Feeder and extrusion device and method of use thereof

A feeder and extruder technology, applied in the field of feeders, can solve problems such as difficult to control extrusion and shearing, and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

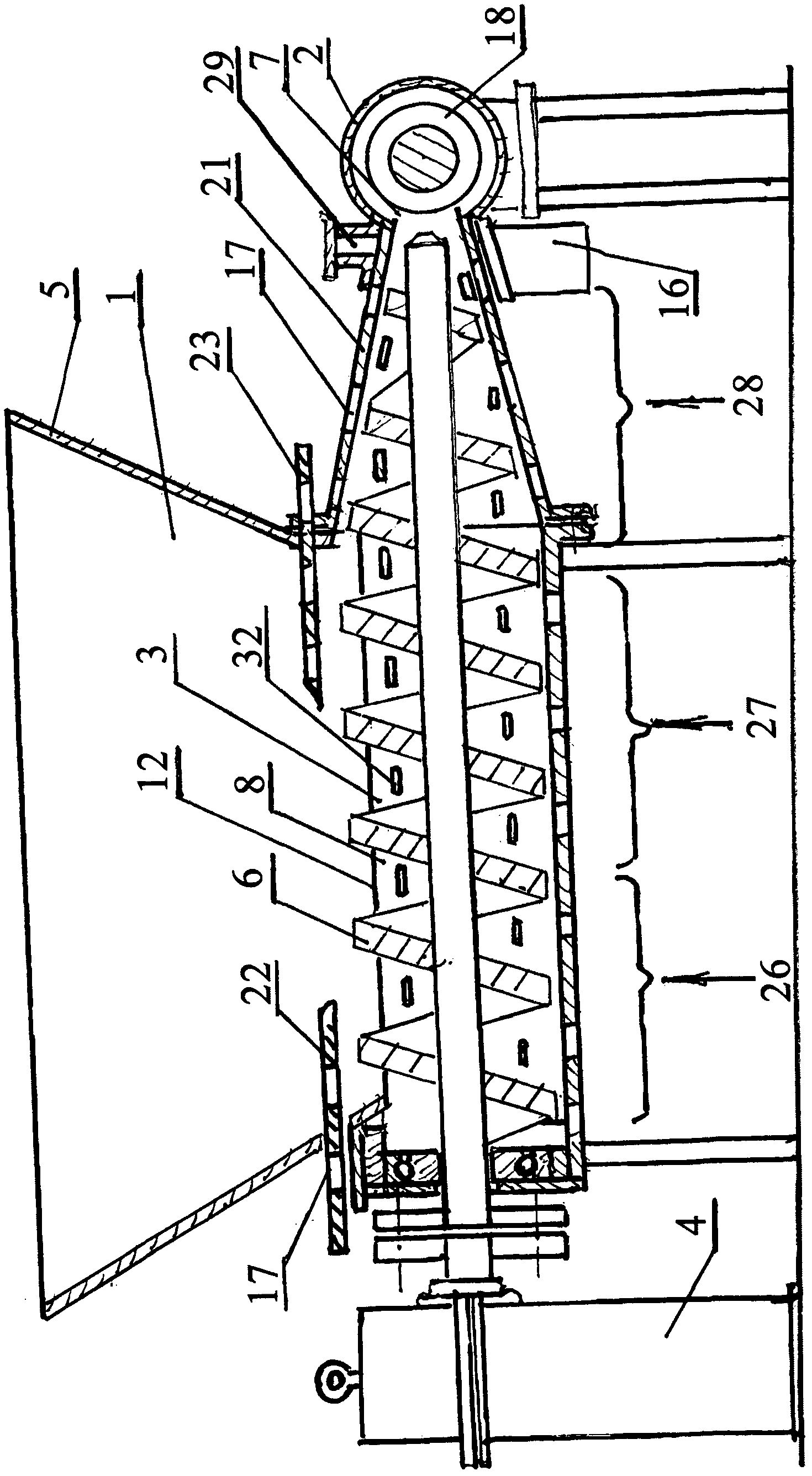

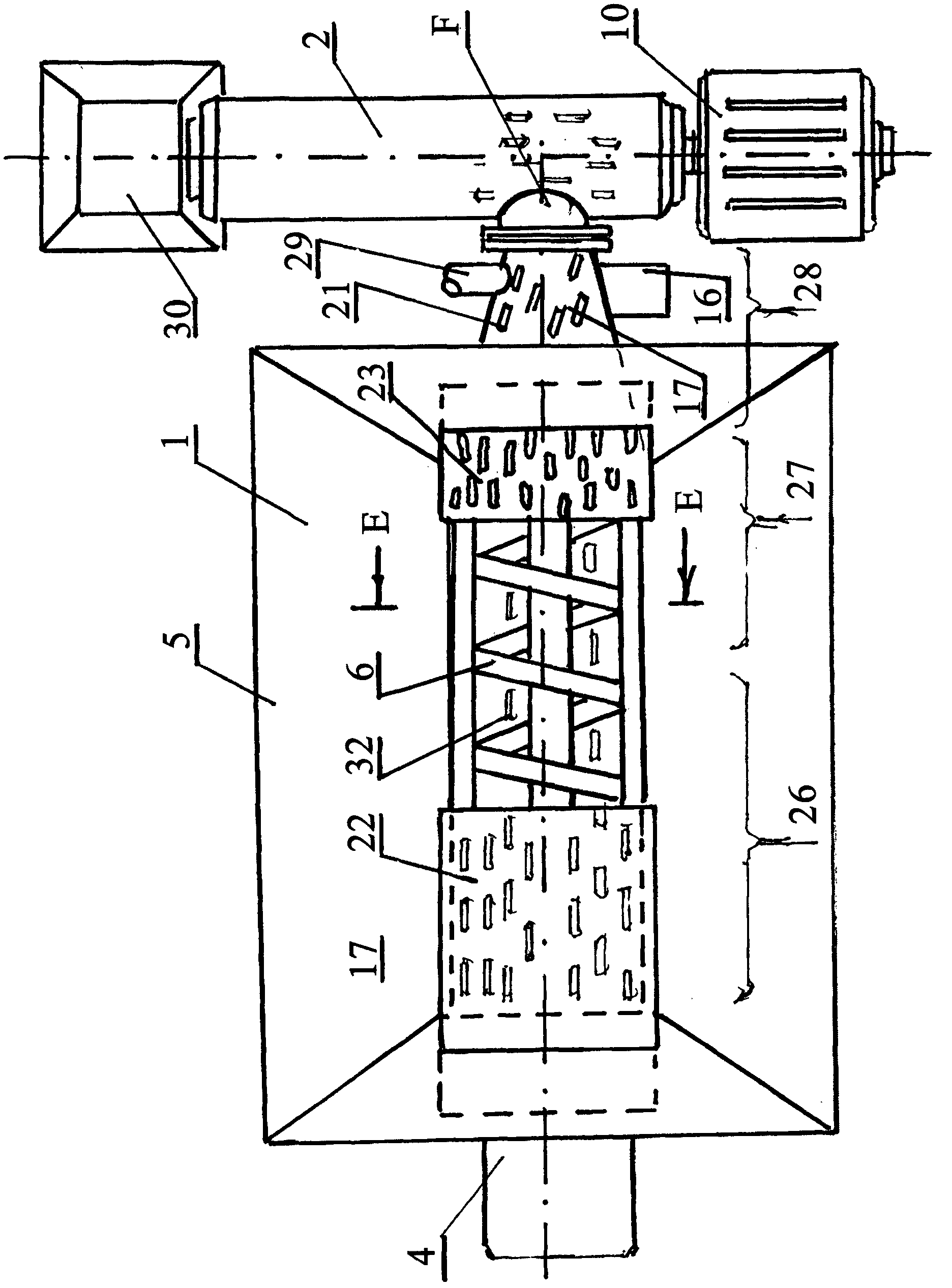

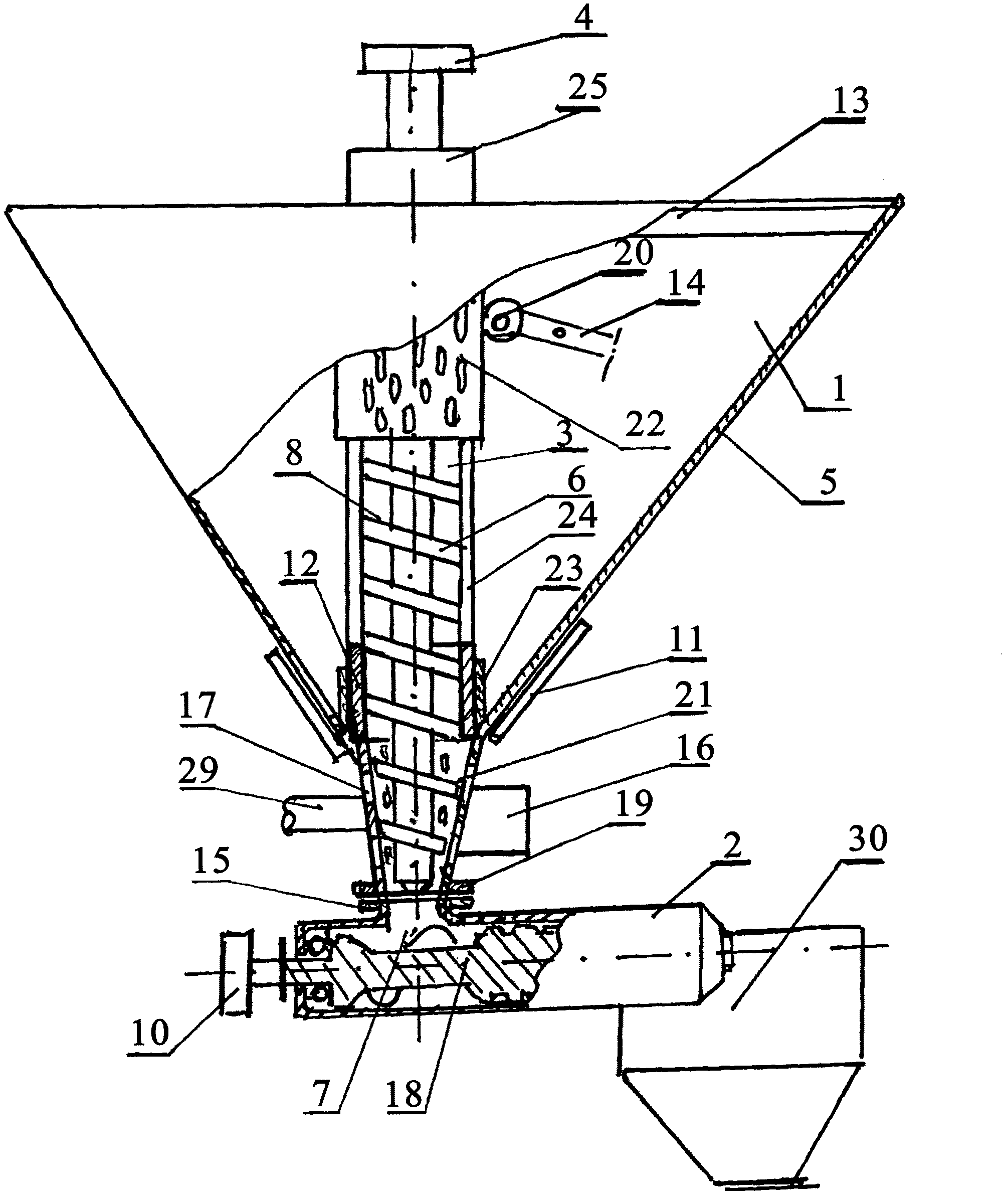

[0125] parts list

[0126] As used herein, reference numerals in the figures correspond to the following parts:

[0127] 1 feeder

[0128] 2 extruders

[0129] 3 Conveyor 6 Housing

[0130] 4 drive for the auger 12

[0131] 5 hoppers

[0132] 6 Conveyor for feeder 1

[0133] 7 Feeding zone of extruder 2

[0134] 8 Feeding zone for conveyor 6

[0135] 9 drive for plunger 33

[0136] 10 drive for extruder screw 18

[0137] 11 hatch

[0138] 12 Auger for conveyor 6

[0139] 13 feeder bracket

[0140] 14 leverage

[0141] 15 feeder output opening

[0142] 16 pulse generators

[0143] 17 holes

[0144] 18 extruder screw

[0145] 19 Bottom of conveyor 6

[0146] 20 Pivot for lever 14

[0147] 21 Anti-flexible part of housing 3

[0148] 22 regulator (part)

[0149] 23 regulator (part)

[0150] 24 connecting rods

[0151] 25 Stationary parts of conveyor 6

[0152] 26 far zone of conveyor 6

[0153] 27 Central Zone of Conveyor 6

[0154] 28 near area of conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com