Method for preparing hydrocarbon with catalysis copyrolysis of biomass and polymer

A hydrocarbon and biomass technology, which is used in the production of hydrocarbons from oxygen-containing organic compounds and hydrocarbon cracking to produce hydrocarbons, etc., can solve the problems of low octane number of liquid oil, low yield of light oil, and hindering wide application. , to achieve the effect of reducing the reaction pressure, reducing the cracking temperature and increasing the octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

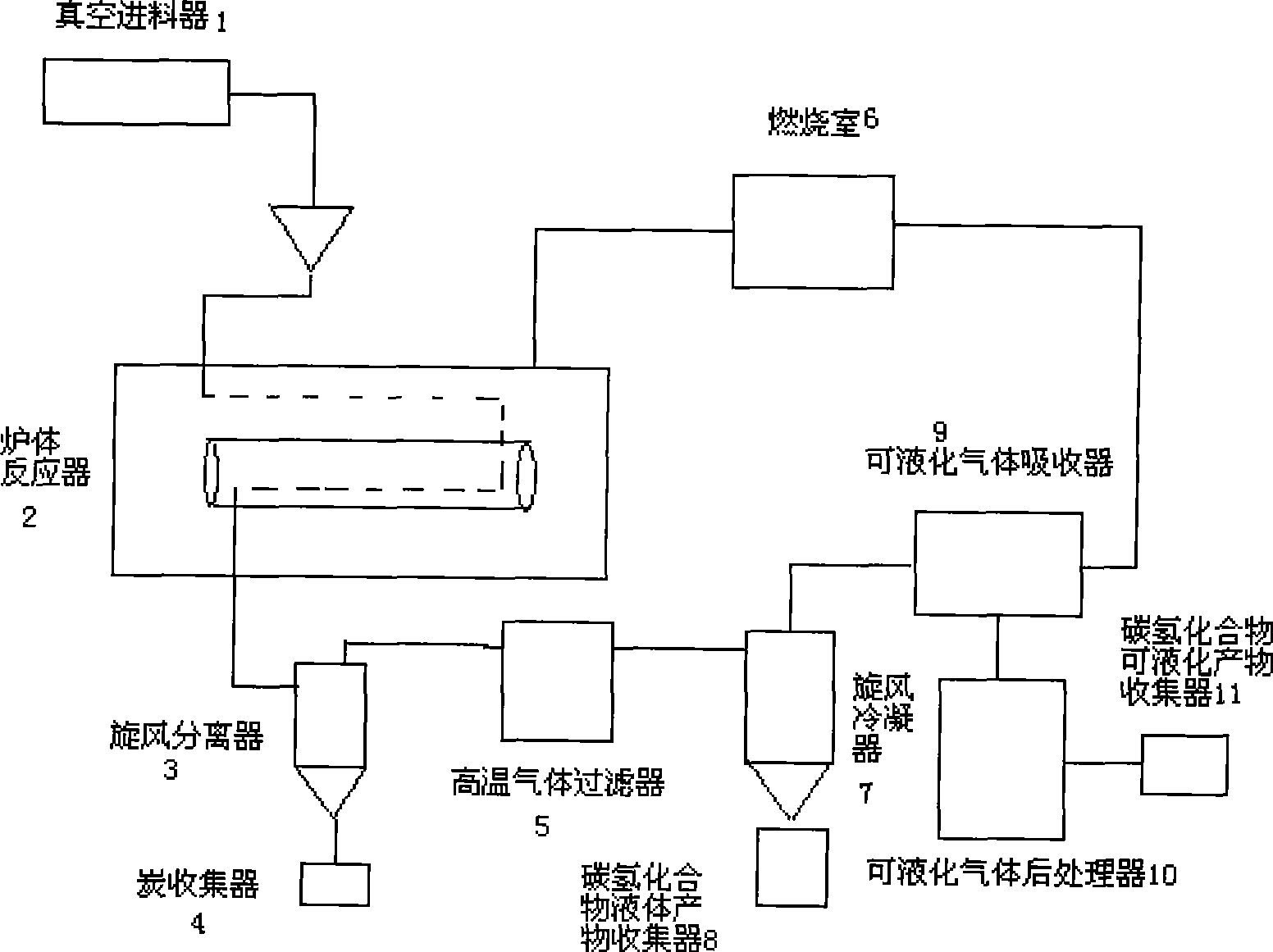

[0028] Refer to attached drawing 1

[0029] Step 1: remove foreign matter from waste and polymer, crush, dry at 110°C for half an hour, mix according to the dry biomass: polymer weight ratio of 10-2:1, and enter the furnace reactor through vacuum feeder 1 In 2, add naphthalene or alcohol hydrogenation solvent according to solvent: raw material weight ratio is 8~4:1;

[0030] Step 2: Exhaust the air in the furnace reactor 2, and feed hydrogen or nitrogen with a pressure of 2-6KPa.

[0031] Step 3: The temperature is raised to 320-450° C. for cracking reaction, and the reaction time is 30 minutes to 6 hours.

[0032] Step 4: After the reaction is completed, the gaseous substances in the reactor 2 pass through the cyclone separator 3 to separate the hydrocarbon solids.

[0033] Step 5: The gaseous hydrocarbons are collected through the high-temperature gas filter 5 and the cyclone condenser 7 to obtain hydrocarbon liquid products, which are collected in the collector 9 .

[00...

Embodiment 2

[0038] According to the preparation steps and method of Example 1, the cracking was carried out in a pressure-resistant reactor. Dry 1 kg of rice husk at 110°C for half an hour, remove foreign matter from waste tires, crush them, and dry at 110°C for half an hour, take 0.125 kg each, mix and dissolve in 5 kg of ethanol, add a metal oxide catalyst according to 1.5% of the weight of the raw materials, Exhaust the air, pass H2 with an initial pressure of 2KPa, heat up to 380°C, crack for 4 hours, cool down to 80°C, use a post-processing system to collect hydrocarbon gas products rich in C1-C4, and obtain hydrocarbon liquid products and residues at the same time . The resulting liquid was divided into oil phase and water phase, extracted and weighed. Liquid products were analyzed by GC-MS. The conversion rate of the total mixed waste was 62%, the total product consisted of 30% hydrocarbon gas, 54% hydrocarbon liquid and 16% residue. Hydrocarbon Liquid Octane 78. The hydrocarbo...

Embodiment 3

[0040] According to the preparation steps and method of Example 1, the cracking was carried out in a pressure-resistant reactor. Dry corncobs at 110°C for half an hour, waste plastics: waste tires at a weight ratio of 1:1 to remove foreign matter, crush them, dry at 110°C for half an hour, mix and dissolve them in naphthalene-based additives at a weight ratio of corncobs to polymers of 4:1 In the hydrogen solvent, the weight ratio of solvent to raw material is 4:1, and molecular sieve catalyst is added according to 1% of the weight of the raw material, the pressure is 6KPa, the temperature is raised to 400° C., and cracked for 3 hours. The conversion rate of the total mixed waste is 60%, the total product consists of 32% hydrocarbon gas, 51% hydrocarbon liquid and 17% residue. Hydrocarbon Liquid Octane 77.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com