Device for collecting polymers from polymer waste liquid

A waste liquid collection and polymer technology, which is applied in wellbore/well parts, earthwork drilling and production, etc., can solve the problems of water absorption capacity decline of water injection wells, impact of oil field development, polymer toxicity, etc., and achieve material cost saving and significant The effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

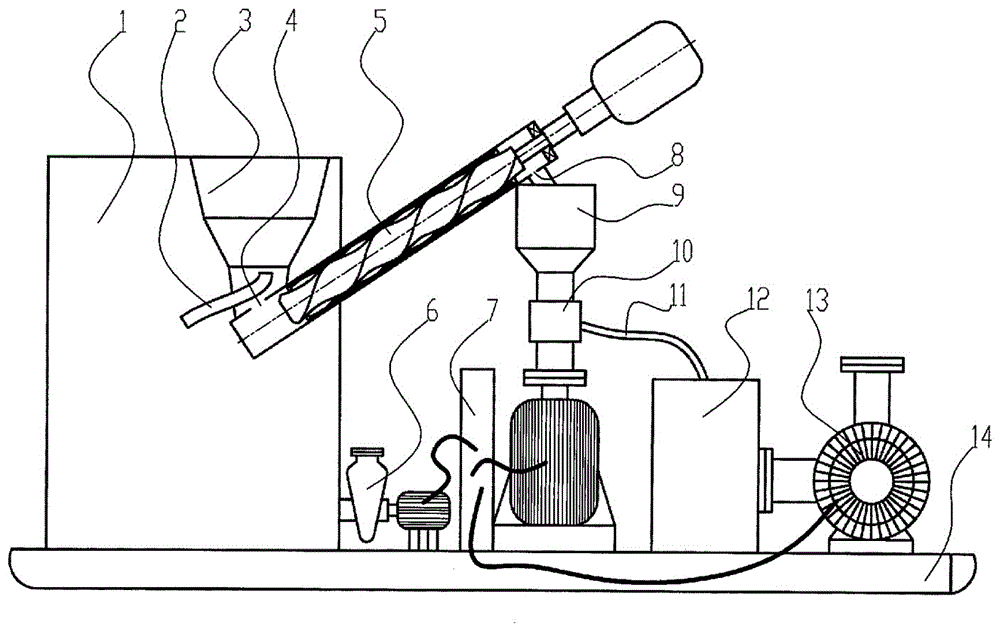

[0010] Combine below figure 1 Examples of the present invention will be described.

[0011] Depend on figure 1 It can be seen that the embodiment of the present invention includes a waste liquid collection tank 1, a waste liquid outlet pipe 2, a separator 3, a polymer delivery pump 5, a waste solution delivery pump 6, a console 7, a polymer receiving cylinder 9, and a polymer pulverizer 10. Polymer conveying pipeline 11, polymer finished product tank 12, polymer finished product conveying pump 13, skid-mounted seat 14, separator 3 is installed on the upper part of waste liquid collection tank 1, and the lower part of separator 3 has waste liquid outlet pipe 2 , the waste liquid outlet pipe 2 is connected to the waste liquid collection tank 1, the inlet end of the polymer delivery pump 5 is installed at the bottom of the separator 3, and the bottom of the separator 3 and the inlet end of the polymer delivery pump 5 are connected by the polymer inlet and outlet 4 Unicom, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com