Process and installation for pyrolysis of a product in the form of divided solids, in particular polymer waste

a technology of divided solids and pyrolysis gas, which is applied in the production of liquid hydrocarbon mixtures, special form destructive distillation, coking carbonaceous materials, etc., can solve the problems of limited yield, low yield, and the above-mentioned document does not enable the extraction of pyrolysis gas with a high methane content, so as to improve the efficiency of pyrolysis and improve the methane content of the pyrolysis gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

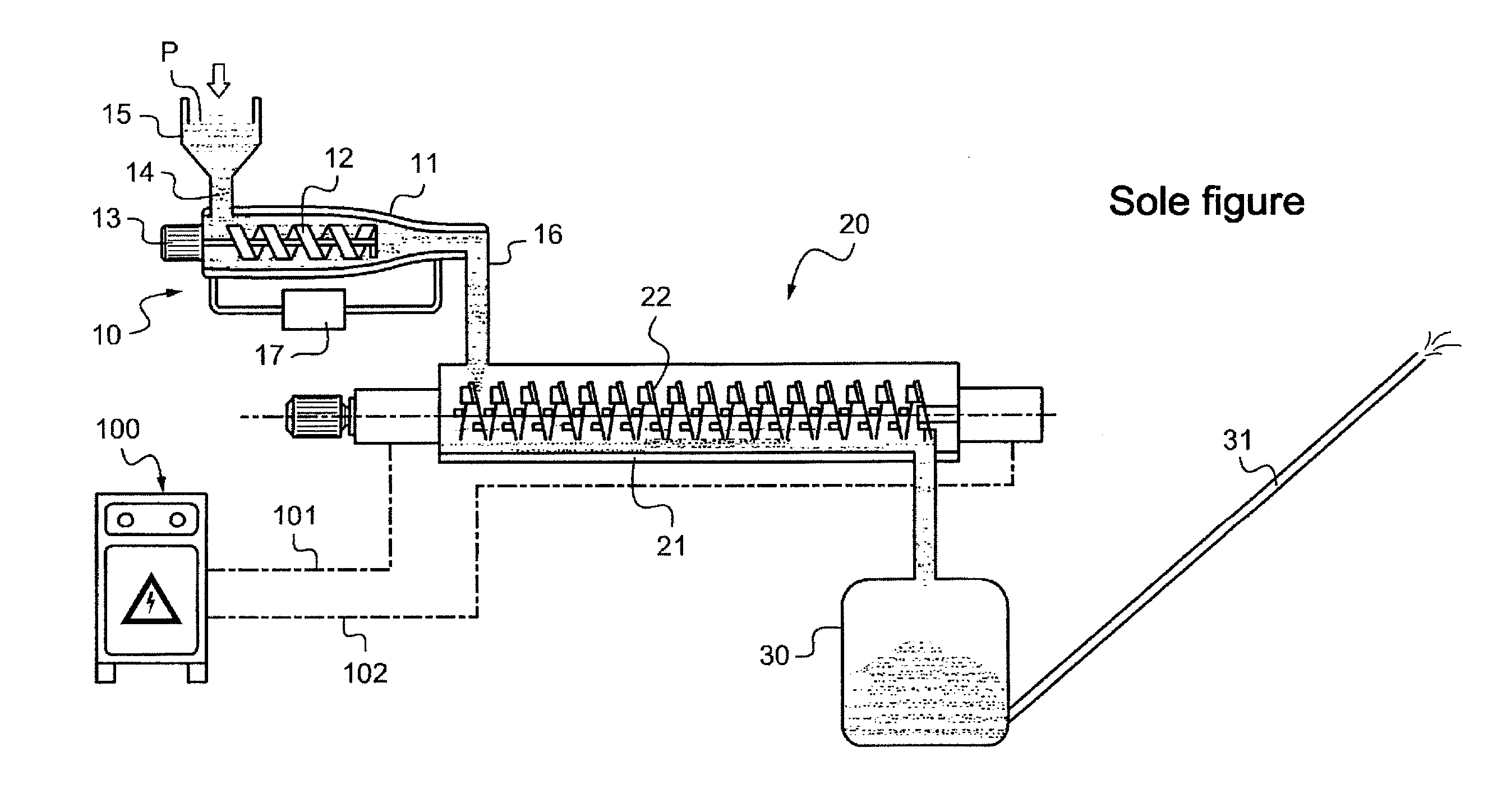

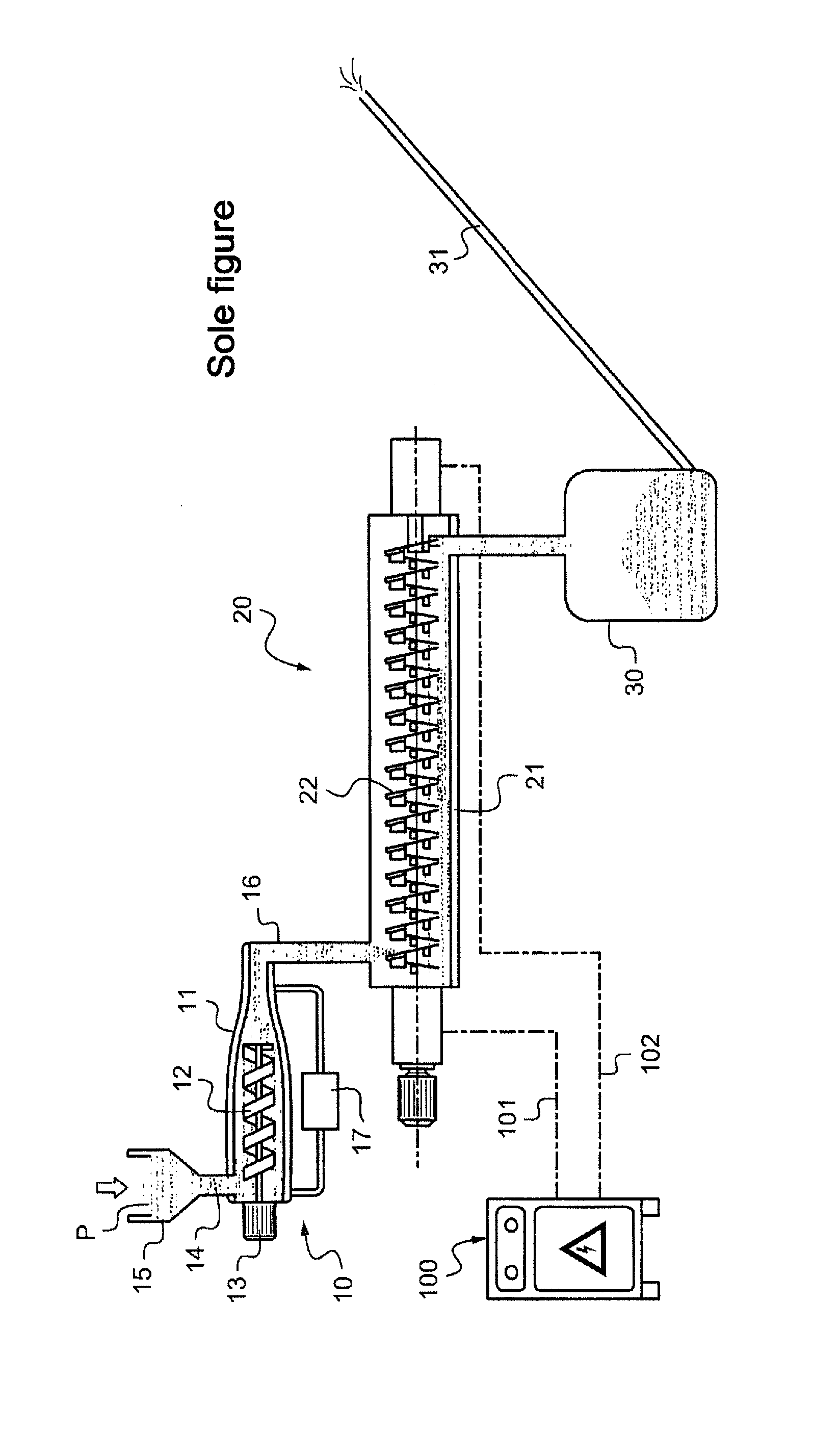

[0022]The FIGURE is a diagrammatic view of an installation for processing a substance in the form of divided solids, in particular polymeric solids such as plastics, rubber, or elastomer waste. It may be household waste, industrial waste, or indeed substances that have previously been micronized.

[0023]In general, the substances concerned are divided solids capable of producing in particular pyrolytic oils by recondensation of gas when the substances are pyrolyzed at temperatures lying in the range 400° C. to 600° C., which oils have energy or chemical content that is suitable for recycling, and the pyrolysis gas also contains components (such as methane, hydrogen, acetylene, . . . ) that are industrially advantageous when the substances are pyrolyzed at temperatures in the range 600° C. to 900° C.

[0024]The substance for treatment, referenced P, is initially inserted into a preconditioning device 10 enabling the substance to be compacted and heated so as to liquefy it before it is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com