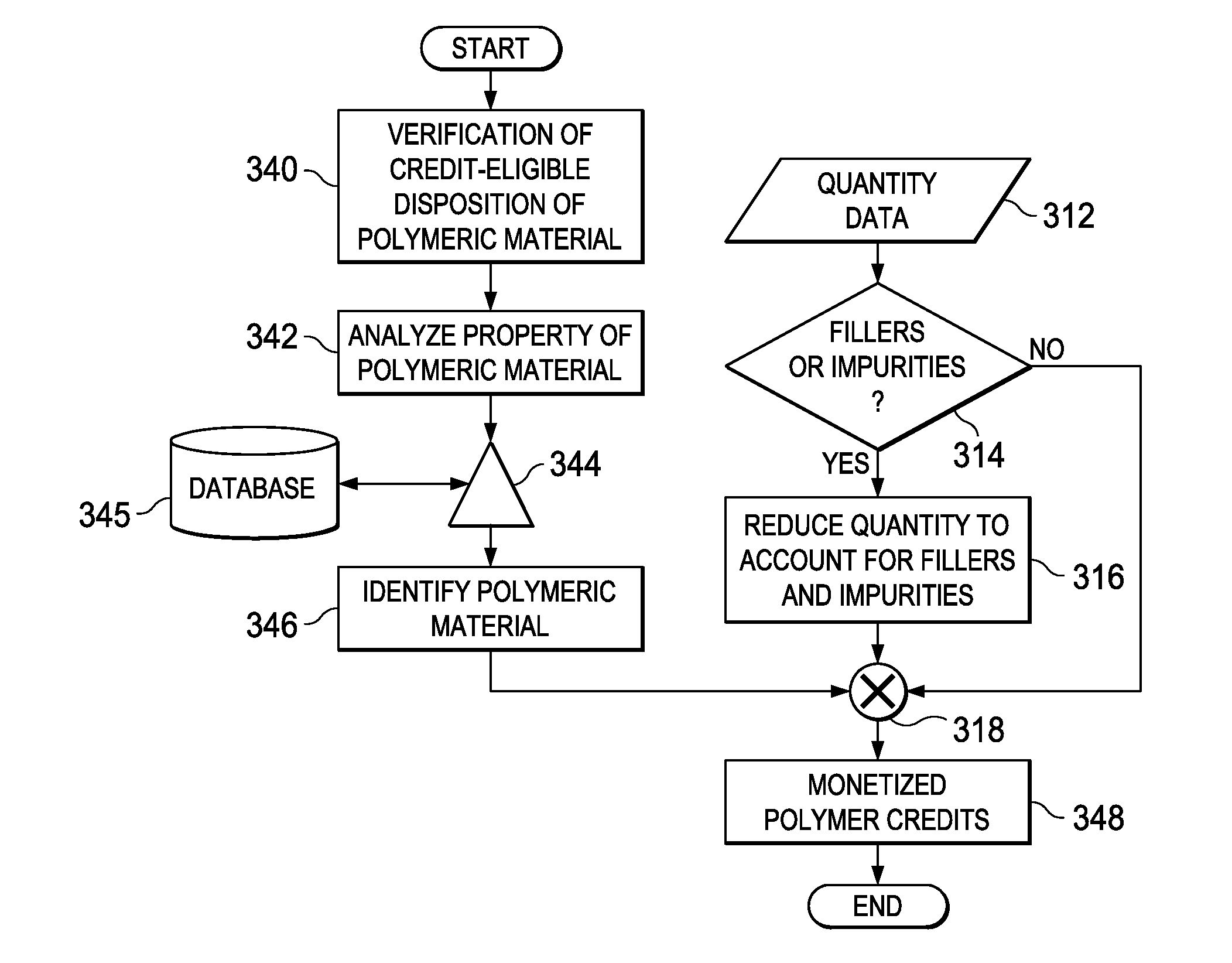

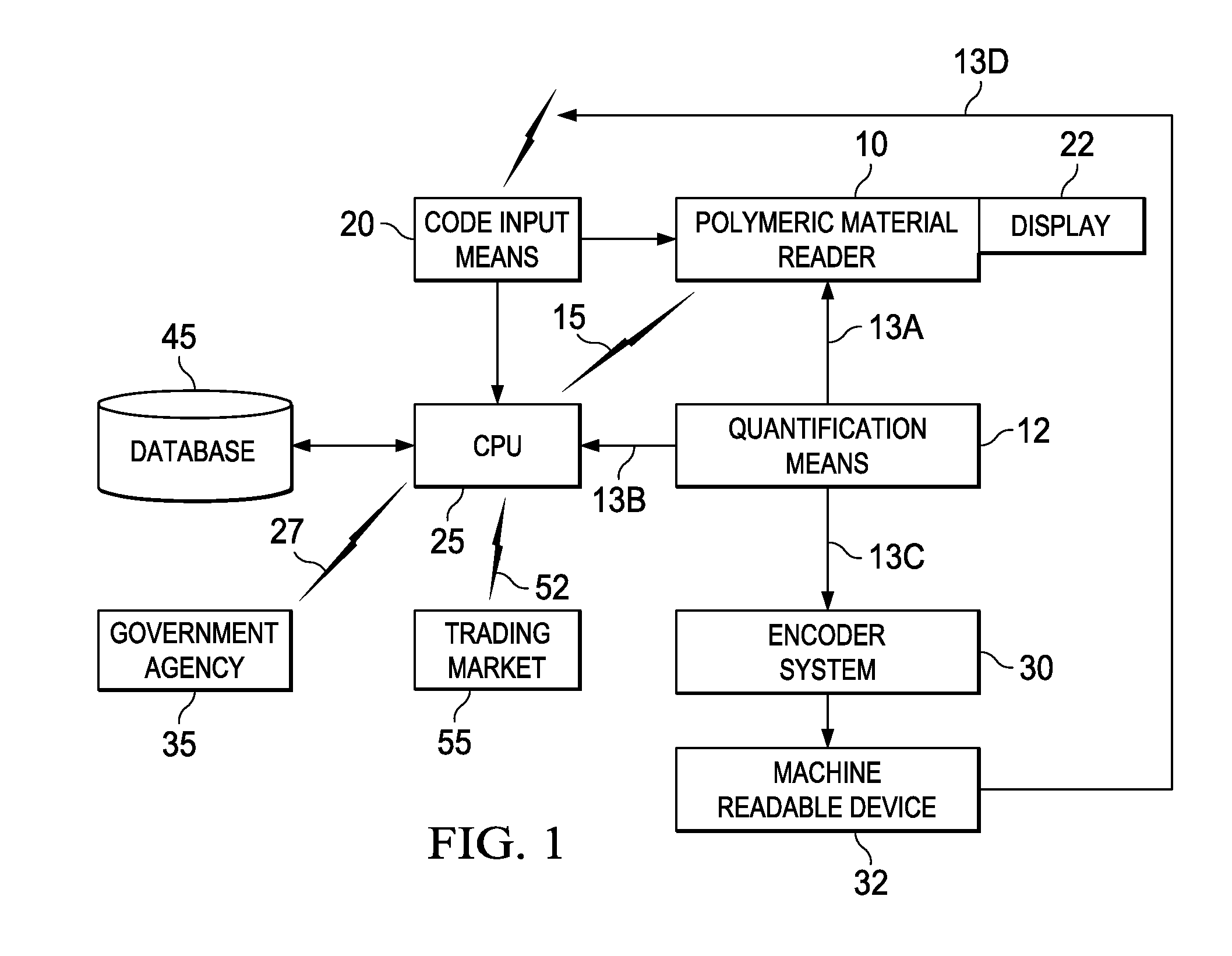

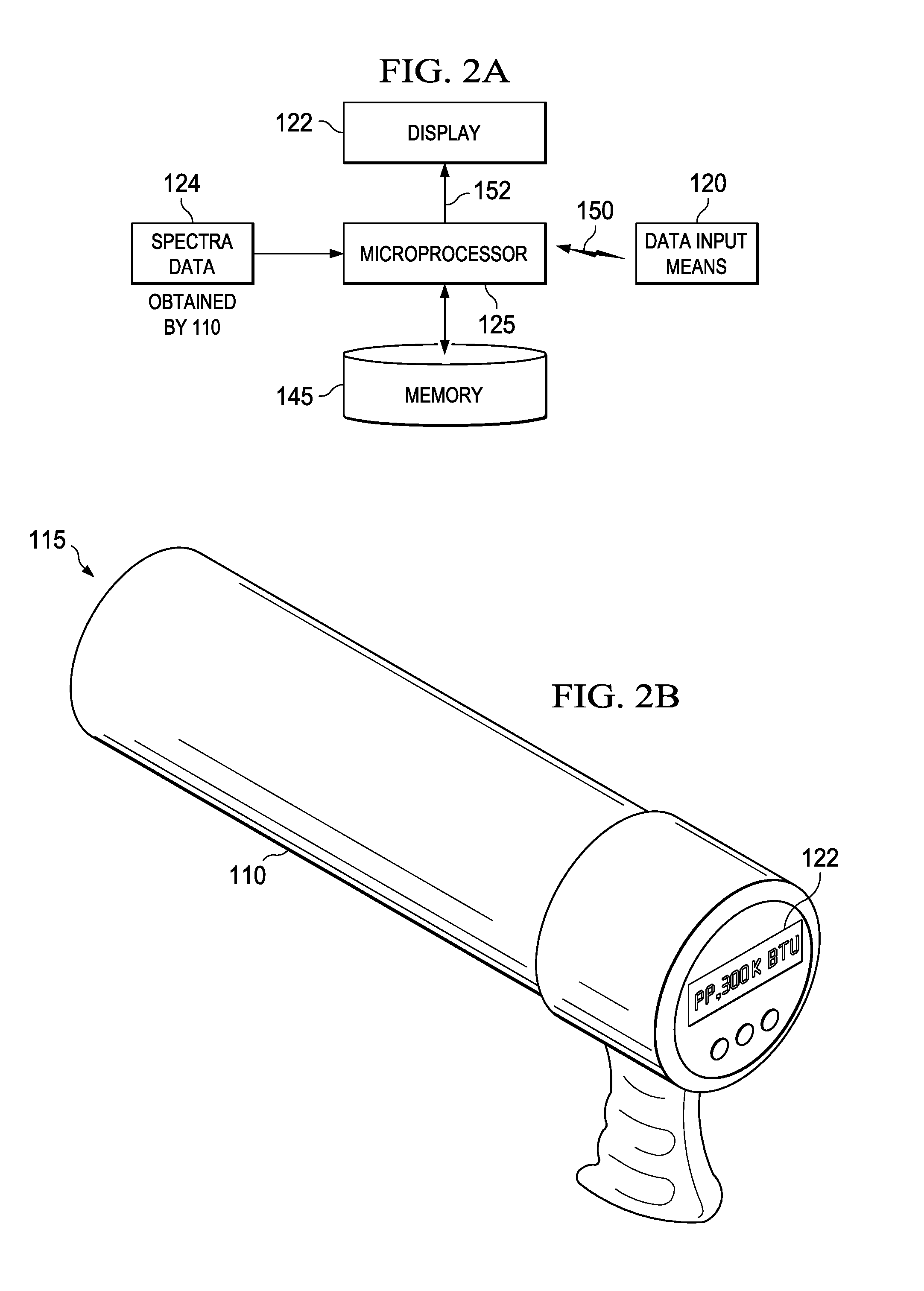

System and method for monetizing and trading energy or environmental credits from polymeric materials

The present invention is a system and method for monetizing and trading value in polymeric materials, forming polymer energy credits and / or polymer environmental credits. The system promotes the highest and best use and disposition of polymer waste, scraps and used material. The new types of credits have a value which can be bought, sold and traded in a market exchange. A polymer manufacturer can assign predetermined credit value to polymeric material sent into commerce which can be realized upon disposition of polymeric material in a predetermined or prescribed manner and credited to the manufacturer and / or user of the polymeric material. Alternatively, a verification authority may be implemented to review claims of entitlement to credits and may take into account factors relevant to the polymeric material to assign value to verified polymer energy or environmental credits and / or to certify various entities engaged in the process.

Owner:EMPIRE TECH DEV LLC

One-pot, high-performance recycling of polymer waste using renewable polymer synthesis

InactiveUS20160376453A1Improve performanceImproved tunable propertyProductsReagentsScrapPolymer waste

Owner:POLY6 TECH

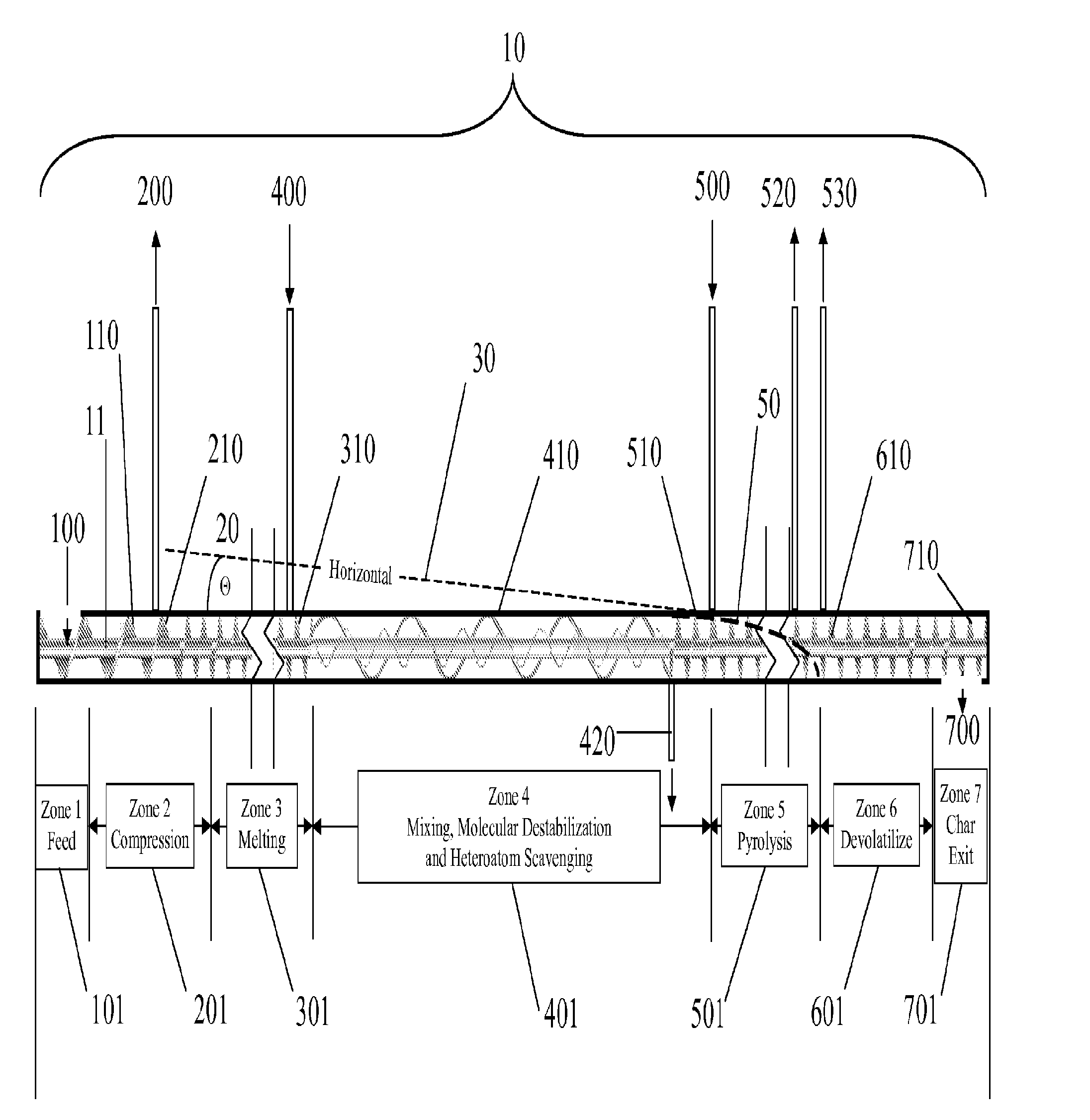

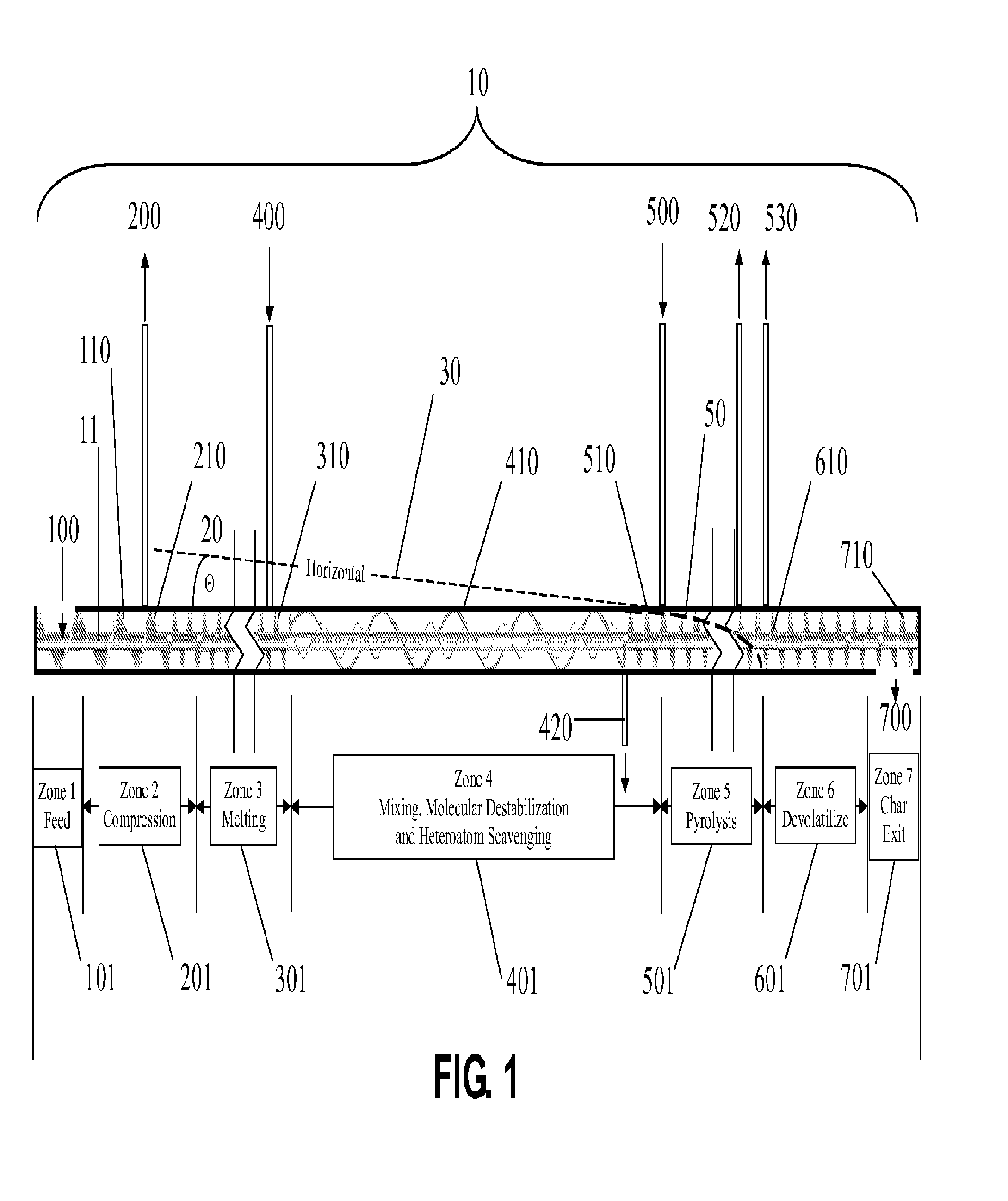

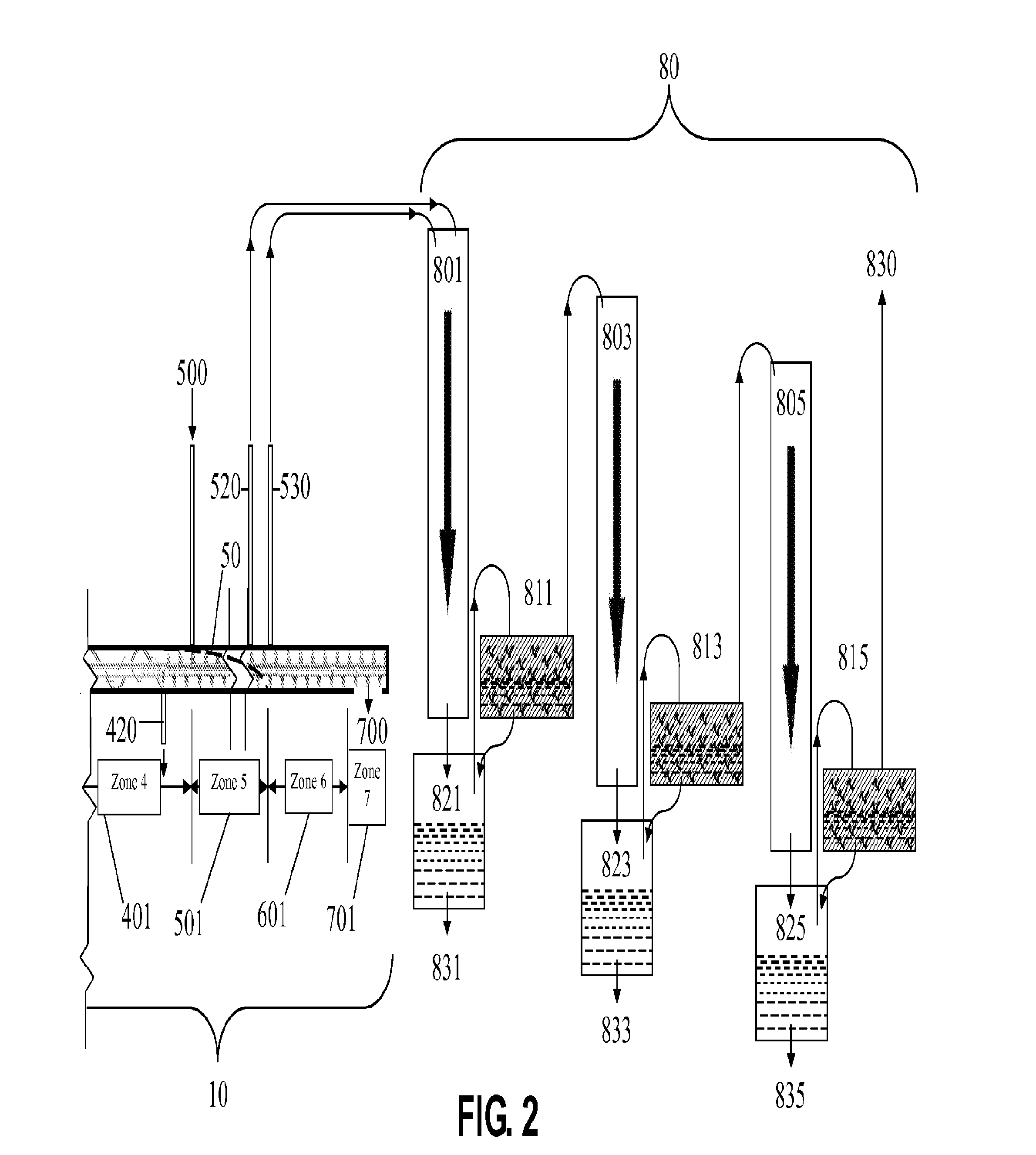

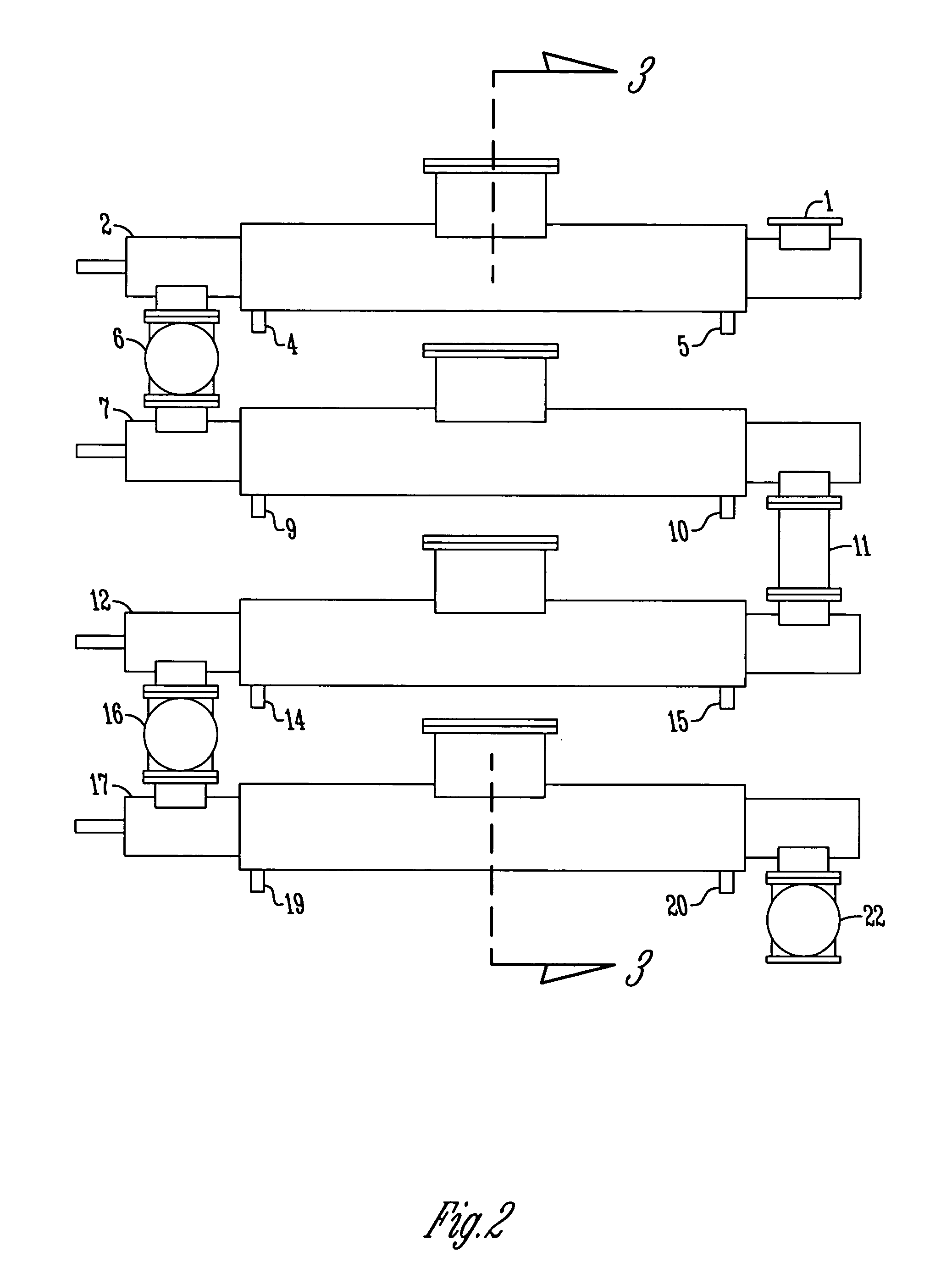

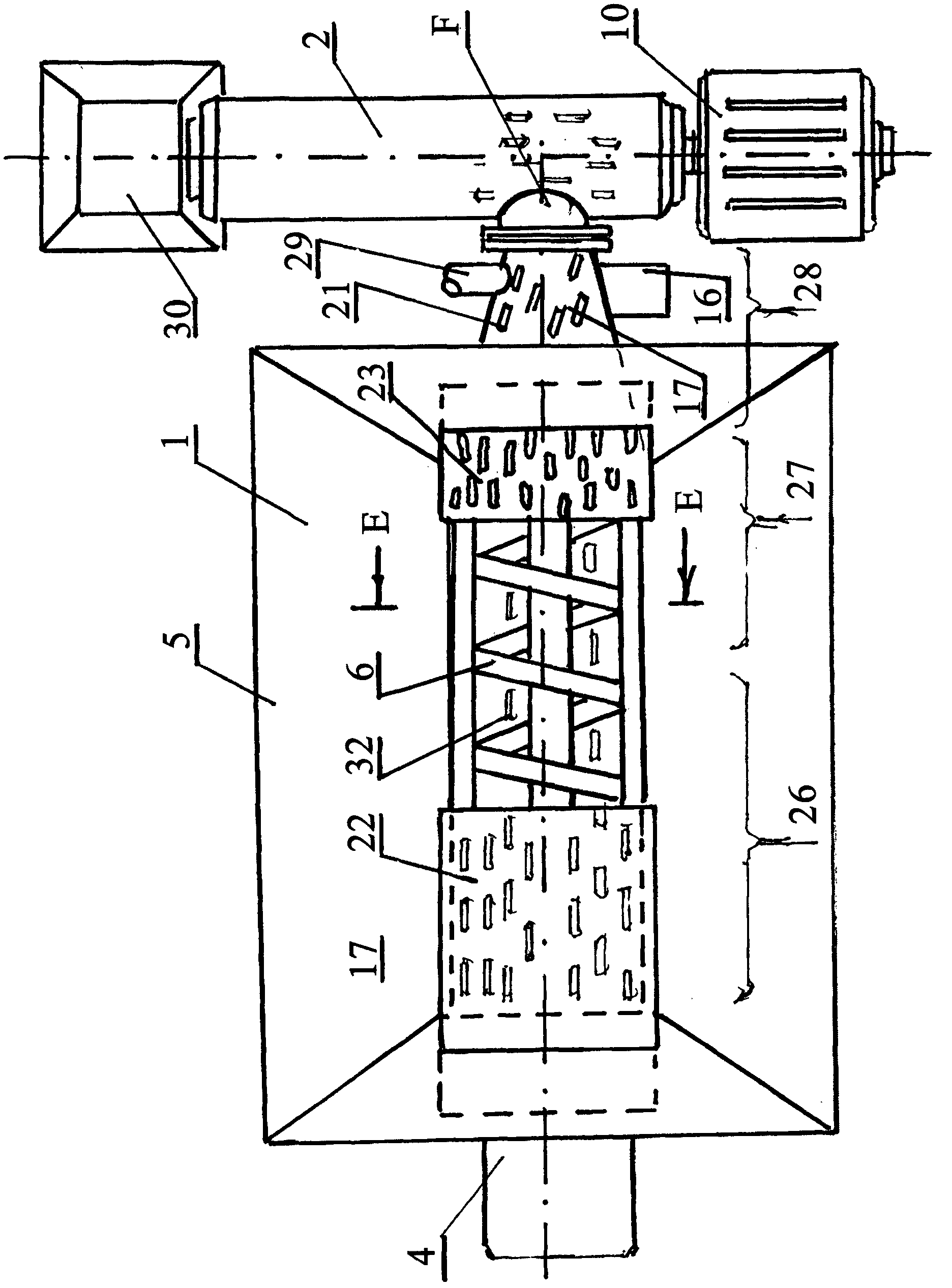

Zone-delineated pyrolysis apparatus for conversion of polymer waste

Apparatus and method for pyrolyzing hydro carbonaceous materials to produce useful vapor and solid products comprising a generally cylindrical, linear reactor having a screw means for transporting hydro carbonaceous materials through said reactor, means for feeding and heating said hydro carbonaceous materials whereby they are processed and pyrolyzed to produce vapor and solid products; means for removing vapor products from said processed hydro carbonaceous materials, means for removing solid products, means whereby said hydrocarbonaceous material is maintained within a zone for a range of defined residence times, means for rotating said screw, which has a plurality of flight configurations for compressing, and for melting said hydro carbonaceous materials to convert them from a solid to a liquid, for mixing, destabilizing and dehalogenating said hydro carbonaceous materials, for pyrolyzing said hydro carbonaceous materials, for devolatilizing the pyrolyzed hydrocarbonaceous materials, and for discharging solid products.

Owner:ALTERRA ENERGY LLC

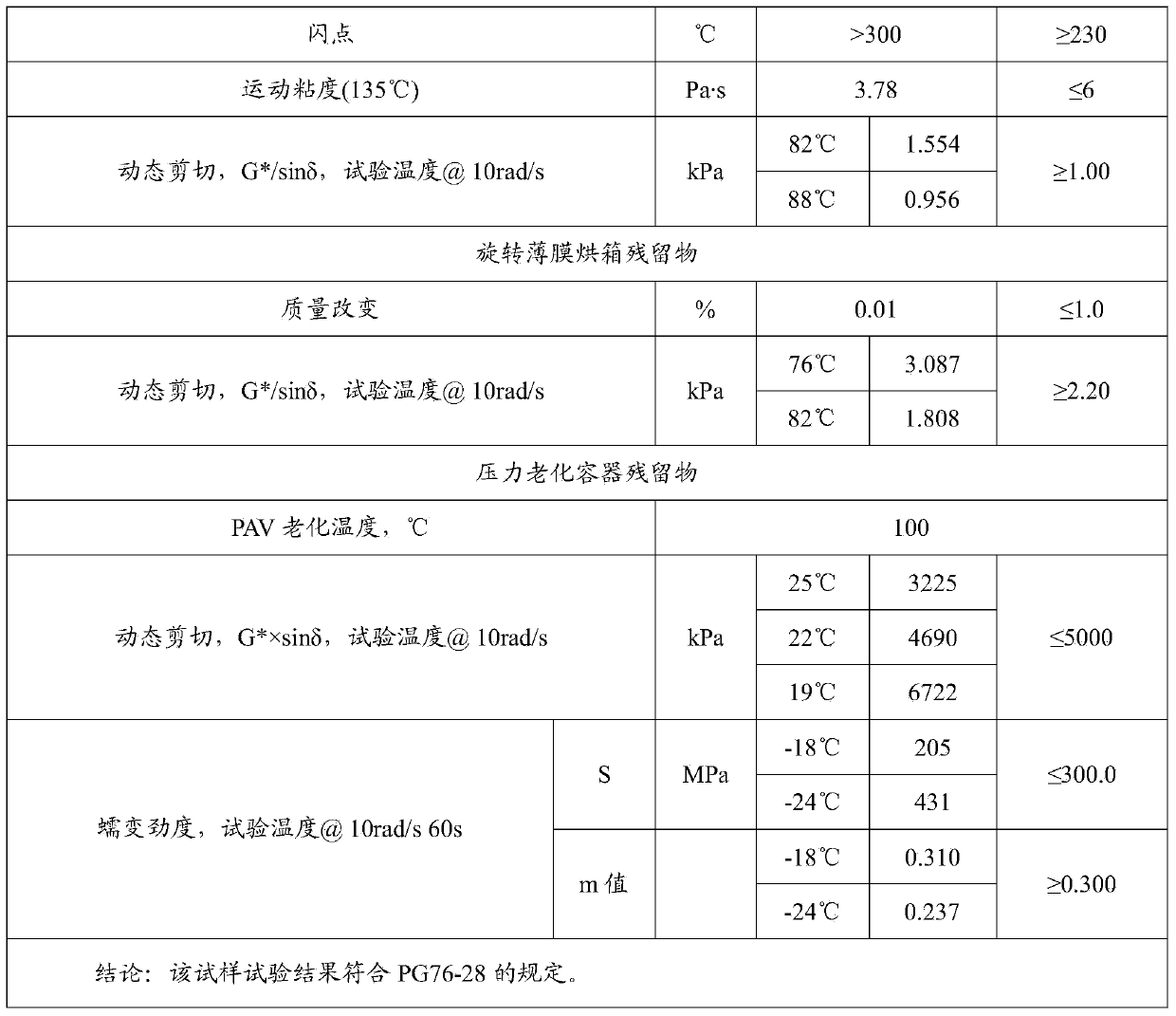

Rubber and plastic alloy modified asphalt and asphalt mixture

InactiveCN103436039AHigh temperature strengthGood modification effectPlastic recyclingBuilding insulationsPolymer scienceAlloy

The invention relates to the field of asphalt. A rubber alloy modifier is obtained with untreated waste plastics and waste tire rubber powder as main raw materials. Modified asphalt which does not affect the rubber / plastic independent modification effects and has good asphalt storage stability and simple production process is finally obtained by utilizing the modifier to modify asphalt. The modified asphalt can be applied to continuous dense gradation of an asphalt mixture. On the premise that the high-and-low temperature performance of the mixture meets the requirement, the water stability is obviously improved, thus achieving effective treatment of two types of polymer waste pollutants such as waste tire rubber powder and waste plastics and change of asphalt properties.

Owner:山东高速交通建设集团有限公司

Method for preparing hydrocarbon with catalysis copyrolysis of biomass and polymer

InactiveCN101508619AImprove conversion rateSimple processHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon crackingPolystyreneCo pyrolysis

The invention provides a method for preparing carbon-hydrogen compound by catalytic co-pyrolysis of biomass and polymer. The biomass and polymer waste are taken as raw material and the carbon-hydrogen compound is prepared by catalytic co-pyrolysis technology. The pyrolysis is carried out in a pressure-proof reactor; the biomass comprises agriculture and forestry processing waste of rice hull, wheat straw, mao bamboo, corn and the like; the polymer waste comprises polystyrene, polyethylene, polypropylene, scrap tire, daily waste plastic and the like. The reaction conditions are as follows: thepressure is 2-6 KPa, the reaction gas is hydrogen or nitrogen, vacuum and no oxygen, the pyrolysis temperature is 320-450 DEG C and the time is 30 minutes to 6 hours. The conversion rate of the overall mixed waste is 55-64%, carbon-hydrogen compound gas accounts for 20-33% of overall product, carbon-hydrogen compound liquid accounts for 60-58% of overall product and residua accounts for 14-19% ofoverall product.

Owner:ZHEJIANG UNIV

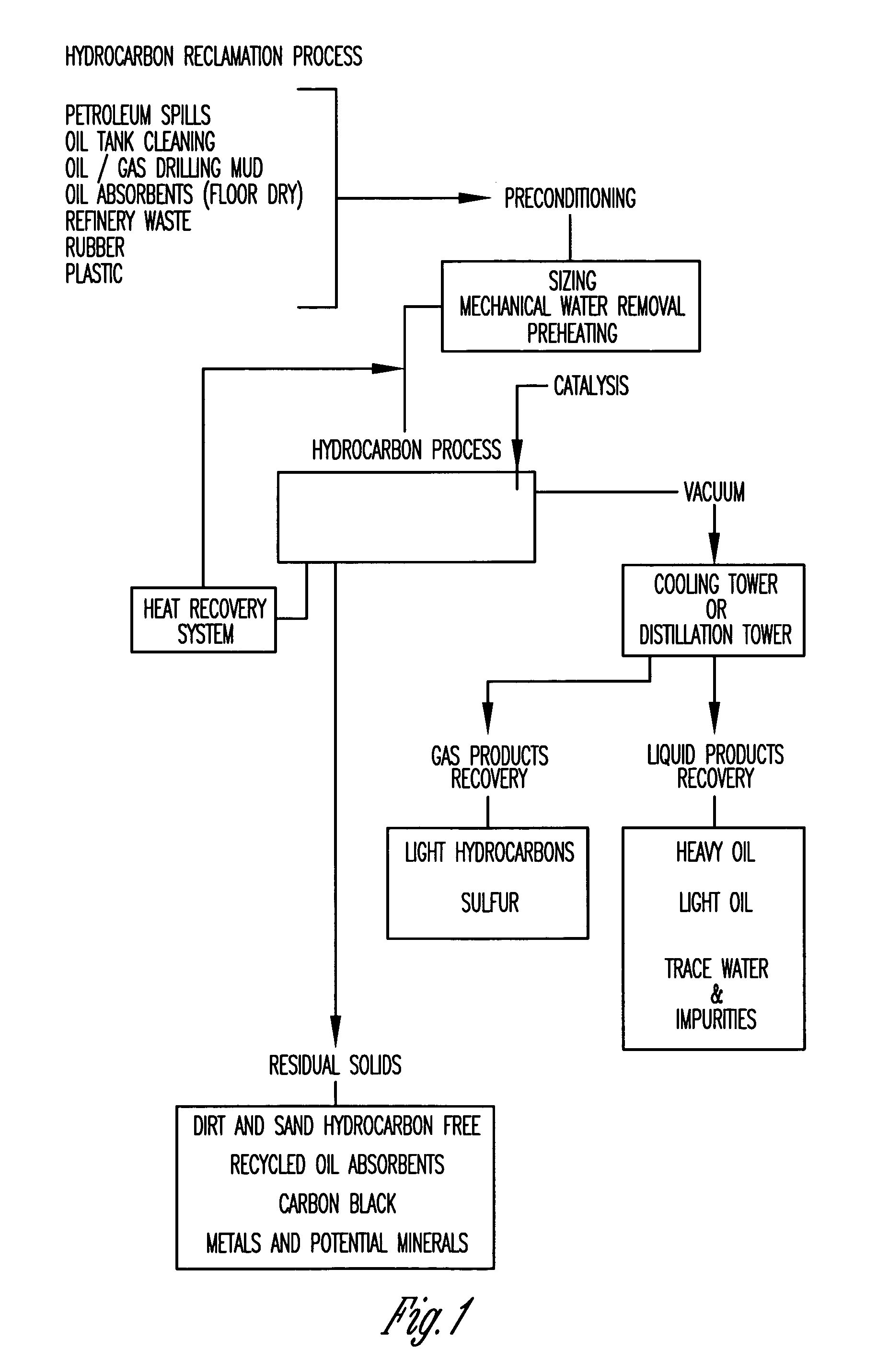

Method of separating and converting hydrocarbon composites and polymer materials

InactiveUS20060004236A1Low costCost-effective and safe and efficientLiquid hydrocarbon mixture productionHydrocarbonsGas phaseHydrocotyle bowlesioides

The process described herein presents a unique method of separating and converting polymers and hydrocarbon composites to light / medium weight hydrocarbons from polymer and hydrocarbon composites waste. The method involves the removal of moisture from the hydrocarbon composite and / or polymer waste followed by or in conjunction with a catalytic reaction which takes place at slight negative pressure in anaerobic conditions. The light / medium weight hydrocarbons are then recovered in the vapor phase. The vapors are condensed and separated by conventional techniques. Residual solids, substantially free of hydrocarbons and polymers may be furthered processed and recycled by conventional means. The conversion process has also been applied to natural occurring heavy and low grade hydrocarbon deposits such as oil and tar sands.

Owner:DREAMCO

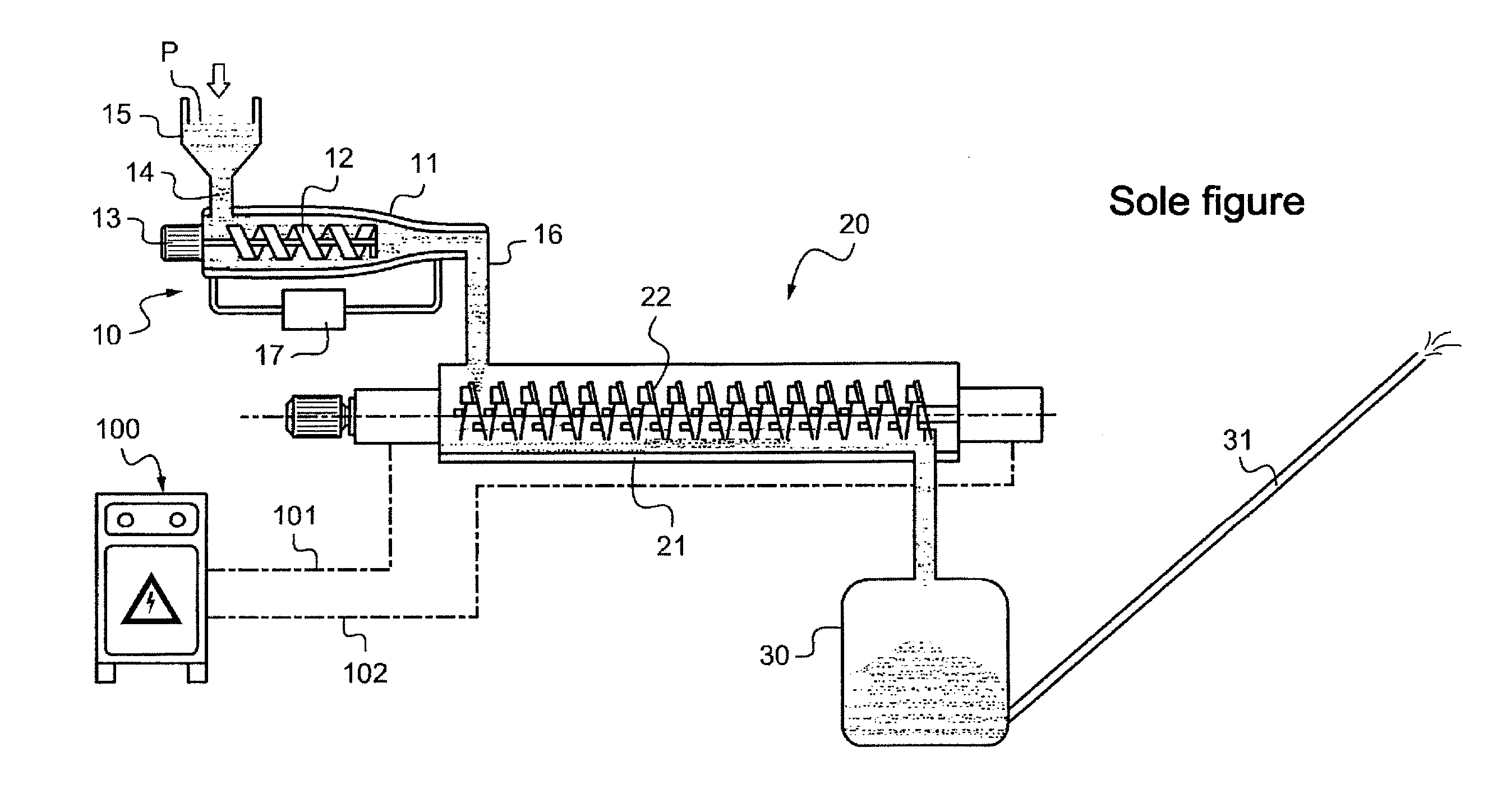

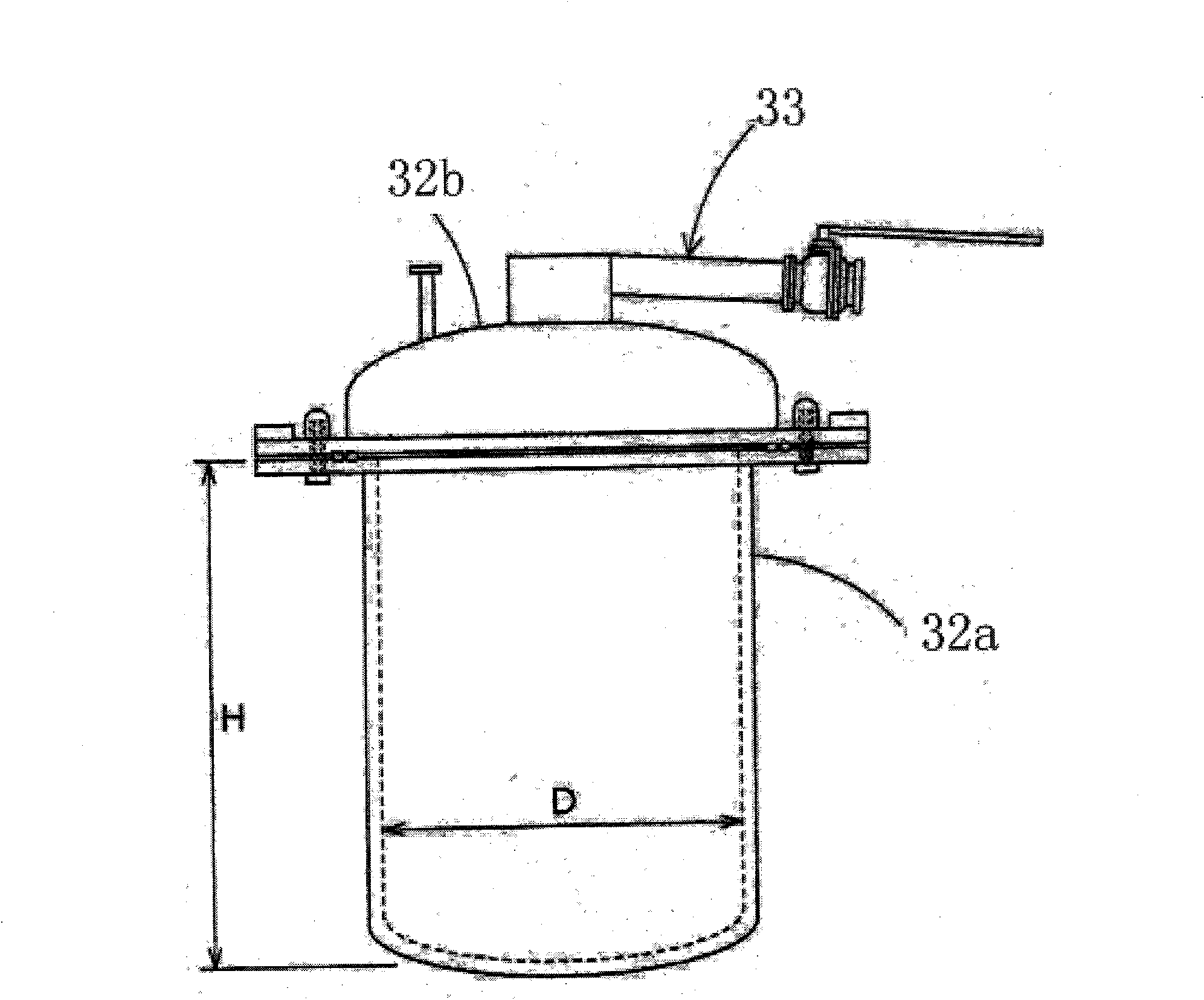

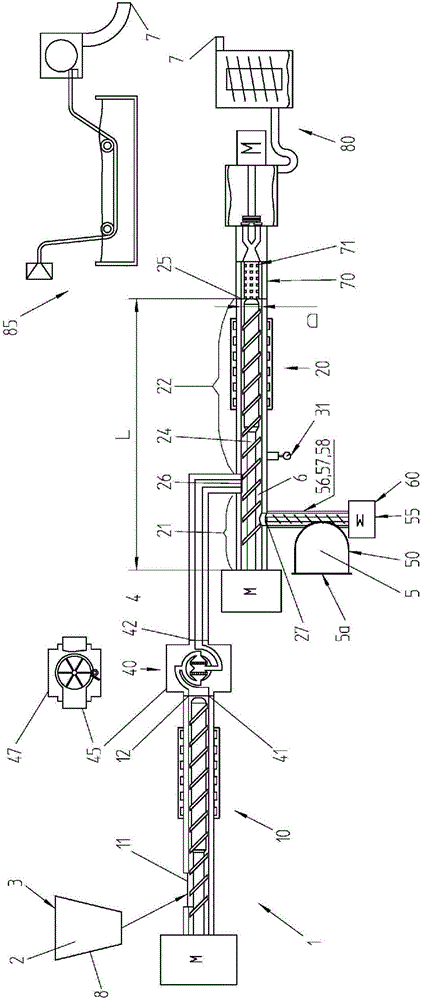

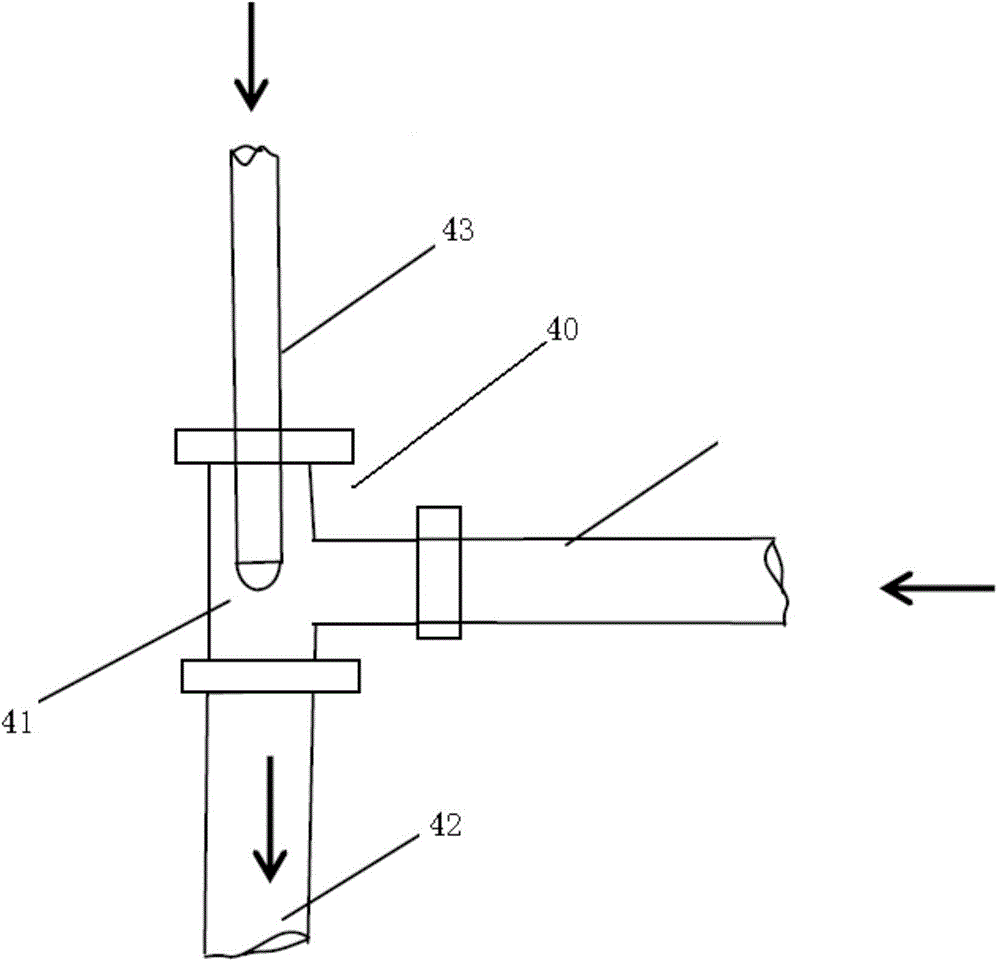

Process and installation for pyrolysis of a product in the form of divided solids, in particular polymer waste

InactiveUS20140284198A1Improve pyrolysis efficiencyHigh methane contentElectrical coke oven heatingDirect heating destructive distillationElastomerLiquid state

An installation for pyrolyzing divided solids, such as waste plastics, rubbers, or elastomers. The installation has a device for making divided solids suitable for facilitating pyrolysis by a pyrolysis reactor. The reactor inlet is leak-tightly connected to the preconditioning device and has at least one heating transfer member for transferring the divided solids within the reactor while also pyrolyzing the solids. The member is a conveyor screw or a vibrating tube, and being made of a material that is associated with means for heating it by the Joule effect. The preconditioning device includes liquefaction means for bringing the substance to the outlet of the preconditioning device in a liquid state at an outlet temperature, and a regulator for regulating the temperature of the substance at the outlet from the preconditioning device as a function of a temperature representative of an inlet temperature of the reactor.

Owner:LEPEZ CONSEILS FINANCE INNOVATIONS LCFI

Resourceful and environment-friendly treatment system for chlorine-containing organic waste gas and waste liquid of organosilicone

PendingCN109654515AAchieve recyclingReduce wasteEmission preventionCombustion technology mitigationSmall footprintSilicon dioxide

The invention discloses a resourceful and environment-friendly treatment system for chlorine-containing organic waste gas and waste liquid of organosilicone, and belongs to the field of waste resourceful treatment, purification and environment protection. The resourceful and environment-friendly treatment system is composed of an incineration section, a waste heat recovery section, a silicon dioxide powder recovery section, a diluted hydrochloric acid recovery section and a tail gas environment-friendly up-to-standard discharge section. The incineration section is connected with the waste heatrecovery section. The silicon dioxide powder recovery section is arranged behind the waste heat recovery section and is connected with the diluted hydrochloric acid recovery section. The tail gas environment-friendly up-to-standard discharge section is arranged behind the diluted hydrochloric acid recovery section. Generated flue gas is environment-friendly and reaches standards after being treated by the tail gas environment-friendly up-to-standard discharge section, the flue gas is discharged into air through a chimney, and resourceful utilization of chlorine-containing organic waste gas and low-boiling-point polymer waste liquid of organosilicone is achieved; and recovery of diluted hydrochloric acid, silicon dioxide powder and other chemical intermediates is achieved while flue gas waste heat recovery is achieved. The system is compact in layout and small in occupied area, and equipment operation sustainability is high.

Owner:大连科林能源工程技术开发有限公司

Internal arc plasma gun

ActiveCN102802335AImprove decomposition ratePromote decompositionPlasma techniqueDecompositionWater jacket

An internal arc plasma gun relates to plasma heating equipment, and consists of a front gun body, a back base and a first electrode, wherein an arc cavity and a cooling water jacket are arranged inside the front gun body; the head part of the first electrode stretches into the arc cavity; the arc cavity and the head part of the first electrode stretching into the arc cavity form an internal arc generator; a metal component at an inlet forms a second electrode; and when the internal arc plasma gun works, an arc is generated inside the arc cavity, sprayed out from a compressing nozzle, and intensely heated after being compressed so as to form a plasma torch. By decomposing water molecules inside the arc cavity, energy of the high-temperature plasma arc is concentrated, the internal arc plasma gun has the characteristics of high heating efficiency and high decomposition rate of the water molecules, is applicable to a daily garbage gasifying furnace, a coal gasifying furnace, an industrial polymer waste gasifying device, a water-pyrolyzing hydrogen making device and a boiler, and compared with the conventional technology, can reduce the consumption of coal resources, improve the quality of synthesized gas and reduce emission of greenhouse gas.

Owner:南通东湖国际旅行社有限公司

Method for preparing hydrocarbon compounds in biomass self-catalysis copyrolysis way

InactiveCN101735844AAchieve recyclingLow costLiquid hydrocarbon mixture productionOxygenNitrogen gas

The invention relates to a method for preparing hydrocarbon compounds in a biomass self-catalysis copyrolysis way, which is realized in a way as follows: biomass and polymer waste are used as raw materials, and a catalyst adjuvant is added to prepare the hydrocarbon compounds by using a biomass self-catalysis copyrolysis technique; the pyrolysis is carried out in a normal pressure reactor; and the reaction is carried out in the reaction atmosphere of hydrogen, nitrogen or vacuum without oxygen at the pyrolysis temperature of 400-550 DEG C for 1-6 hours. In the invention, the total conversion rate of mixed waste reaches 65-81%, and the content of hydrocarbonaceous gases in the total product is 10-20%; and the hydrocarbon compounds contain 38-56% of liquid, 19-25% of oxygenic organic substances and 14-19% of residues. The hydrocarbon compound products of the invention comprise gas hydrocarbons, oily hydrocarbons, oxygenic organic substances and amorphous silicon.

Owner:ZHEJIANG UNIV

Preparation method for suspension polymer

InactiveCN102732235AOnline profile control is easy to operateEasy to prepareDrilling compositionPolymer scienceOxygen

The invention relates to a preparation method for a suspension polymer. The preparation method comprises: adding an additive to polymer dry powder to form a uniform and stable suspension polymer, wherein the suspension polymer is applicable for oilfield water shutoff profile modification construction. The preparation steps comprise: adding a wetting agent to polymer dry powder with a particle size of 80-150 meshes; uniformly stirring at a stirring speed of 50-70 rotations per minute, and sequentially adding a dispersing agent, white oil, and a stabilizer while continuously stirring; and continuously stirring for 0.5-1.5 hours at the same stirring speed to obtain the suspension polymer. The preparation method of the present invention has the following characteristics that: the polymer dry powder is liquefied; the online profile modification is achieved; the operation is simple; the preparation is convenient; the labor intensity is low; the well site pollution is low; energy saving and consumption reducing are achieved; the construction cost is low; the metering is precise; the error of the preparation concentration is low; adverse factors on on-site operator health are reduced; the fish-eye is not easily generated; the polymer waste is reduced; aeration oxygen degradation of the polymer is eliminated; the solution quality and the profile modification implementation effects are ensured; and the like. In addition, the preparation method of the present invention is widely applicable for oilfield water shutoff profile modification processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

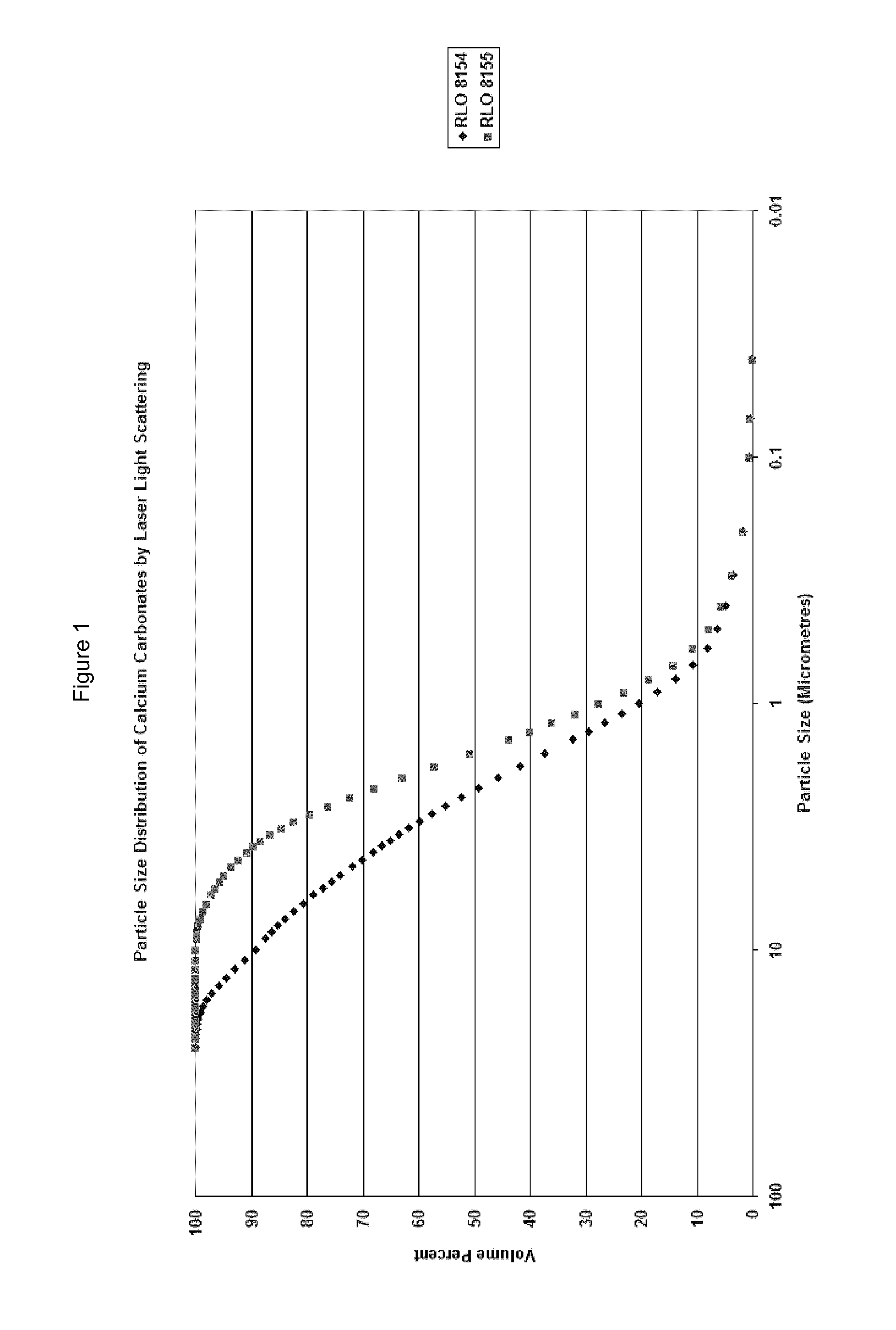

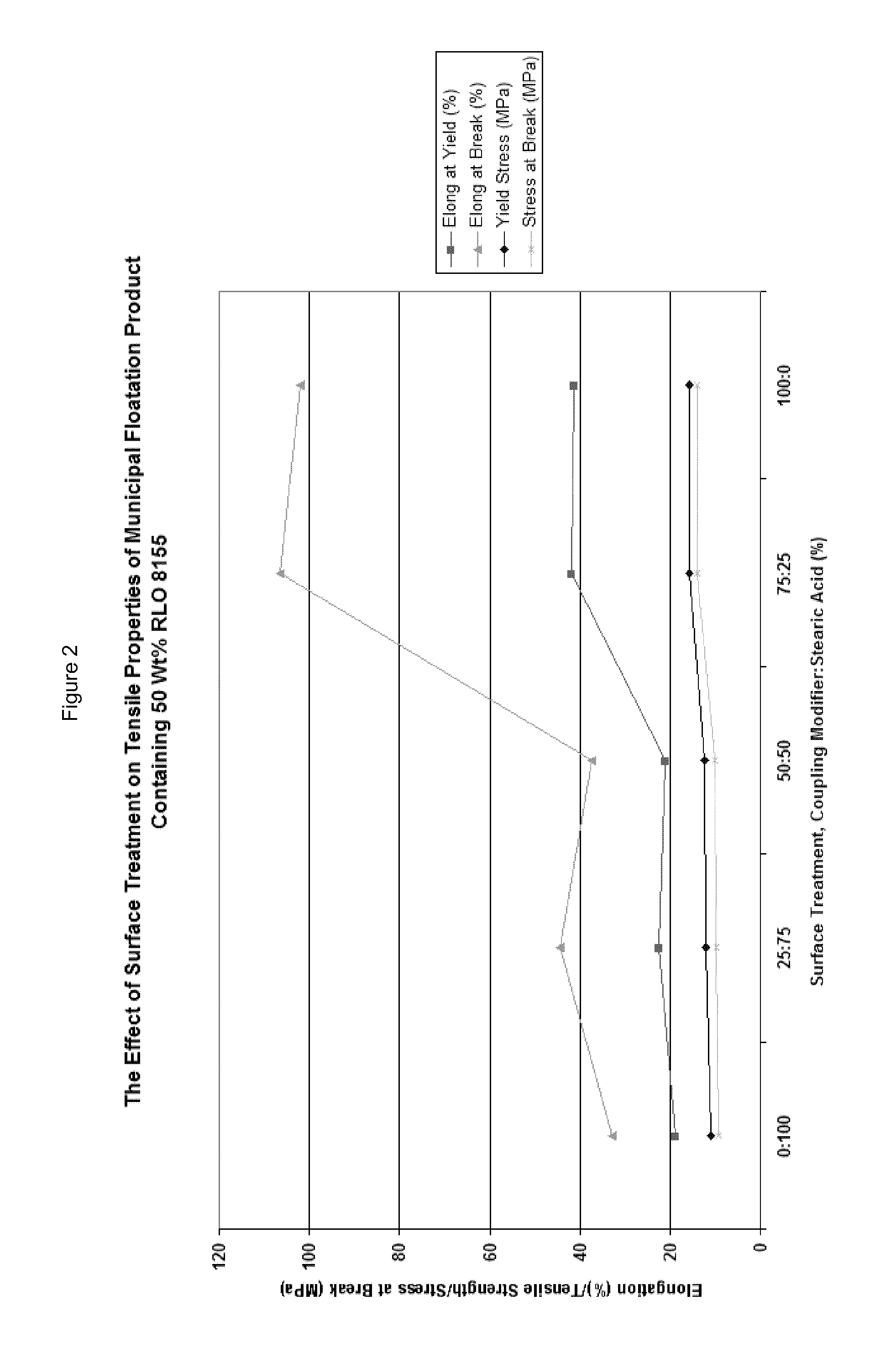

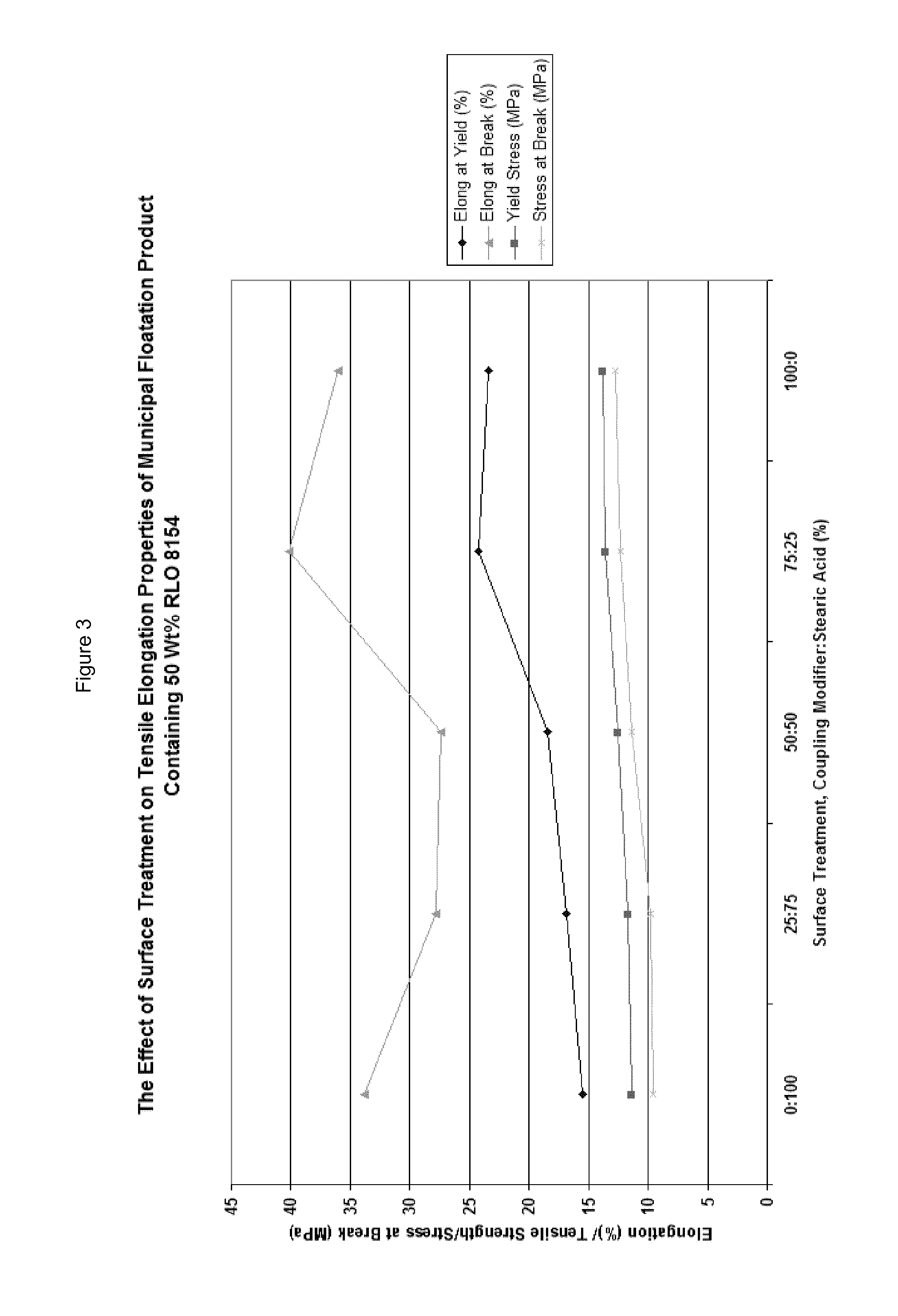

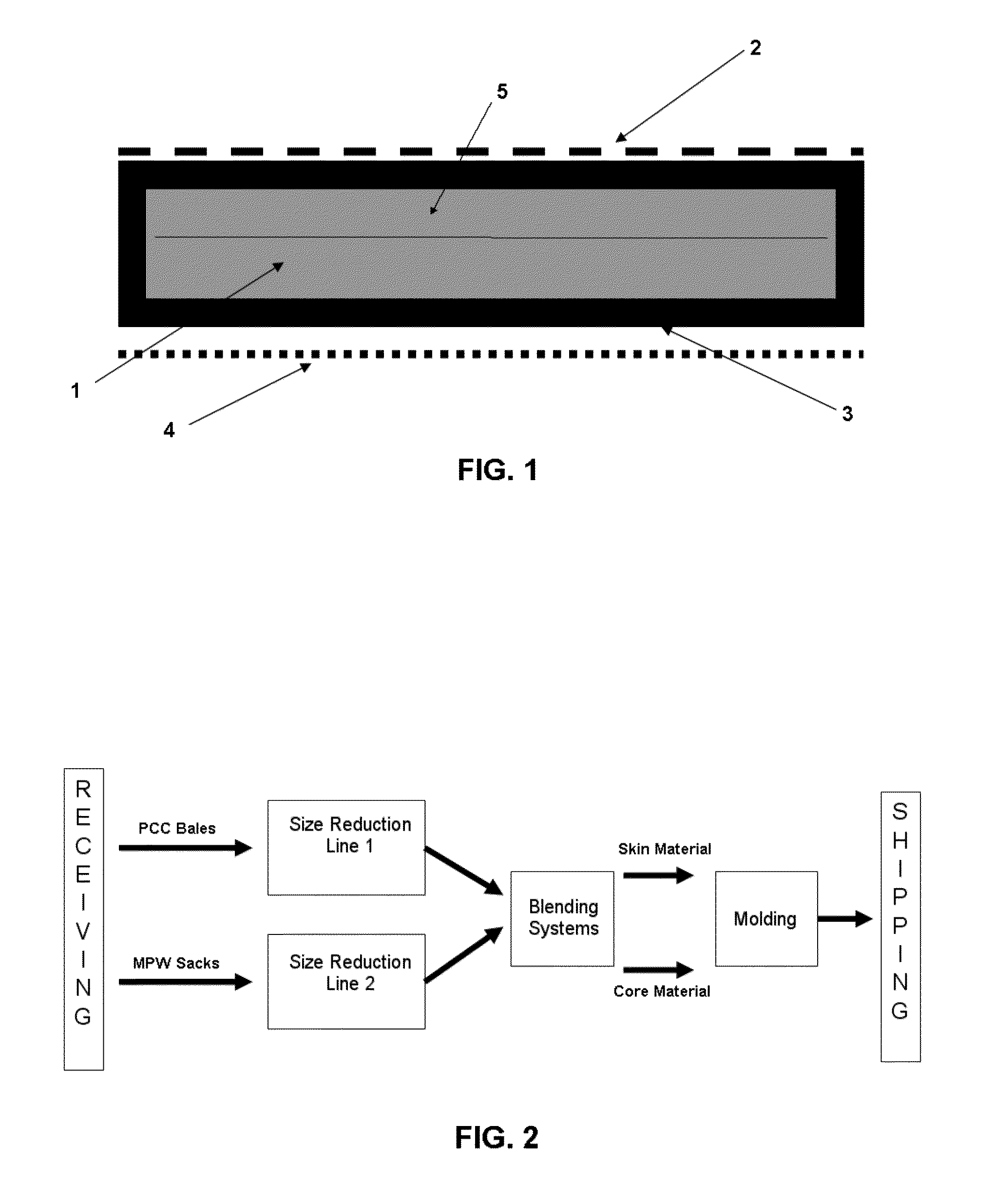

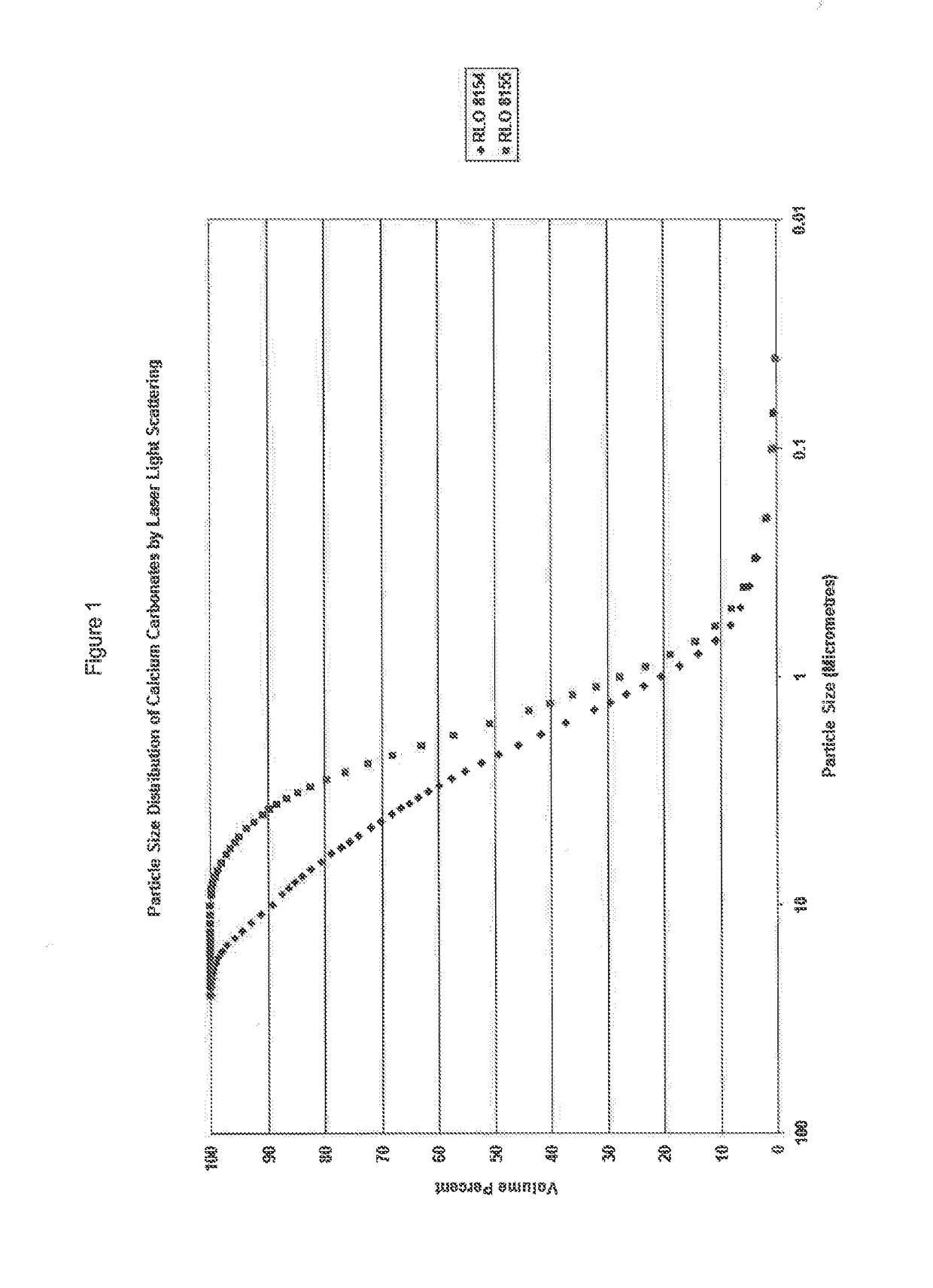

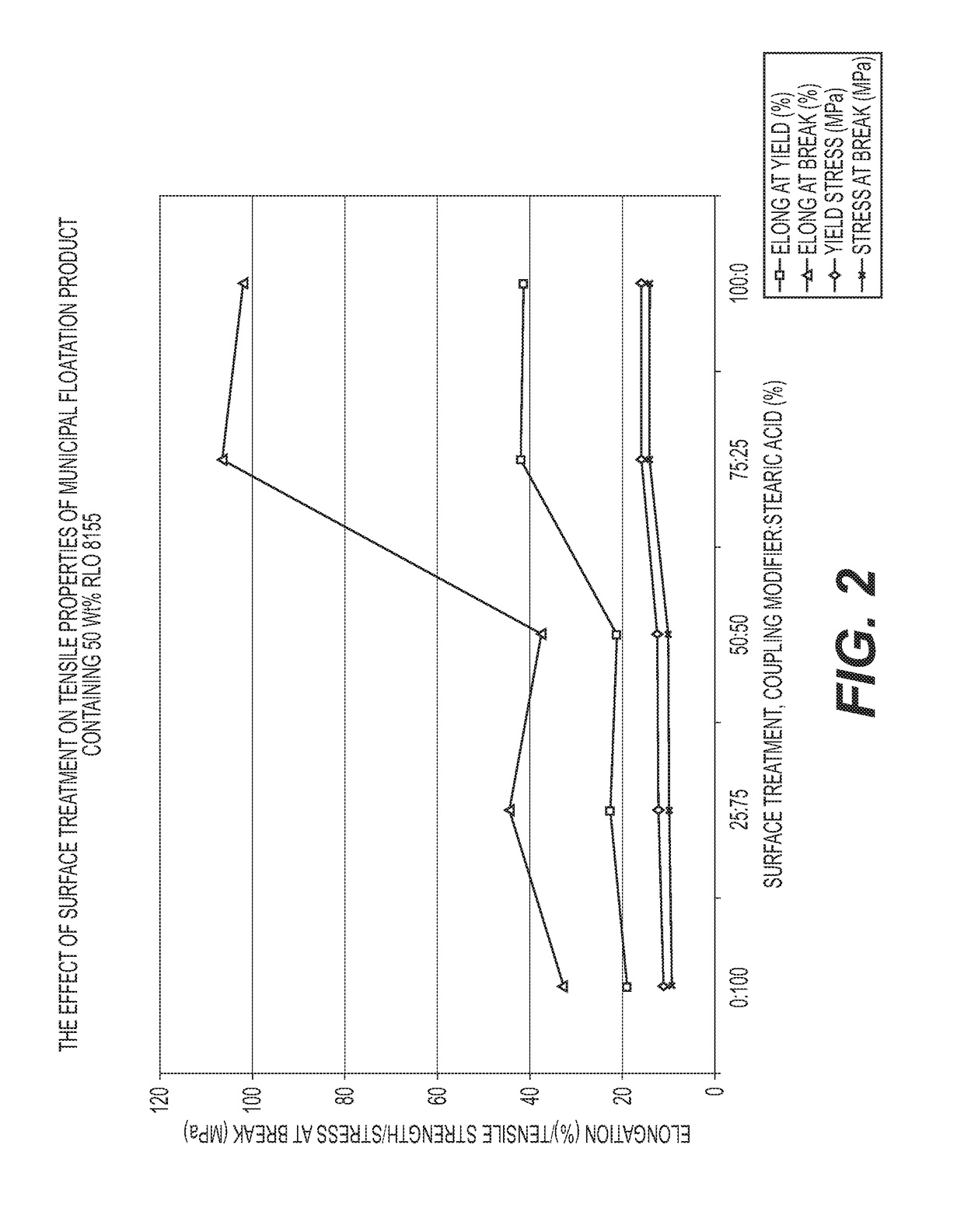

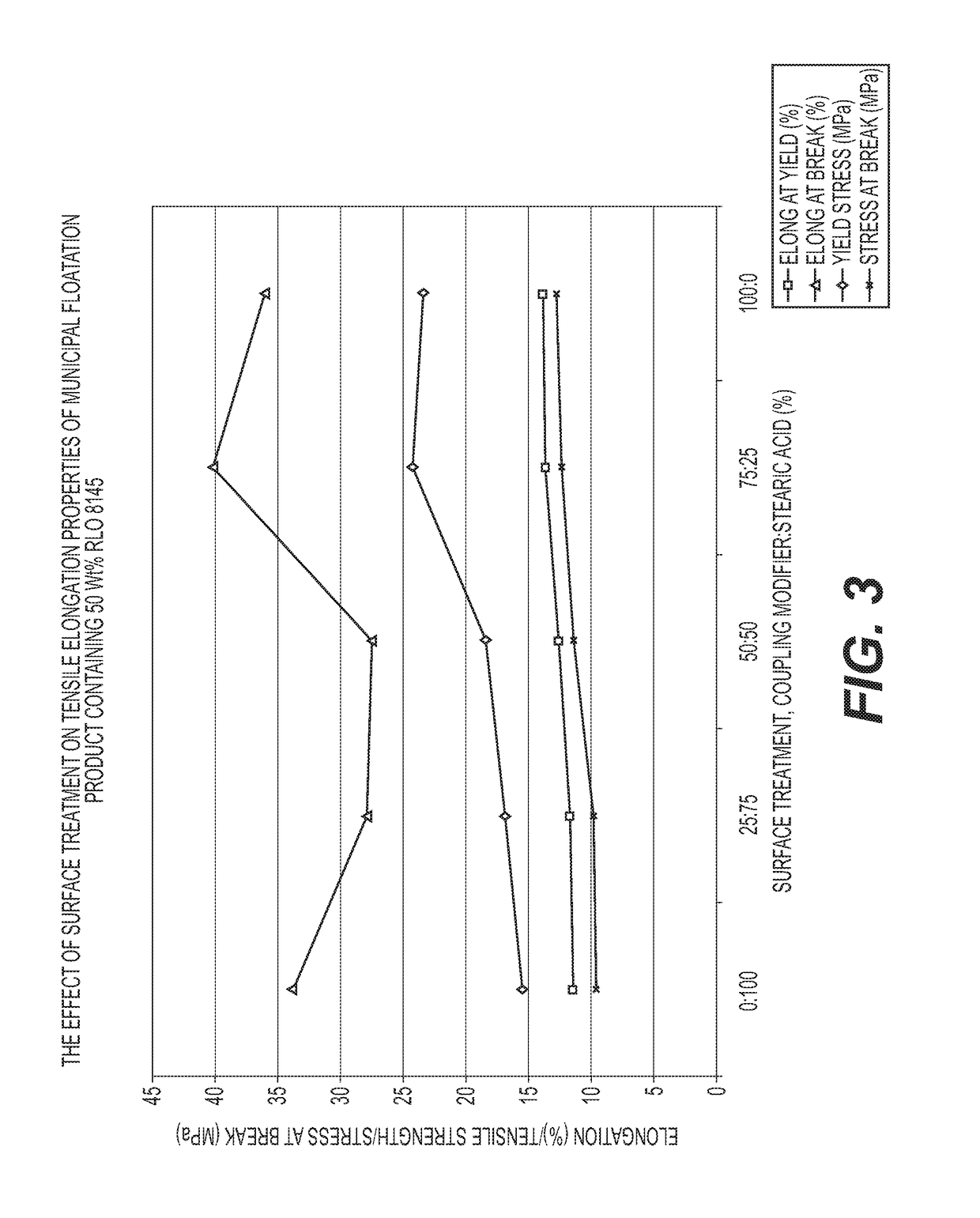

Methods and compositions related to recycling polymer waste

ActiveUS20140154445A1Improving notched Charpy impact propertyProductsOrganic chemistryPolymer sciencePolymer composition

Owner:IMERTECH SAS

Method for synthesizing o-cresol formaldehyde epoxy resin by using cosolvent and recovering cosolvent

The invention discloses a method for synthesizing o-cresol formaldehyde epoxy resin by using a cosolvent and recovering the cosolvent. The method comprises the following steps: mixing chloropropylene oxide with the cosolvent, adding the mixture into o-cresol formaldehyde resin, and carrying out a base catalysis pre-reaction; carrying out a base catalysis ring closure reaction, and carrying out reduced pressure distillation to separate out reaction wastewater; distilling the cosolvent and excess chloropropylene oxide after the ring closure reaction to obtain crude resin; and adding chloropropylene oxide and the wastewater obtained after the ring closure reaction into the crude resin, carrying out salt-out extraction, discharging the above obtained salt-out extracted water phase, distilling the above obtained organic phase to recover chloropropylene oxide and the cosolvent, and refining the remaining crude resin to obtain the o-cresol formaldehyde epoxy resin. The method has the advantages of effective enhancement of the ring closure reaction effect, reduction of the amount of polymer wastes, effective recovery and cycle use of the cosolvent, and great reduction of the production cost.

Owner:CHINA PETROLEUM & CHEM CORP

Method, process and device for polymeric waste processing

A method and device for processing of polymeric waste which may be associated with elements such as non-polymeric material or metals. In a specific embodiment the method includes the steps of (1) loading preliminarily deformed waste into a reaction chamber, (2) applying an aggressive medium to the waste for a time sufficient to convert the one or more polymers to fragments, and separate one of more polymers from their associated elements, and (3) subjecting the products of step (2) to mechanical separation of the associated elements from the polymer fragments. The method and device is particularly useful for the processing of tires including preliminarily deformed tire segments or shredded tire waste.

Owner:VR TEK PTY LTD

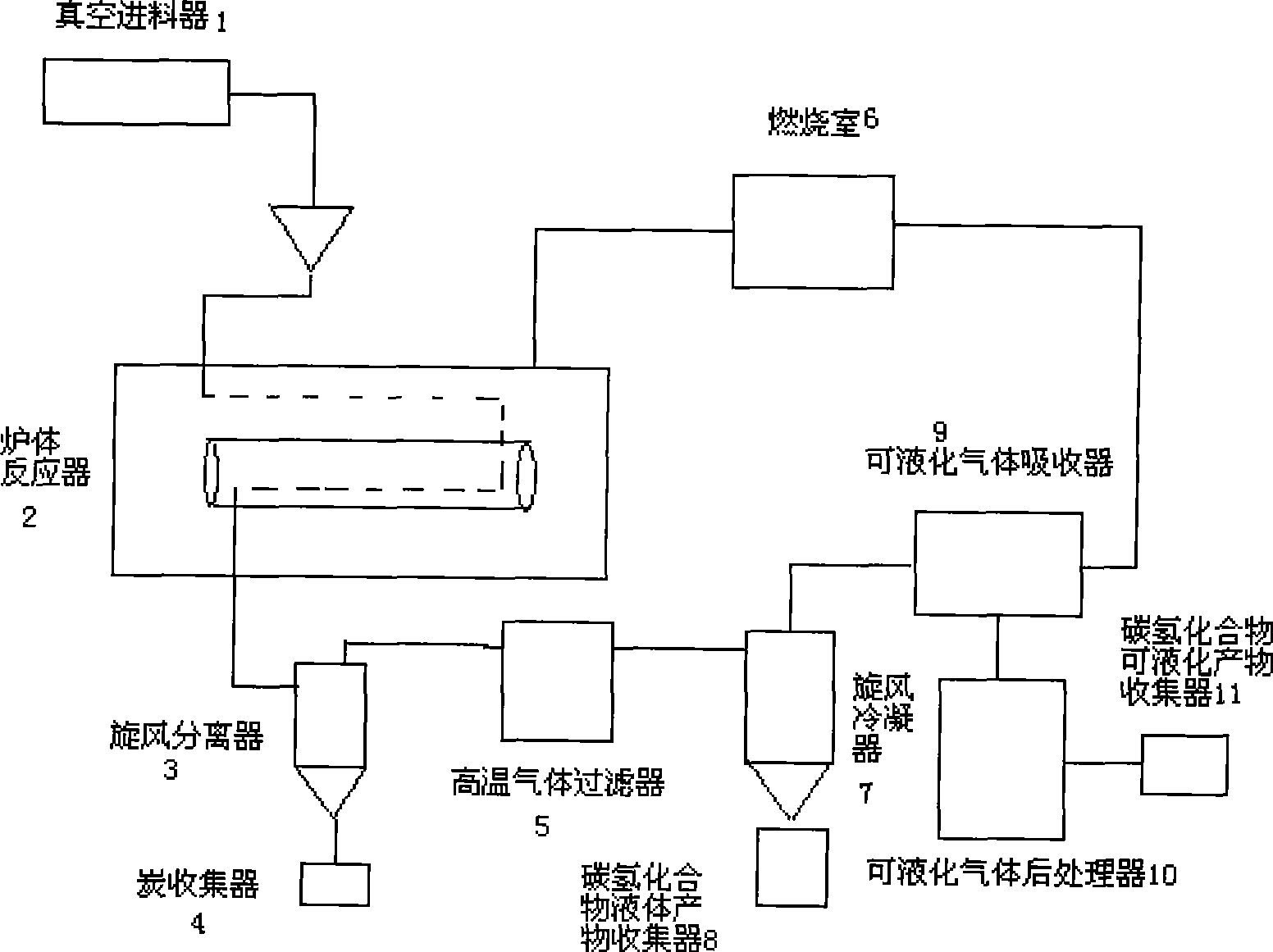

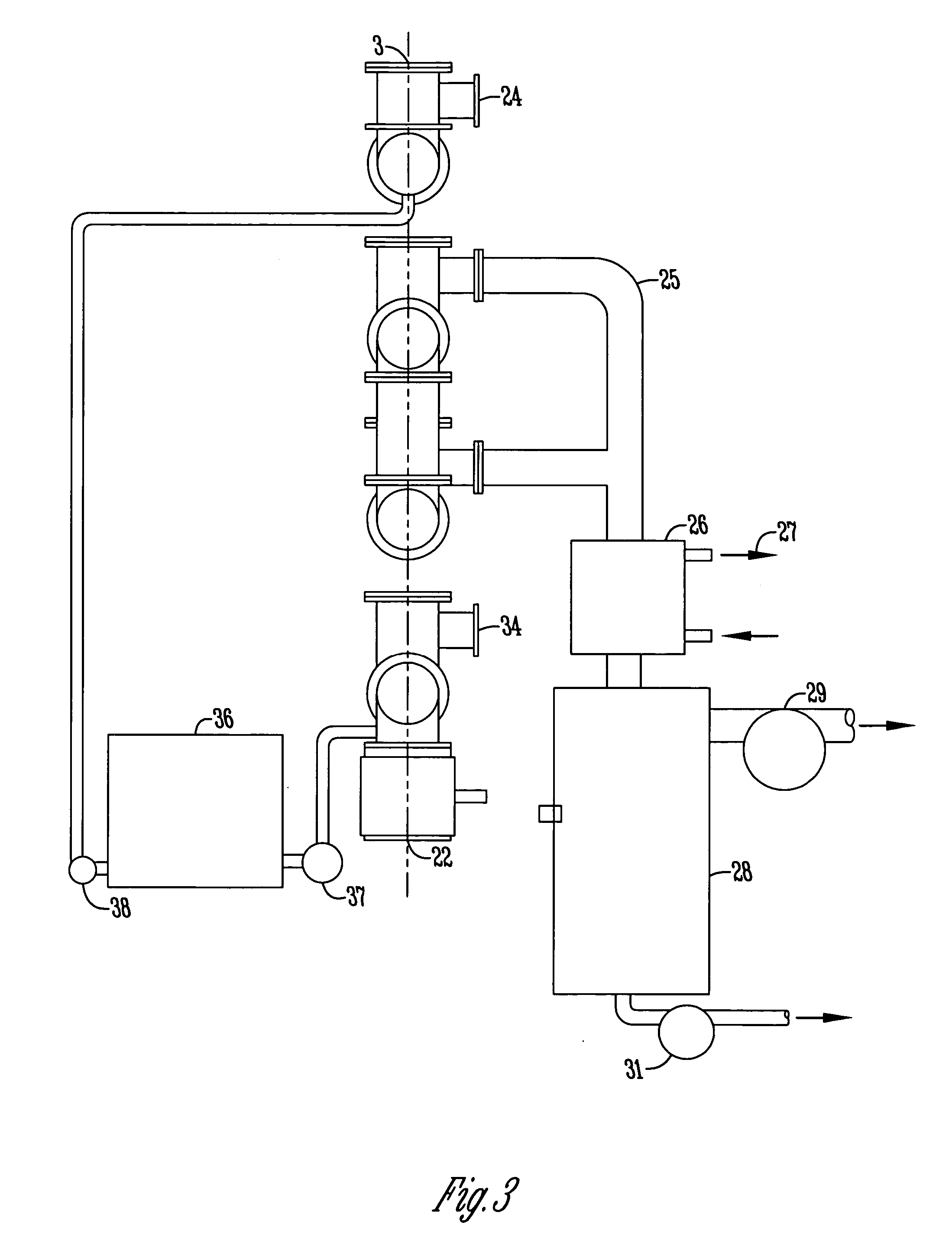

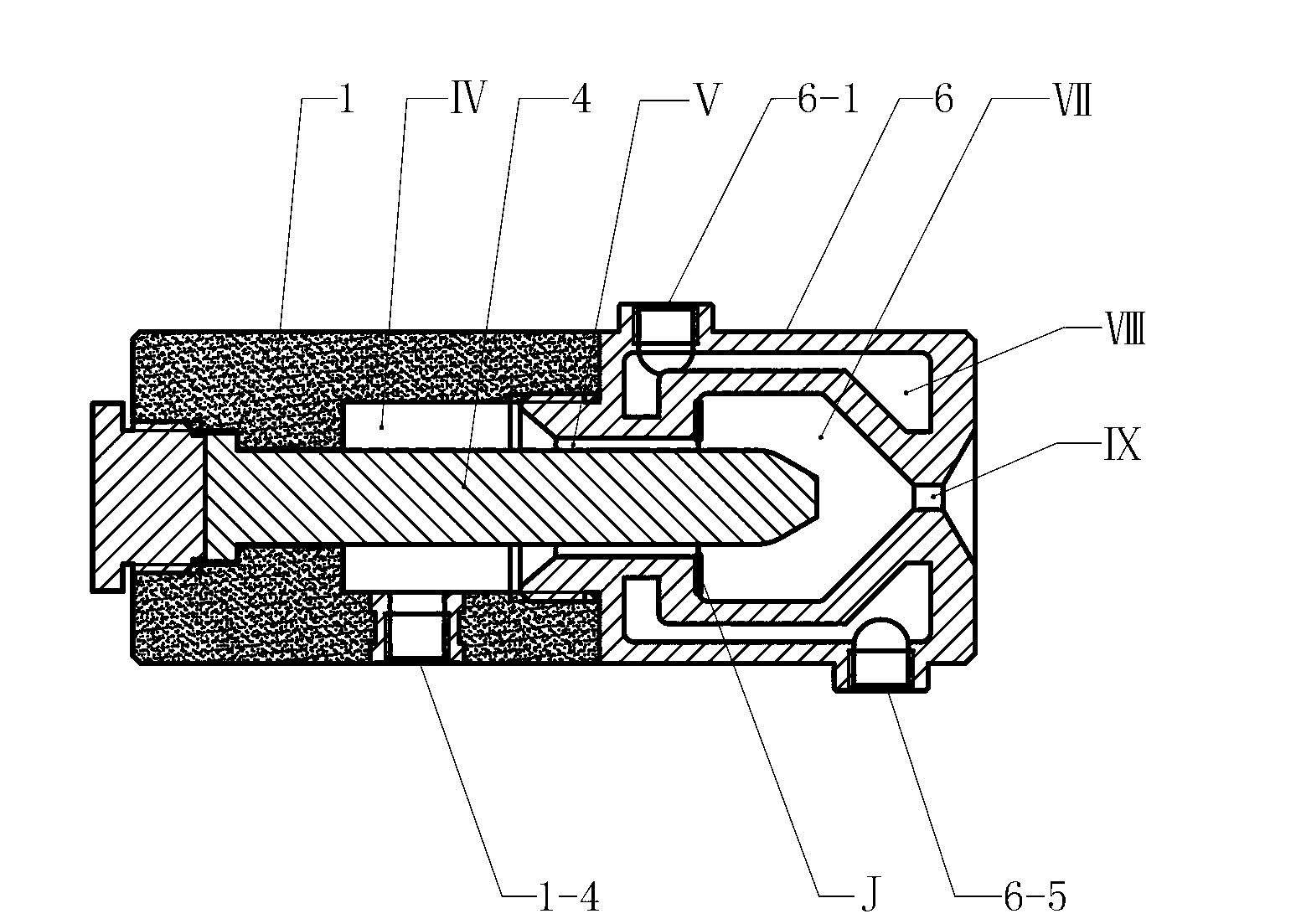

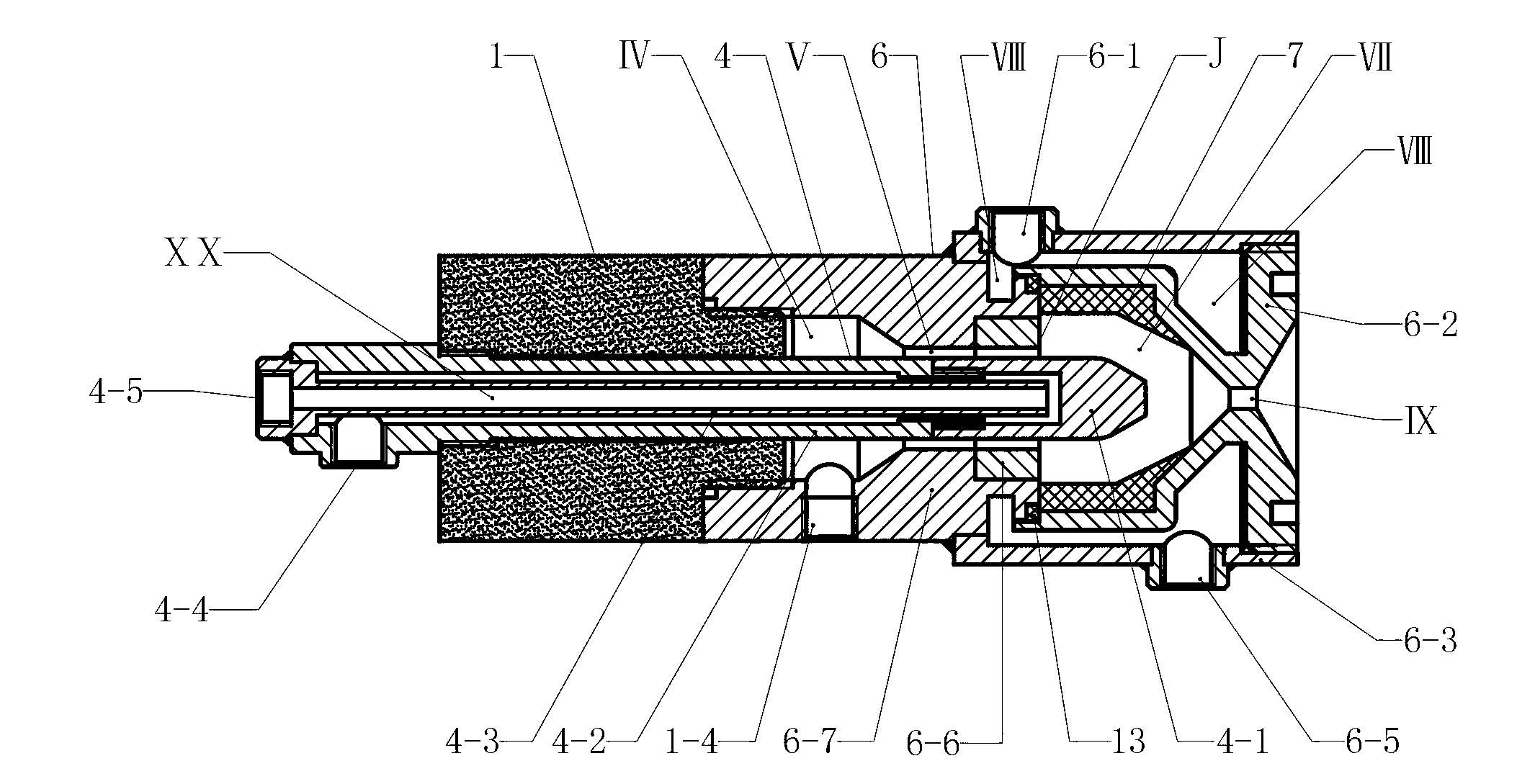

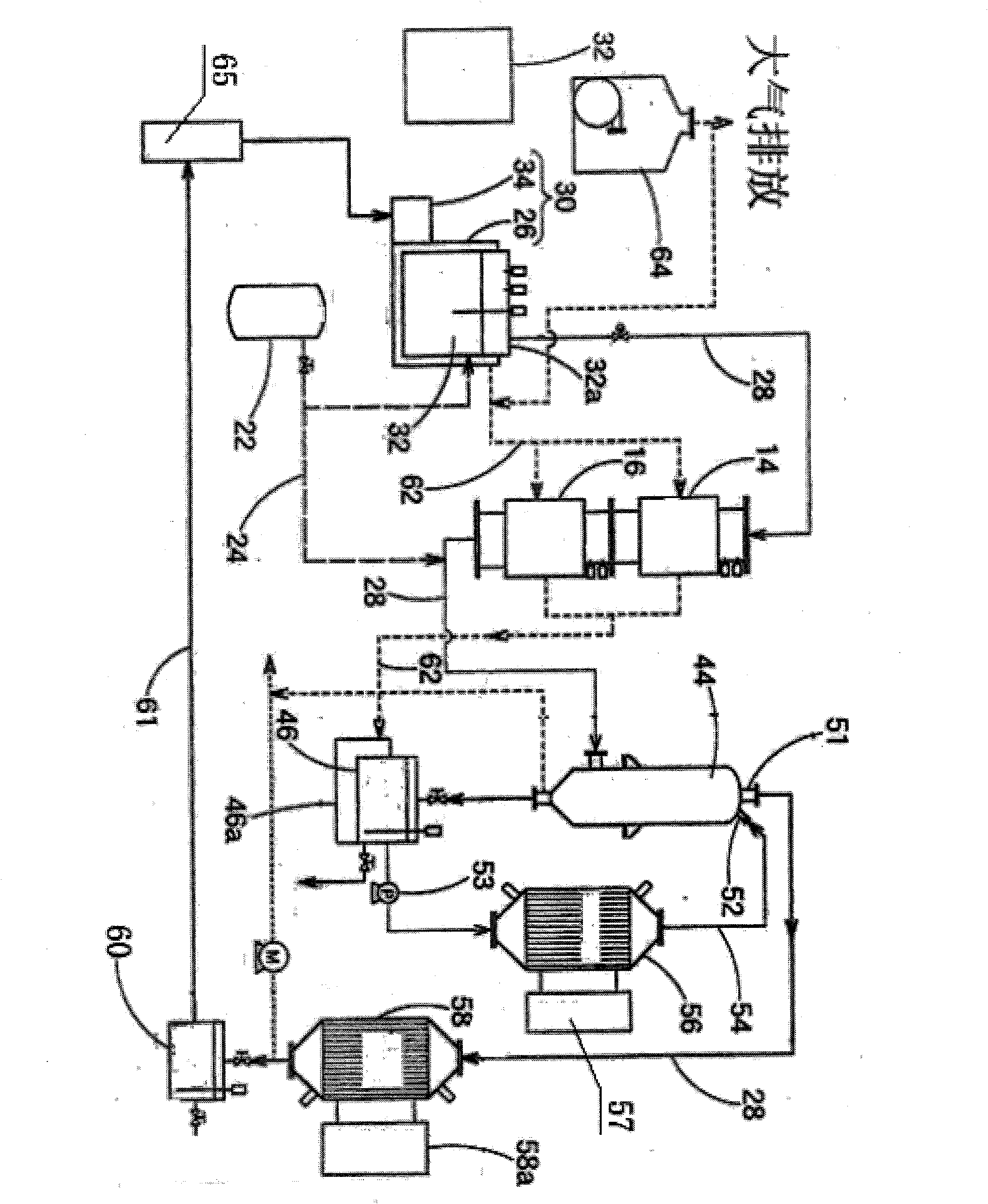

Innocent treatment and oily recovery device of polymer waste

InactiveCN102041010AImprove operational efficiencyRealize separation and upgradingProductsReagentsTemperature controlBoiling point

The invention discloses an innocent treatment and oily recovery device of polymer waste, comprising a dry distillation and thermal decomposition system, a high-boiling-point oil recovery system and a low-boiling-point oil recovery system. The innocent treatment and oily recovery device is characterized in that three systems are connected in sequence; finally, oily recovery is carried out on the polymer waste according to difference of boiling points, after the polymer waste is thermally-decomposed by low-temperature dry distillation in the dry distillation and thermal decomposition system, the generated thermal decomposition gas is temperature-controlled and is subjected to backflow by the high-boiling-point oil recovery system so as to realize separation of low-boiling-point oil and high-boiling-point oil; and low-boiling-point is cooled and condensed in the low-boiling-point oil recovery system and then is further recovered as low-boiling-point oil. In the innocent treatment and oily recovery device, the operating efficiency of the equipment is high, the separation and the modification of the low-boiling-point oil and the high-boiling-point oil can be successfully realized, low energy consumption is realized by heat circulation, and therefore, the device disclosed by the invention is a novel innocent treatment and oily recovery device.

Owner:SHANGHAI JINTAI NEW ENERGY ENVIRONMENTAL PROTECTION TECH INC +1

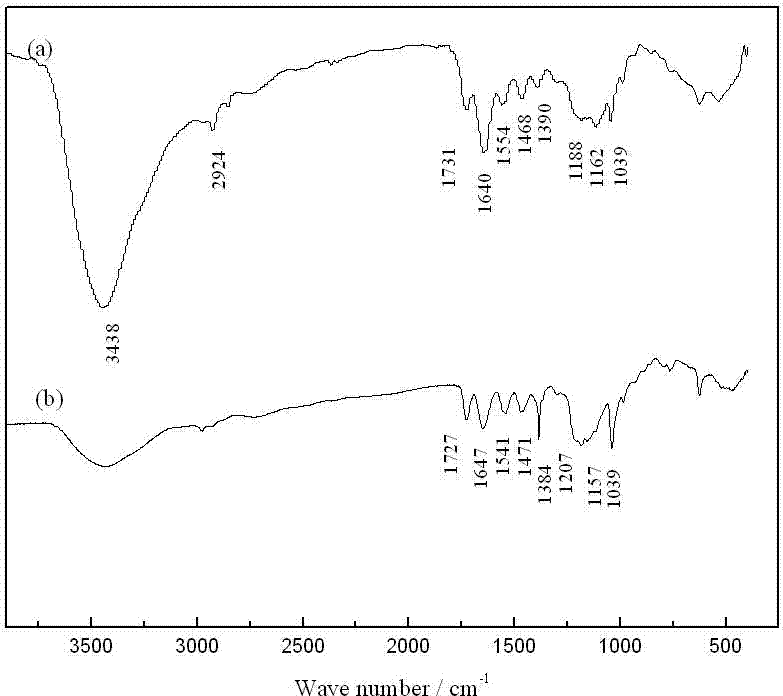

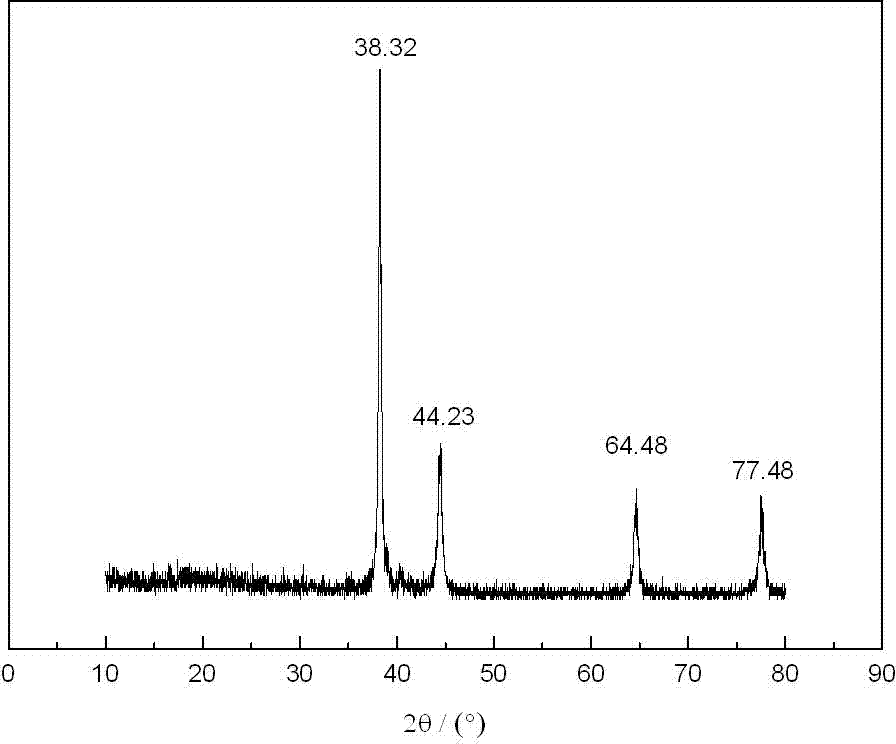

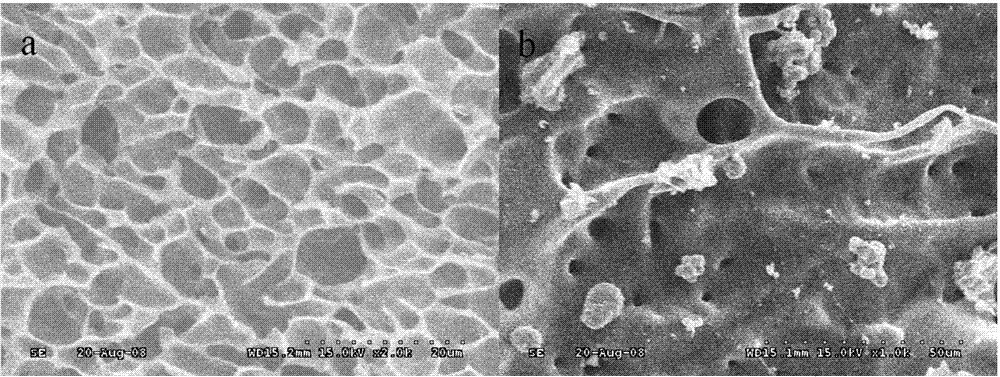

Double in-situ synthesis method of temperature-responsive nano silver composite hydrogel

The invention relates to a double in-situ synthesis method of temperature-responsive nano silver composite hydrogel. By adopting an ultraviolet radiation method, under a condition without an initiator and a reducing agent, with dimethylaminoethyl methacrylate and 2-acrylamide-2-methylpropanesulfonic acid as monomers, N,N'-methylene bisacrylamide as a cross-linking agent, polyethylene glycol 400 as a pore forming agent, and silver nitrate as a metal source, and under a nitrogen atmosphere, the temperature-responsive nano Ag / P(DMAEMA-g-AMPS) composite hydrogel is synthesized. The prepared nano silver composite hydrogel has uniform dispersed nano silver particles and good chemical cross-linking stability, allows the swelling degree to be increased by 294.8 compared with that of pure water gel, and improves water absorbency and water retention of the hydrogel; the composite hydrogel allows temperature responsiveness to be enhanced, thereby being beneficial for medical drug release and other applications; and the composite hydrogel allows the thermal decomposition temperature to be decreased by 78 DEG C compared with that of pure hydrogel, thereby being beneficial for polymer waste post-processing.

Owner:ANHUI UNIV OF SCI & TECH

One-pot, high-performance recycling of polymer waste using renewable polymer synthesis

Owner:POLY6 TECH

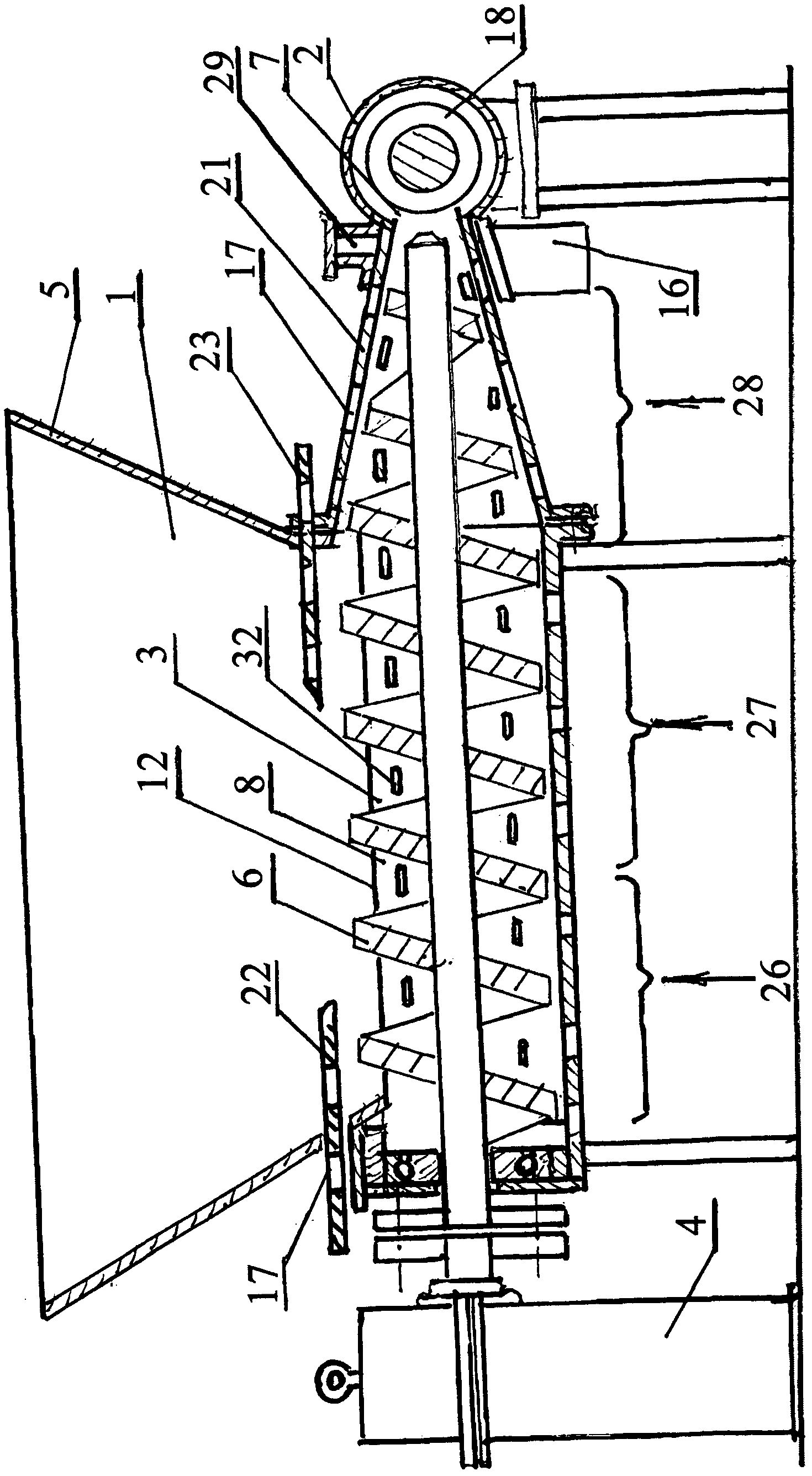

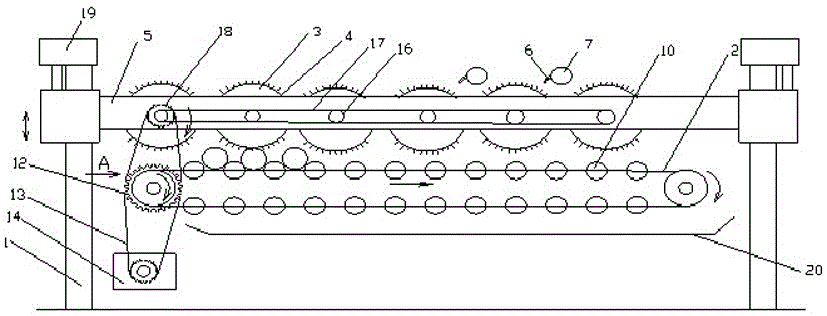

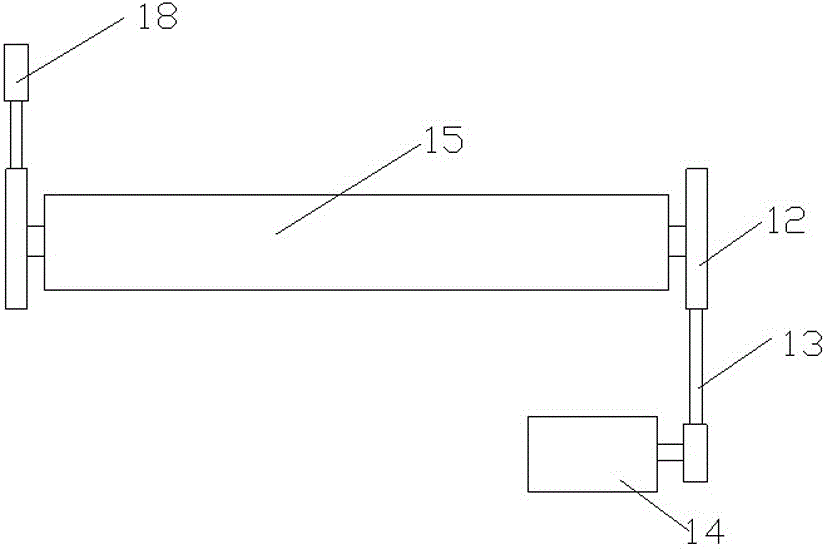

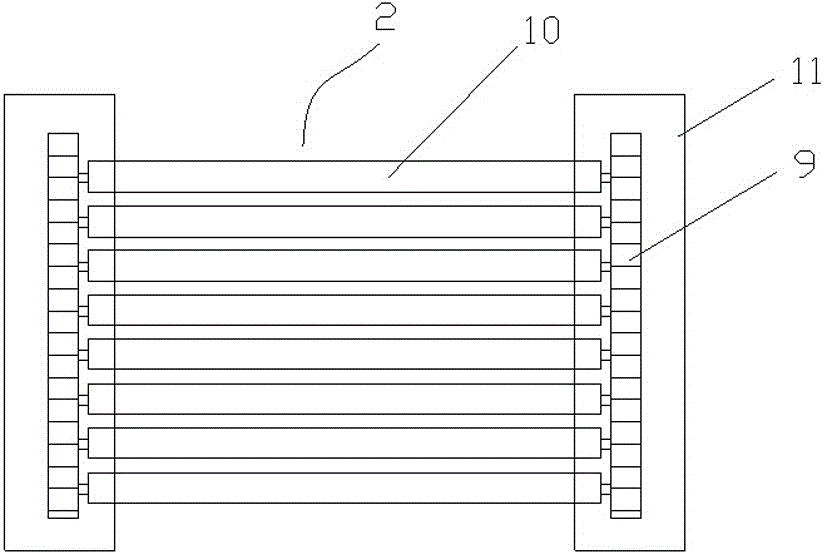

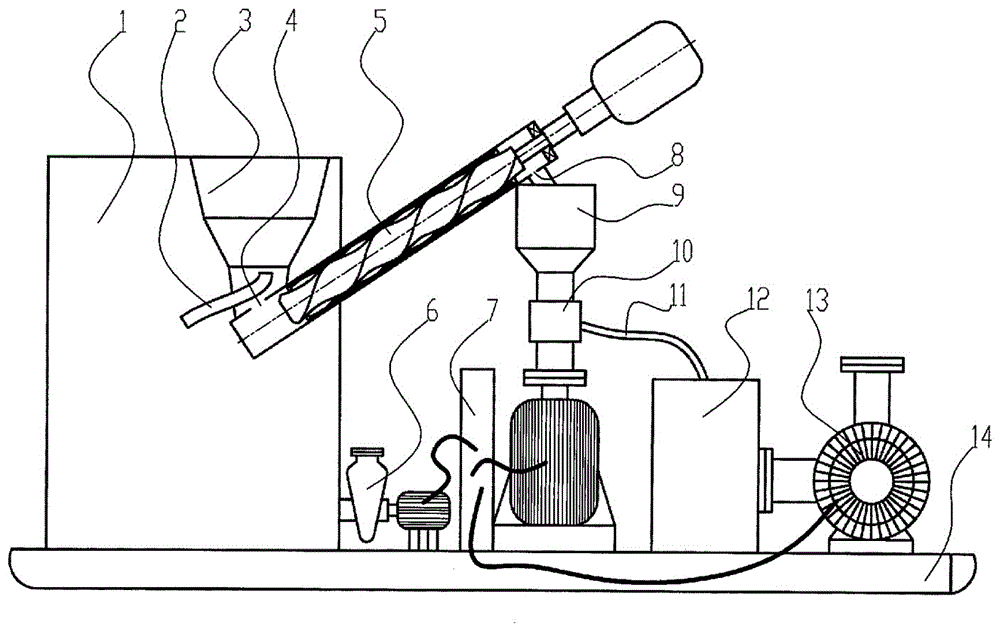

Feeder and extrusion device and method of use thereof

The present invention generally relates to a feeder for particulate material such as particulate polymer waste. More particularly, the present invention relates to an extrusion device including the feeder for improved extrusion of materials such as particulate polymer waste which effectively changes the quality and characteristics / properties of the polymer waste to, for example, create commercially useful products such as, for example, devulcanised rubber powders or composite materials. In a specific embodiment the method includes the steps of (1) storing one or more batches of waste polymer in one or more respective hoppers, (2) regulating the flow of waste polymer supplied to a conveyor from the one or more hoppers, (3) transporting the waste polymer from the one or more hoppers and along the one or more conveyors to an extruder such that at least some interstitial air is expelled from the waste polymer, (4) feeding the waste polymer from the one or more conveyors to an extruder, and (5) passing the waste polymer through the extruder to provide a pulverised activated and devulcanised polymer product. The present invention is particularly useful for the processing of tyres including tyre segments or shredded tyre waste.

Owner:VR TEK PTY LTD

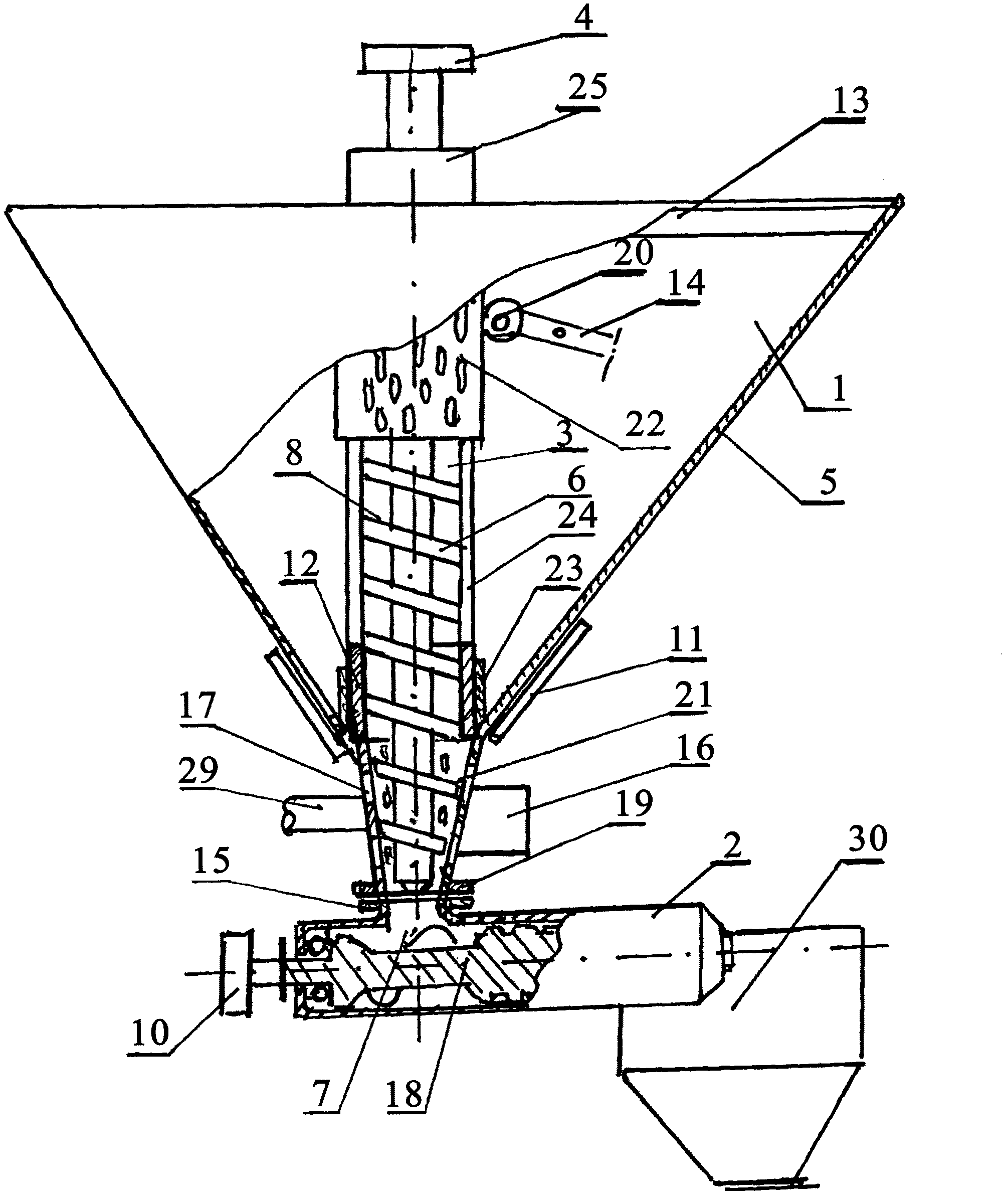

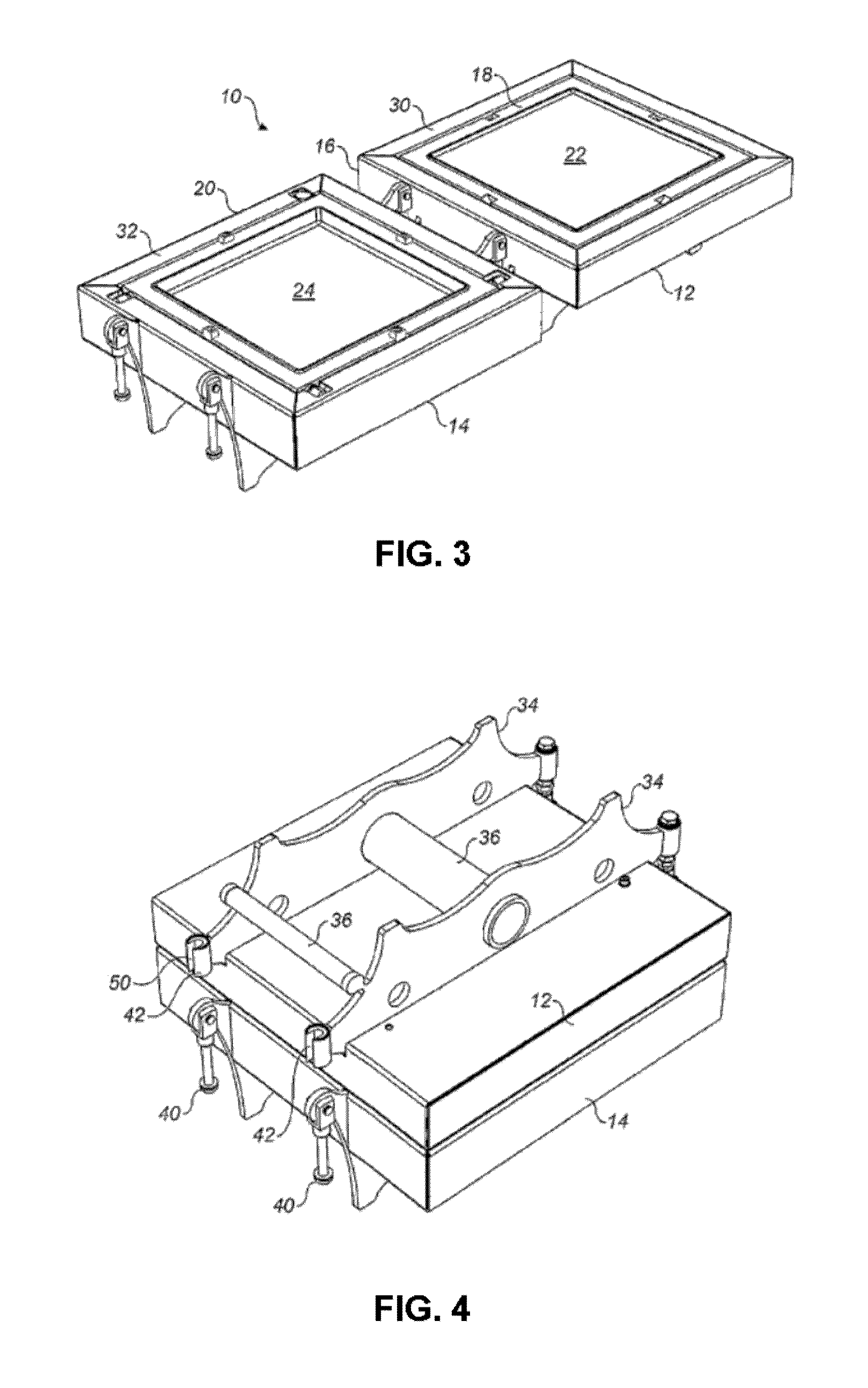

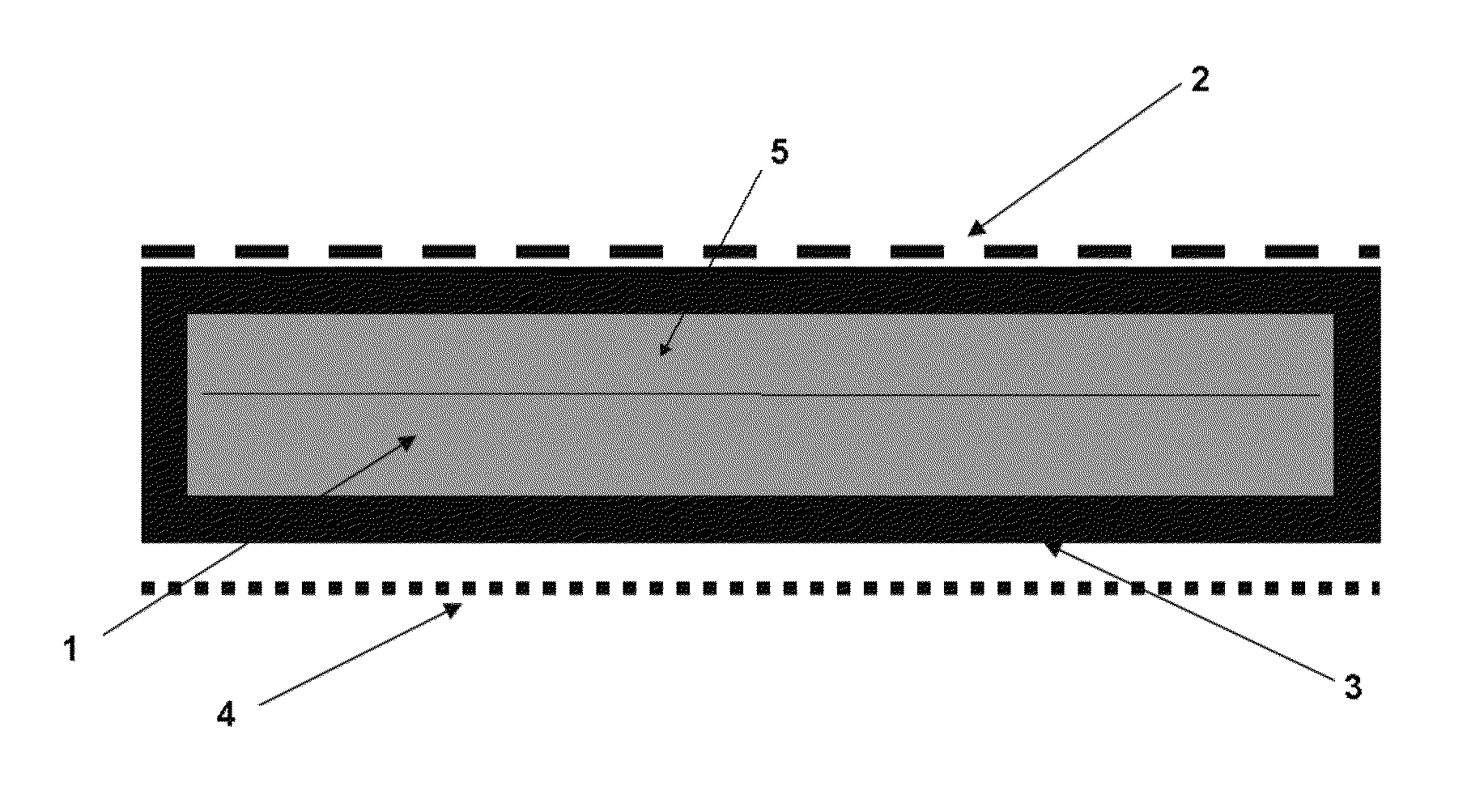

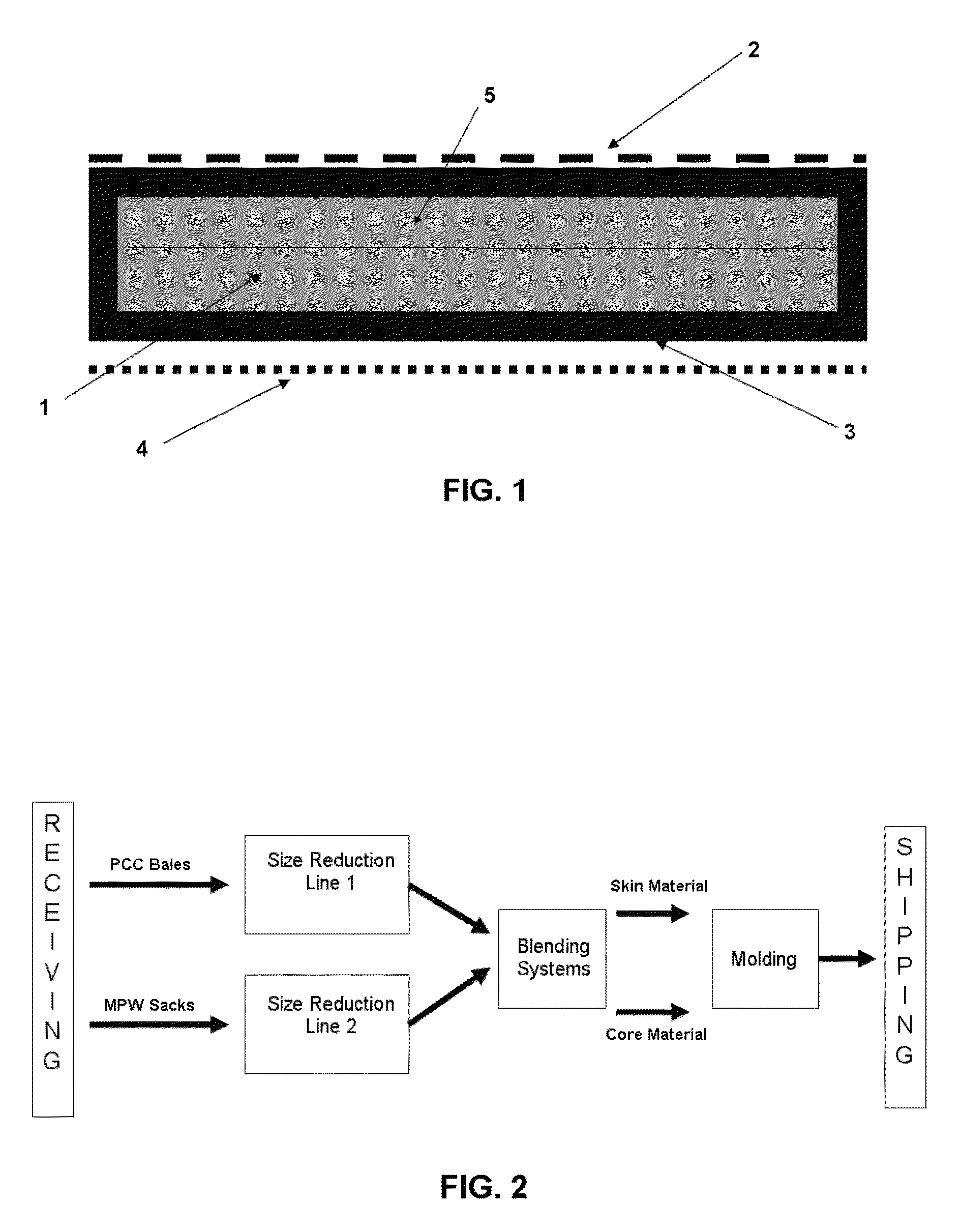

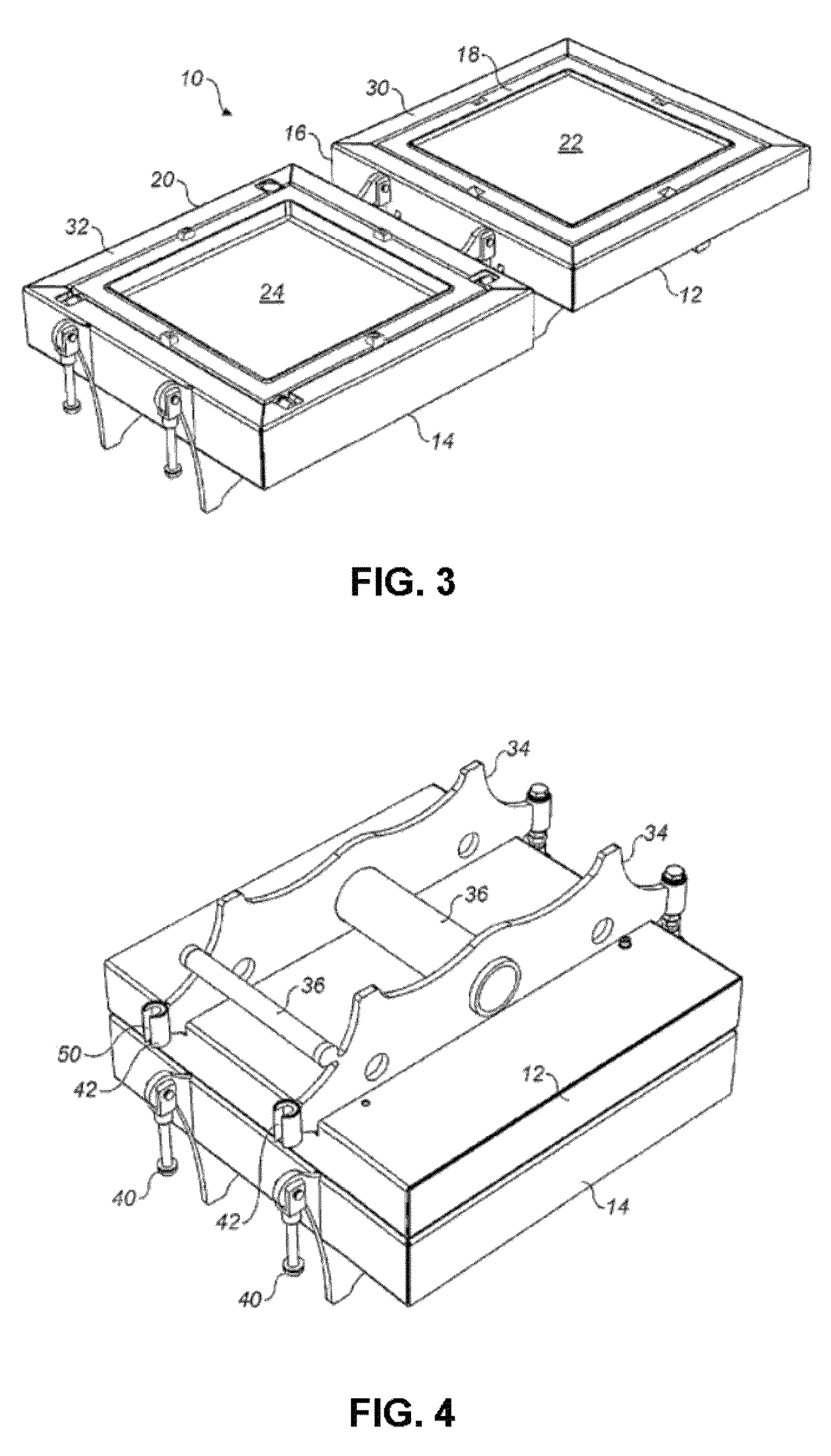

Carpet waste composite product and method for making same

ActiveUS20130040092A1Efficient productionPlastic recyclingSynthetic resin layered productsBuilding productShell molding

A composite building product formed through formed molding. The composite product having an exterior skin surrounding a foamed core. The exterior skin being formed from particulate material that includes carpet waste material and mixed polymer waste materials.

Owner:COLUMBIA INSURANCE CO

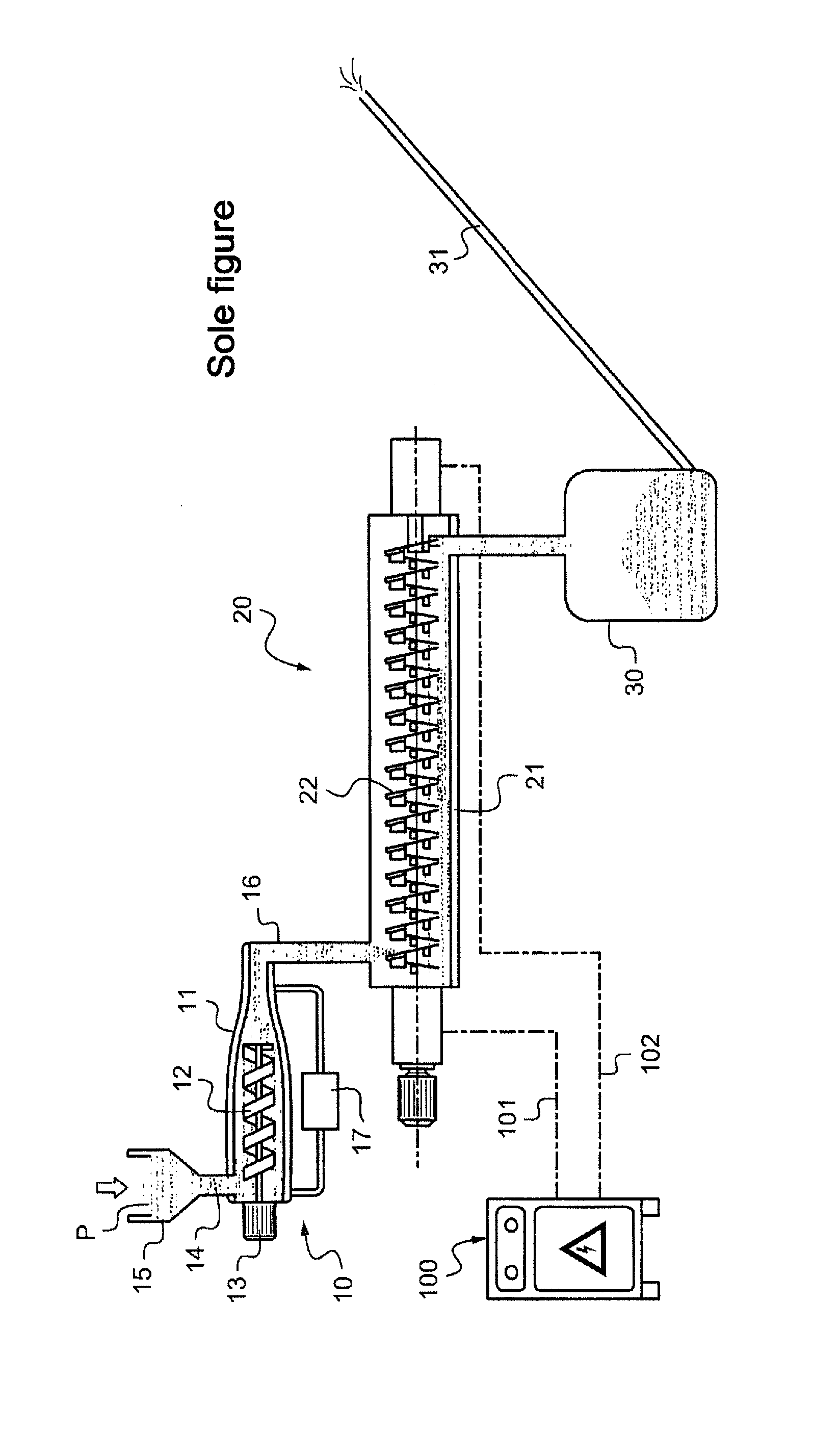

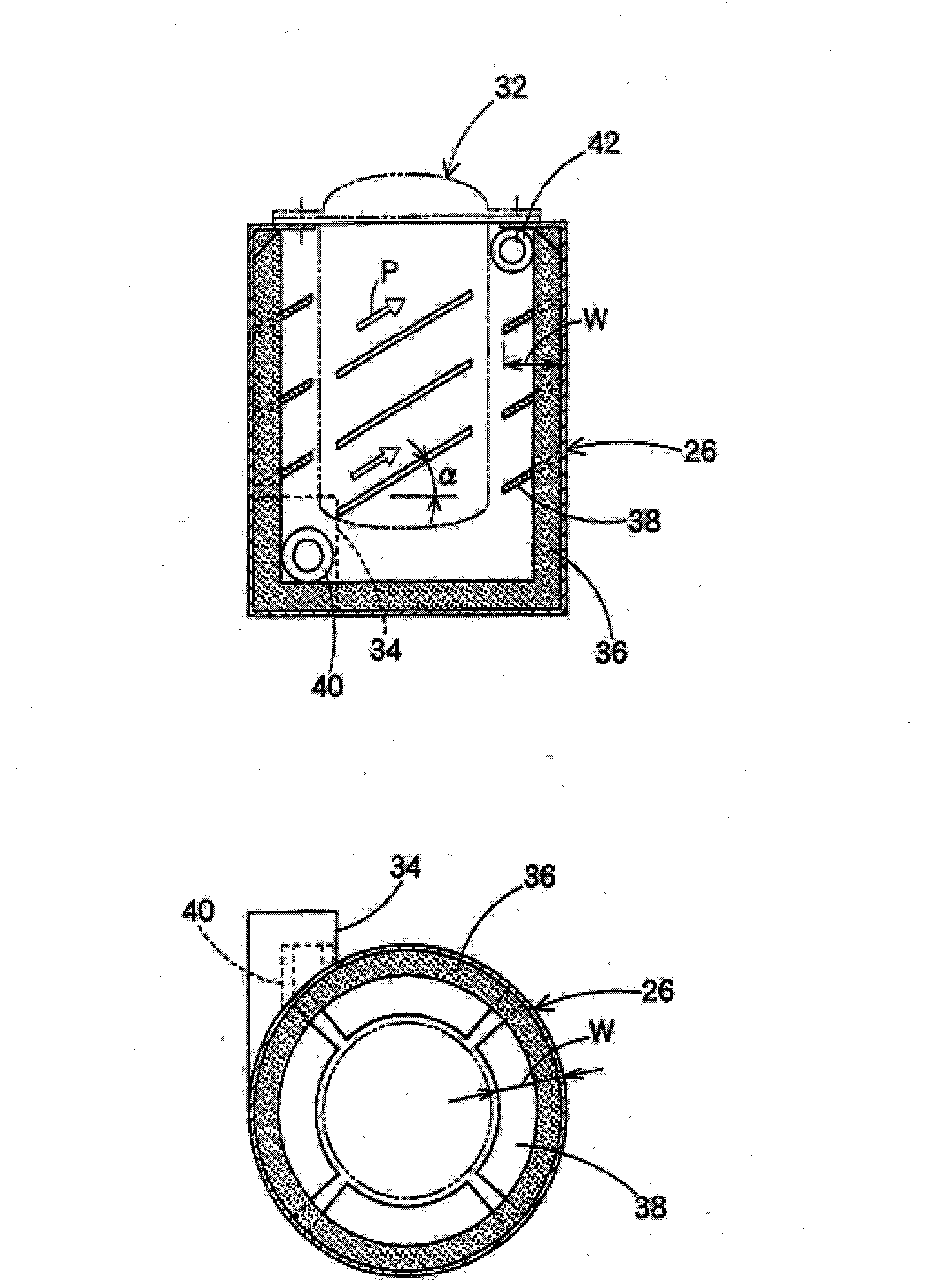

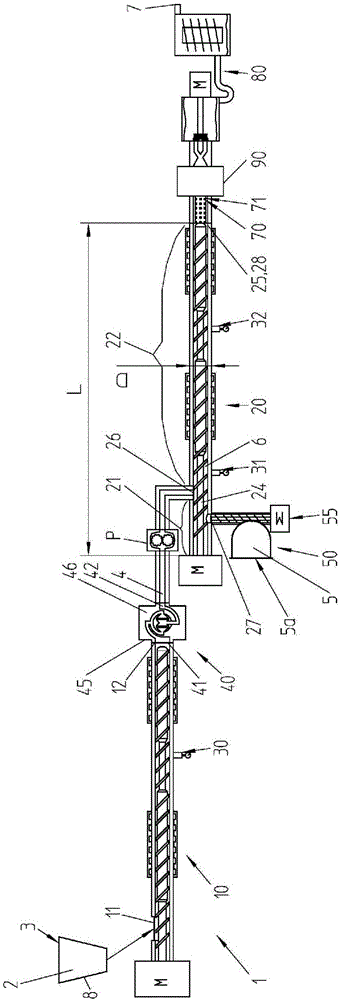

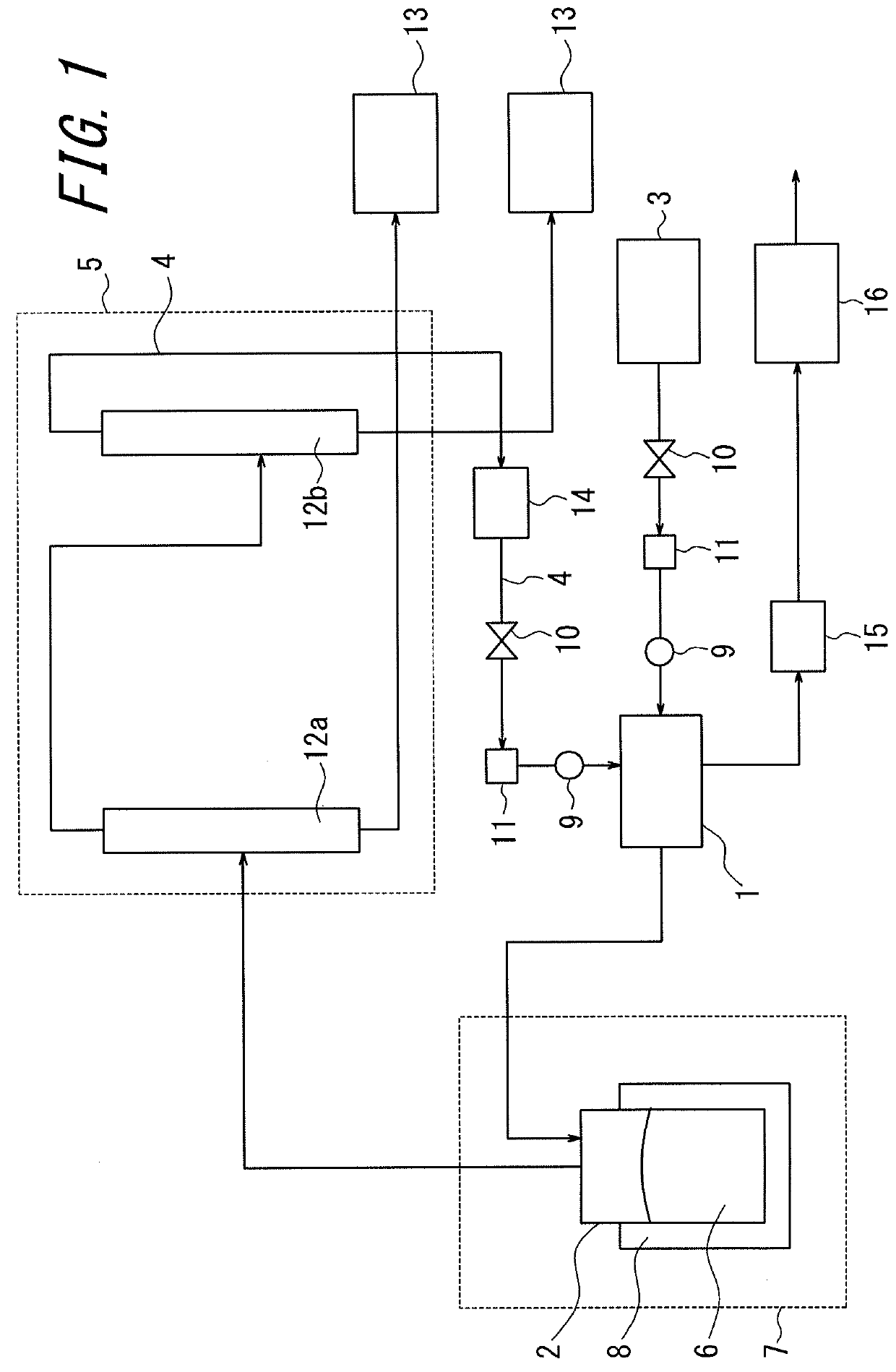

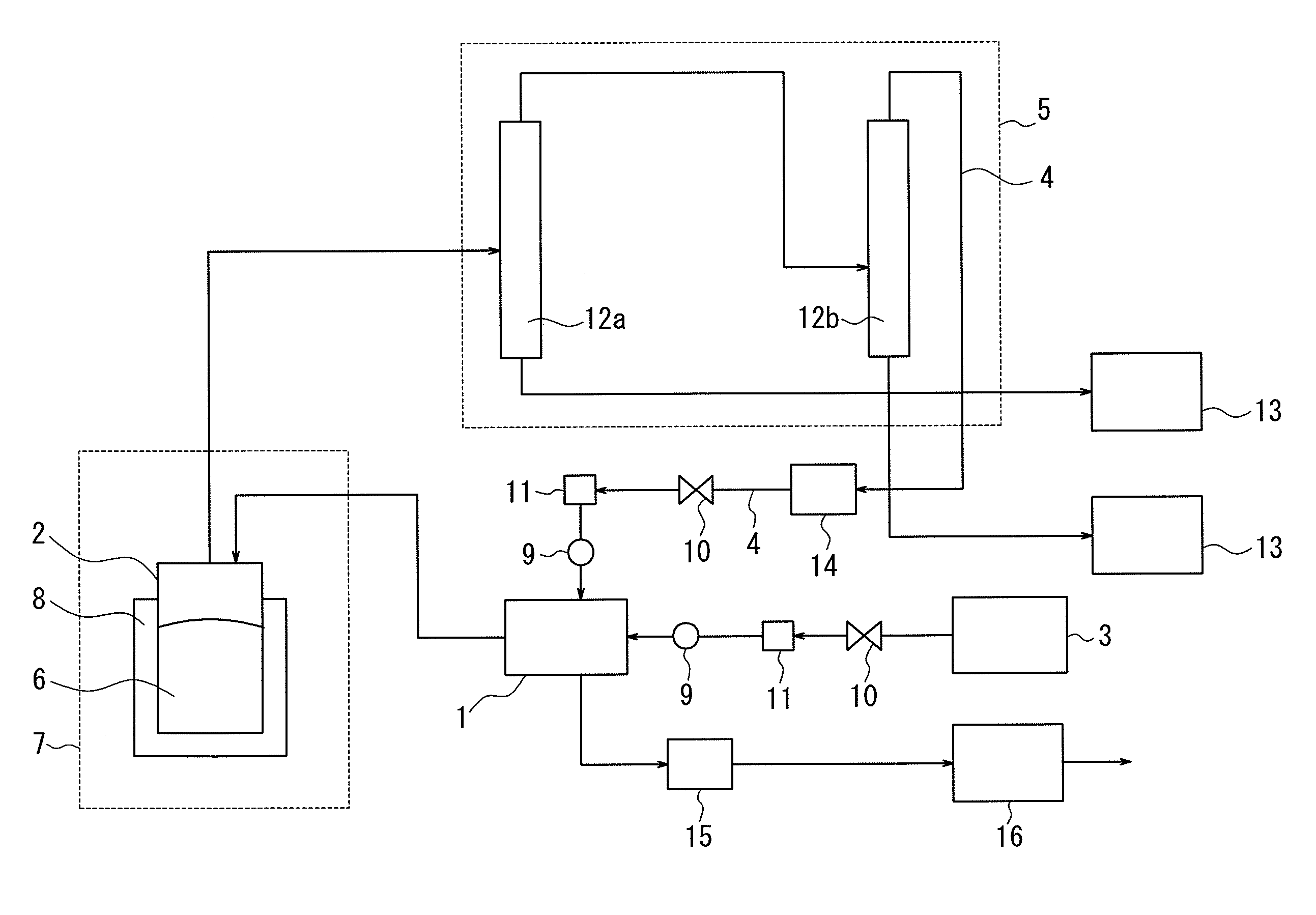

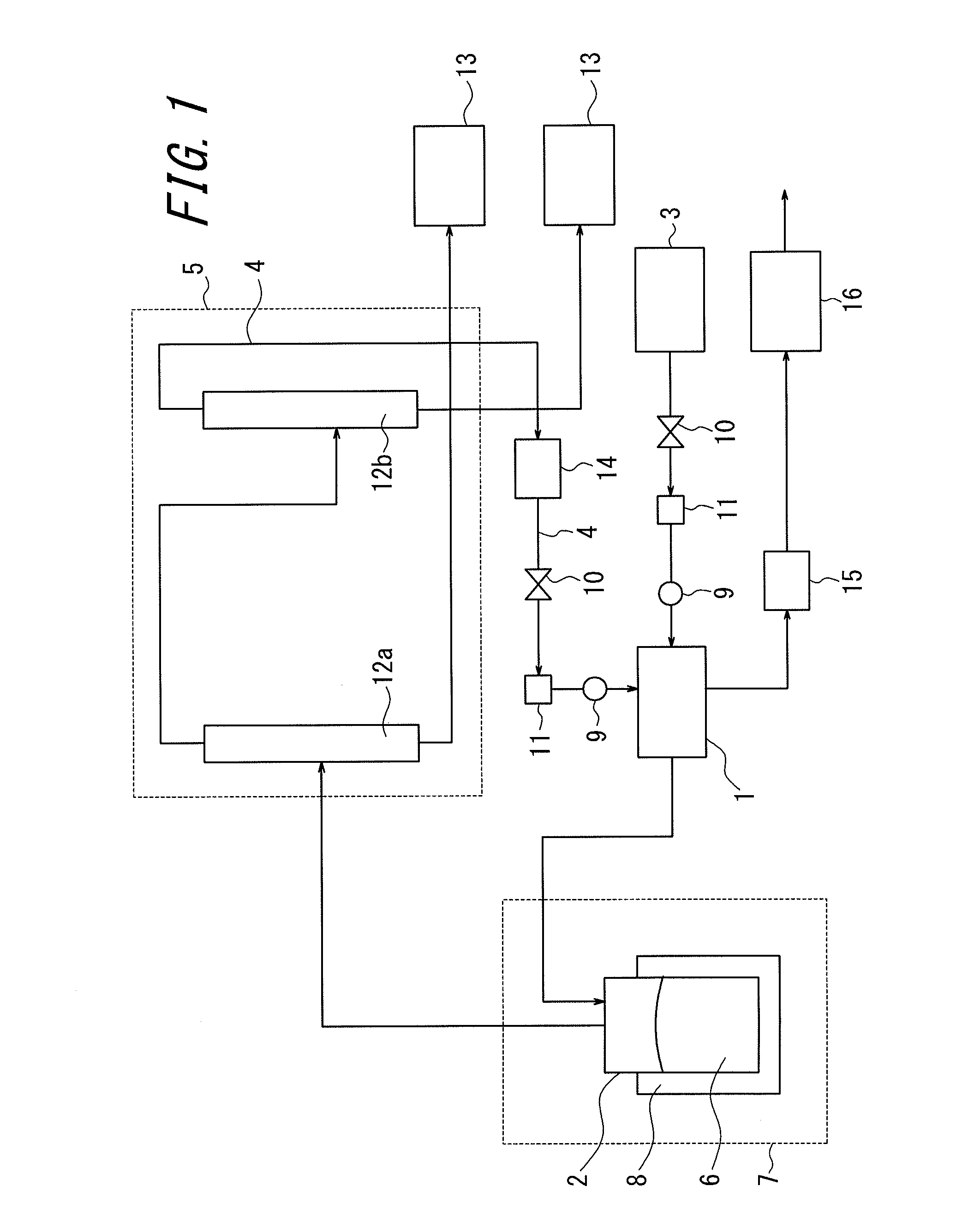

Device and method for producing a filled polymeric composite material

ActiveCN106715066AEffective resourcesSuitable for productionPlastic recyclingChemical recyclingFiberPolymer chemistry

The invention relates to a method and to a device (1) for producing a filled polymeric composite material (7), which contains a polymeric carrier material (2) and a fiber material (2) as a filling material, wherein the polymeric carrier material preferably contains a main fraction of recycling polymer waste (3). The device (1) comprises a first extrusion apparatus (10), which has an inlet (11) for the polymeric carrier material and an outlet (12) for the melted polymeric carrier material, a melt-processing apparatus (40) for cleaning the melted polymeric carrier material, which melt-processing apparatus is connected to the outlet of the first extrusion apparatus, and a second extrusion apparatus (20). The second extrusion apparatus has a melt inlet (26), which is connected to the exit (42) of the melt-processing apparatus, and a fiber material inlet (27) for the fiber material, which fiber material inlet is arranged upstream of the melt inlet. The second extrusion apparatus comprises at least one degassing apparatus (31, 32).

Owner:STARLINGER & CO GMBH

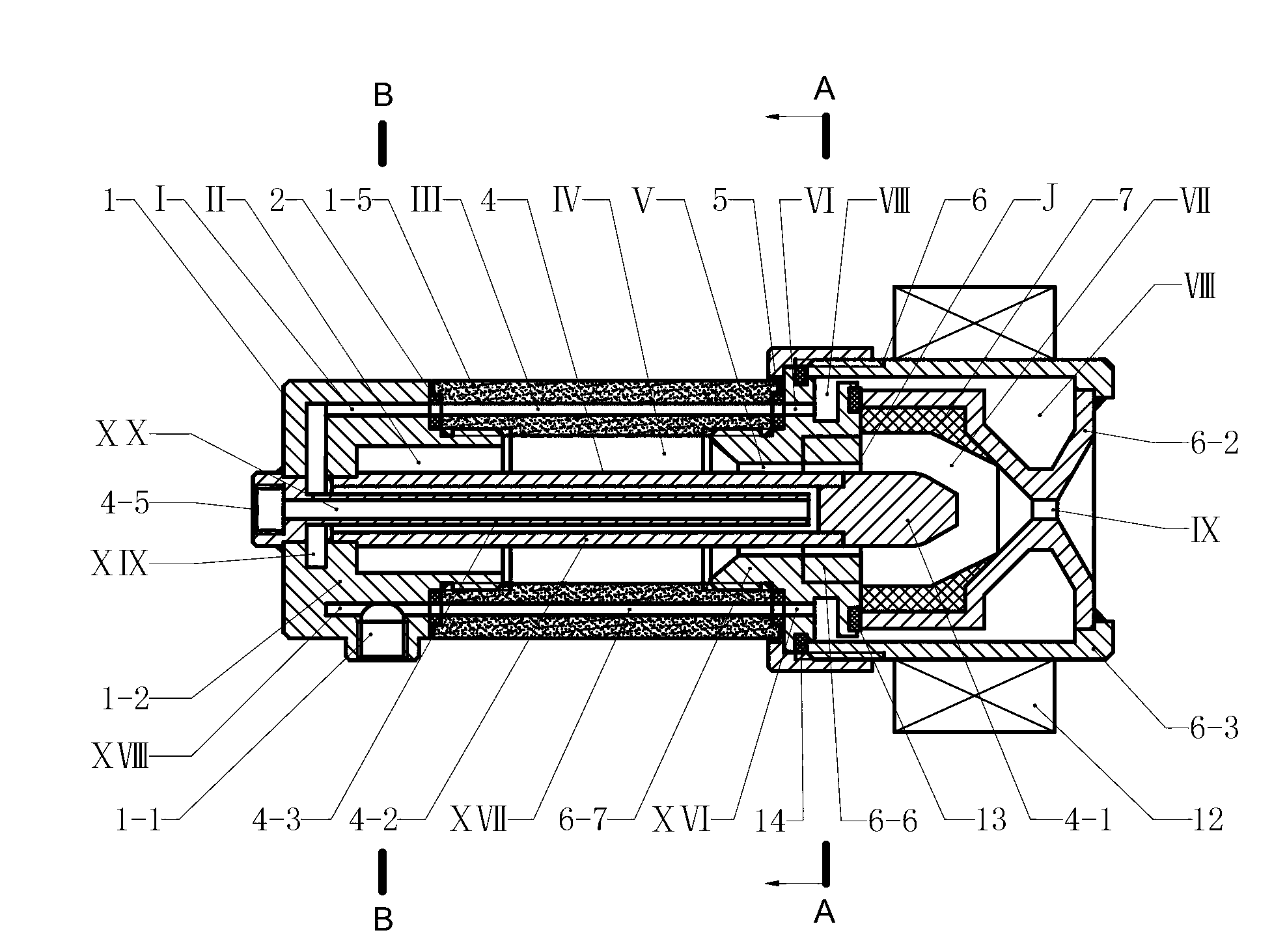

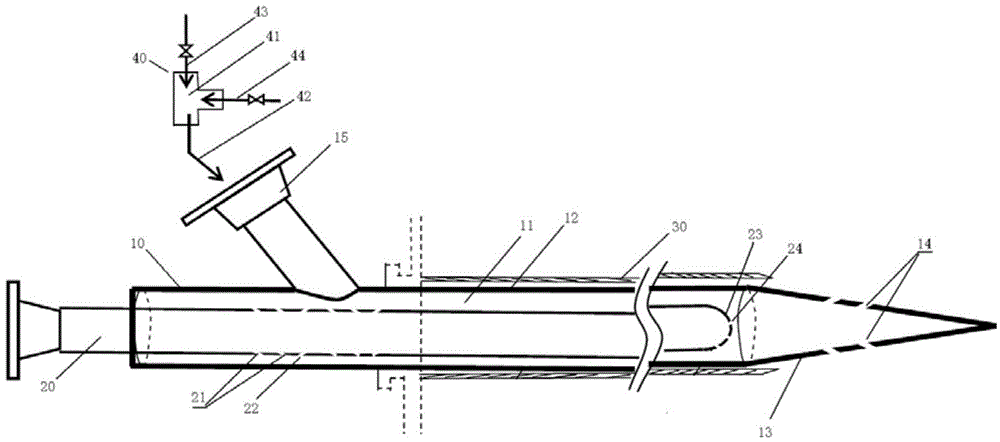

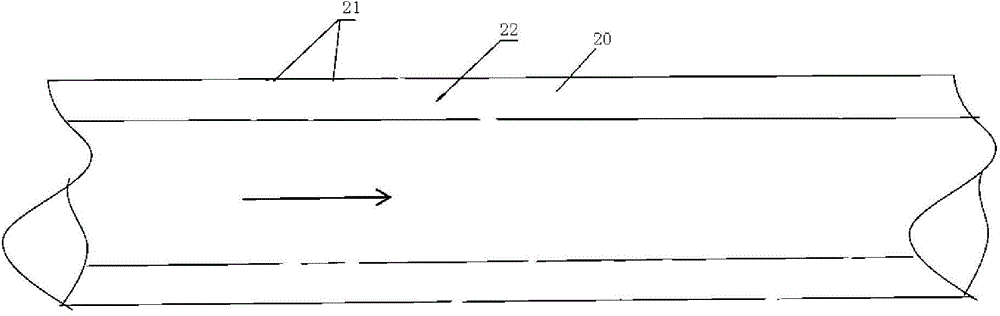

Vapor phase polymerization system and nozzle device thereof

ActiveCN104815606AWell mixedAvoid generatingChemical/physical/physico-chemical nozzle-type rreactorsSpray nozzleProduct gas

The invention provides a vapor phase polymerization system and a nozzle device thereof. The nozzle device comprises a catalyst feeding pipe and an auxiliary gas injection pipe, wherein the auxiliary gas injection pipe is inserted in the catalyst feeding pipe, and a mixing chamber is formed between the catalyst feeding pipe and the auxiliary gas injection pipe and extends towards the direction of an injection opening of the nozzle device; a first through hole and a second through hole are formed in a pipe wall of a pipe section, positioned in the catalyst feeding pipe, of the auxiliary gas injection pipe, and extending directions of the first through hole and the second through hole are inclined to the material flowing direction in the nozzle device; in the material moving direction, the outlet of the first through hole faces the outer side of the auxiliary gas injection pipe, and the outlet of the second through hole faces the inner side of the auxiliary gas injection pipe. According to the nozzle device, a catalyst and auxiliary gas can be mixed uniformly, and the problems that the existing nozzle device generates multiple sheet polymer wastes, and polymer fine powder blocks condenser distribution plates are overcome.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for manufacturing carbide for reinforcing rubber articles

Owner:BRIDGESTONE CORP

Carpet waste composite product and method for making same

ActiveUS9221104B2Efficient productionSynthetic resin layered productsPlastic recyclingBuilding productShell molding

Owner:COLUMBIA INSURANCE CO

Regenerative method of PET wastes

InactiveCN101531581ASolve the technical problem that the transesterification reaction cannot be carried out directlyImprove protectionPreparation from carboxylic acid esters/lactonesPolyethylene terephthalate glycolAlkaline earth metal

The invention discloses a regenerative method of PET wastes, belonging to the field of a recycling method of polymer wastes. The method utilizes ester exchange reaction to reduce polyethylene terephthalate into alkali metal salts or alkaline-earth metal salts of phthalic acid and weak acid radical salts of ethylene glycol and then utilizes acid to reduce alkali metal salts or alkaline-earth metalsalts of phthalic acid into terephthalic acid; and esterolysis and distillation are carried out to weak acid of ethylene glycol so as to obtain the ethylene glycol. Compared with the prior art, the regenerative method of the PET wastes has the characteristics of being economic and environment-friendly and being easy to realize and has good promotion and application values.

Owner:HONGKONG VISCOCHEM CO LTD

Liftable and adjustable cleaning device for producing Christmas balls through cyclic utilization of polymer waste plastic and production technology of liftable and adjustable cleaning device

PendingCN106824848ASimple structureReasonable designCleaning using toolsEngineeringMechanical engineering

The invention relates to a liftable and adjustable cleaning device for producing Christmas balls through cyclic utilization of polymer waste plastic and a production technology of the liftable and adjustable cleaning device. The liftable and adjustable cleaning device is characterized by comprising a rack, a circulating conveyer belt arranged on the rack for containing the Christmas balls, and a plurality of rollers distributed at the upper part of the circulating conveyer belt; and hairbrushes are densely distributed on the rollers. The liftable and adjustable cleaning device for producing the Christmas balls through cyclic utilization of the polymer waste plastic is simple in structure and reasonable in design, and is beneficial to improvement of the cleaning efficiency.

Owner:FUJIAN YINGHAO CULTURAL & CREATIVE CO LTD

Methods and compositions related to recycling polymer waste

ActiveUS20180298169A1Improving notched Charpy impact propertyProductsReagentsPolymer sciencePolymer composition

Owner:IMERTECH SAS

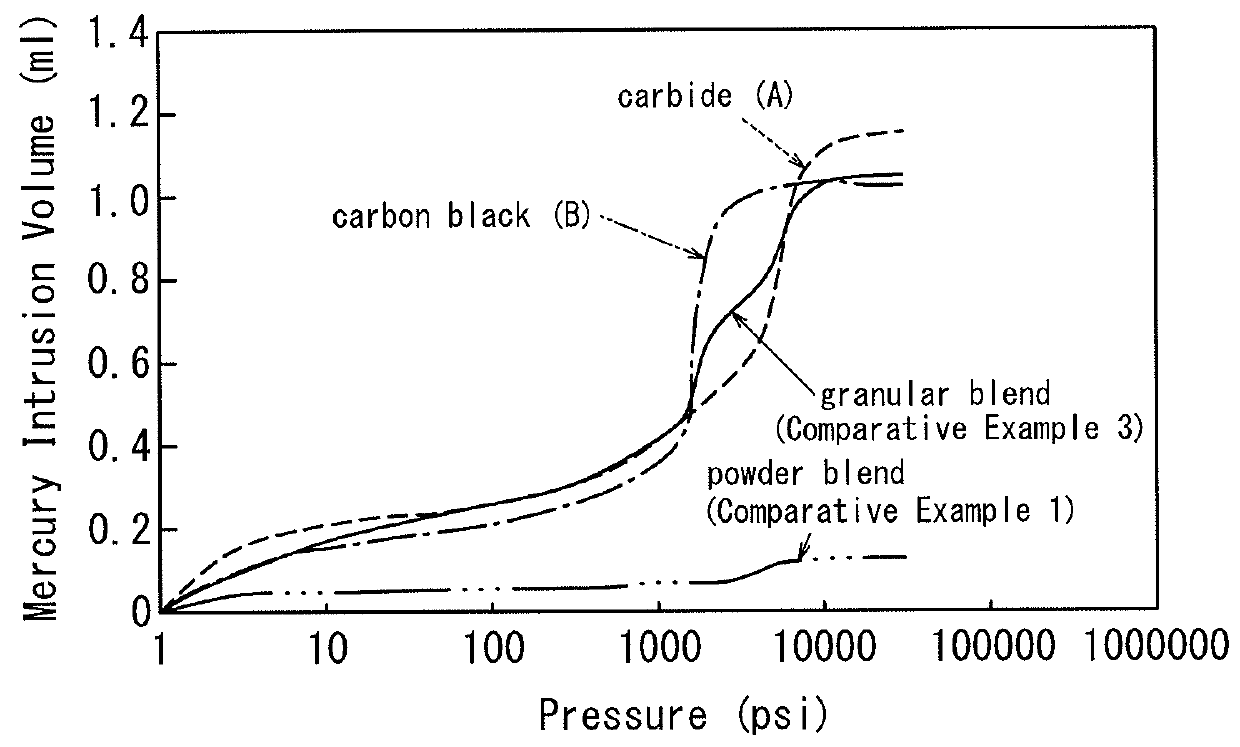

Method for manufacturing carbide for reinforcing rubber articles

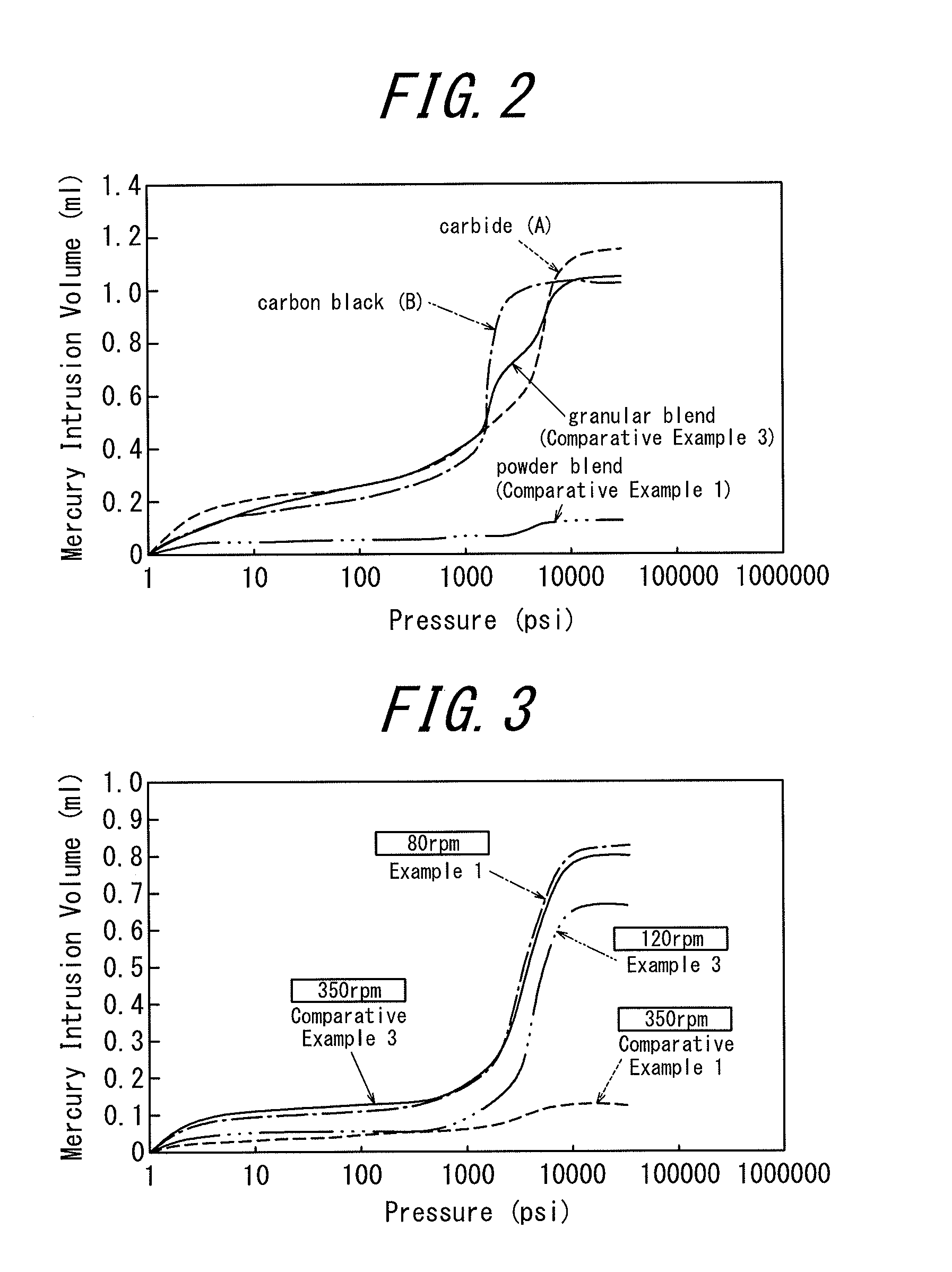

ActiveUS20140001293A1Inferior rubber propertyEfficient use ofPigmenting treatmentGrain treatmentsCombustionPolymer science

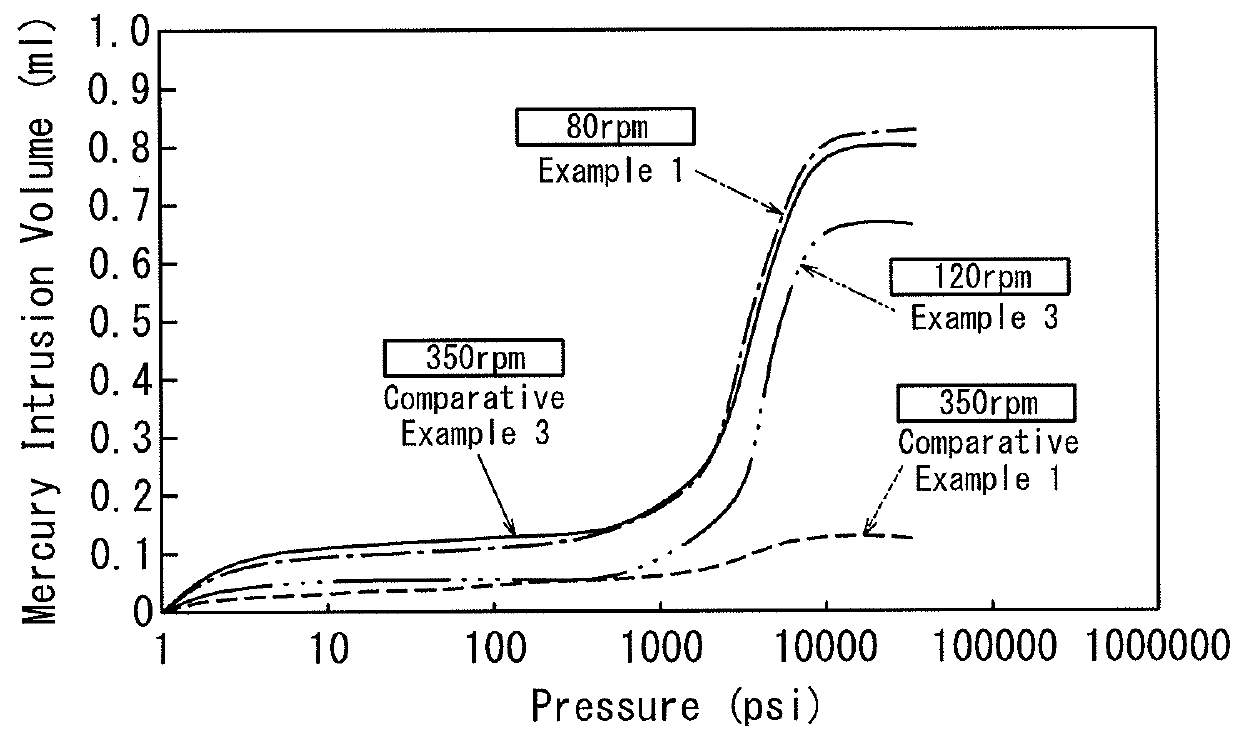

Disclosed is a method for manufacturing a carbide for reinforcing rubber articles that is capable of effectively utilizing polymer waste. The method includes the steps of mixing a carbide, obtained by thermal decomposition or incomplete combustion of polymer waste and pulverized by grinding, with carbon black to obtain a mixture of the carbide and the carbon black, and granulating the mixture using a granulating machine at a rotation speed of 70 rpm to 130 rpm.

Owner:BRIDGESTONE CORP

Device for collecting polymers from polymer waste liquid

The invention discloses a device for collecting polymers from polymer waste liquid. A separator is installed on the upper portion of a waste liquid collection tank. The lower portion of the separator is provided with a waste liquid drainage pipe which is connected into the waste liquid collection tank. The inlet end of a polymer conveying pump is installed at the bottom of the separator. The bottom of the separator and the inlet end of the polymer conveying pump are made communicated through a polymer inlet and outlet. The outlet end of the polymer conveying pump is provided with an outlet, a polymer receiving barrel is arranged below the outlet and installed on a polymer smashing machine, a polymer finished product pot is connected with a polymer finished product conveying pump, a waste liquid conveying pump is installed outside the lower portion of the waste liquid collection pot, power lines of the waste liquid conveying pump, the polymer smashing machine and the polymer finished product conveying pump are connected to a control console, waste liquid in which polymers are extracted can enter a produced liquid processing system of an oil field to become injected water for the waterflooding oil field after being processed, and the extracted polymers can be used as raw materials for oil field stratum water shut-off and profile control after being smashed by the polymer smashing machine.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com