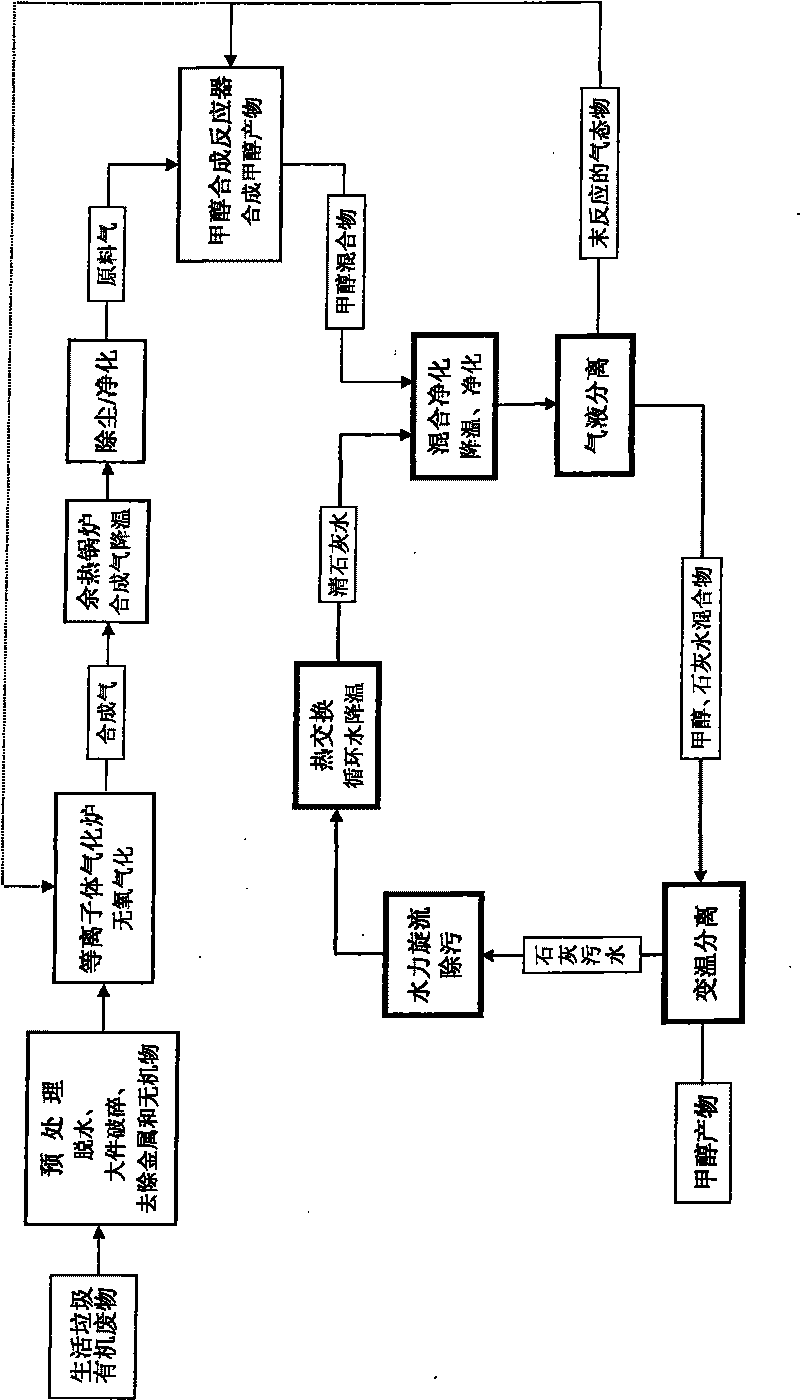

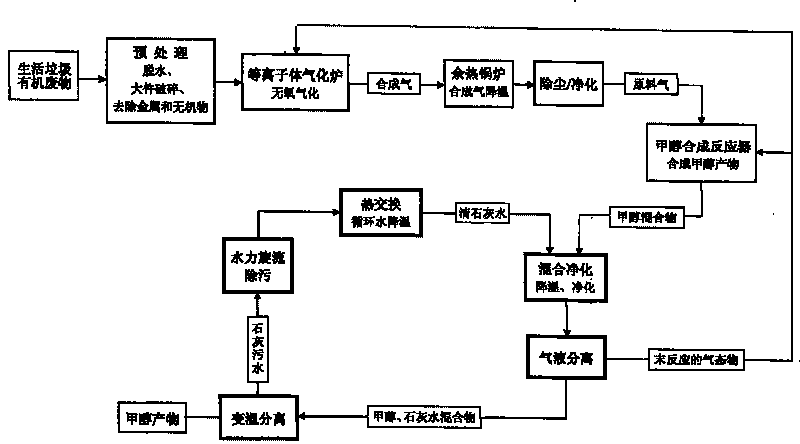

Process for gasification-liquefaction disposal of domestic garbage and organic waste

A technology for organic waste and domestic waste, which is applied in the field of harmless disposal of solid waste, and can solve problems such as environmental pollution and dioxin pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: In this embodiment, before the domestic garbage enters the gasifier, the content of the inorganic matter is within 5%, and the water content is within Below 15%, the calorific value reaches more than 9000kj / kg, in order to reduce the energy consumption in the gasifier and facilitate the subsequent purification. The domestic waste pretreatment adopts conventional technology or applies the Chinese patent ZL 2008201391055 "Pretreatment system for domestic waste as fuel utilization and equipment” technology; the plasma gasifier applies the gasifier of the tenth embodiment in the Chinese patent ZL 2008202082326 “Garbage and organic waste gasification system and equipment”, and the structure of the gasifier can achieve the present invention process requirements. The pretreated domestic garbage or organic waste is fed into the furnace from the feed port on the top of the gasifier, and at the same time, 0.5-1Mpa water vapor is fed into the plasma spray gun and hea...

Embodiment 2

[0051] Embodiment 2: In this embodiment, the same plasma gasification furnace as in Embodiment 1 is used, and the waste materials after dehydration, large-scale crushing, and removal of metal and inorganic substances are sent into the plasma gasification furnace. Under the condition of providing oxygen or air, the complete gasification of waste materials is realized, and hydrogen-rich synthesis gas without oxygen components is generated. into the methanol synthesis reactor to catalyze the synthesis of methanol products, and then mix the methanol products with lime water for terminal purification operations to remove possible pollutants such as dioxins, and then purify the methanol products through temperature-variable operations. The difference between this embodiment and the first embodiment is: the calcium oxide powder of 20-50 microns is sprayed into the furnace from the air distributor arranged on the side wall of the first gasification area, and is used as a degasification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com