Resourceful and environment-friendly treatment system for chlorine-containing organic waste gas and waste liquid of organosilicone

A technology for organic waste gas and environmental protection treatment, applied in combustion product treatment, incinerator, climate sustainability, etc., can solve problems such as uneconomical, waste of resources, inability to by-produce silica powder, etc., and achieve long continuous working time , the effect of saving operating costs and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

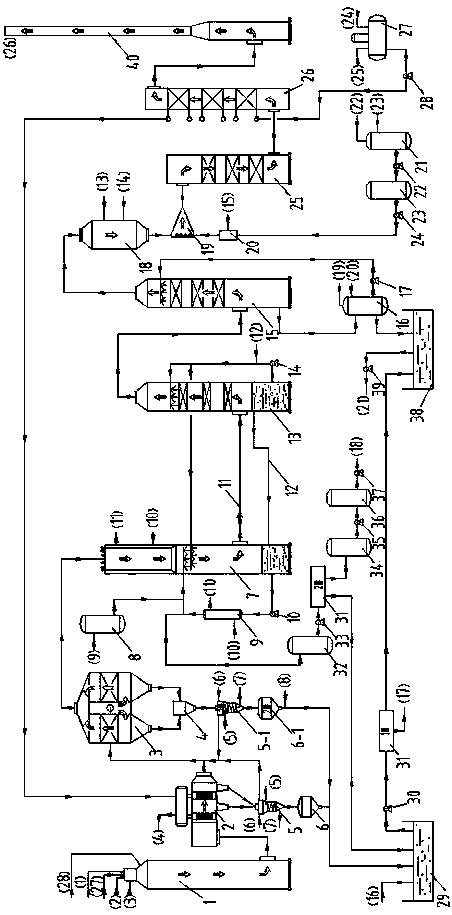

[0014] Embodiment: An environmental protection treatment system for organosilicon and chlorine-containing organic waste gas and waste liquid recycling. The incinerator 1 is connected to the two-stage fire tube waste heat boiler 2, and the left end of the two-stage fire tube waste heat boiler 2 is dedusted by the ceramic membrane through the pipeline. The lower end of the two-stage fire tube waste heat boiler 2 is connected to the 1# replacement bin 5; the lower end of the 1# replacement bin 5 is connected to the 1# ash storage bin 6, and the 1# ash storage bin 6 is connected to the neutralization tank 29; The upper end of the ceramic membrane dust collector 3 is connected to the upper end of the graphite quenching tower 7, the lower end of the ceramic membrane dust collector 3 is connected to the ash bin 4, the lower end of the ash bin 4 is connected to the 2# replacement bin 5-1, and the 2# replacement The lower end of the bin 5-1 is connected to the 2# ash storage bin 6-1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com