Device and method for producing a filled polymeric composite material

A technology for filling polymers and composite materials, which is applied in the field of producing filled polymer composite materials and can solve problems such as clogging of filter devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

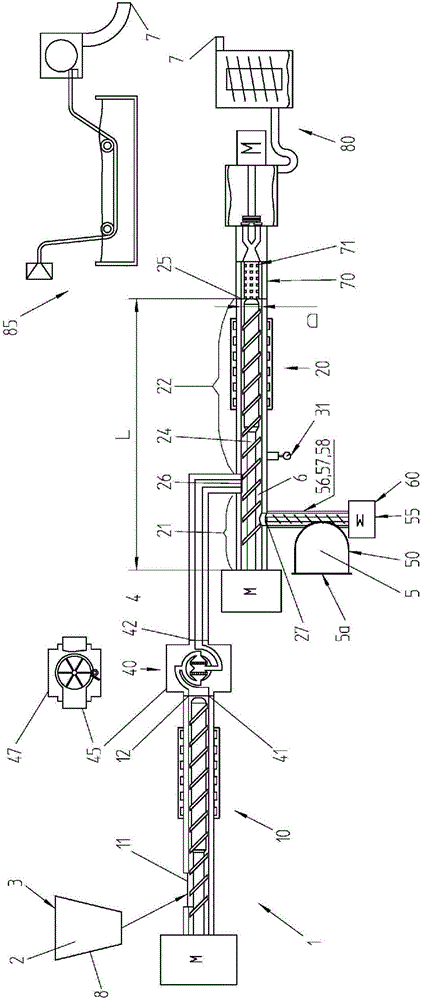

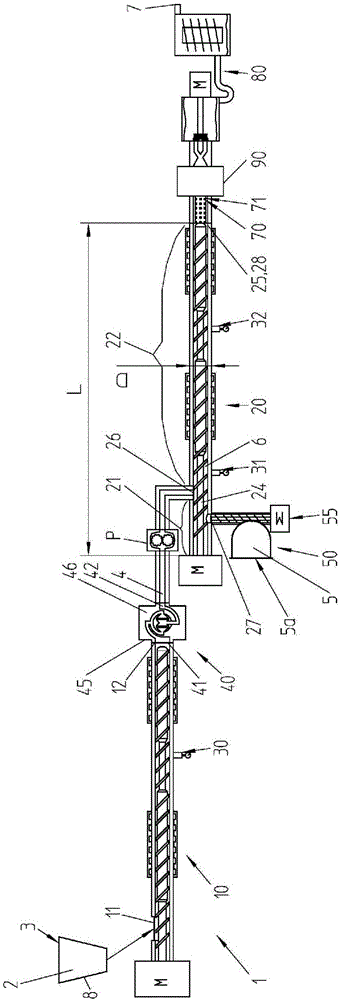

[0049] figure 1 A device 1 according to the invention for producing a composite material 7 from a polymeric matrix material 4 and a fiber material 5 is illustrated. For this purpose, a polymeric matrix material 2, in particular a polymeric matrix material whose main part is recycled polymer waste 3, is used as starting material, as purified polymeric matrix material 4 and fiber respectively after suitable preparation or purification Materials 5 are mixed to form mixture 6 .

[0050] The device 1 comprises a first extrusion device 10 having an inlet 11 for a polymeric matrix material 2 in which the polymeric matrix material 2 is melted, the first extrusion device 10 also having a At the outlet 12 of the molten polymeric matrix material 2. The outlet 12 is connected to an inlet 41 of a melt preparation device 40 in which the molten polymeric matrix material 2 is purified. In the described embodiment, the melt preparation device 40 comprises a filter device 45, wherein, by way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com