Patents

Literature

121 results about "Joule effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Joule effect and Joule's law are any of several different physical effects discovered or characterized by English physicist James Prescott Joule.

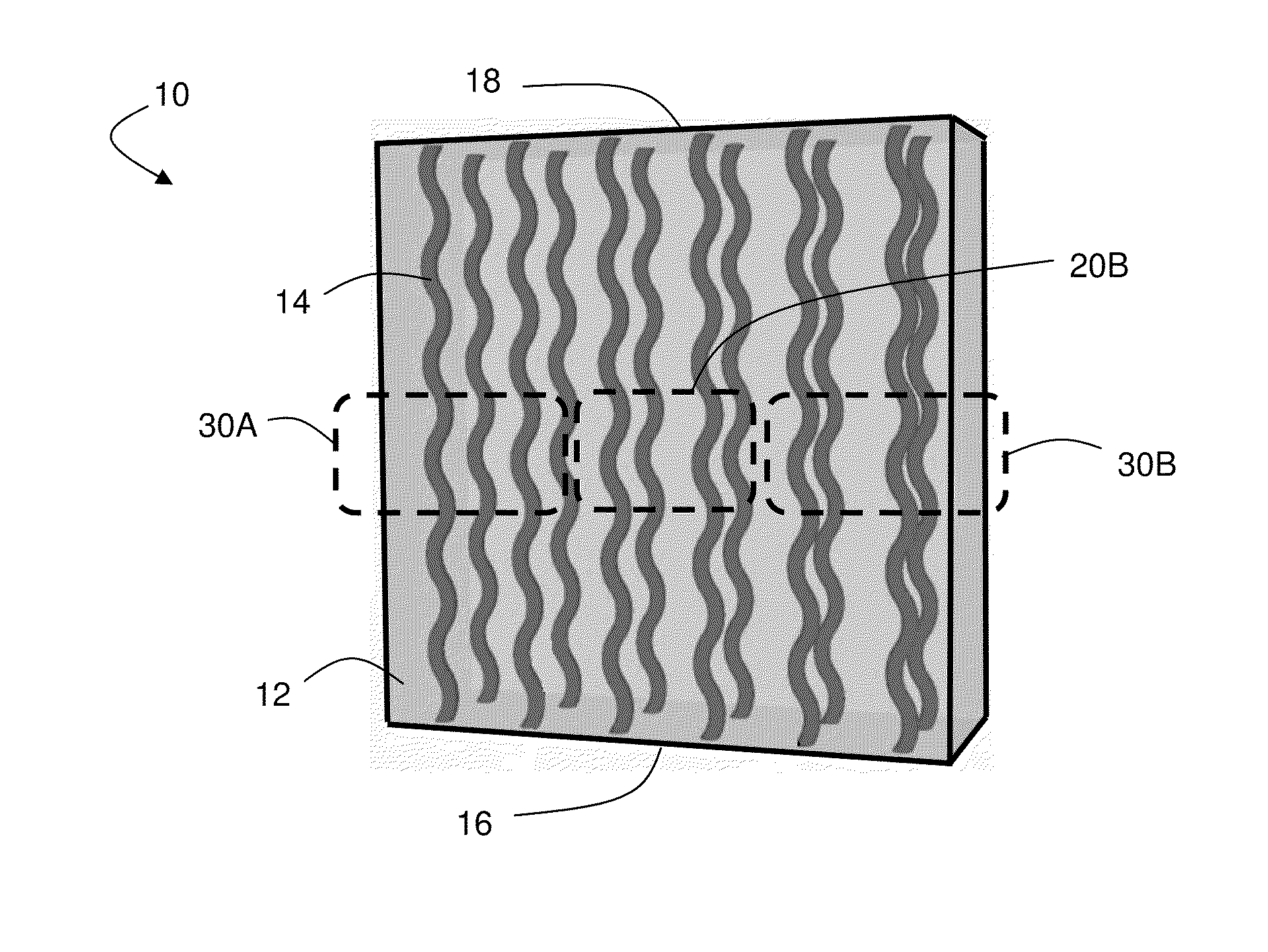

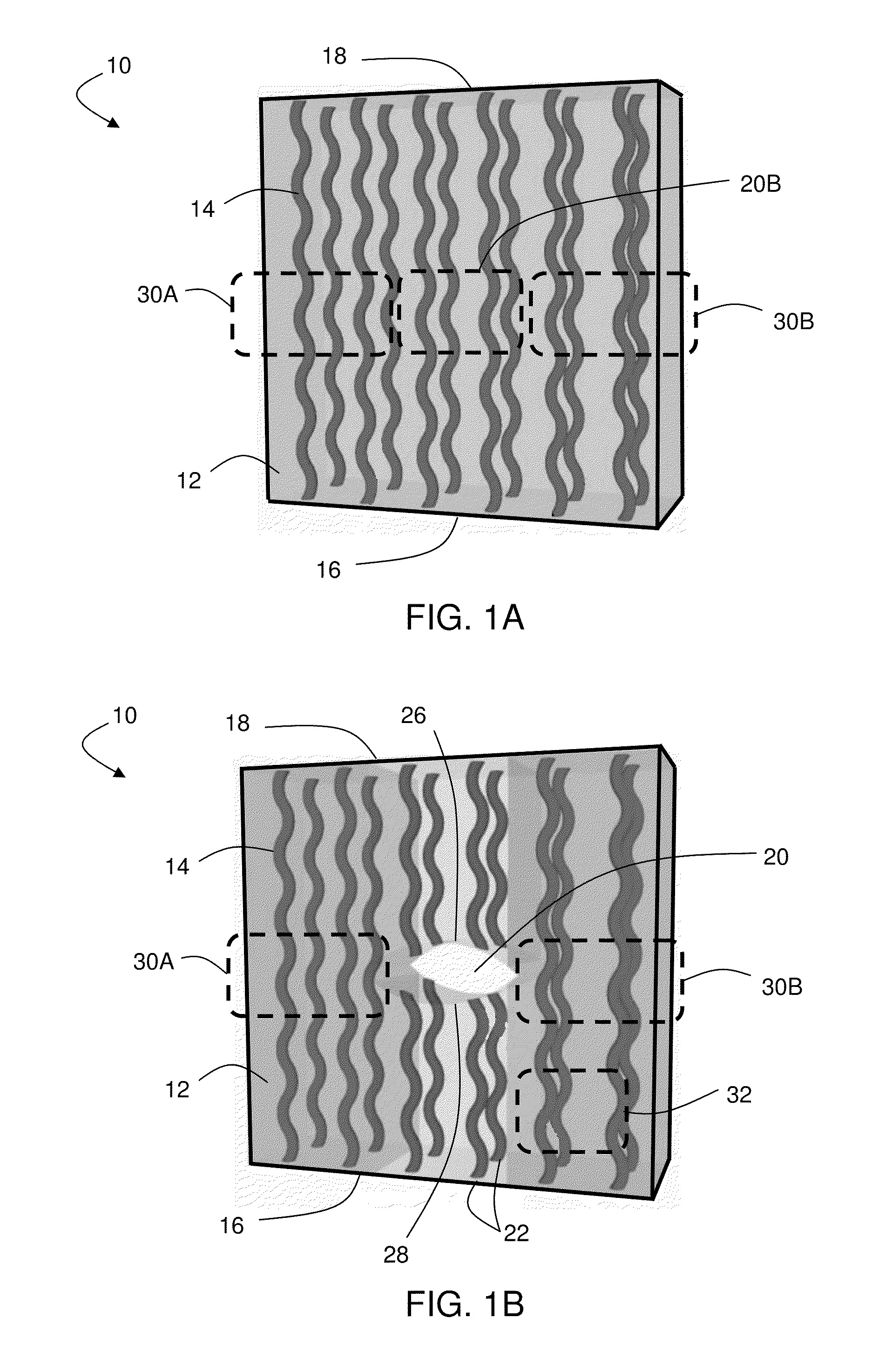

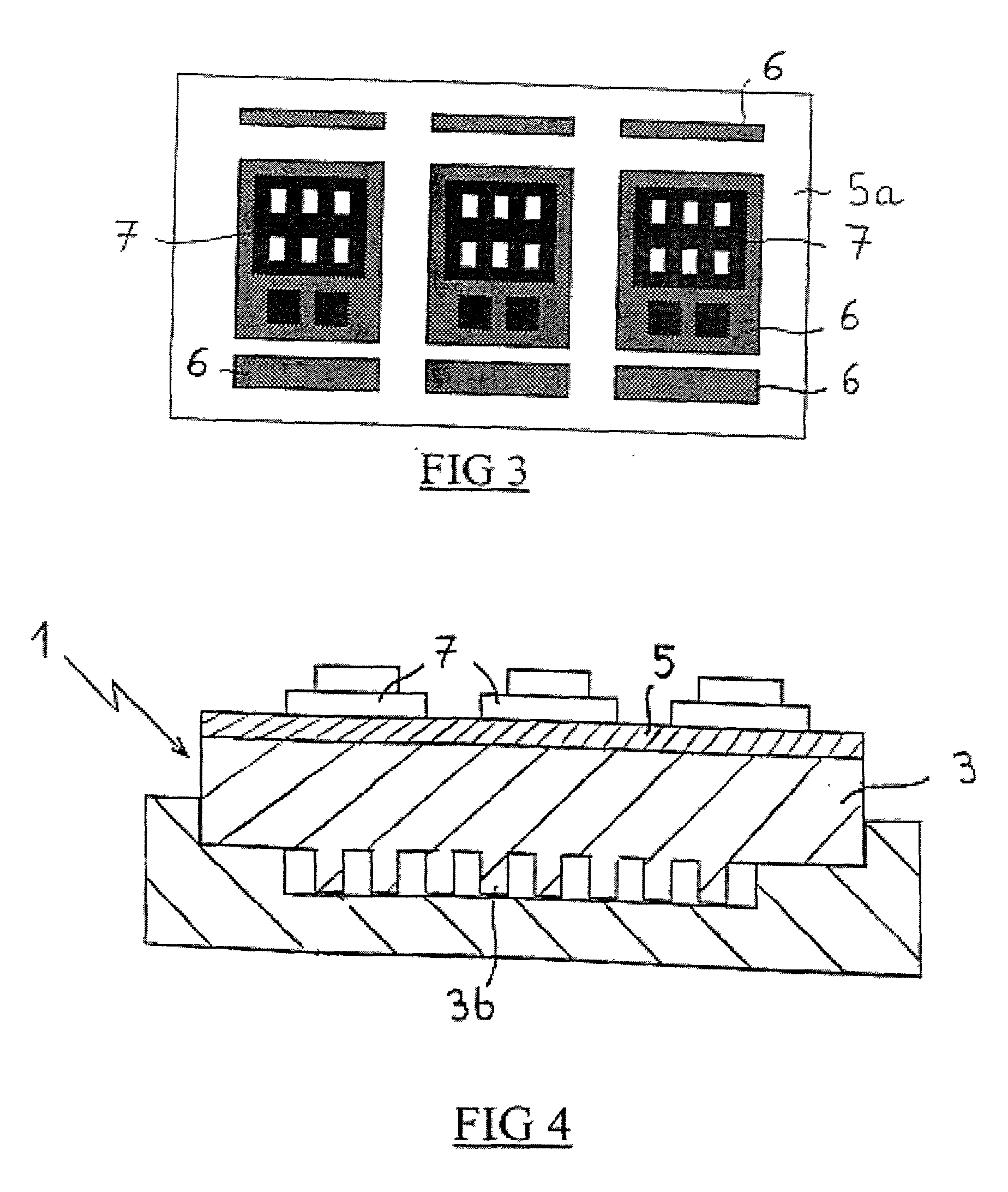

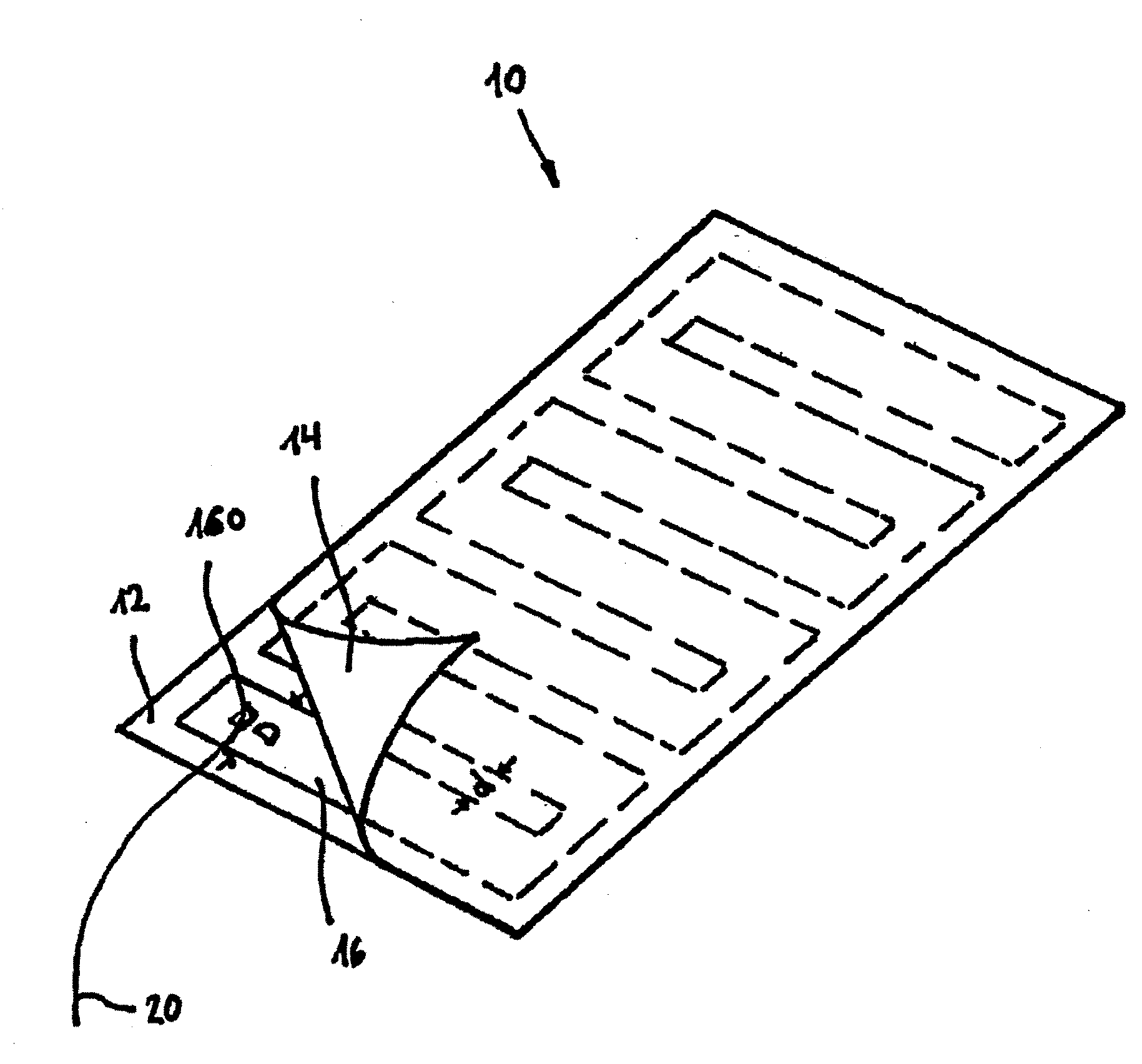

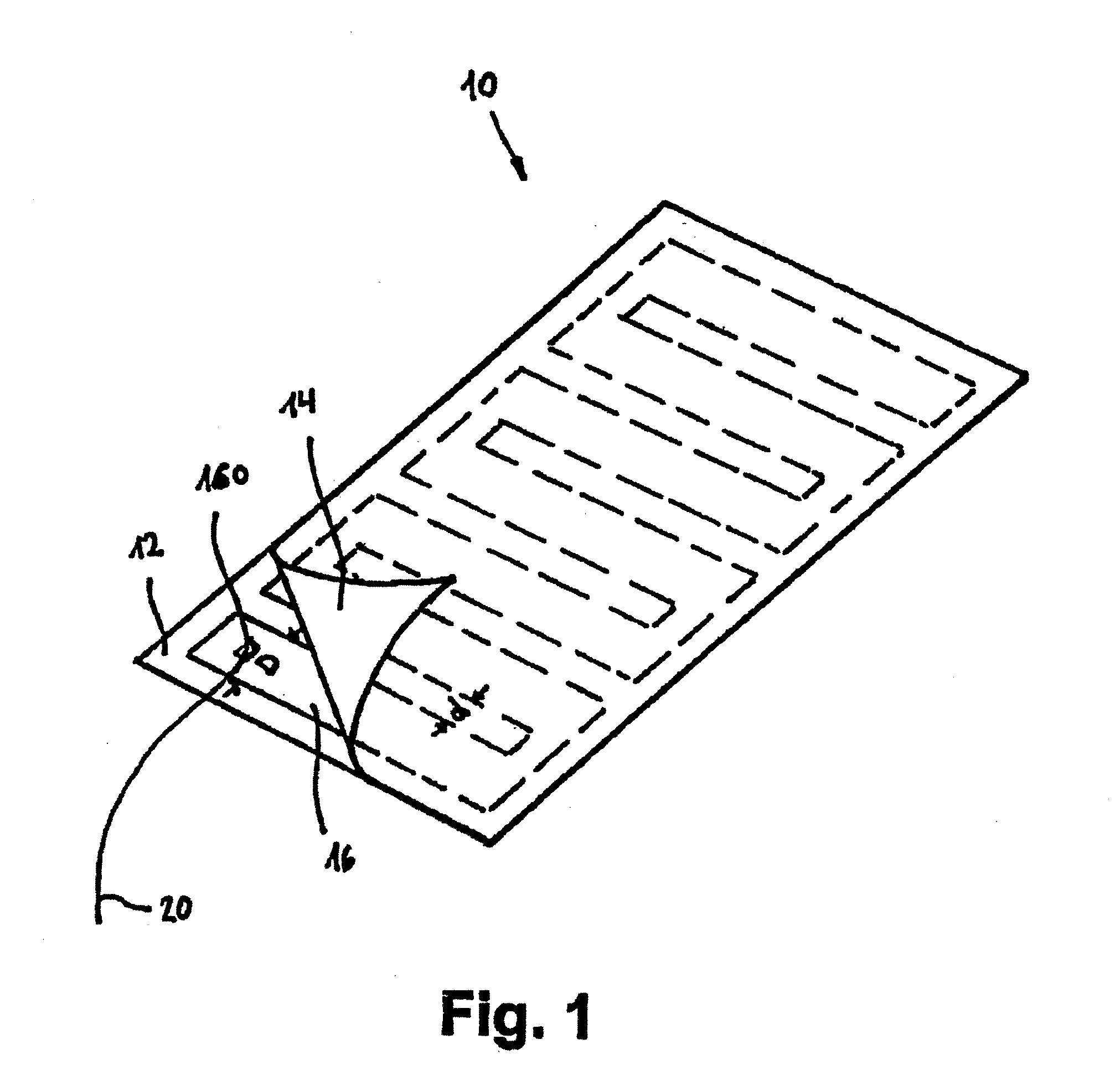

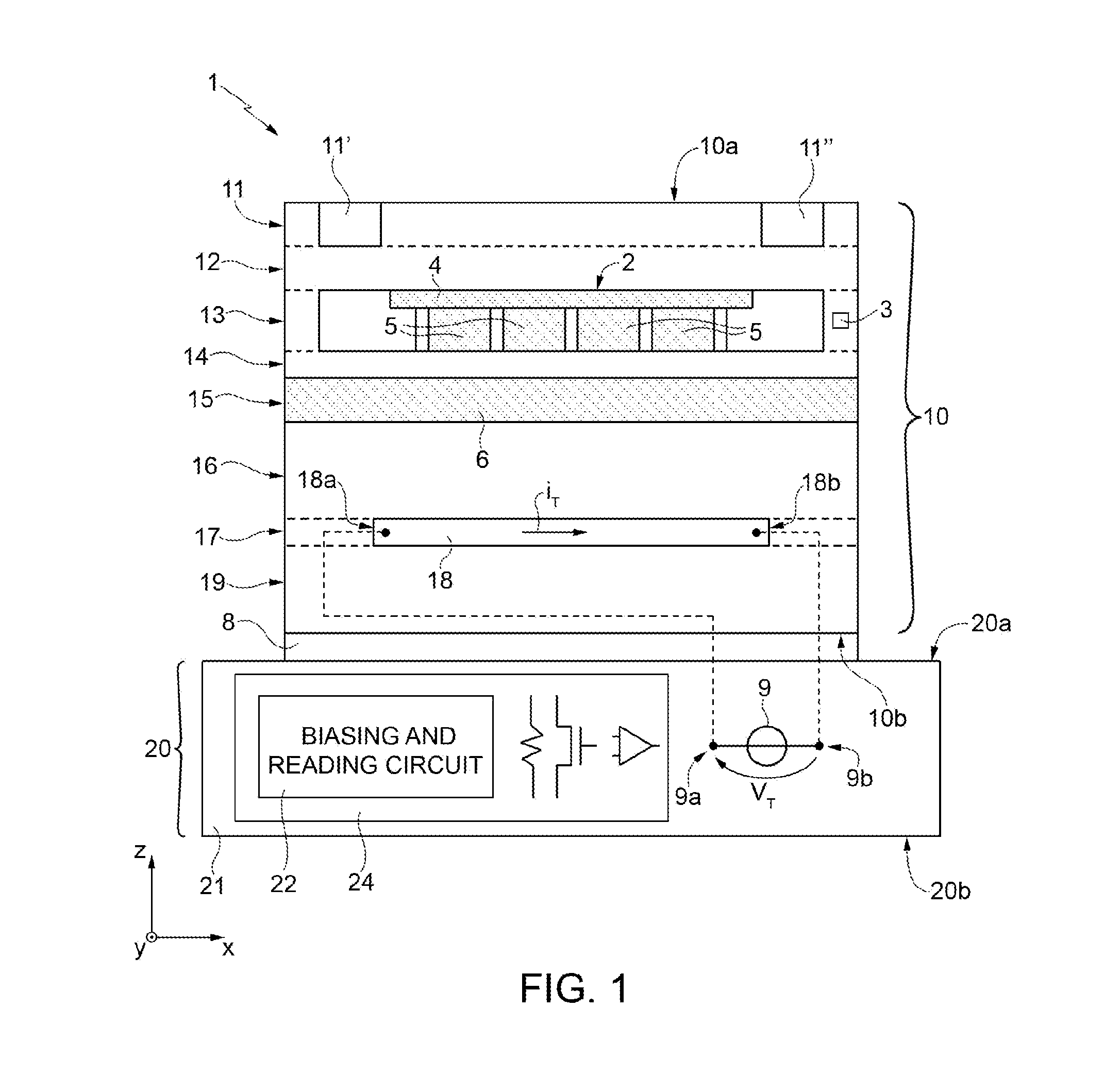

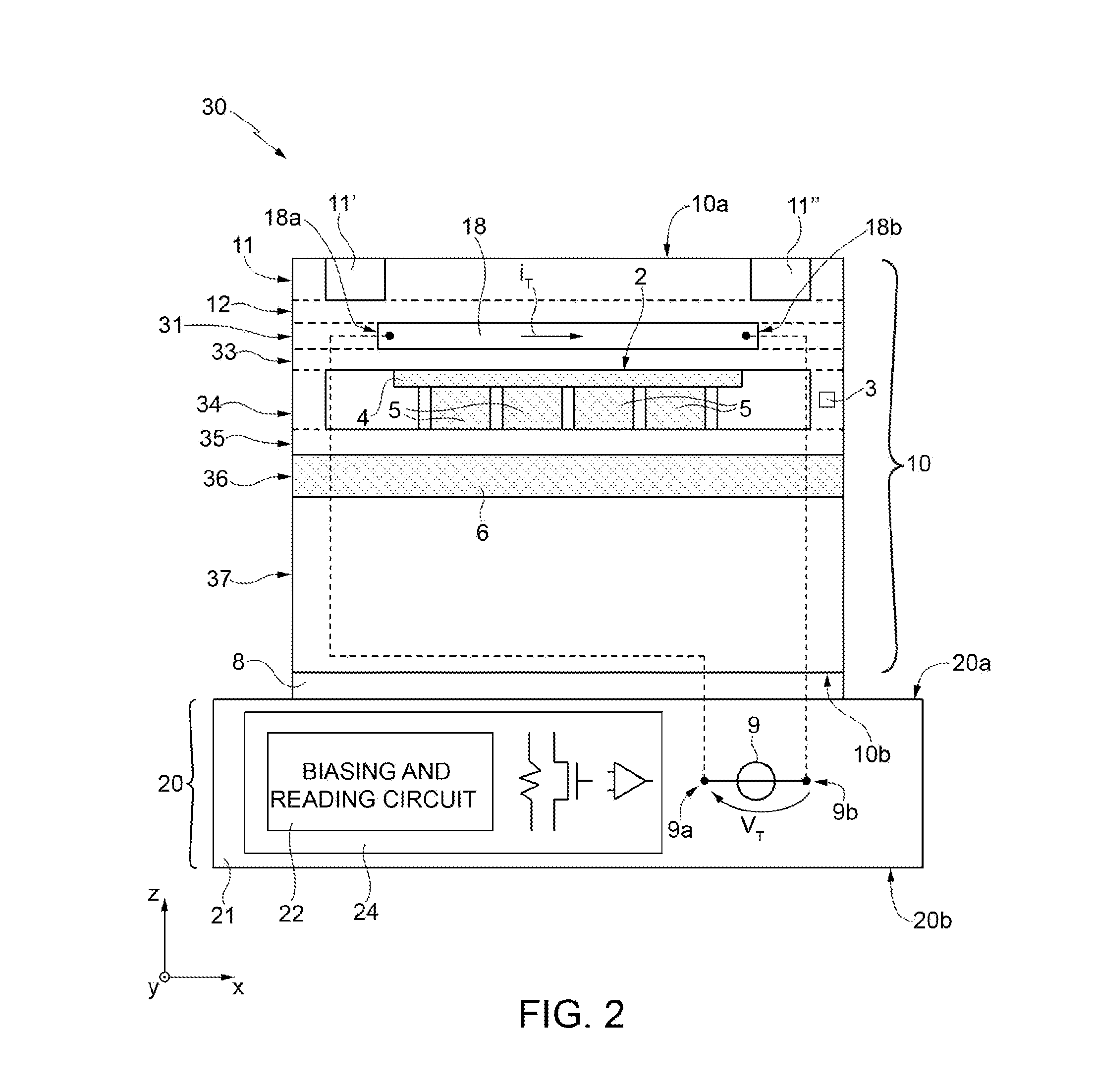

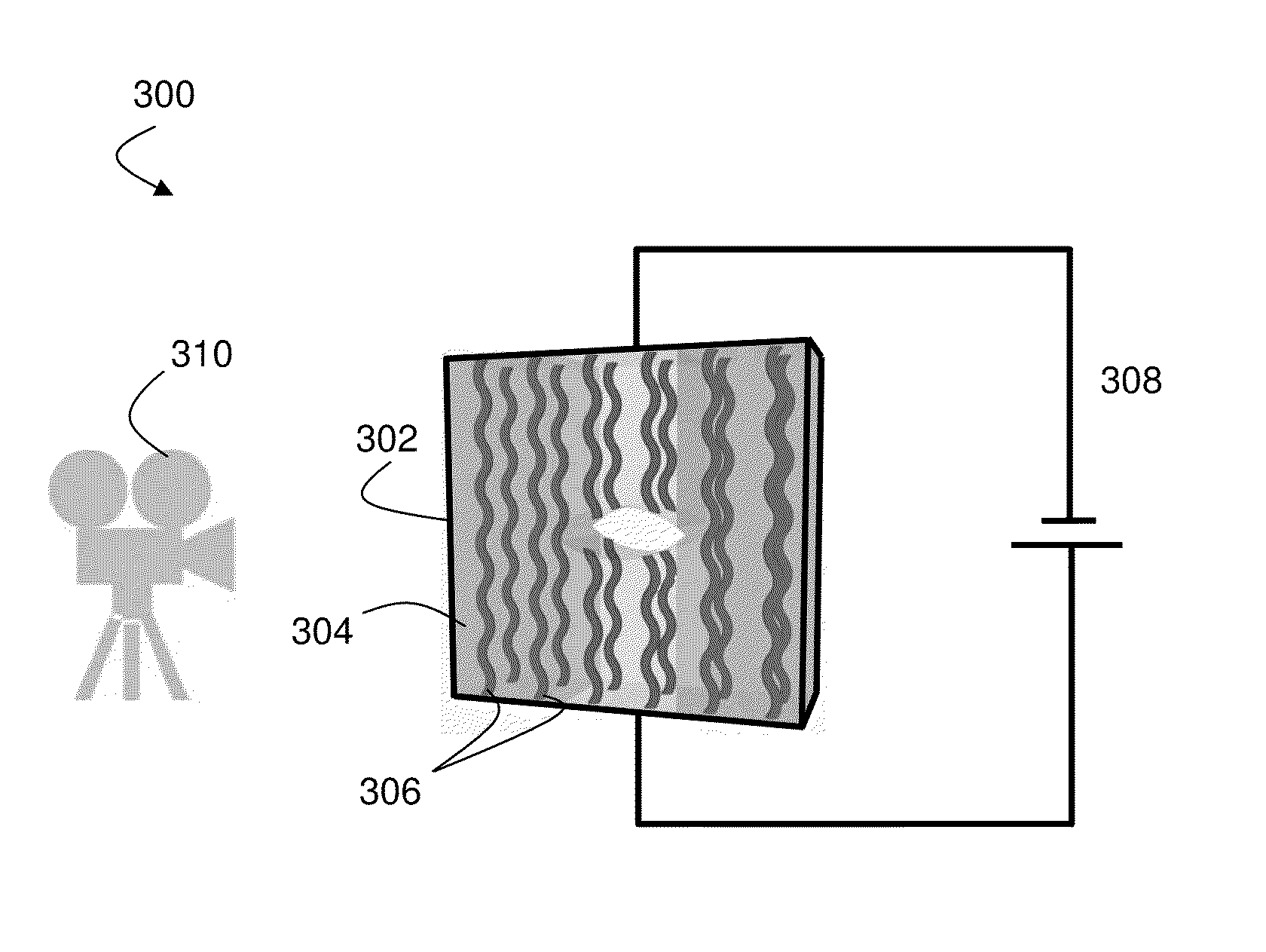

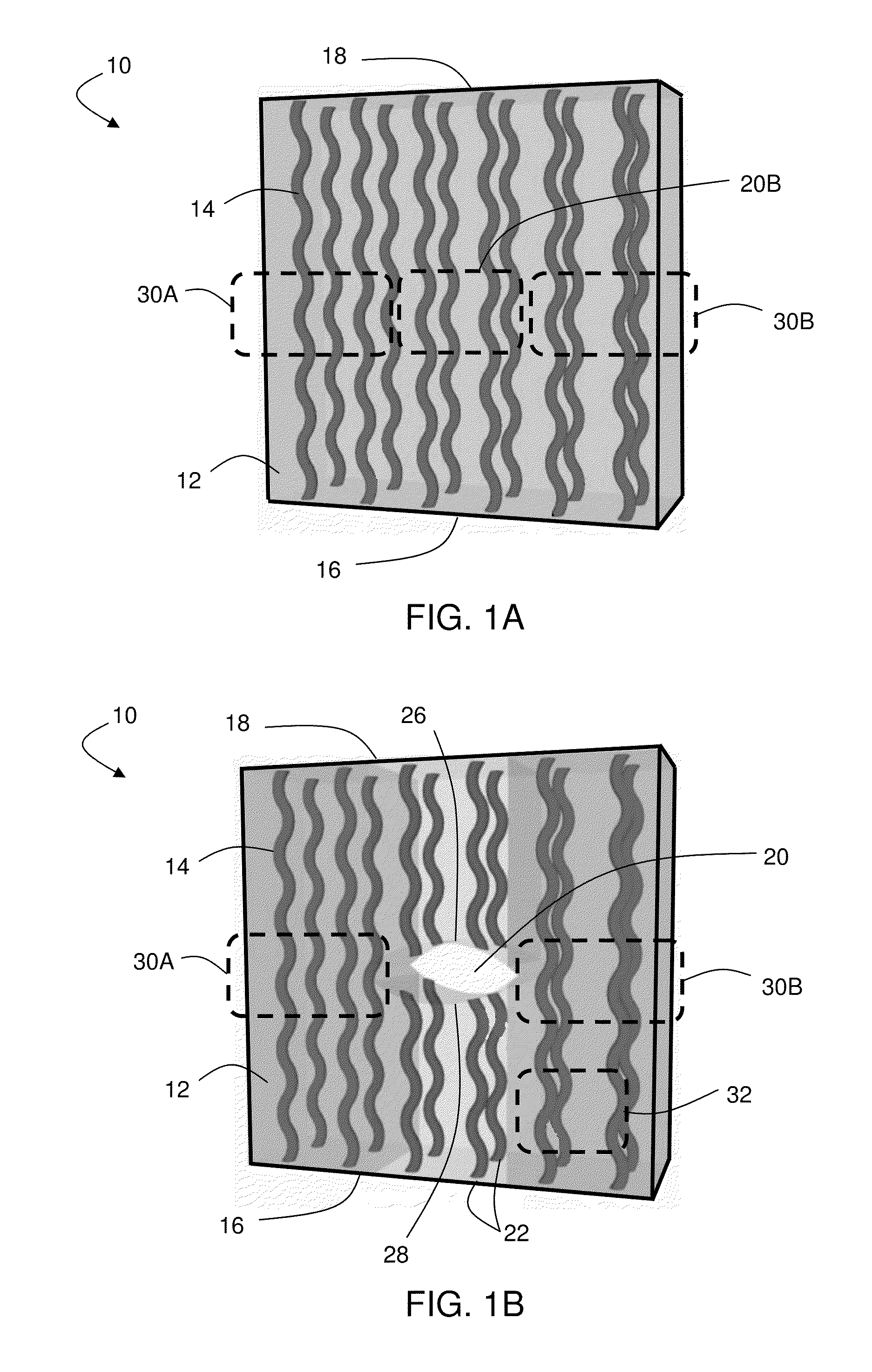

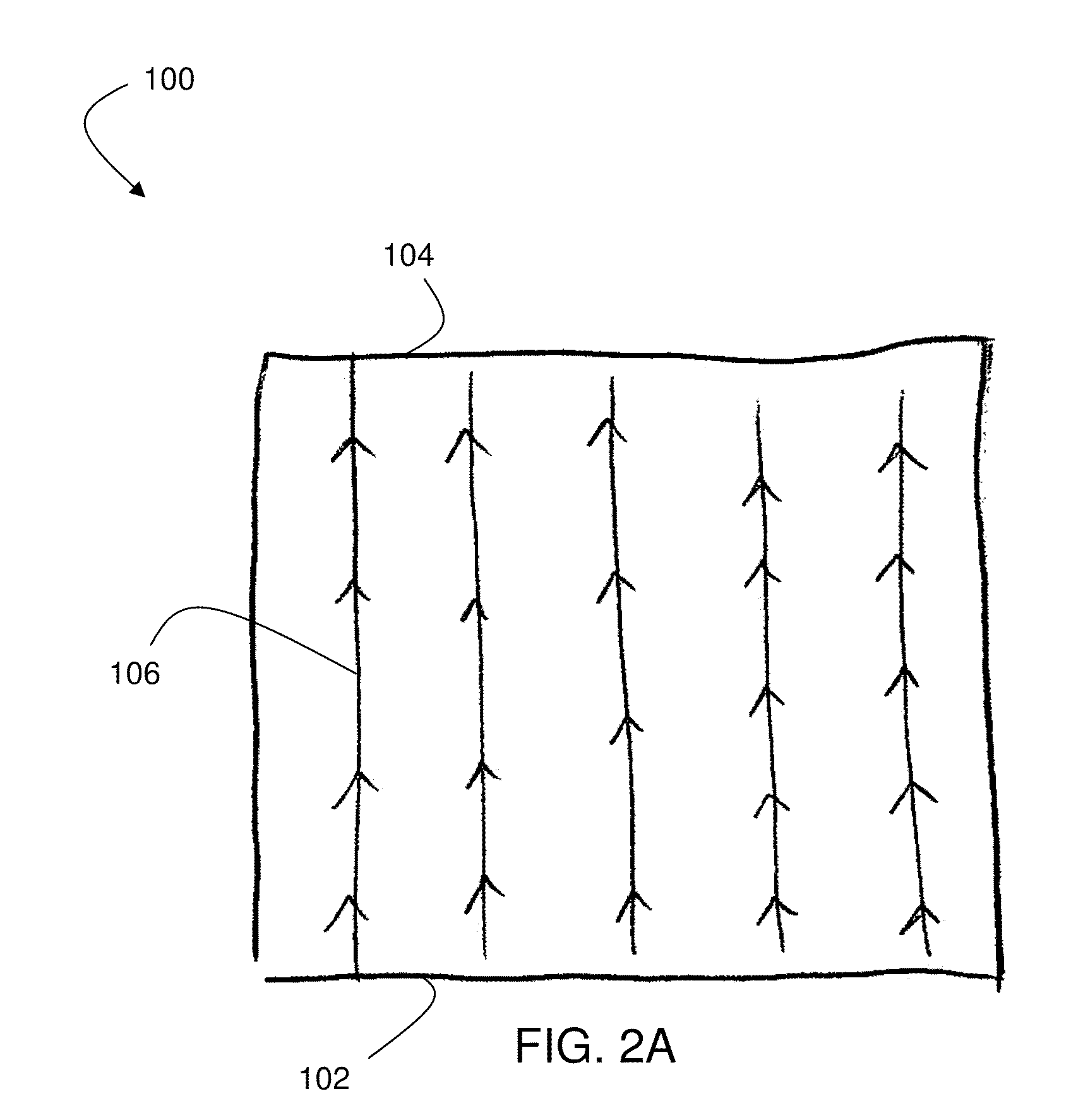

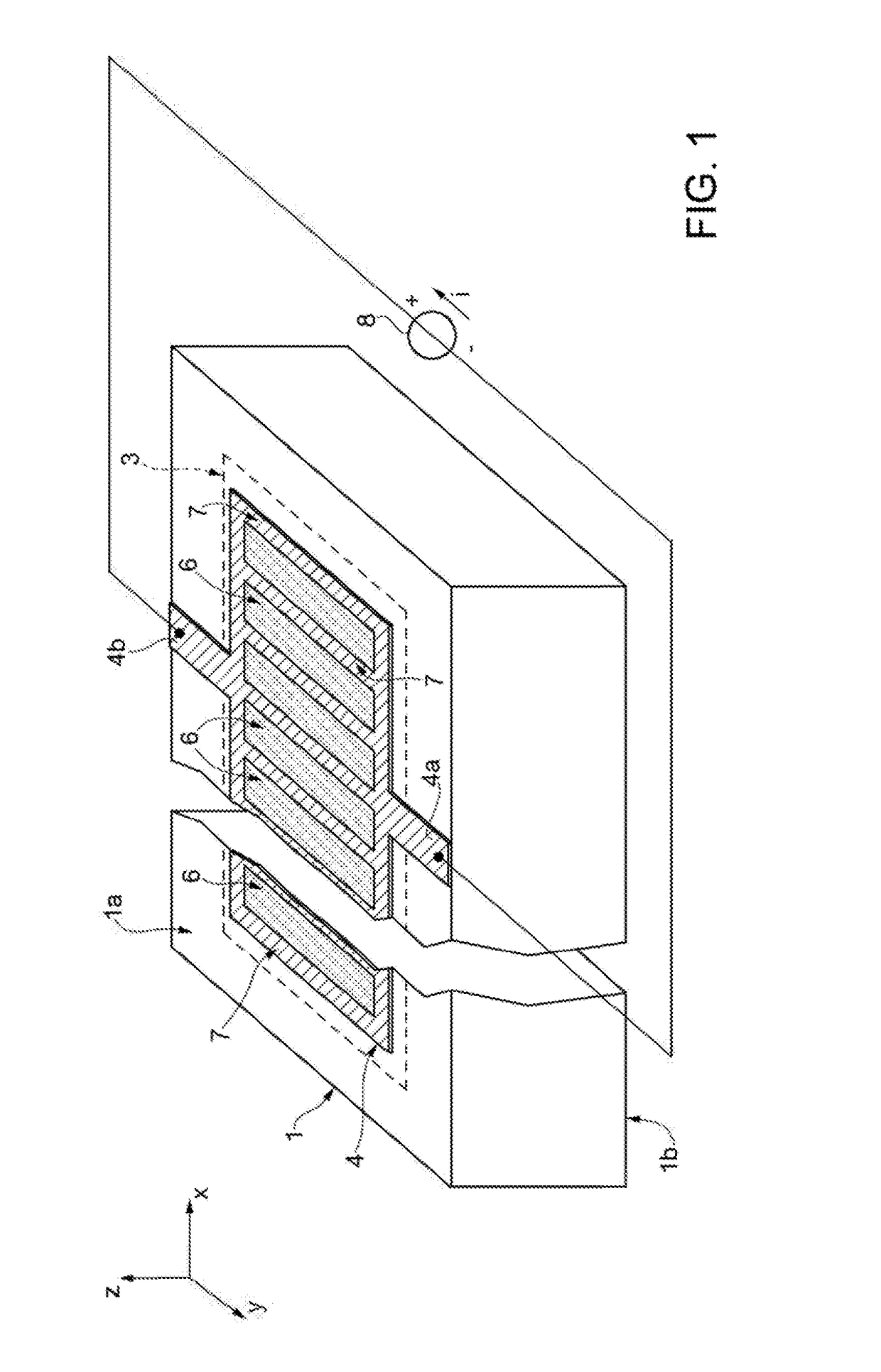

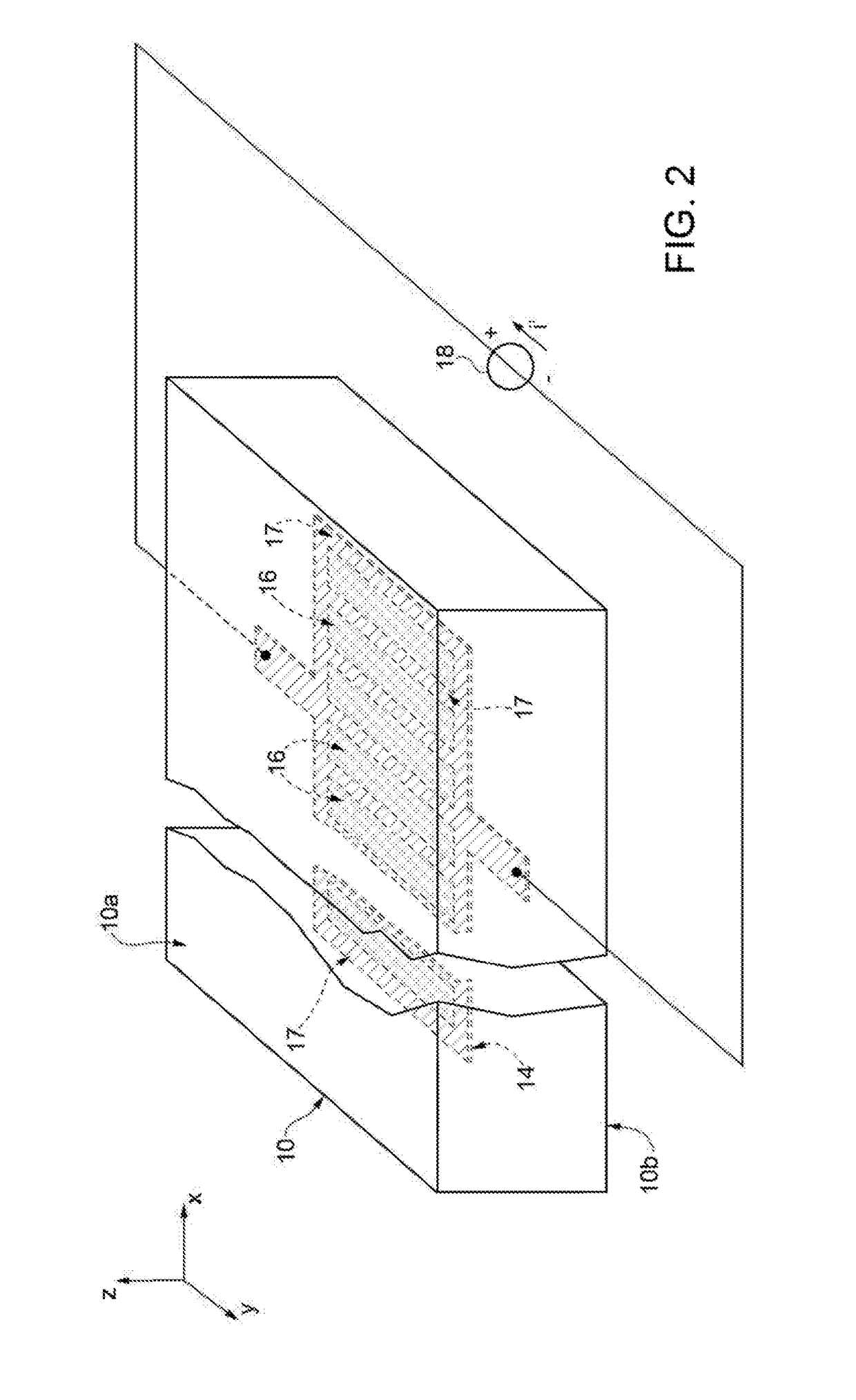

Systems and methods for structural sensing

InactiveUS20110142091A1Thermometer detailsNanosensorsElectrical resistance and conductanceEngineering

Systems and methods related to the determination of one or more mechanical characteristics of a structural element are generally described. In some embodiments, a mechanical characteristic (e.g., a crack, a deformation, an inclusion, etc.) can be determined based at least in part upon the determination of a temperature generated, for example, by passing a current through a network of structures within the structural element. For example, in some embodiments, the structural element can comprise a network of electrically conductive nanostructures and, in some cases, a primary structural material that is not substantially electrically conductive. An electrical current can be passed through the network of electrically conductive nanostructures (e.g., by passing current through an electrical circuit comprising the network of electrically conductive nanostructures). This may result in resistive heating (also known as Joule-effect heating) of the nanostructure network. In some embodiments, a first temperature of the network and / or structural elements can be determined (e.g., via a sensor associated with the electrical circuit). This first temperature can be, in some cases, indicative of a mechanical characteristic of the structural element. In some embodiments, one or more mechanical characteristics of the structural element can be determined based at least in part upon the determination of the first temperature of the structural element.

Owner:MASSACHUSETTS INST OF TECH

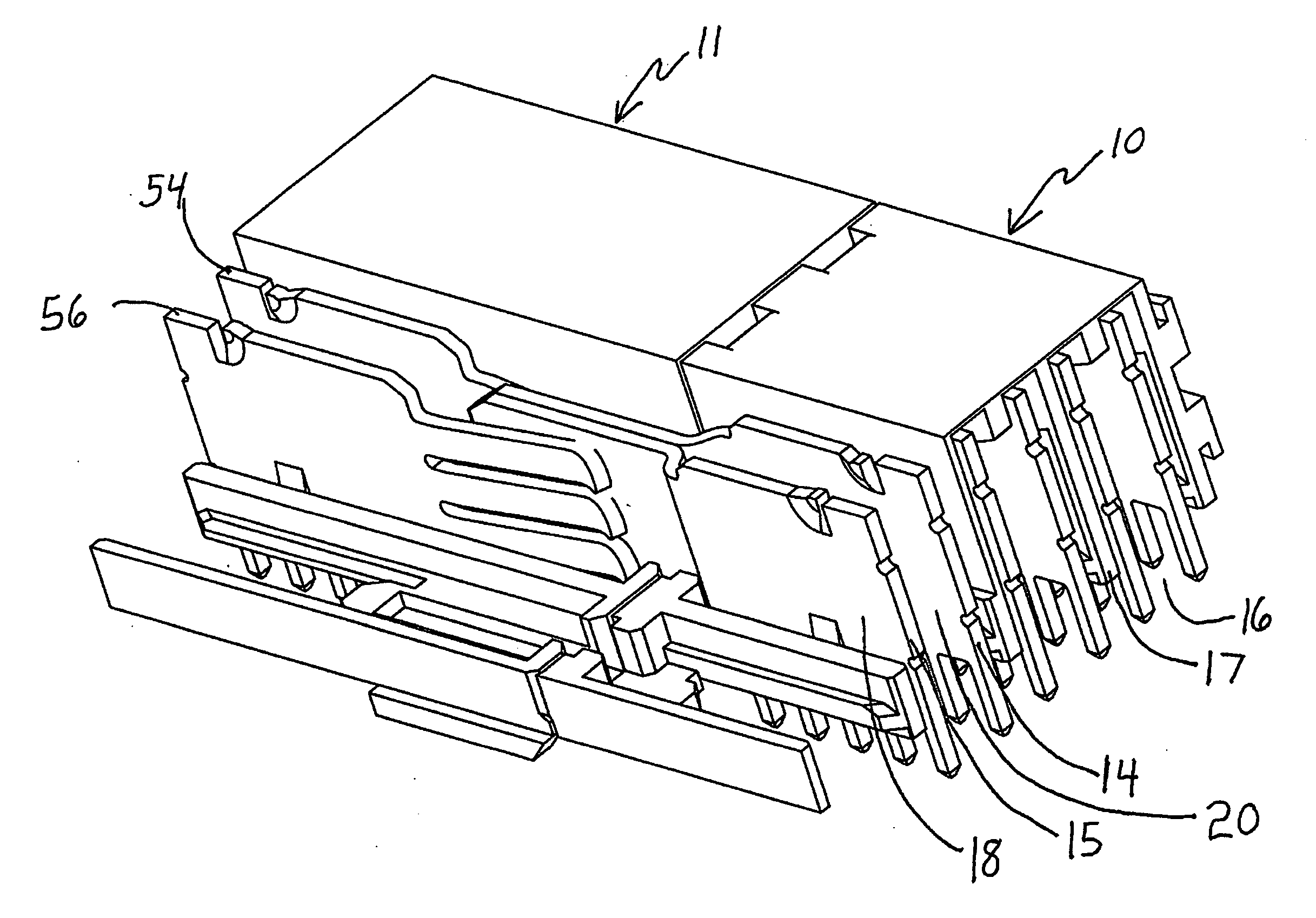

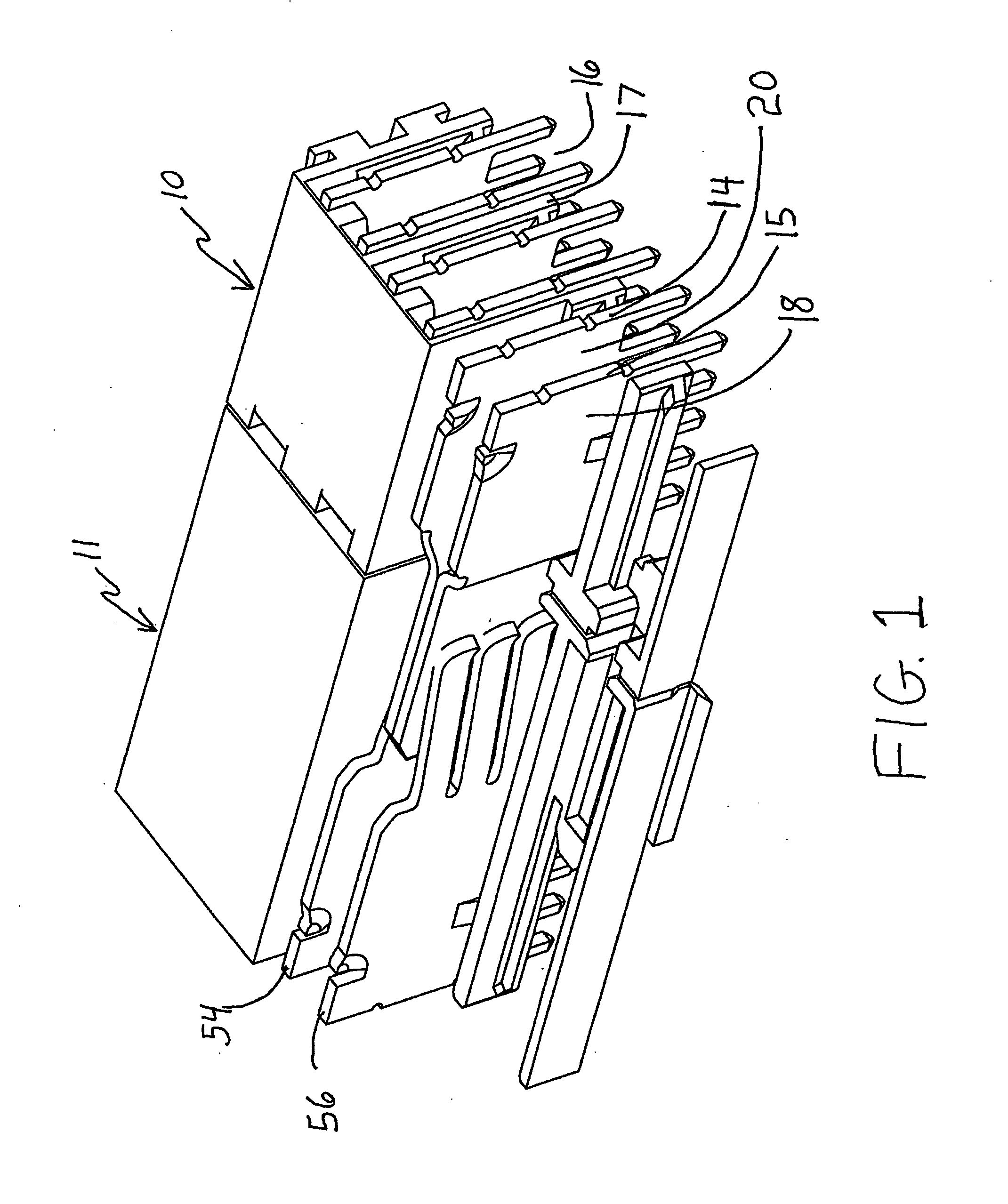

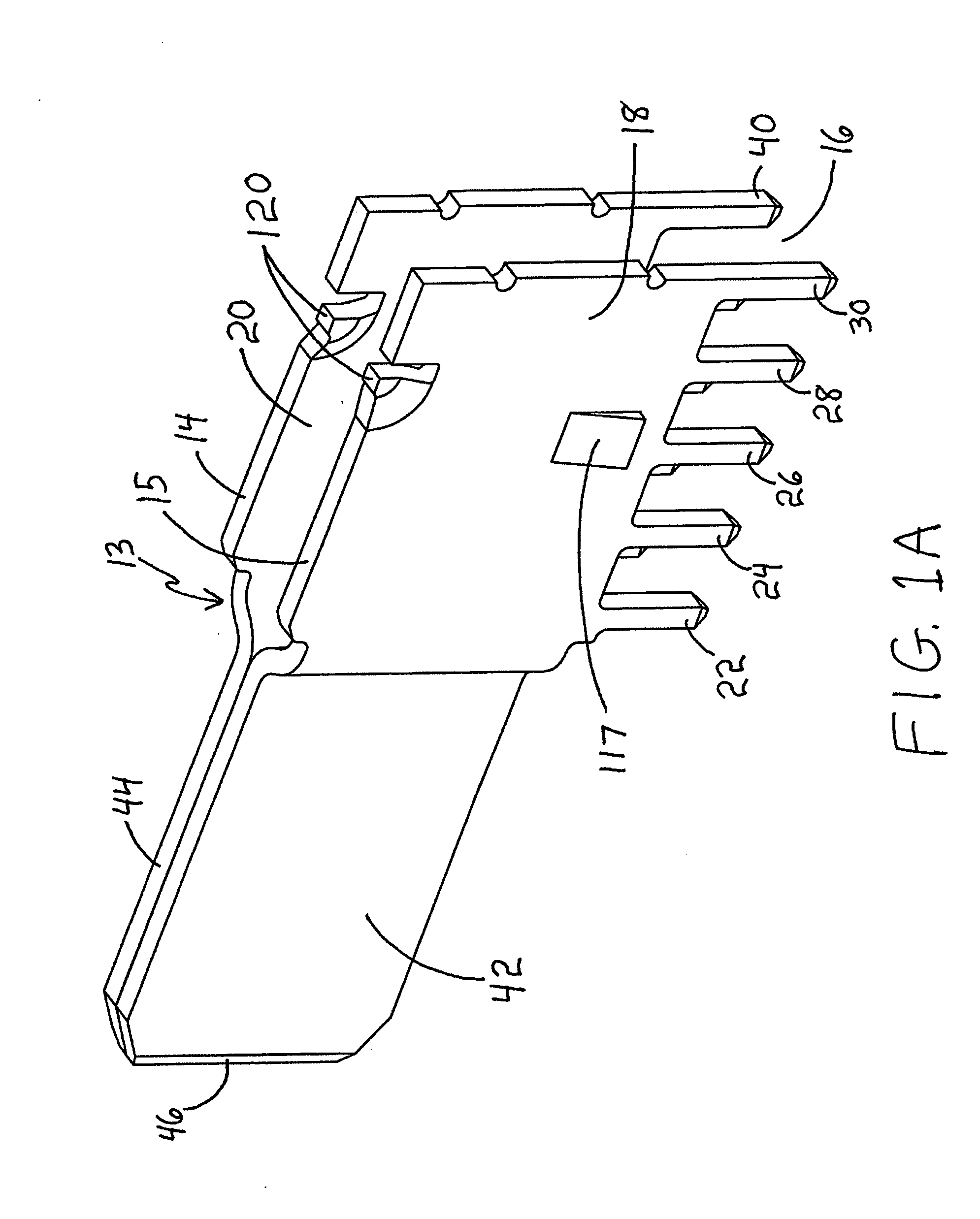

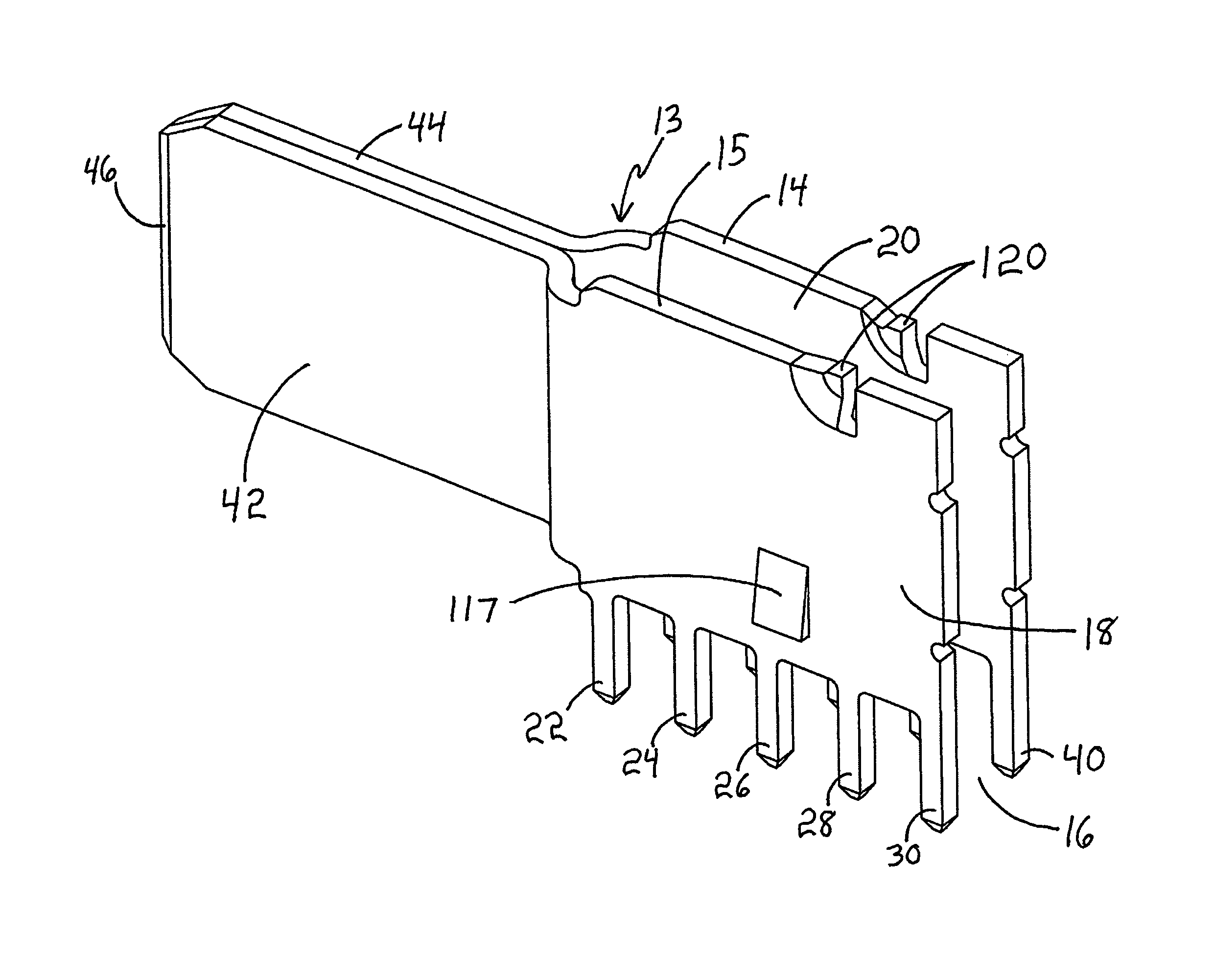

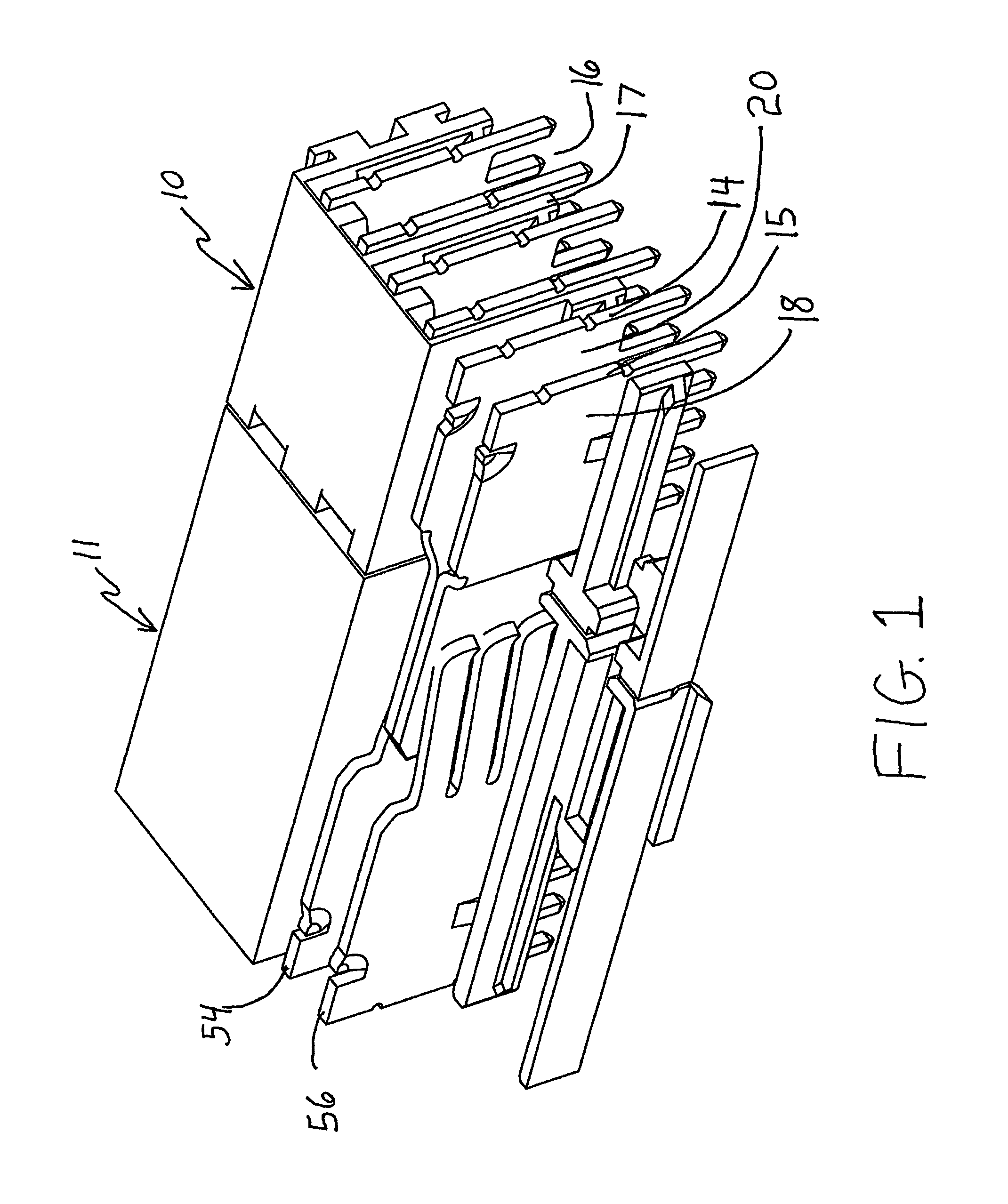

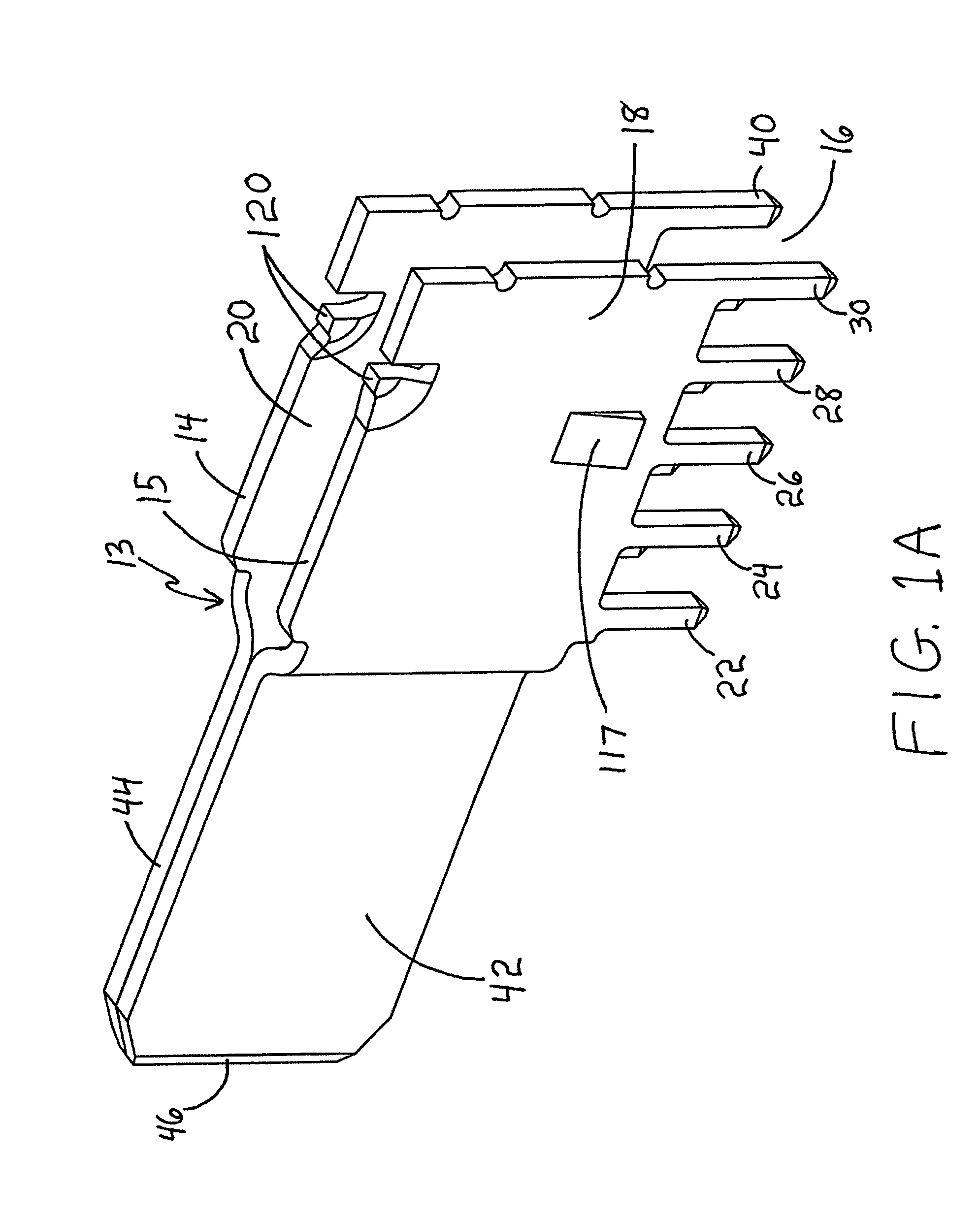

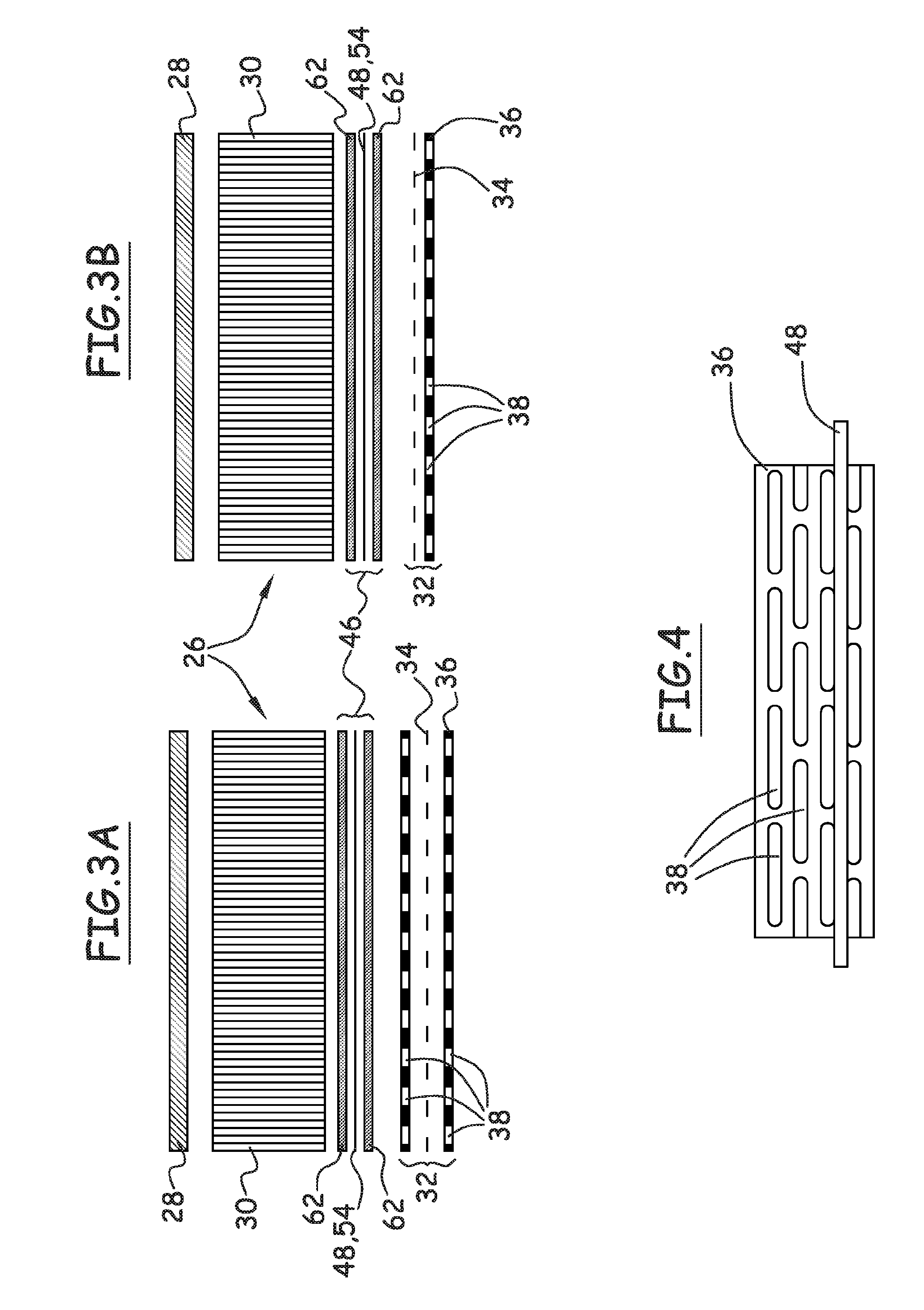

Low profile modular electrical connectors and systems

ActiveUS20090142953A1Increase current densitySacrifice of qualityElectric discharge tubesCoupling device detailsEngineeringElectrical connector

Power connector modules are provided that can be plug connectors, receptacle connectors, or a system of plug and receptacle connector modules and optionally other modules, that mate together. Each connector has an uncoupled contact feature. The uncoupled contacts have exposed surfaces to dissipate heat resulting from Joule effects. The uncoupled contacts for the plug connector converge to form a blade structure at one side. The uncoupled contacts for the receptacle connector form a receiving section that engages the blade structure of the plug connector when the plug connector and receptacle connector are used together.

Owner:MOLEX INC

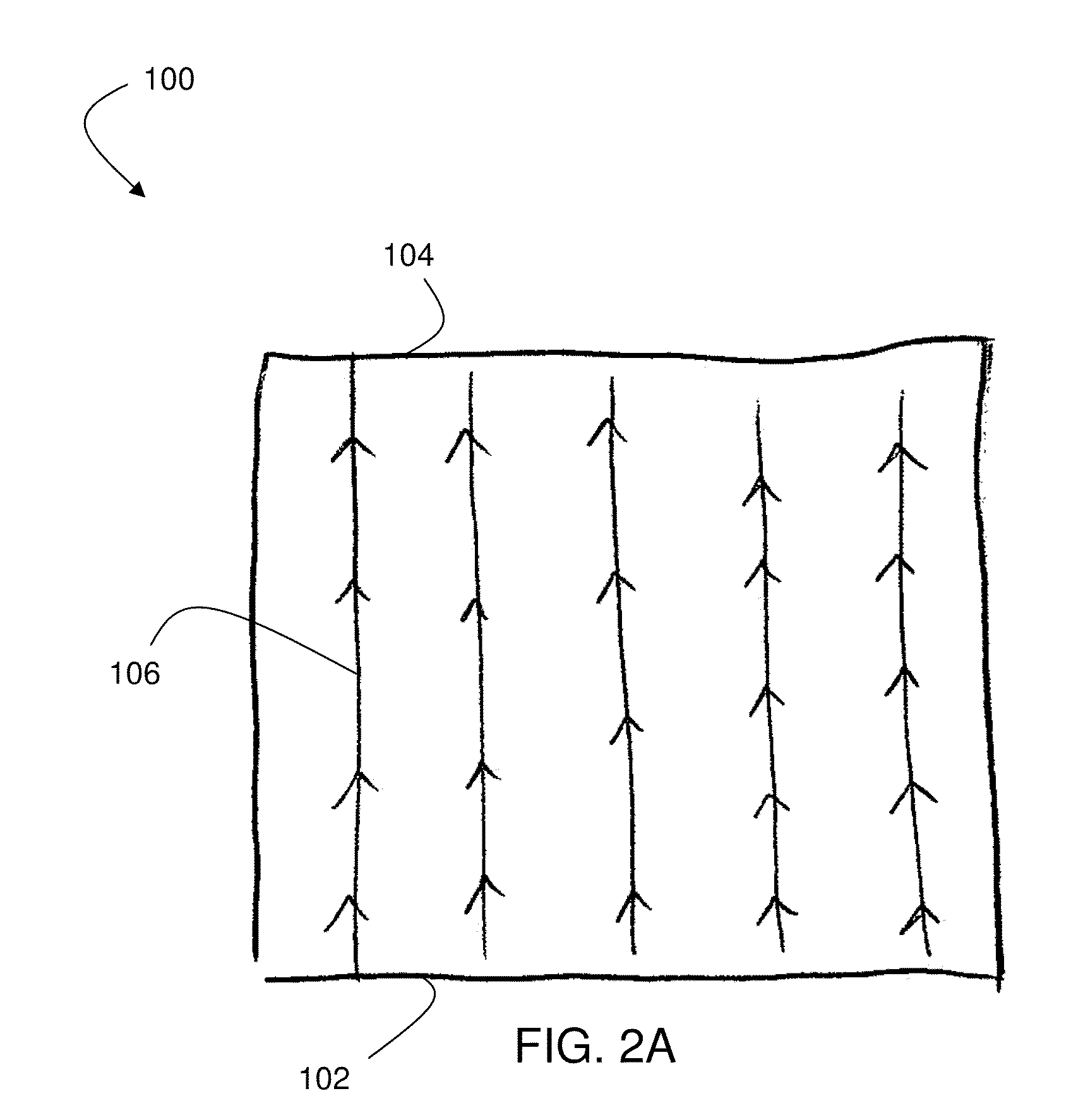

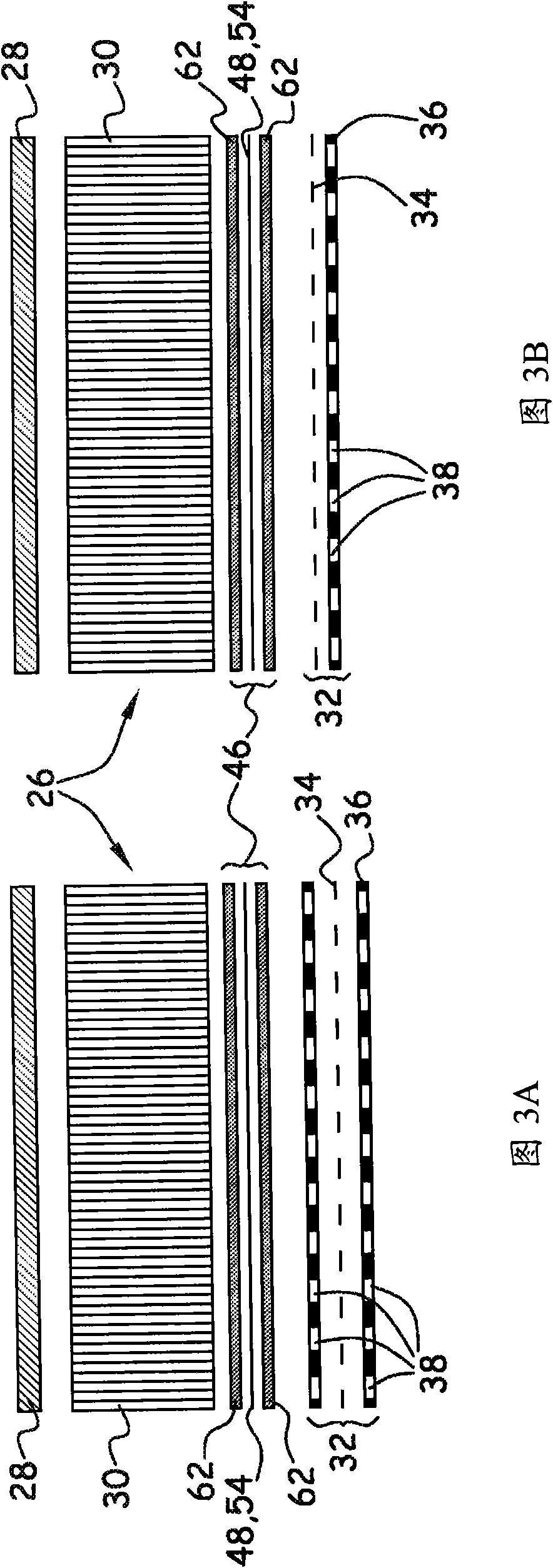

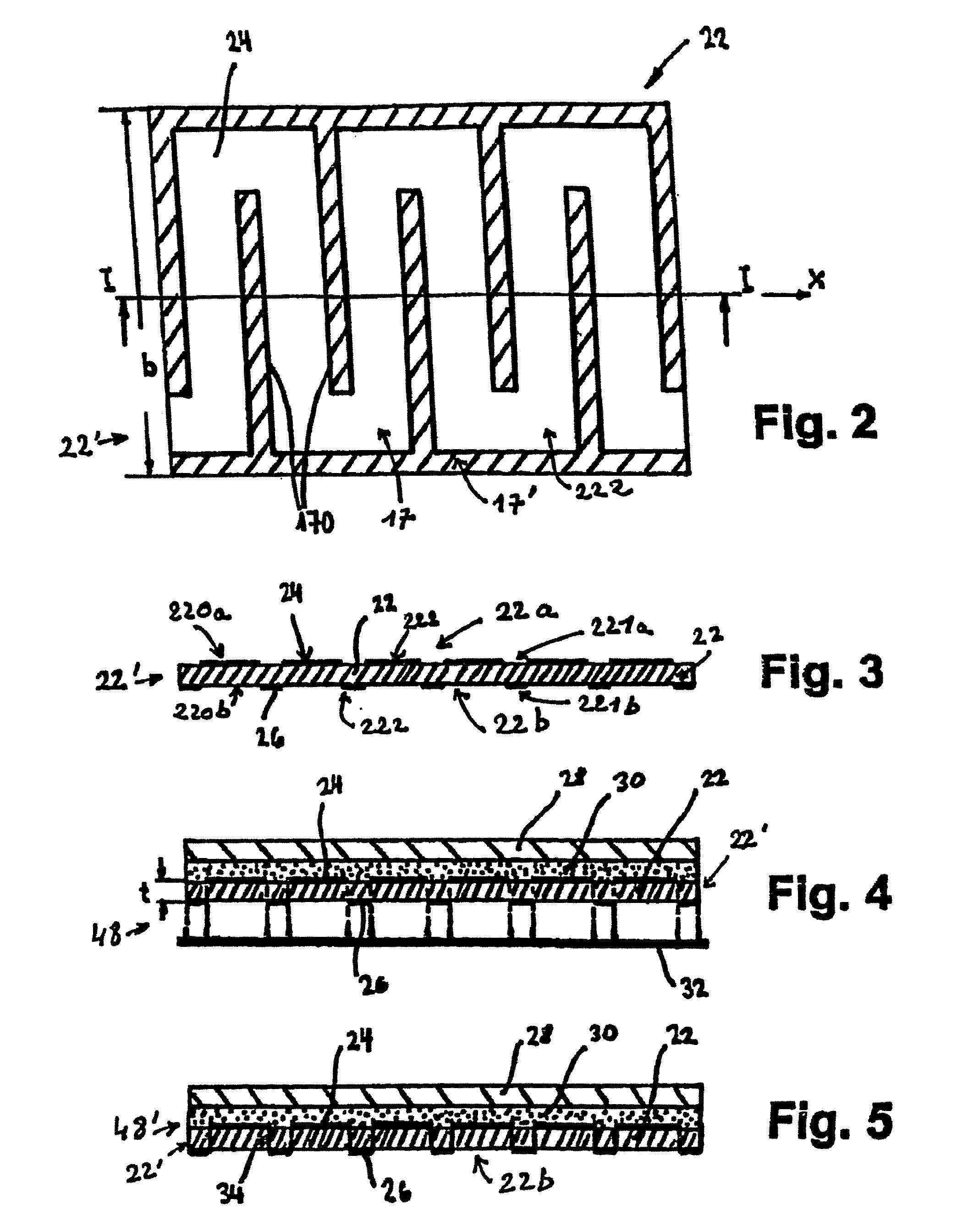

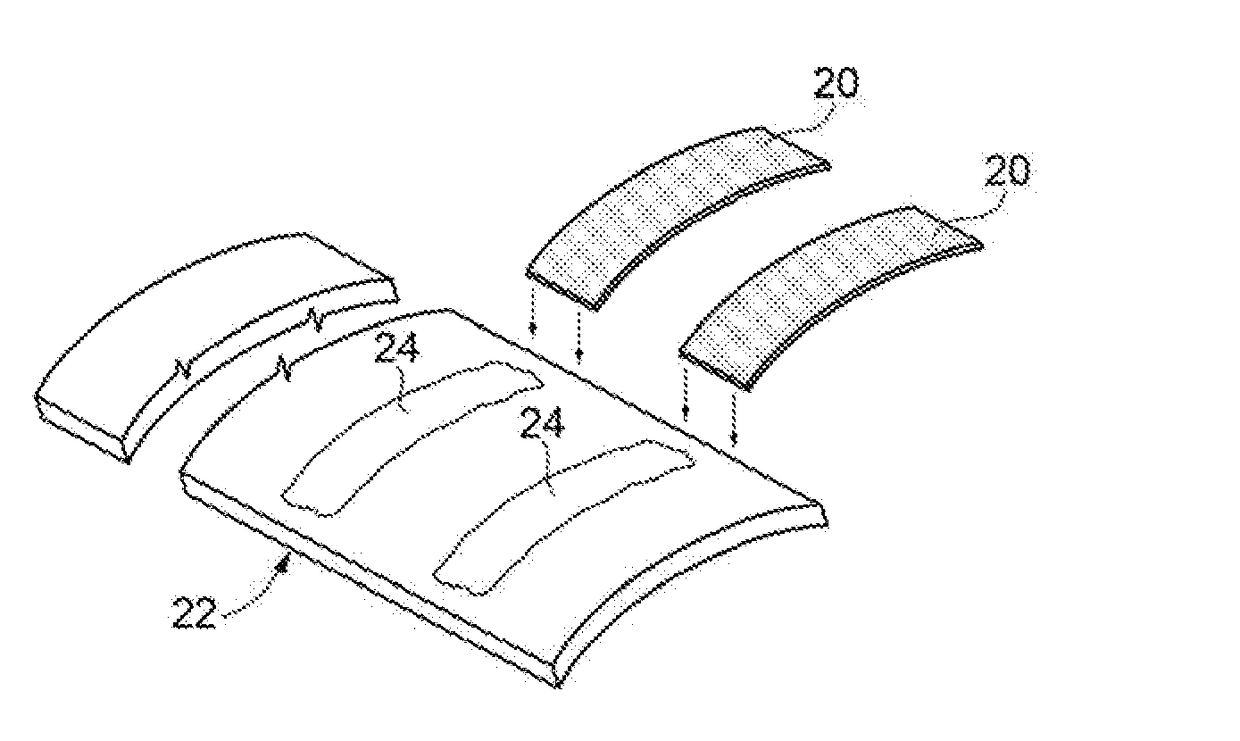

Heater mat made of electrically-conductive fibers

A heater mat for using the Joule effect to heat an aerodynamic surface. The heater mat is provided with a resistor element including at least two substantially parallel segments of electrically-conductive fibers disposed on the aerodynamic surface. The segments come from a single strip of electrically-conductive fibers, with two adjacent segments being obtained by folding a portion of the single strip at least twice.

Owner:EUROCOPTER

Low profile modular electrical connectors and systems

ActiveUS7976317B2High trafficNo sacrifice of quality and power handlingElectric discharge tubesCoupling device detailsComputer moduleEngineering

Power connector modules are provided that can be plug connectors, receptacle connectors, or a system of plug and receptacle connector modules and optionally other modules, that mate together. Each connector has an uncoupled contact feature. The uncoupled contacts have exposed surfaces to dissipate heat resulting from Joule effects. The uncoupled contacts for the plug connector converge to form a blade structure at one side. The uncoupled contacts for the receptacle connector form a receiving section that engages the blade structure of the plug connector when the plug connector and receptacle connector are used together.

Owner:MOLEX INC

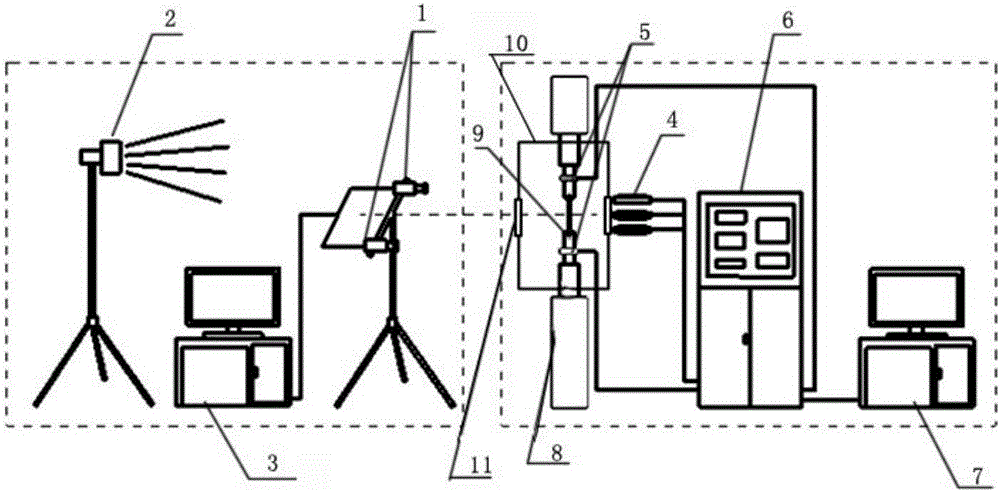

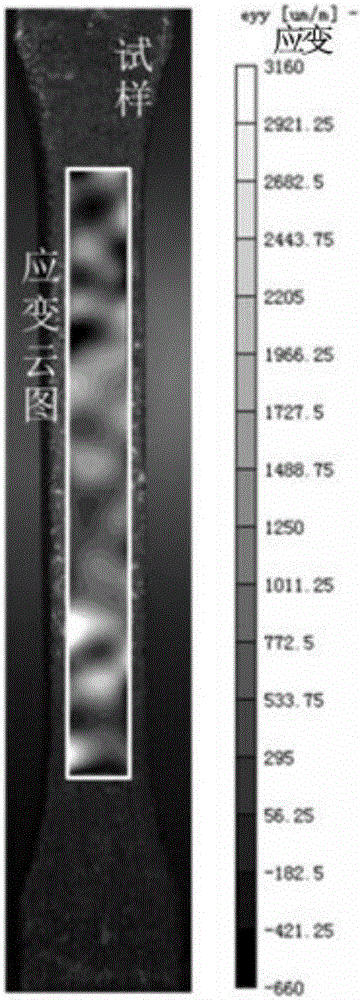

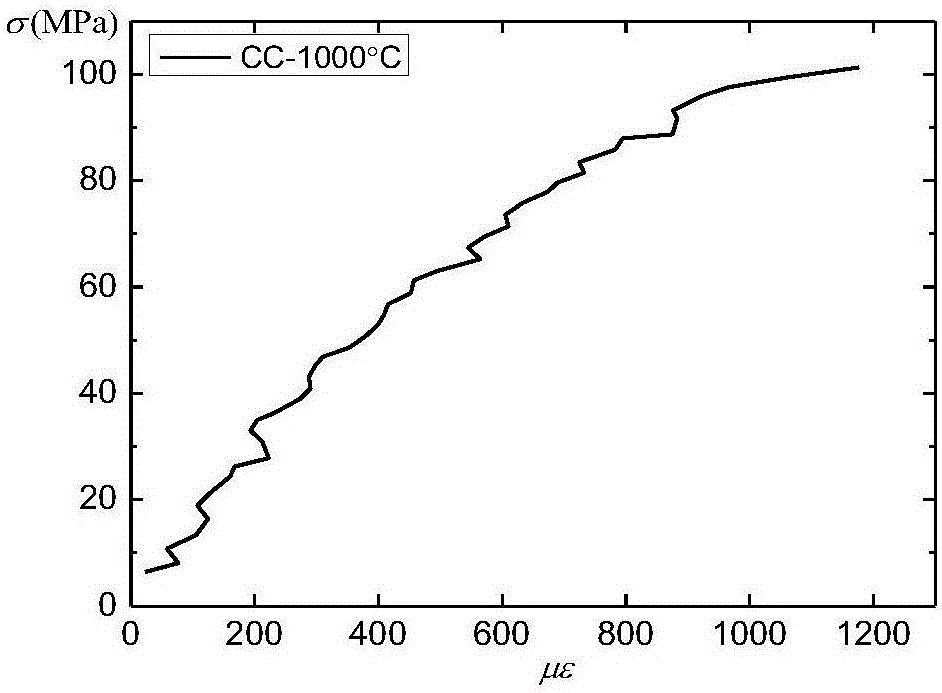

System and method for testing mechanical properties of conductor material at high-temperature vacuum environment

ActiveCN106769525ARealize strain full field testImprove test efficiencyMaterial analysis by optical meansMaterial strength using tensile/compressive forcesElectrical conductorLow voltage

The invention provides a system and method for testing mechanical properties of a conductor material at a high-temperature vacuum environment. According to the system and the method, the problems that the high-temperature strain is difficult to test, the sample heating efficiency is low, and the like are solved. The system comprises a high-temperature strain test subsystem, a temperature control subsystem and a loading subsystem; and a stretch process is carried out in a vacuum environmental chamber, and a sample is loaded by virtue of a mechanical test machine. According to the method, a Joule effect is adopted, a material is put into the vacuum environmental chamber, the normal temperature absolute vacuum degree can reach 0.025Pa, low voltage and high current are introduced to the conductor material so as to rapidly heat the sample, the loading is carried out after reaching a target temperature, meanwhile, data collection is carried out on a high-temperature deformation field by virtue of a DIC strain test technique so as to obtain a strain field of a whole sample scale distance section and a displacement-load curve of the sample, and subsequent processing is carried out so as to obtain high-temperature tensile / compression modulus and tensile strength of the sample. The system and the method have the advantages of high heating speed, uniform temperature field, high deformation measurement precision and the like.

Owner:HARBIN INST OF TECH

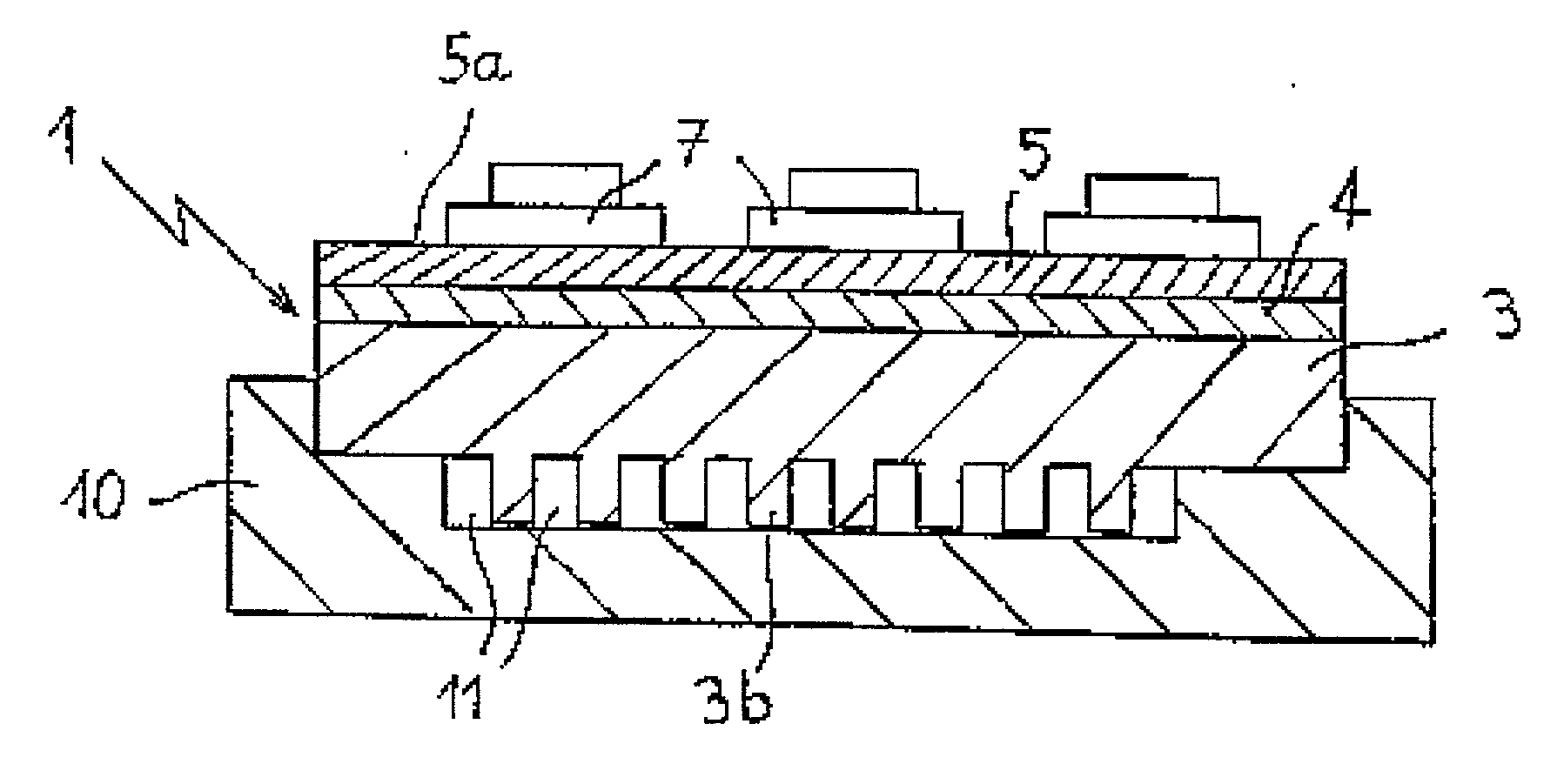

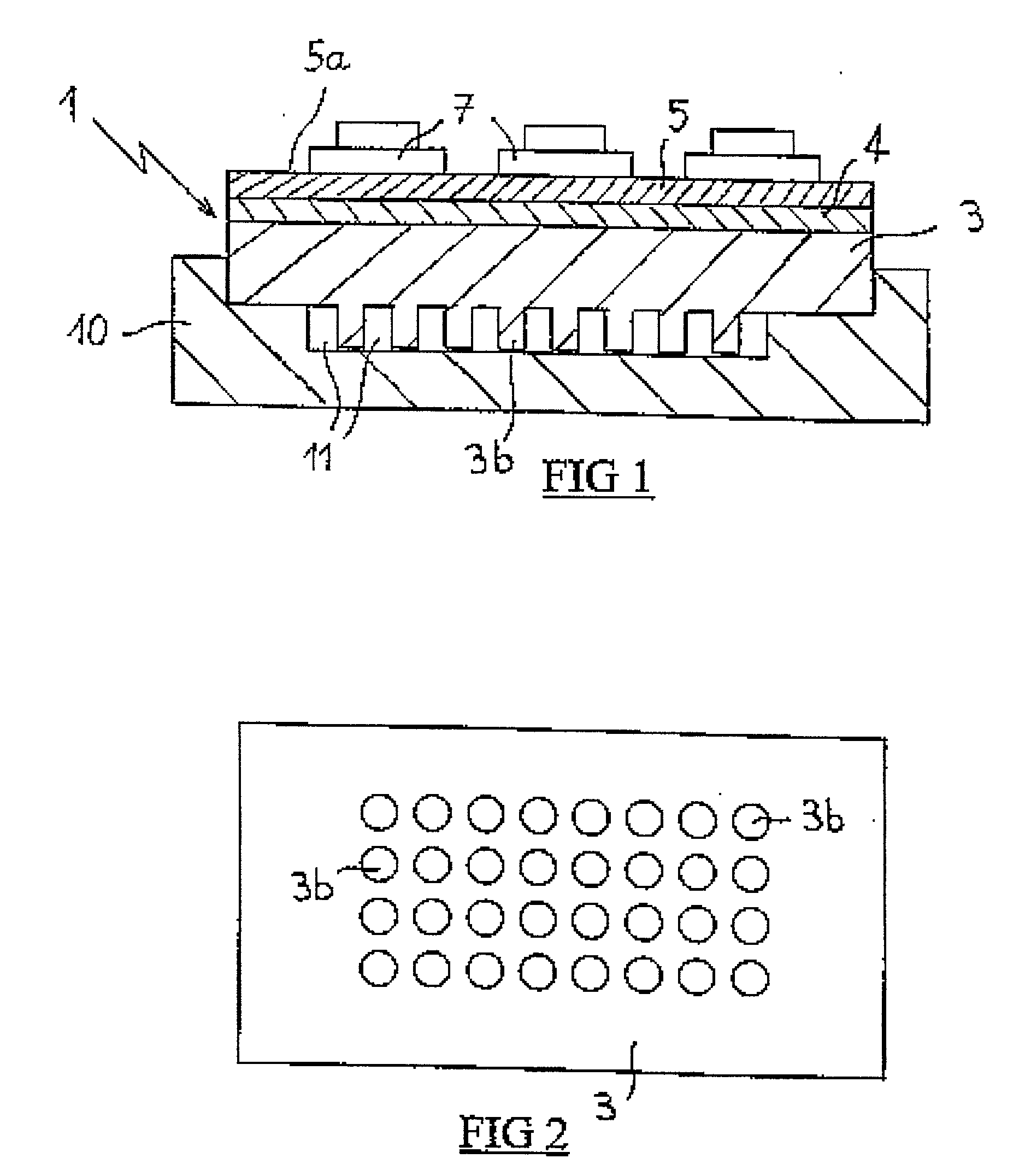

Power module having electronic power components, and a method of manufacturing such a module

InactiveUS20020001177A1Improve cooling effectReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

power module having electronic power components, the module comprising a soleplate constituting a heat exchanger for dumping the power dissipated by the Joule effect in said power components, wherein said soleplate has a face that is provided with a skin of aluminum alloy, said skin being covered in an insulating layer of aluminum oxide obtained by anodizing said skin, said insulating layer constituting a substrate on which metallized tracks are made in order to receive said electronic components, the other face of said soleplate being in contact with a cooling fluid.

Owner:ALSTOM SA

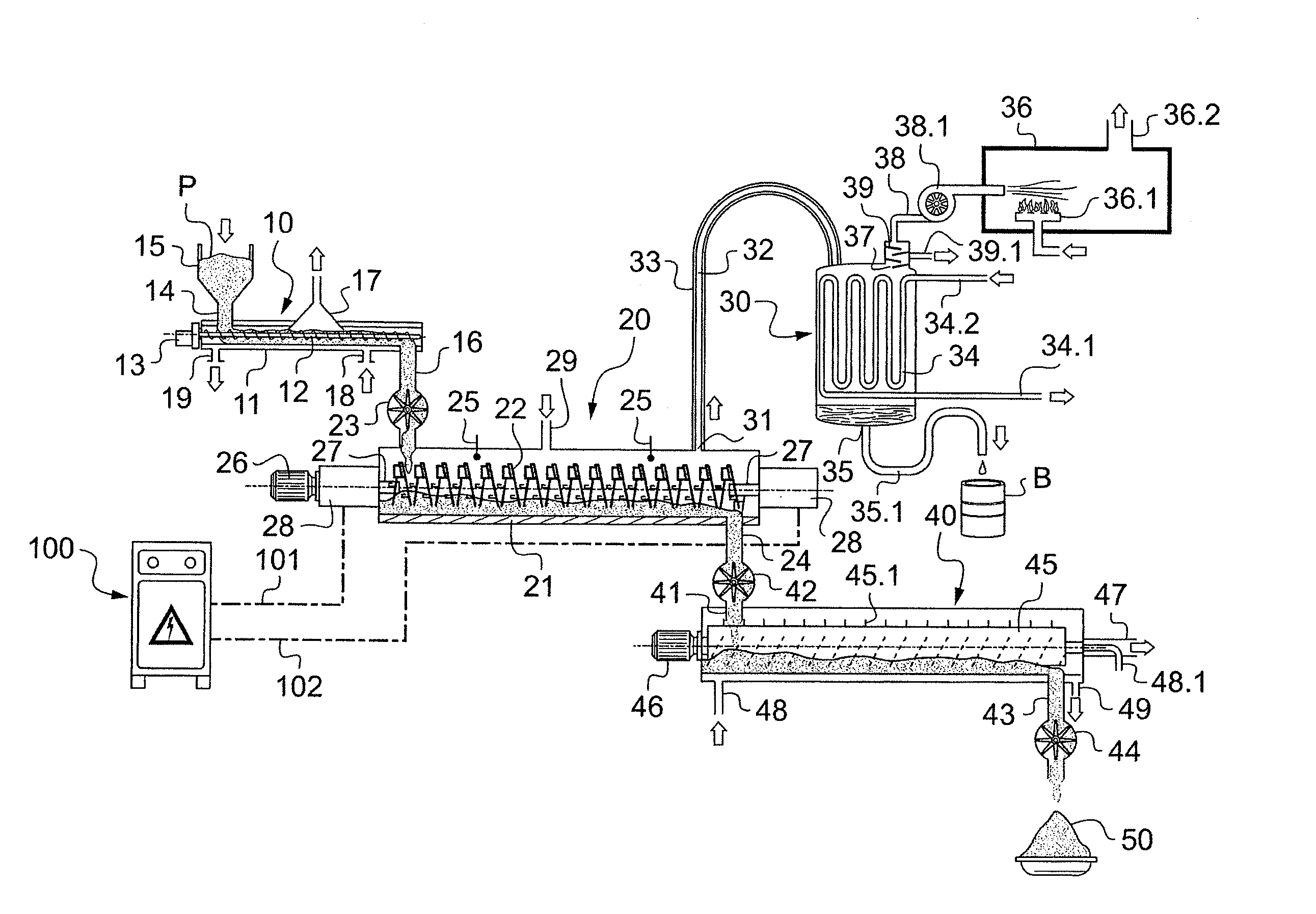

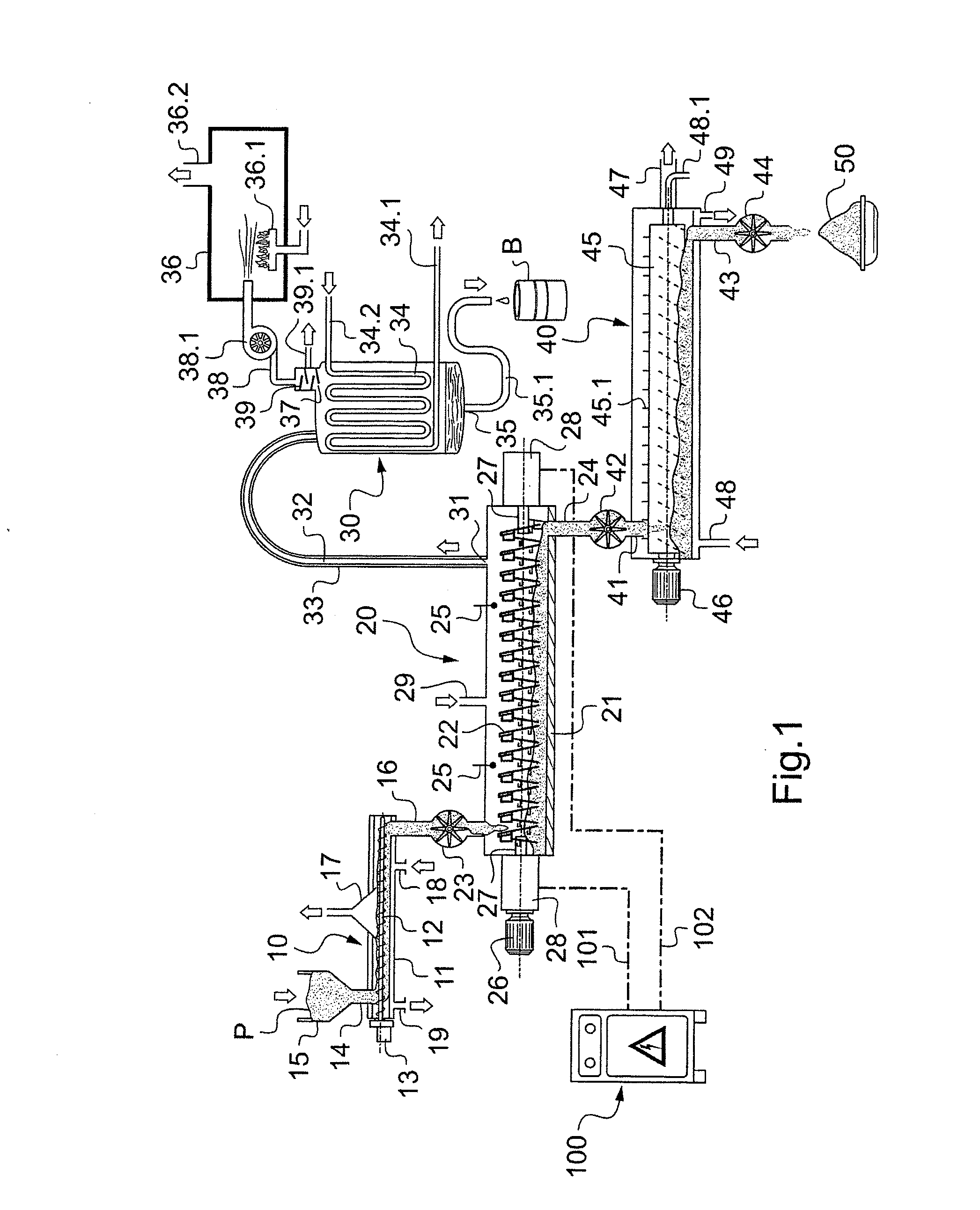

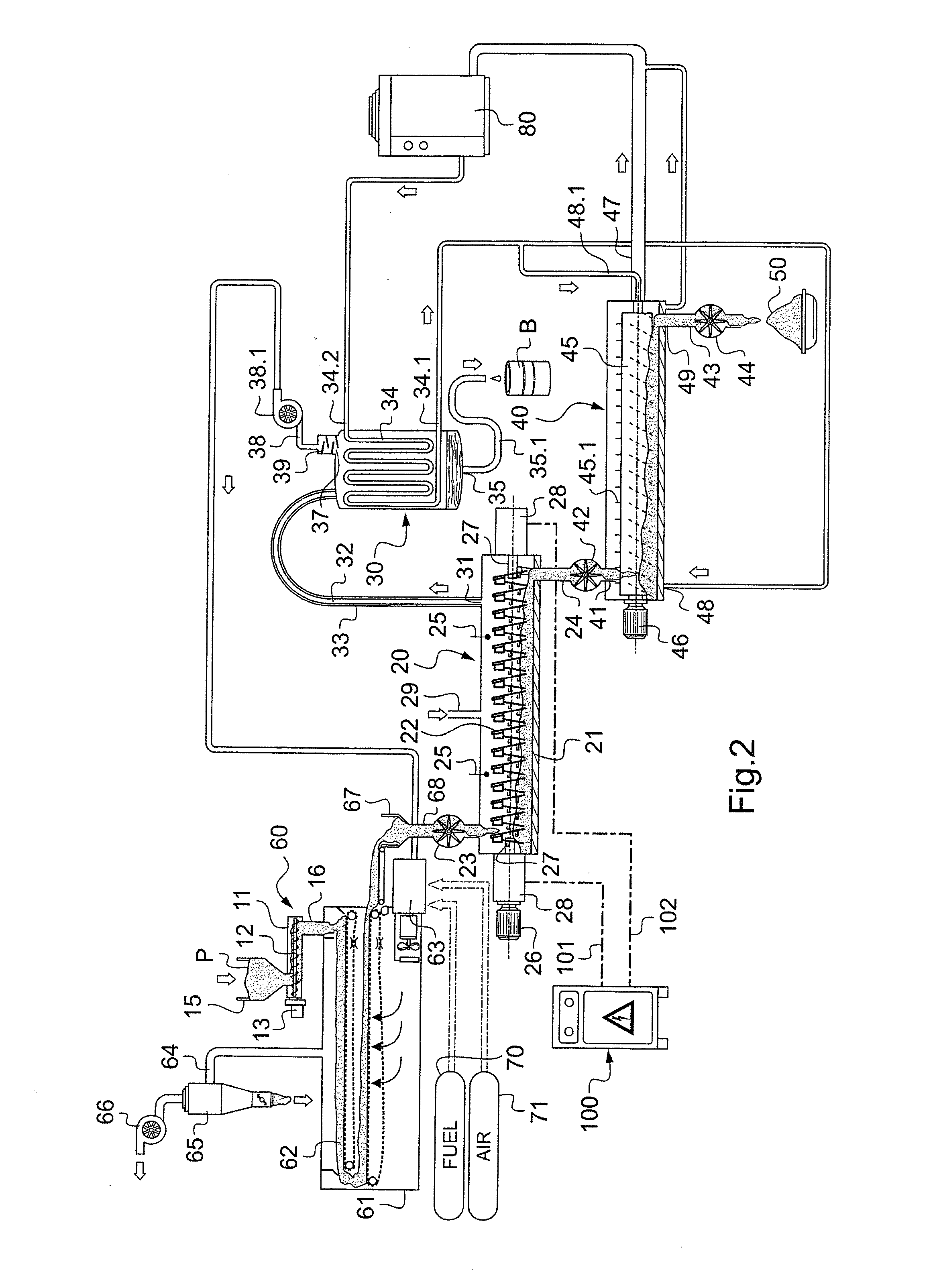

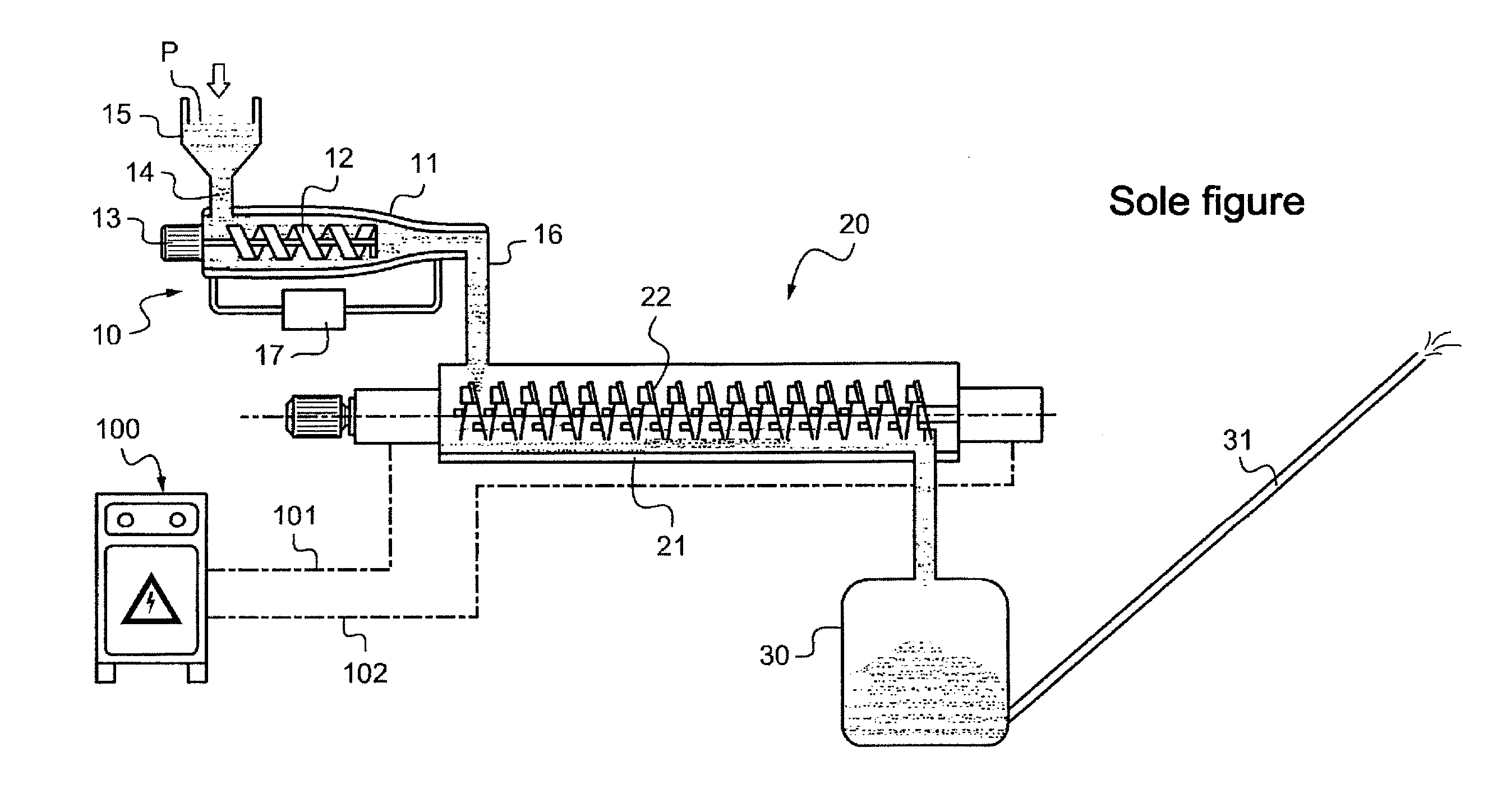

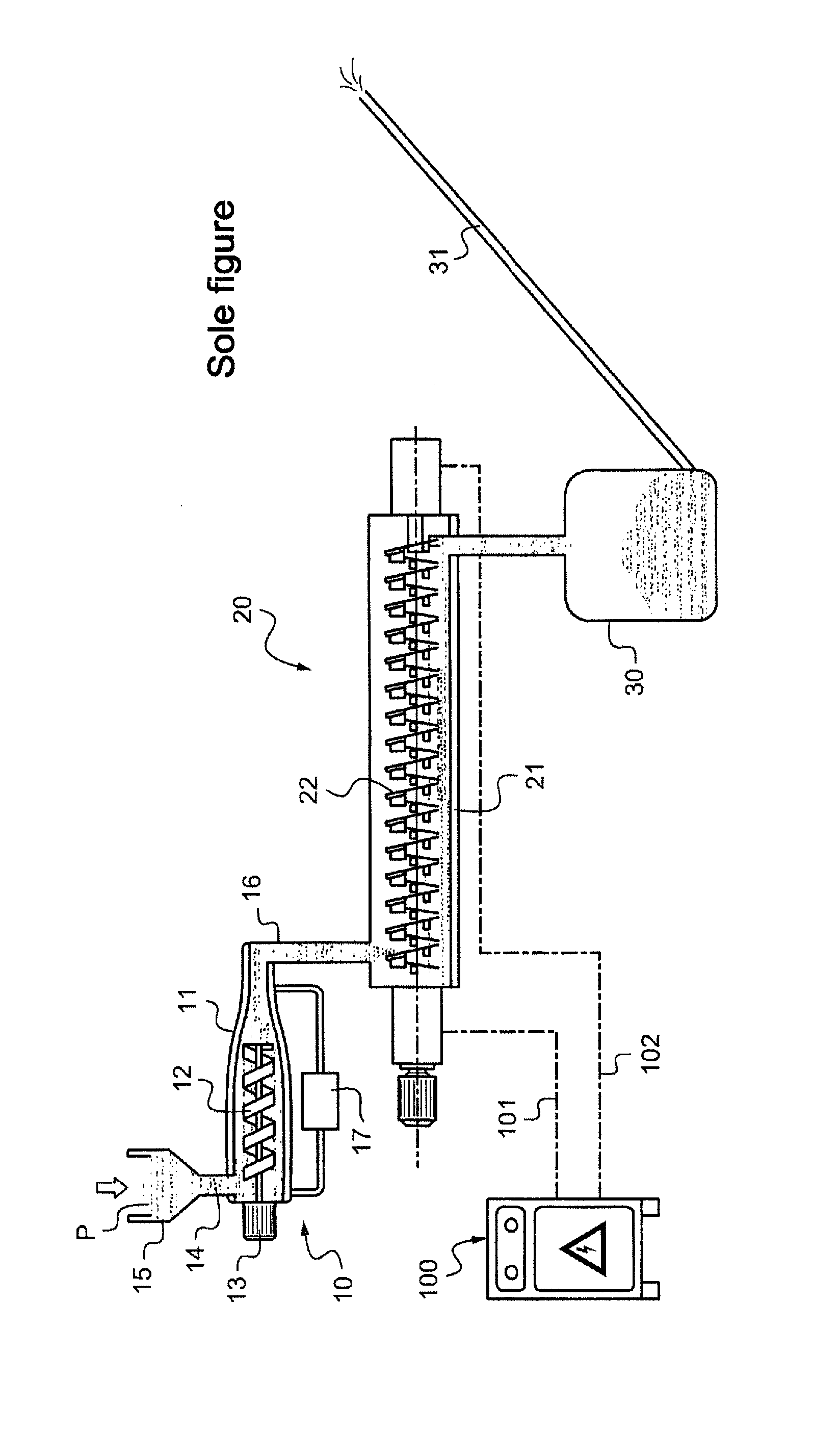

Method and apparatus for the energy densification of a material in the form of divided solids, with a view to obtaining pyrolysis oils for energy purposes

ActiveUS20120043194A1High calorific valueImprove operating conditionsMechanical conveying coke ovensElectrical coke oven heatingPre treatmentRelative humidity

A method and installation for energy densification of a material to obtain pyrolytic oils for energy. The method includes preconditioning the material by heating and drying to raise the material temperature close to 100° C. and a relative humidity not exceeding about 10%; pyrolyzing the material that is subsequently caused to flow through a substantially hermetic reactor containing at least one transfer screw or vibrating tube heated by the Joule effect, the material heated progressively in the range of 300° C. to 850° C., the electrical power passing through the transfer screw or the vibrating tube for providing heating regulated as a function of the material in order to obtain the desired temperature level during the transit time of the material through the reactor; extracting pyrolysis gas from a high portion of the reactor for rapid recondensation in a vertical condenser; and recovering pyrolytic oils from a low portion of the vertical condenser.

Owner:LEPEZ CONSEILS FINANCE INNOVATIONS LCFI +1

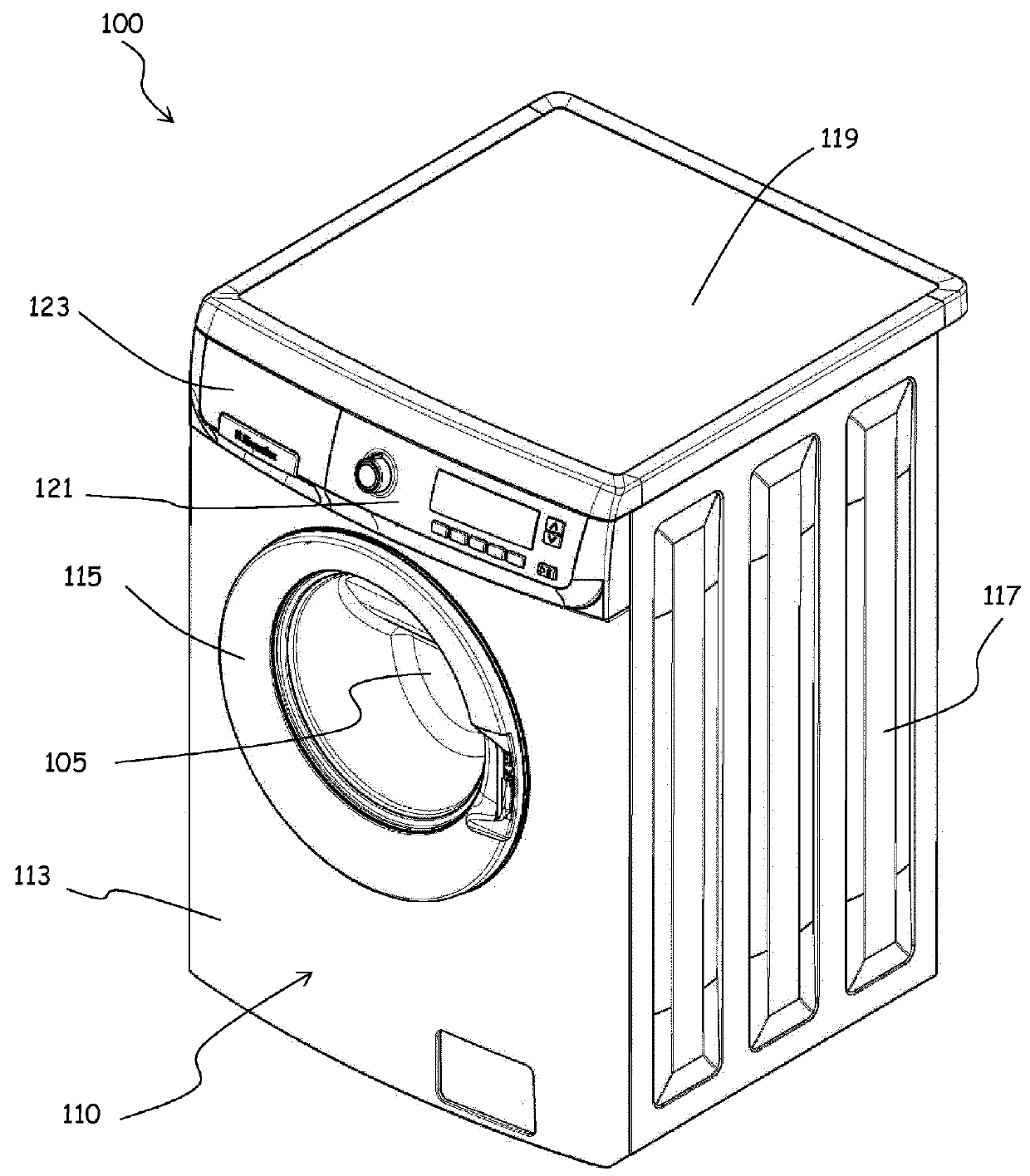

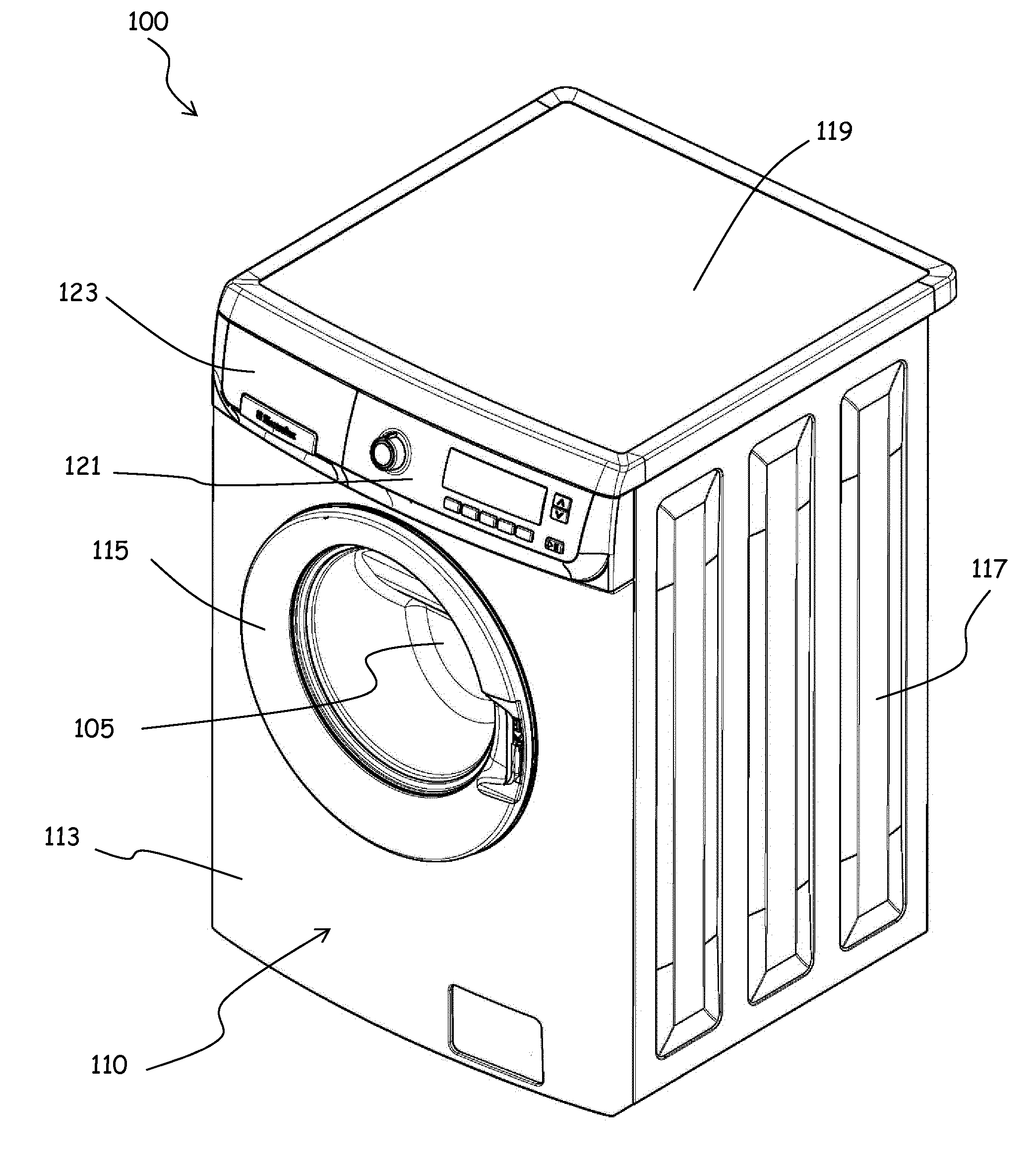

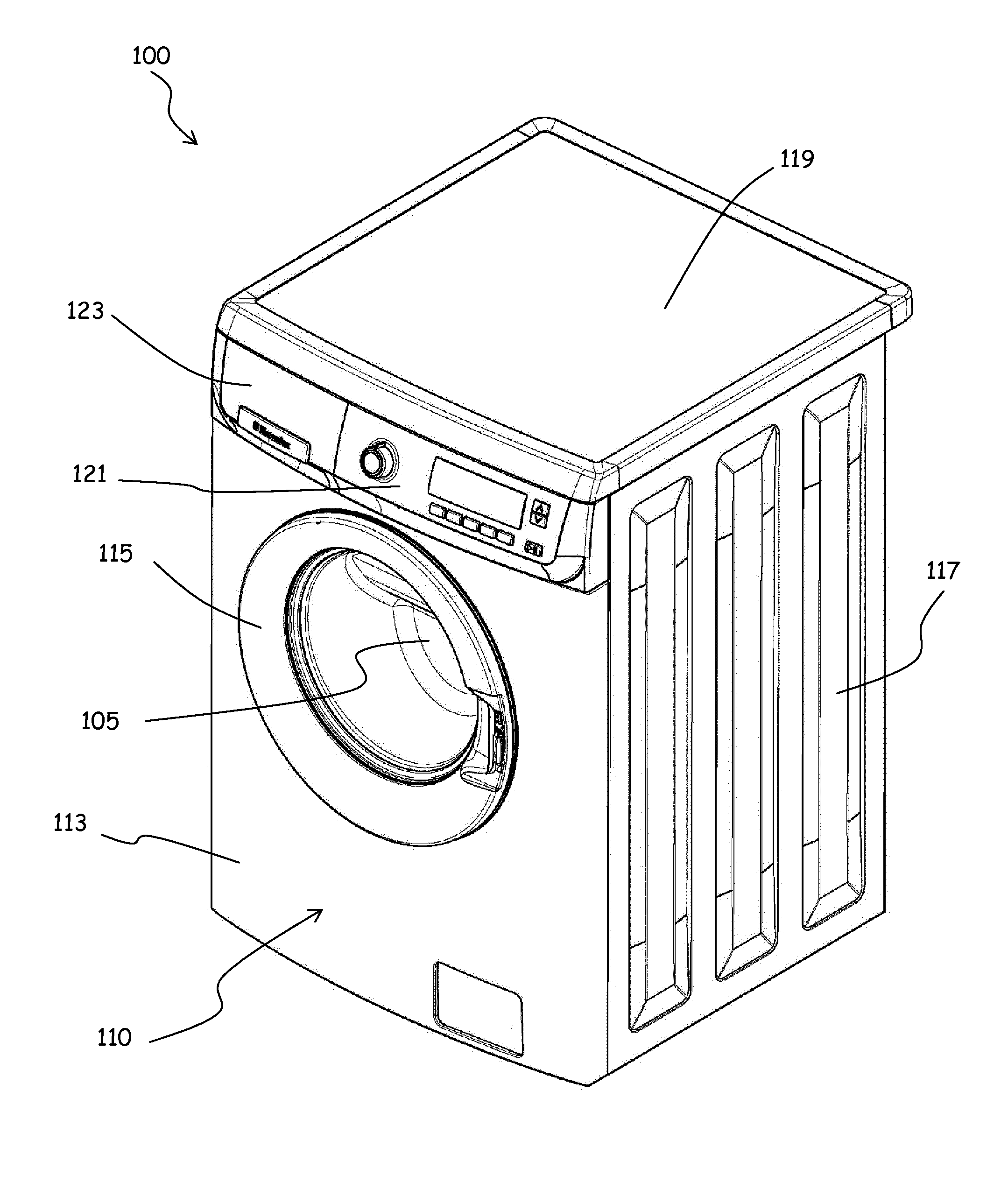

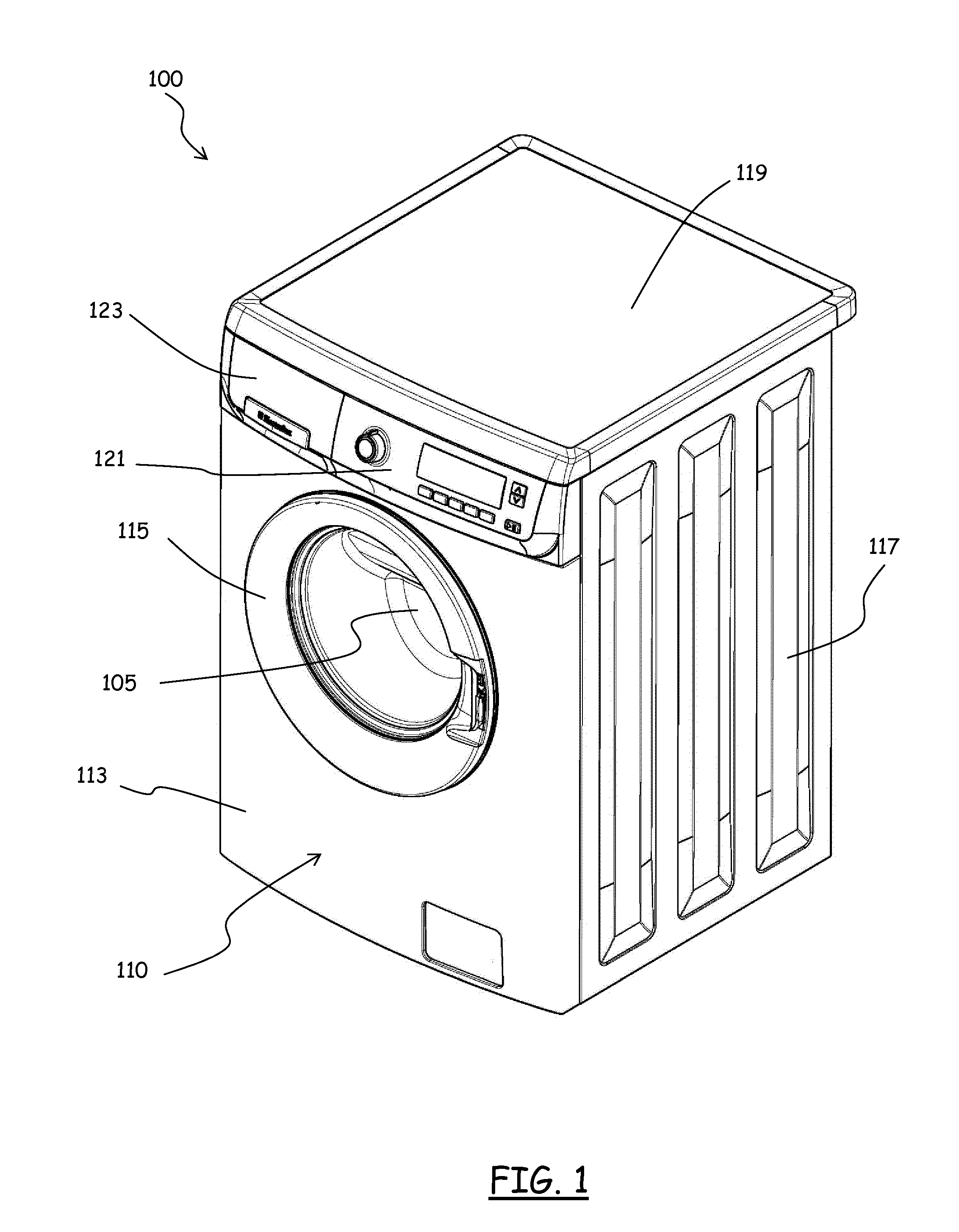

Appliance for drying laundry

ActiveUS9534329B2Improve the heating effectEasy to carryOther washing machinesWashing machine with receptaclesPropellerProcess engineering

Owner:ELECTROLUX HOME PROD CORP NV

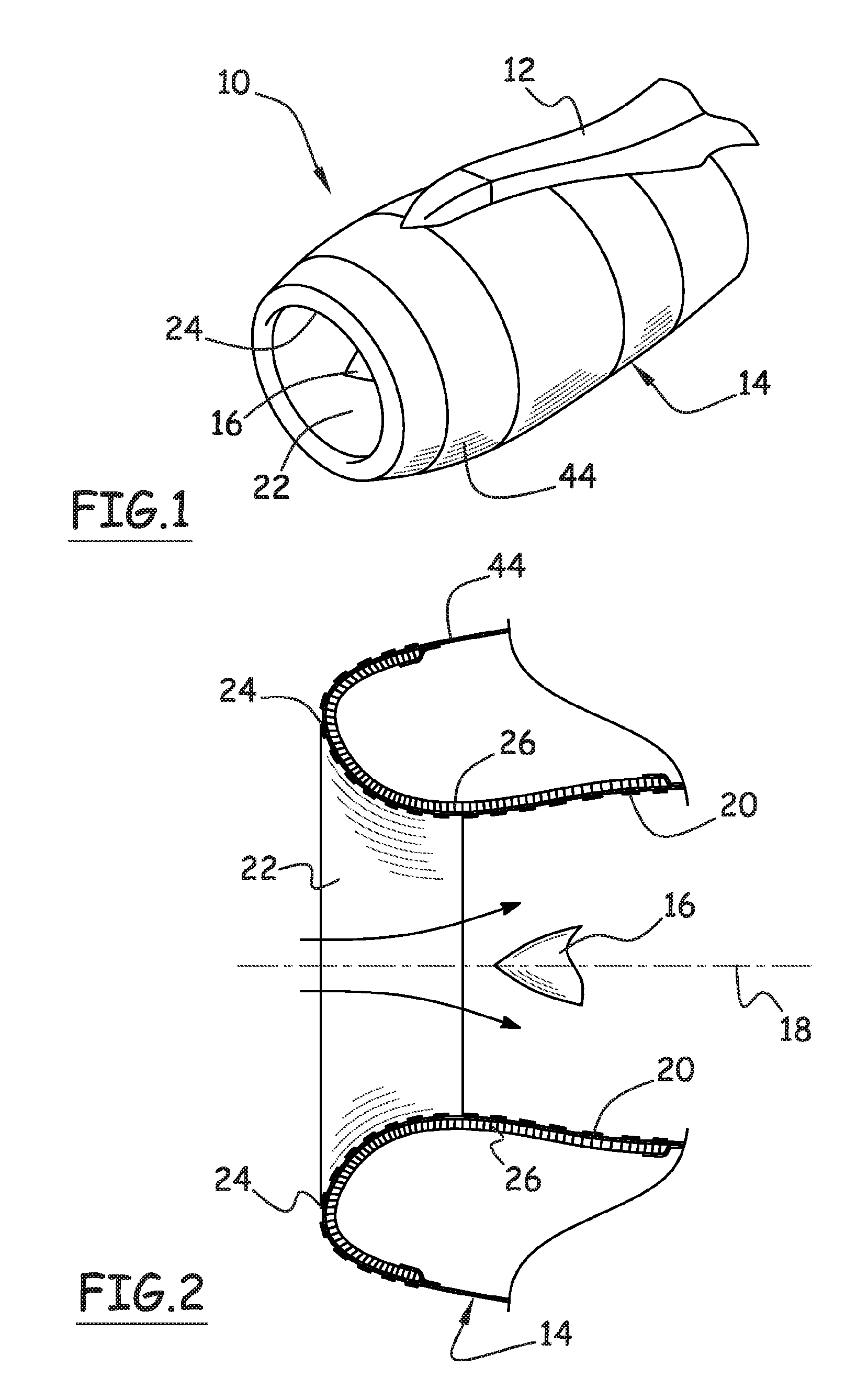

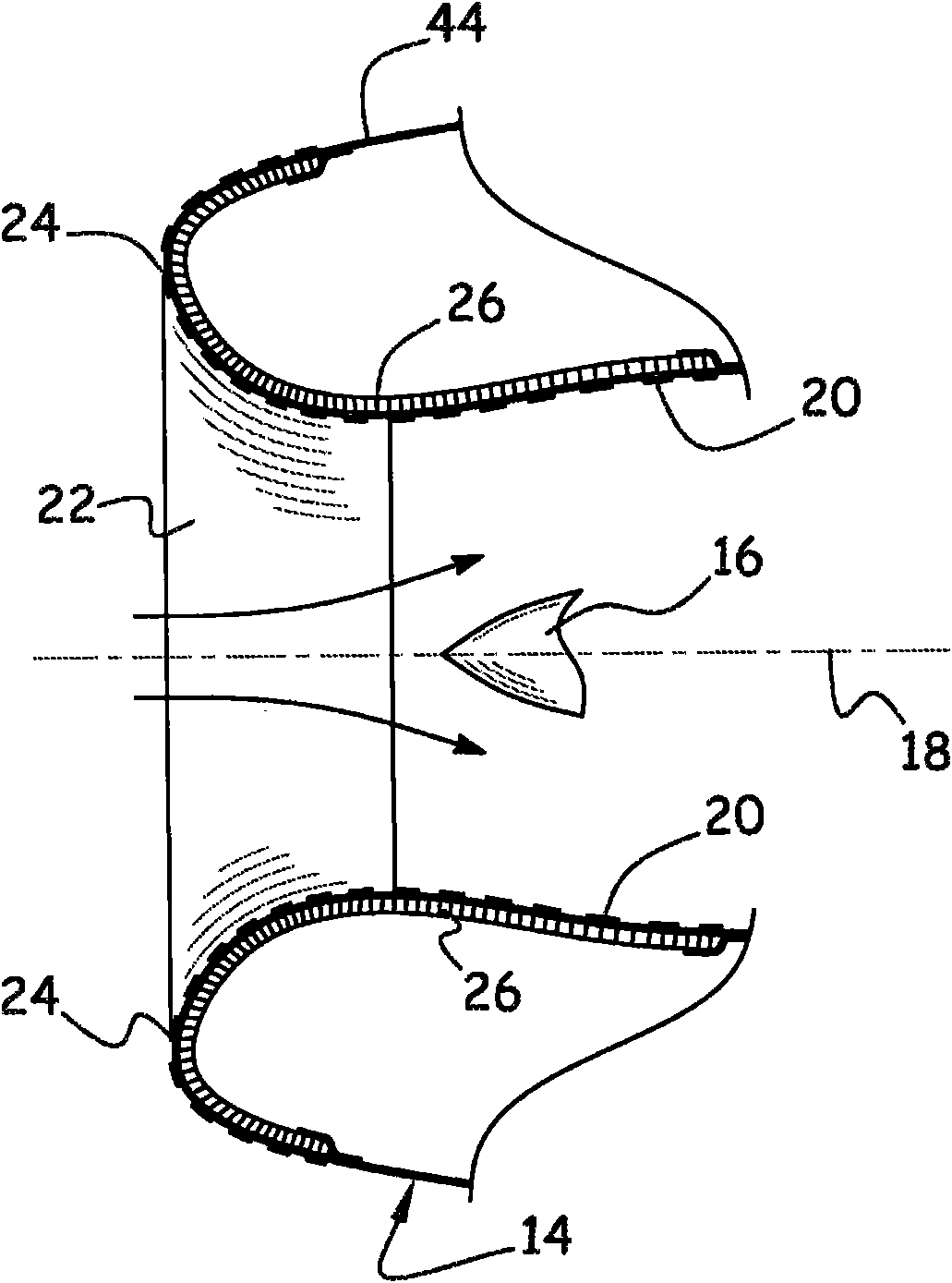

Acoustic coating for an aircraft incorporating a frost treatment system by joule effect

ActiveUS8181900B2Reduce down timeShorten maintenance timeEngine fuctionsDe-icing equipmentsLeading edgeNacelle

The invention relates to acoustic lining for an aircraft, which can cover a leading edge, such as an air inlet in the nacelle of a propulsion unit, said lining comprising: (i) from the inside outwards, a reflective layer (28), at least one cellular structure (30) and an acoustically resistive structure (32) having a pre-determined proportion of open surface; and (ii) at least one frost treatment system in the form of at least one heating layer (46) comprising open zones through which acoustic waves can pass, which co-operate at least partially with the open zones in the acoustically resistive structure. The invention is characterized in that the acoustically resistive structure (32) includes at least one structural layer (36) with openings (38) and in that said at least one heating layer (46) is disposed under the structural layer (36).

Owner:AIRBUS OPERATIONS (SAS)

Appliance for drying laundry

Owner:ELECTROLUX HOME PROD CORP NV

Acoustic lining for an aircraft, including a frost treatment system using the joule effect

InactiveCN101622174AReduce dwell timeShorten maintenance timeEngine fuctionsDe-icing equipmentsLeading edgeElectrical resistance and conductance

The invention relates to acoustic lining for an aircraft, which can cover a leading edge, such as an air inlet in the nacelle of a propulsion unit, said lining comprising: from the inside outwards, a reflective layer (28), at least one cellular structure (30) and an acoustically resistive structure (32) having a pre-determined proportion of open surface; and at least one frost treatment system in the form of at least one heating layer (46) comprising open zones through which acoustic waves can pass, which co-operate at least partially with the open zones in the acoustically resistive structure. The invention is characterized in that the acoustically resistive structure (32) includes at least one structural layer (36) with openings (38) and in that said at least one heating layer (46) is disposed under the structural layer (36).

Owner:AIRBUS OPERATIONS (SAS)

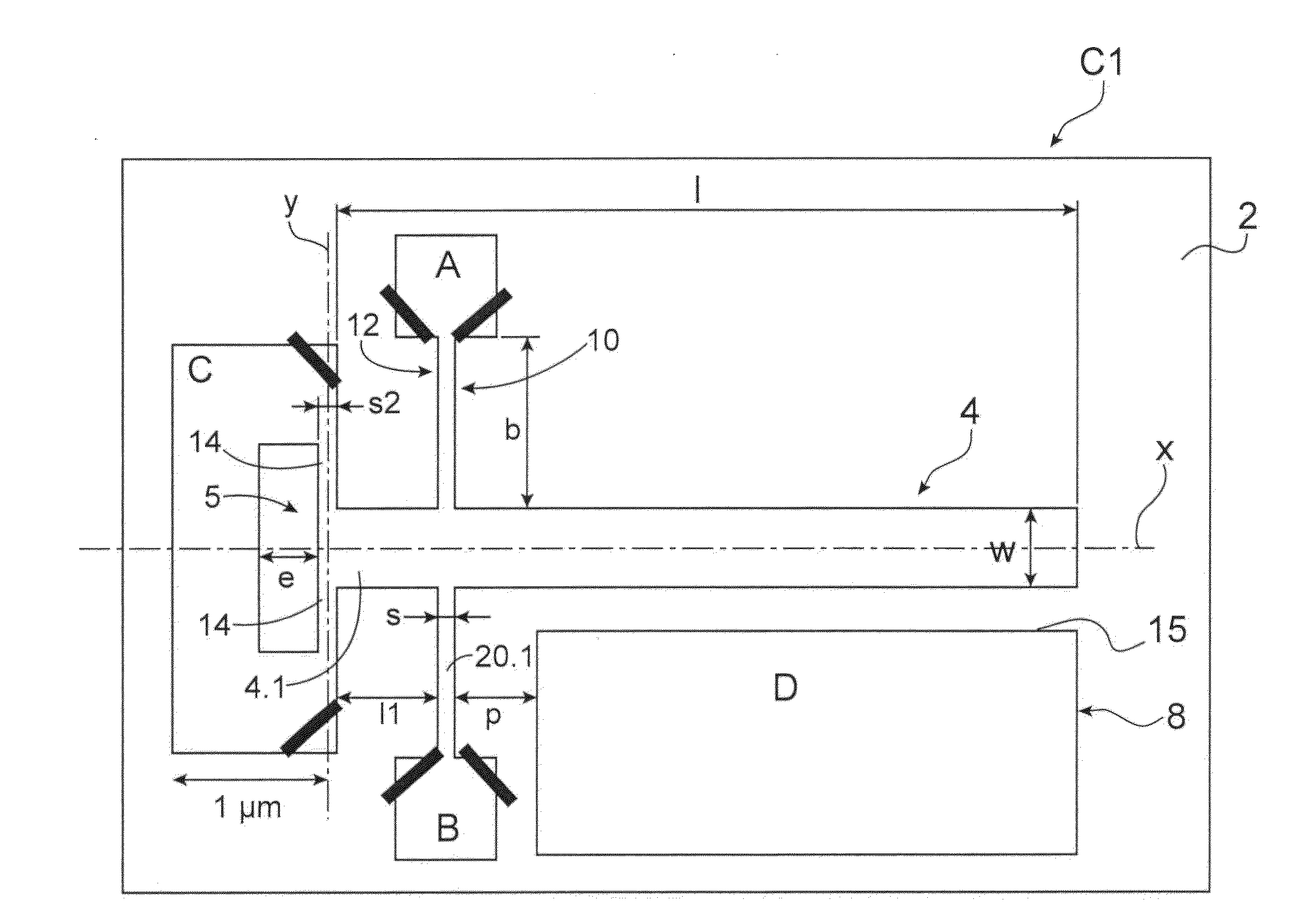

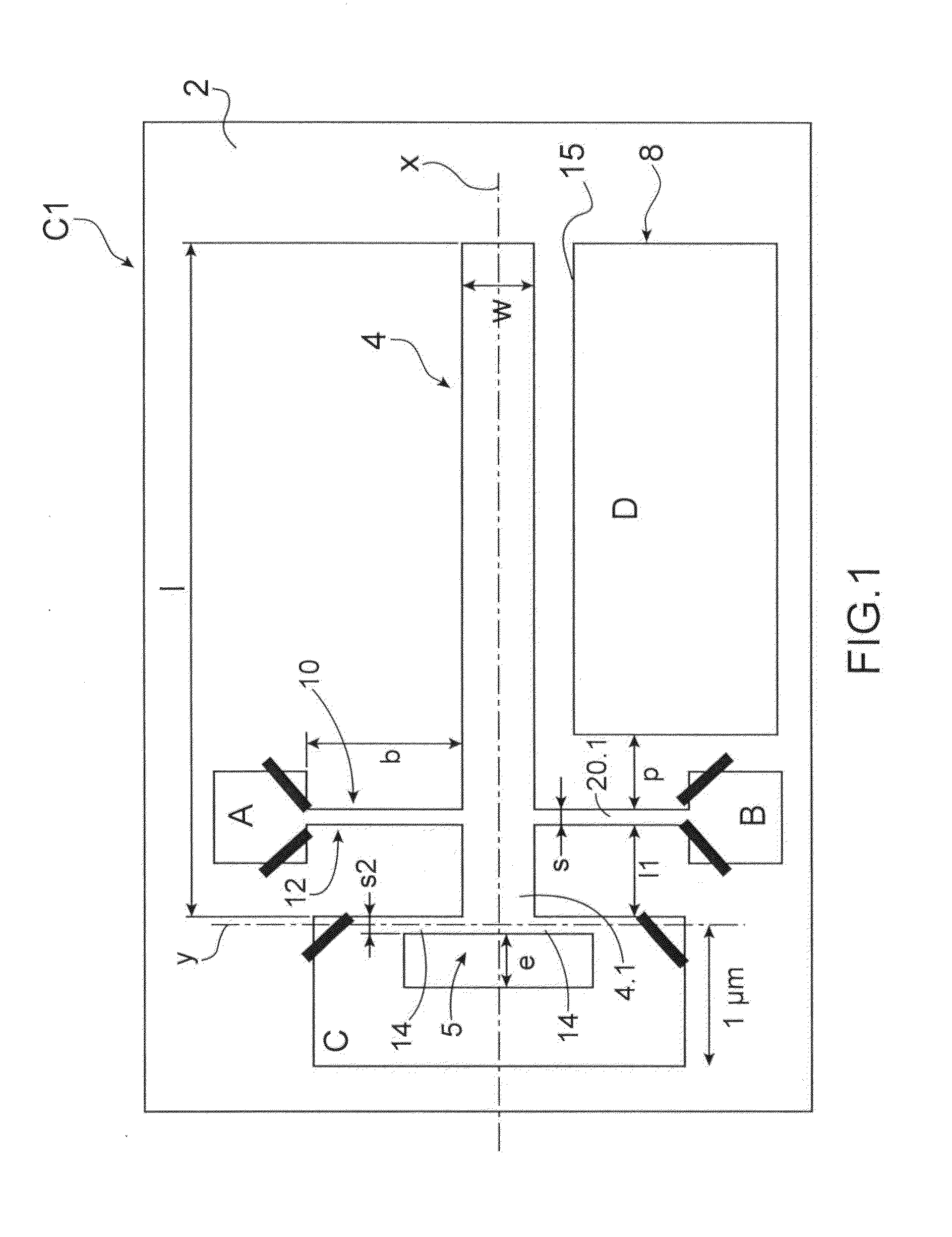

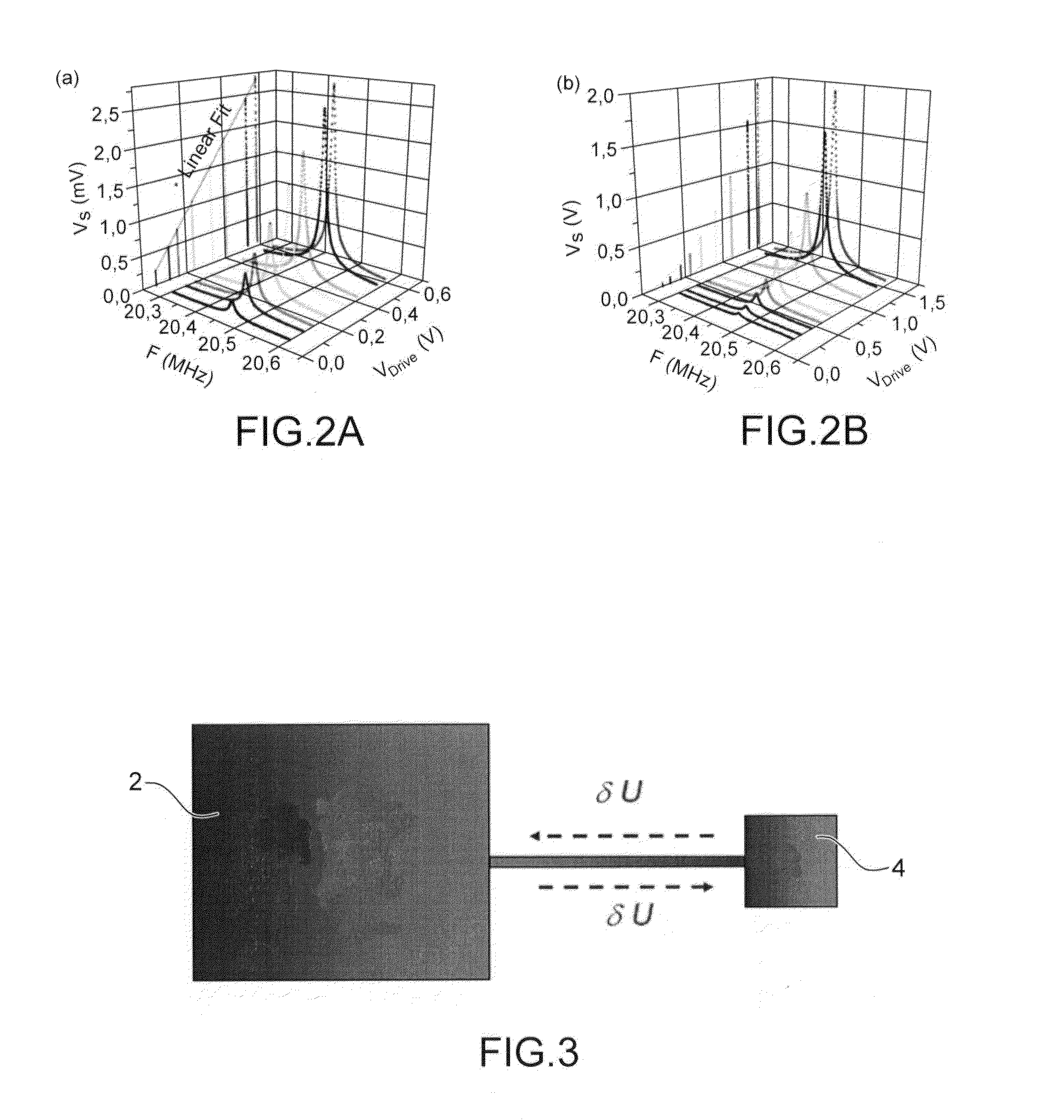

Thermal flow sensor with vibrating element and gas sensor comprising at least one such sensor

ActiveUS20140076024A1High sensitivityMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial thermal conductivityFlow transducerNanowire

The invention relates to a thermal flow sensor comprising:a support,at least one element intended to be vibrated relative to the support,suspension means for said vibrating element relative to the vibrating element,means for heating the vibrating element,means for electrostatic excitation of the vibrating element so as to vibrate it at its resonance frequency,piezoelectric gauges for detecting the resonance frequency variation of the vibrating element, the gauges forming means for heating the vibrating element by Joule effect and the suspension means comprising two beams formed by nanowires so as to reduce the heat losses from the vibrating element toward the support.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

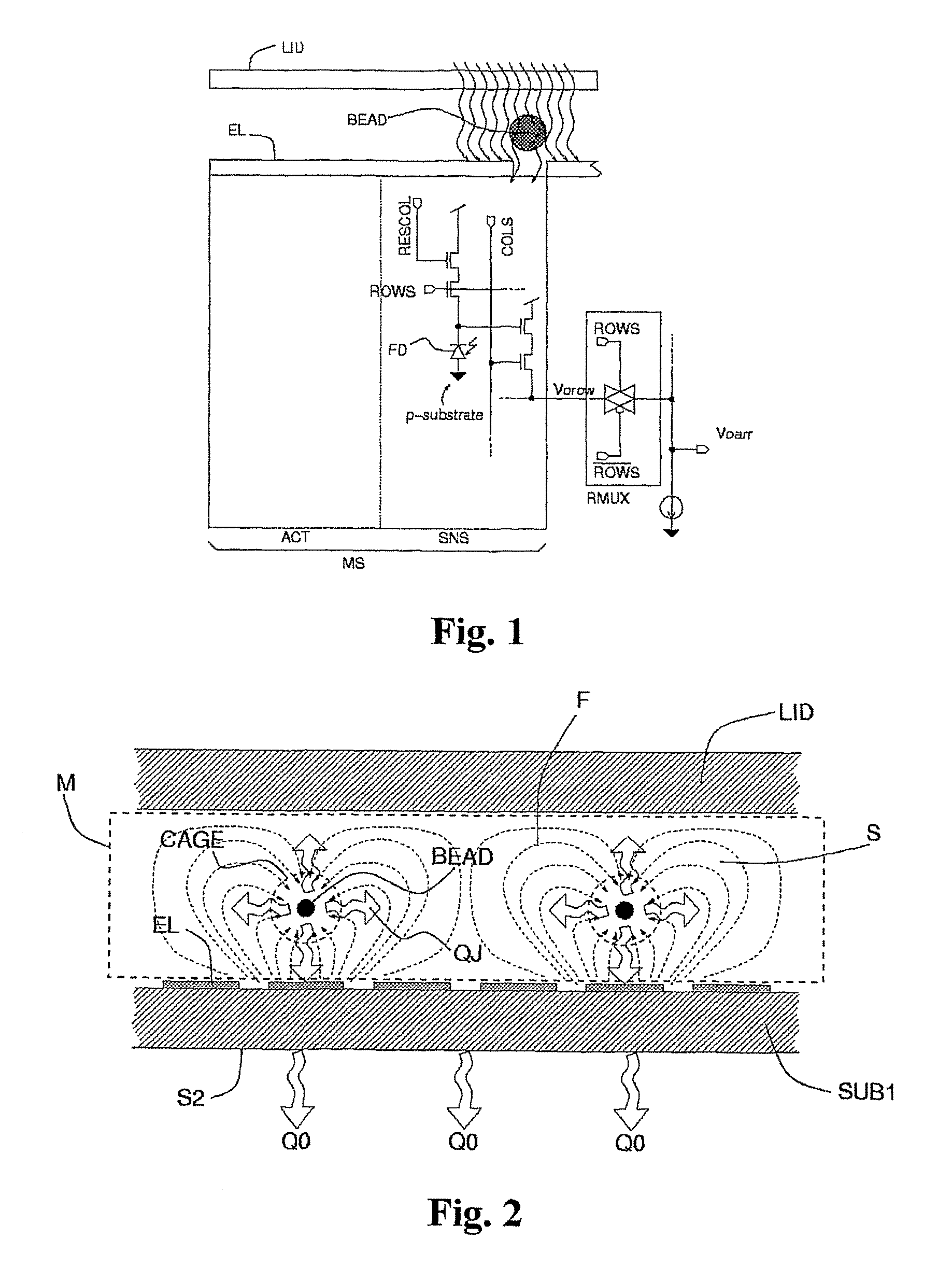

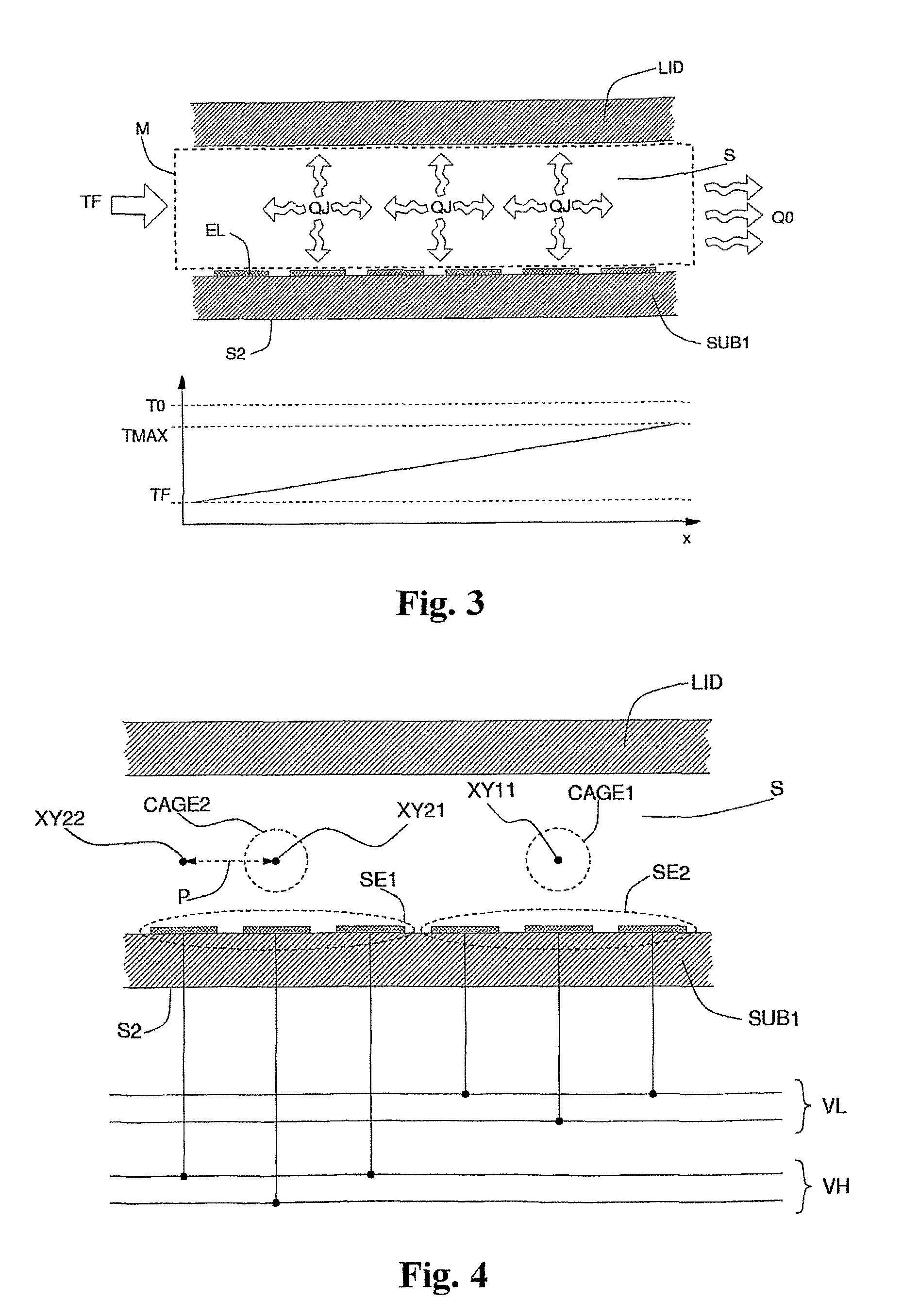

Method and apparatus for the manipulation of particles in conductive solutions

ActiveUS8349160B2Short timeIncrease the number ofDielectrophoresisSludge treatmentEngineeringElectrode array

The present invention relates to an apparatus and method for manipulation and / or position control of particles by means of force fields of electrical nature in electrically conductive solutions, wherein power dissipated by Joule effect, which may cause the death of biological specimens under examination, is advantageously removed. The apparatus comprises a first substrate, upon which lies an array of electrodes, the application of a set of electric voltages to the electrodes generating a force field; a second substrate at a distance from, and parallel to, the first substrate so as to delimit a microchamber within which a liquid containing the particles is inserted; and cooling means for extracting an appropriate amount of heat from the microchamber, the cooling means comprising a second microchamber made in contact with, or by means of, the first or second substrate and through which a flow of cooling liquid or gas is pumped.

Owner:MENARINI SILICON BIOSYSTEMS SPA

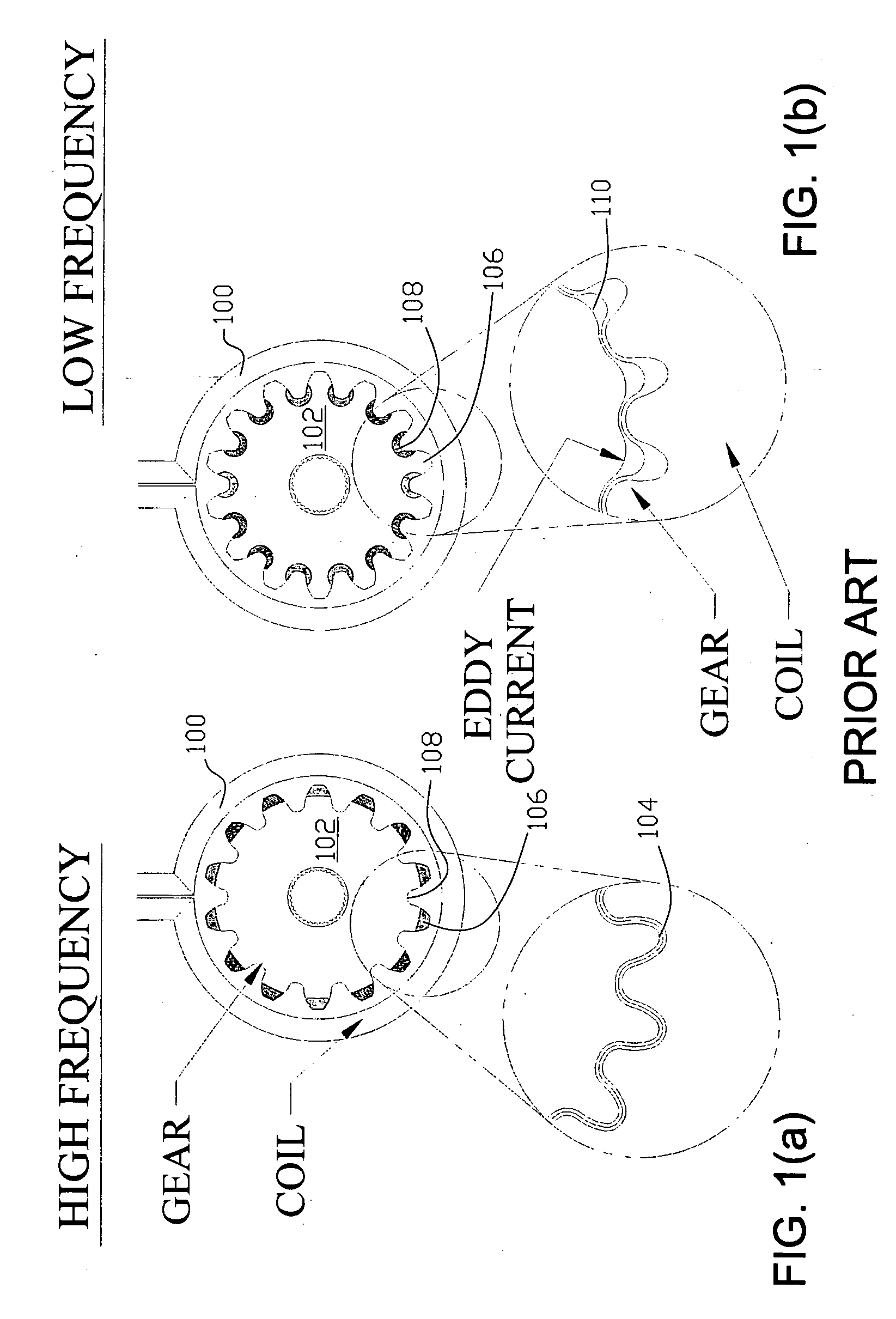

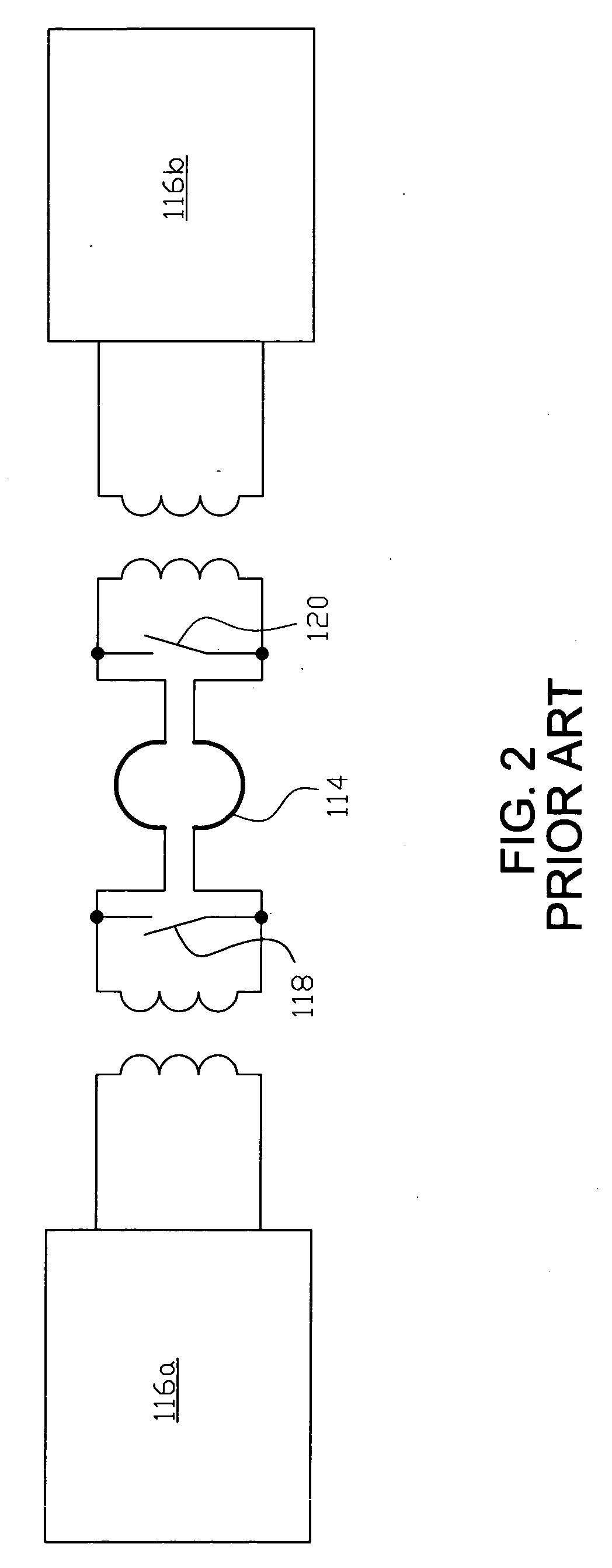

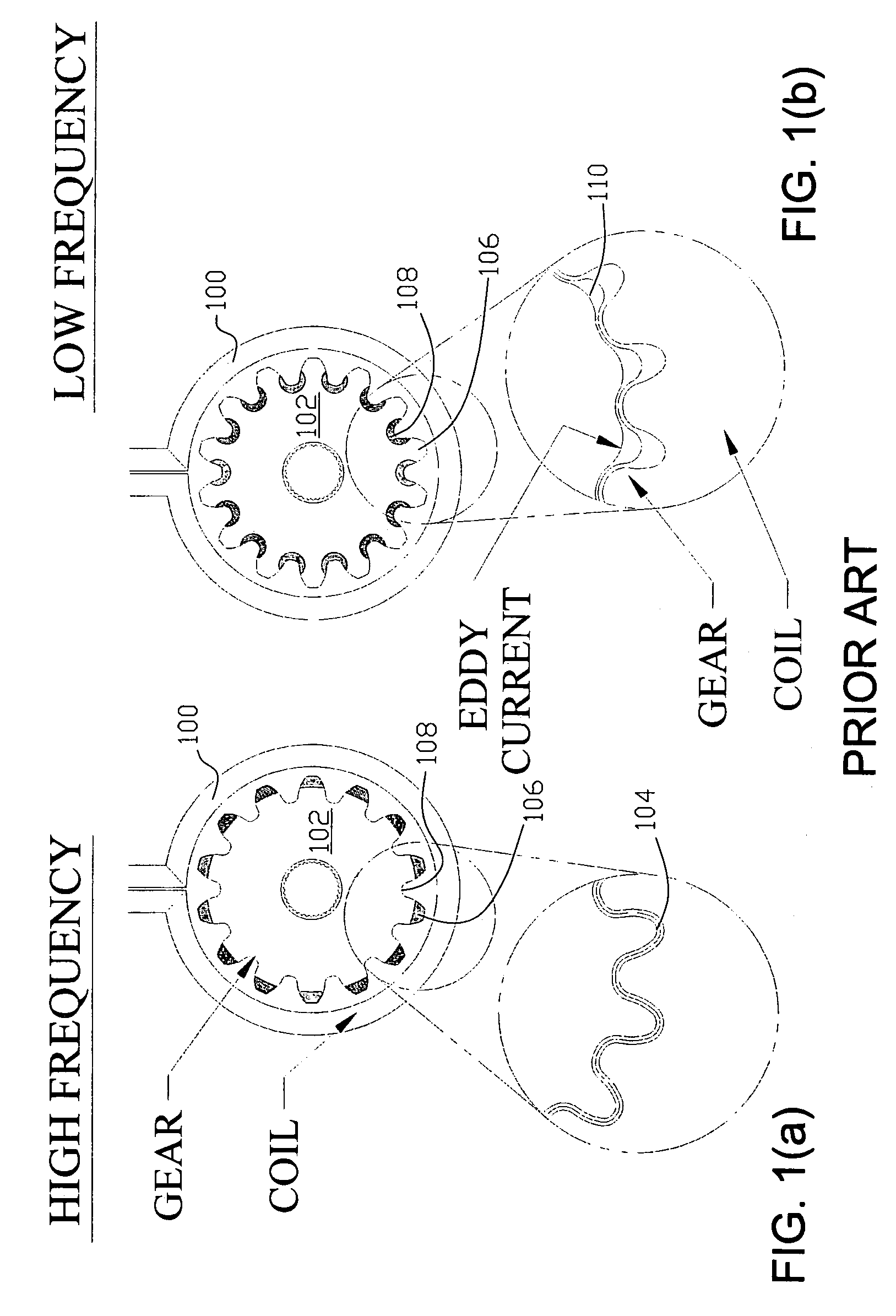

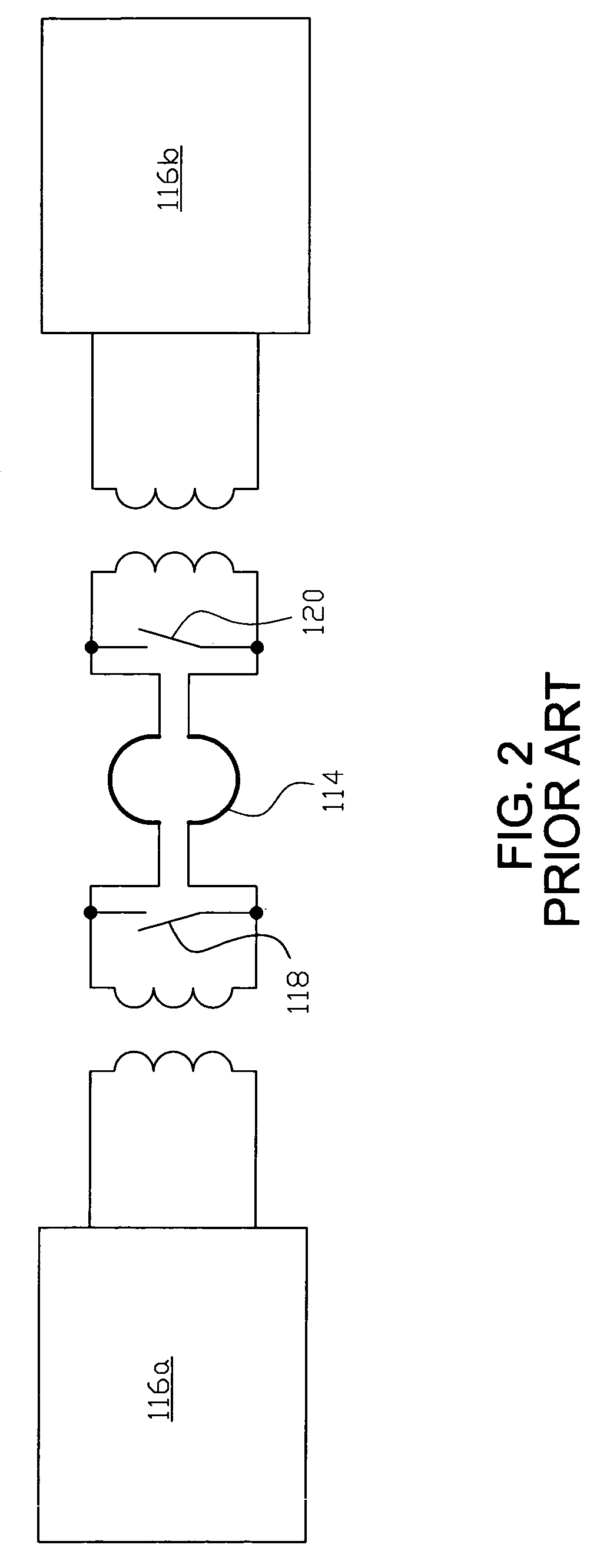

Multi-frequency heat treatment of a workpiece by induction heating

InactiveUS20050247704A1High resistivityReduce the amount requiredCoil arrangementsFurnace typesHigh frequency powerMagnetic field coupling

An apparatus and process are provided for multi-frequency induction heat treatment of workpieces including gears. High frequency power is applied to an induction coil that surrounds the workpiece so that a high frequency magnetic field couples with the workpiece to inductively heat the workpiece. A C-core inductor is coupled to a coil that has low frequency power applied to it. The workpiece is inserted in a gap in the C-core inductor magnetic circuit so that it experiences low frequency Joule effect heating when the low frequency current is applied to the coil coupled with the C-core inductor. Alternatively the workpiece may be inserted around the C-core inductor when the workpiece has an opening.

Owner:INDUCTOHEAT INC

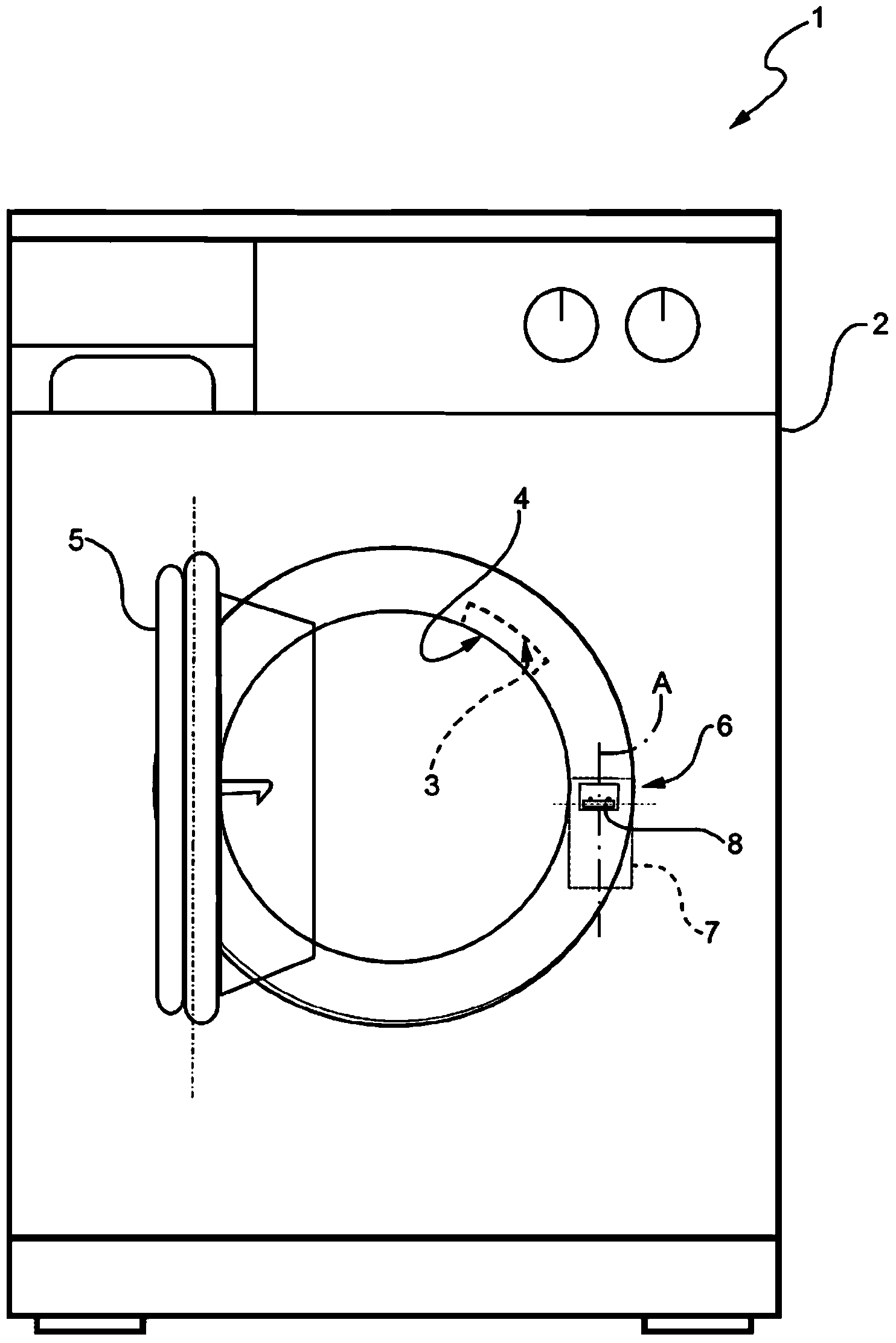

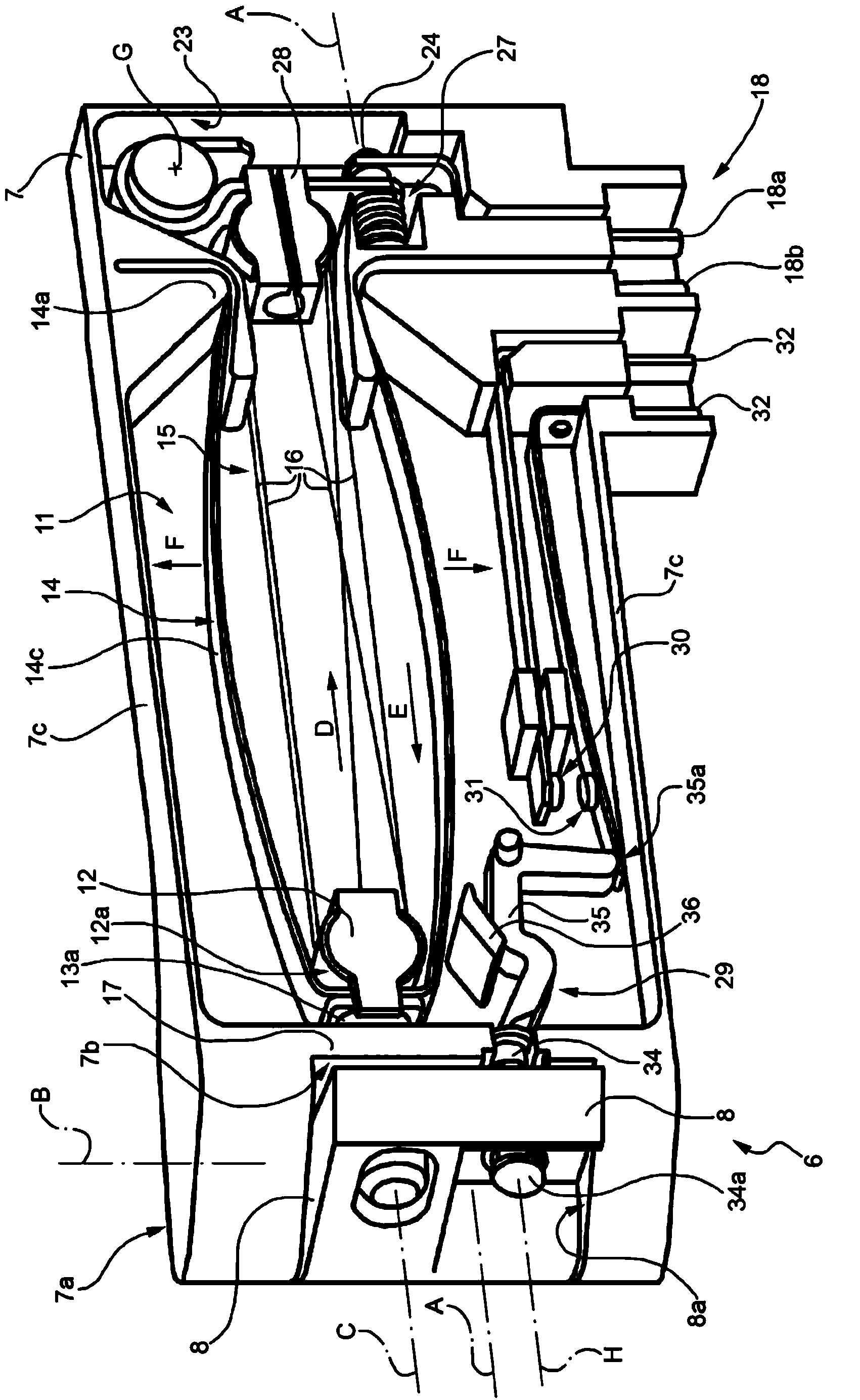

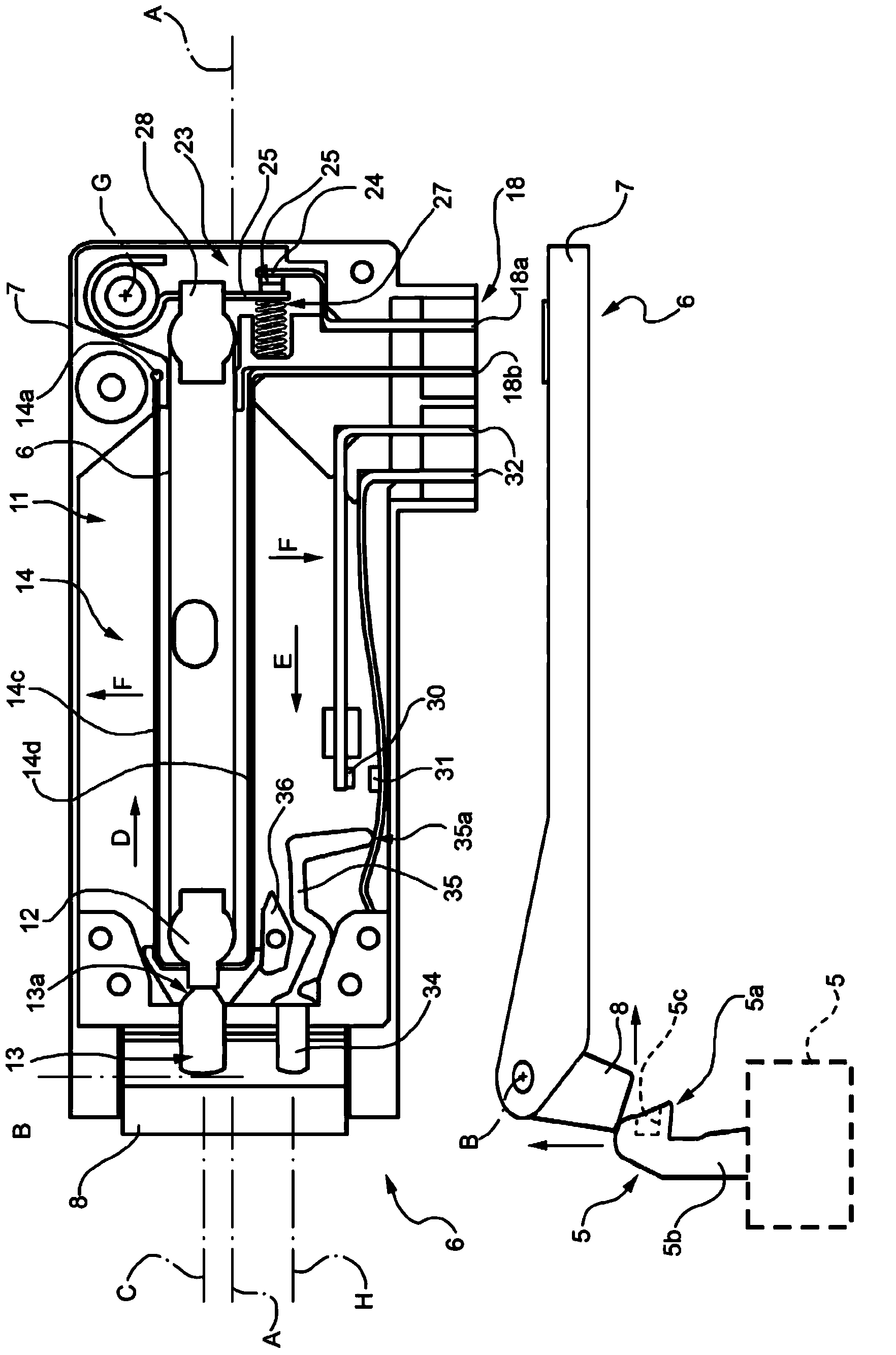

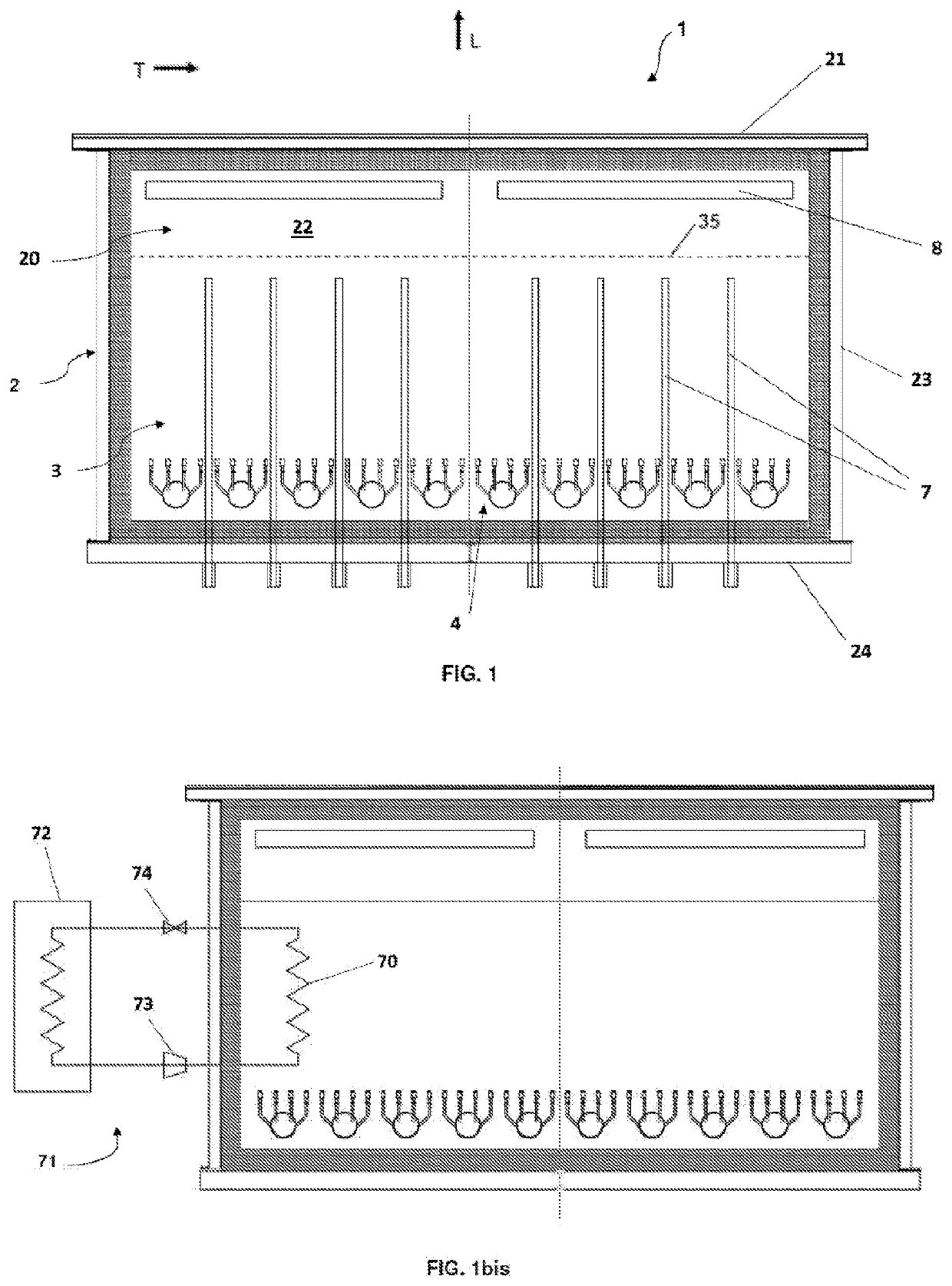

Electric household appliance door locking device

ActiveCN103562478ASimple electricitySimple mechanical propertiesDomestic stoves or rangesLighting and heating apparatusShape-memory alloyEngineering

An electric household appliance having a casing (2); a compartment (3) housed inside the casing (2) and facing an opening (4); a door (5) fitted to the casing (2) and movable between an open position and a closed position; and a locking device (6); the locking device (6) having a box body (7) fixed to the casing (2), alongside the door (5); latch means (8, 13) fitted to the box body (7) to move between a lock position locking the door (5), and a release position releasing the door (5); and an actuating device (11) for selectively moving the latch means (8, 13) between the lock position and the release position, and which has at least an electrically conducting resistance wire (16) made of a shape-memory alloy and designed to vary in length alongside a variation in temperature, and electric power devices (18) for powering the resistance wire (16) and producing a controlled Joule-effect variation in temperature.

Owner:ELECTROLUX HOME PROD CORP NV

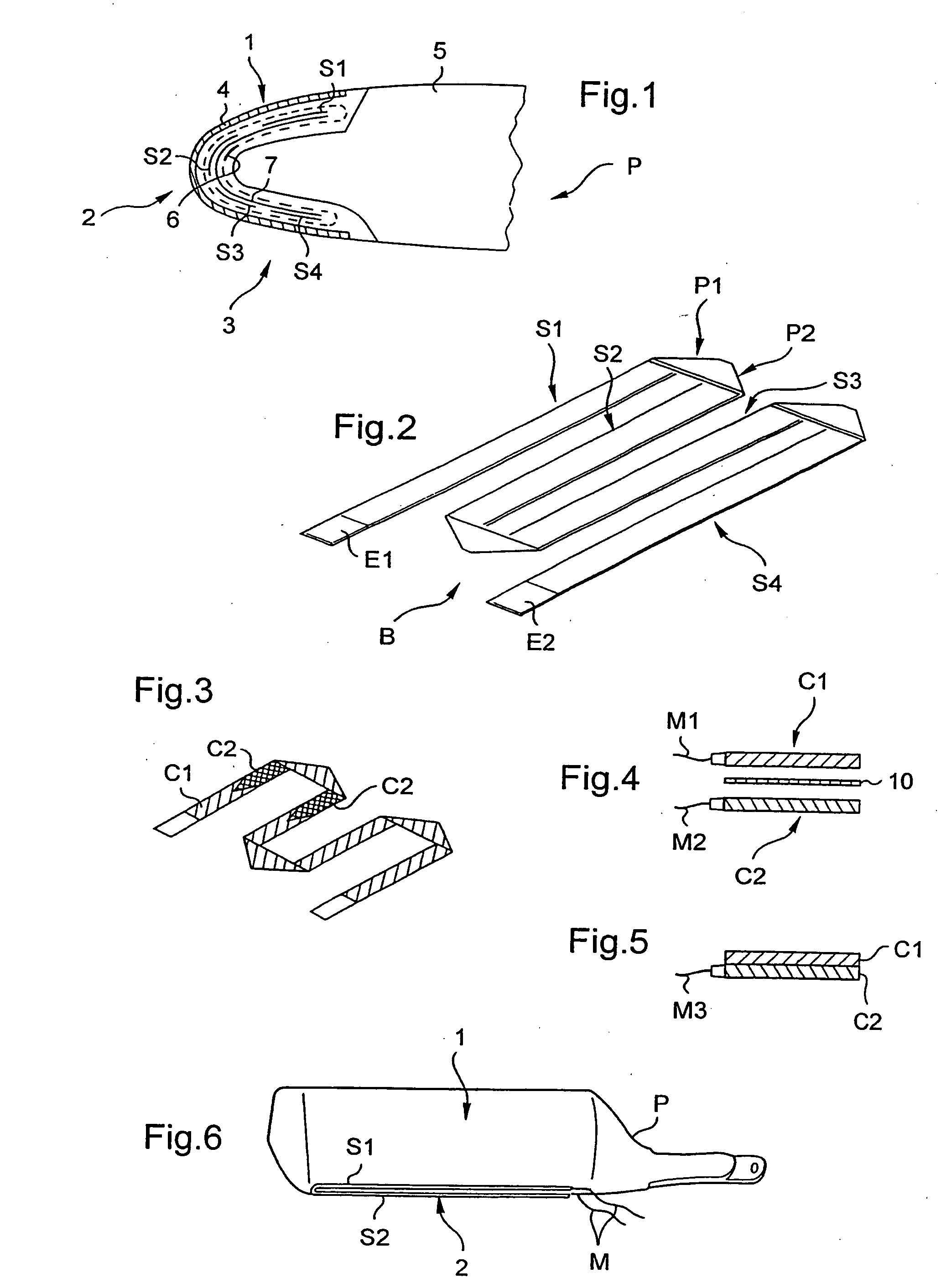

Process for Manufacturing a Heating Sheet

A process for manufacturing a flexible heating sheet comprising two outer layers made of plastic material and a metal foil ribbon, arranged sinuously between the outer layers and acting as an electrical heating conductor using the Joule effect, includes a) printing a first face of a metal foil strip with a sinuous ribbon pattern and a second face with a pattern in an anti-bond lacquer complementary to the sinuous ribbon pattern, b) masking the first face of the metal strip by extrusion with a metal support film using a first extruded layer made of plastic, c) slicing the metal strip masked with the support film from the second face as far as the first extruded layer along the delimitation lines of the sinuous ribbon pattern and the complementary pattern, d) covering the second face of the metal foil strip with a second extruded layer made of plastic, e) covering the second face of the foil strip coated by extrusion using a first layer of glue with a first outer layer with a plastic film, f) separating the support film from part of the metal foil strip corresponding to the complementary pattern and bonding to the first extrusion layer, and g) covering the face of part of the metal strip forming the sinuous ribbon, released after separation from the support film, using a second layer of glue with a second outer layer made of plastic.

Owner:ALCAN PACKAGING SELESTAT

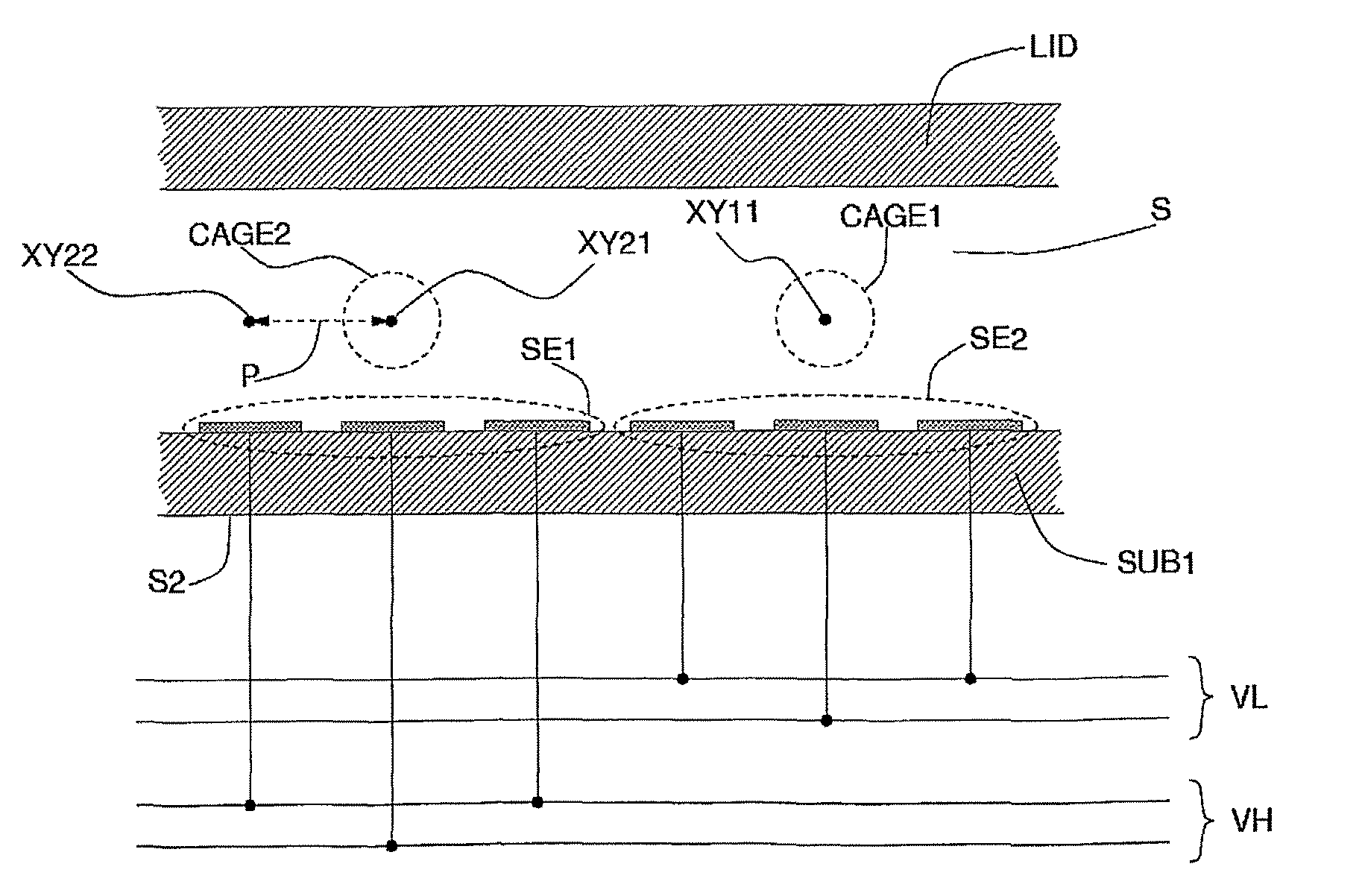

Sensor device with integrated calibration system and calibration method

ActiveUS20150082856A1Increase production costWave based measurement systemsMagnetic field offset compensationPower flowEngineering

An integrated sensor device including a first die, housing a sensor element to detect a quantity external to the sensor device and transduce the external quantity into an electrical sensing signal; a second die mechanically coupled to the first die so that the first and second dies are stacked on one another along one and the same axis; and at least one heater of a resistive type integrated in the first die and / or in the second die, having a first conduction terminal and a second conduction terminal configured to couple respective first and second conduction terminals of a signal generator for causing an electric current to flow, in use, between the first and second conduction terminals of the heater and generate heat by the Joule effect. It is possible to carry out calibration in temperature of the sensor element.

Owner:STMICROELECTRONICS INT NV

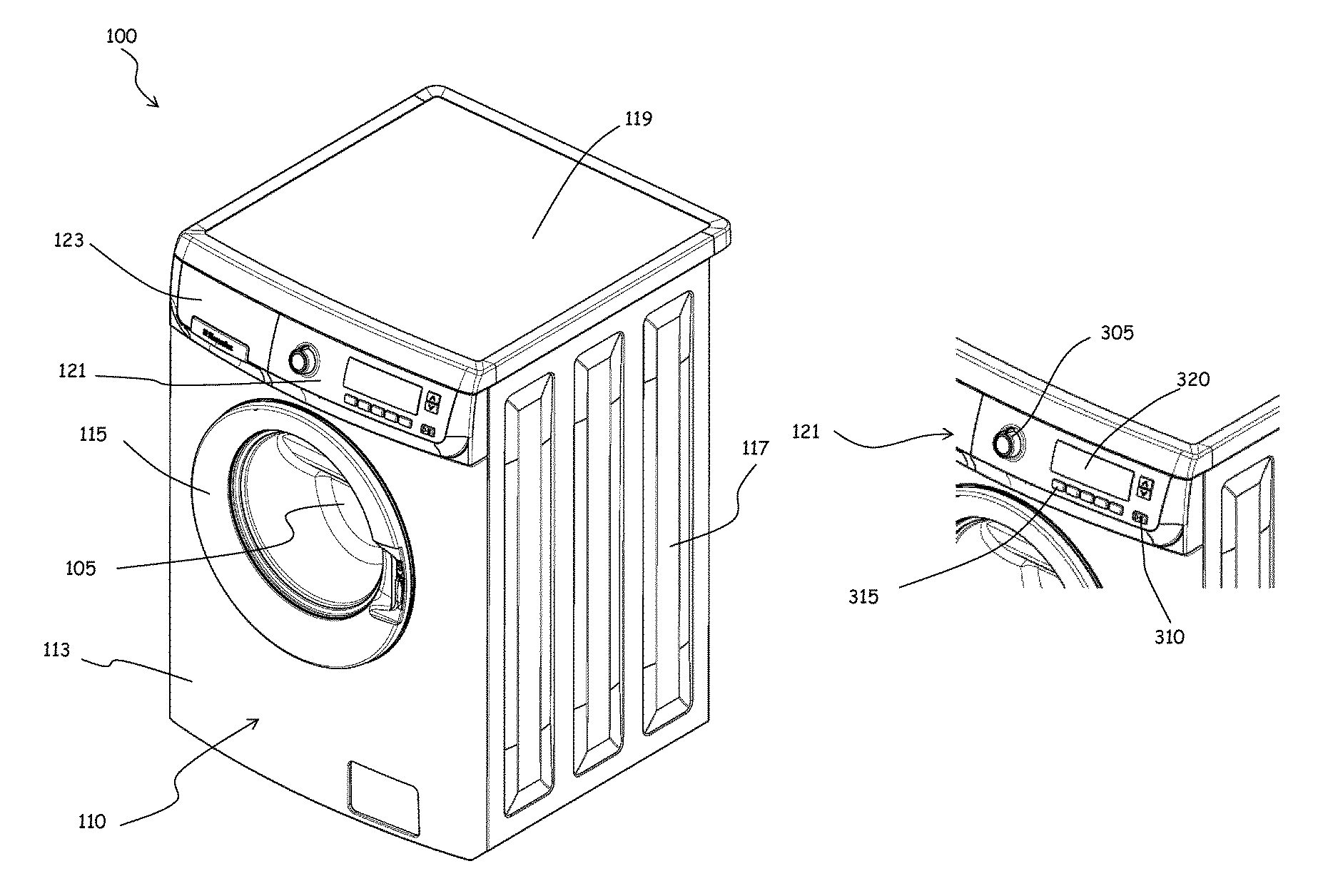

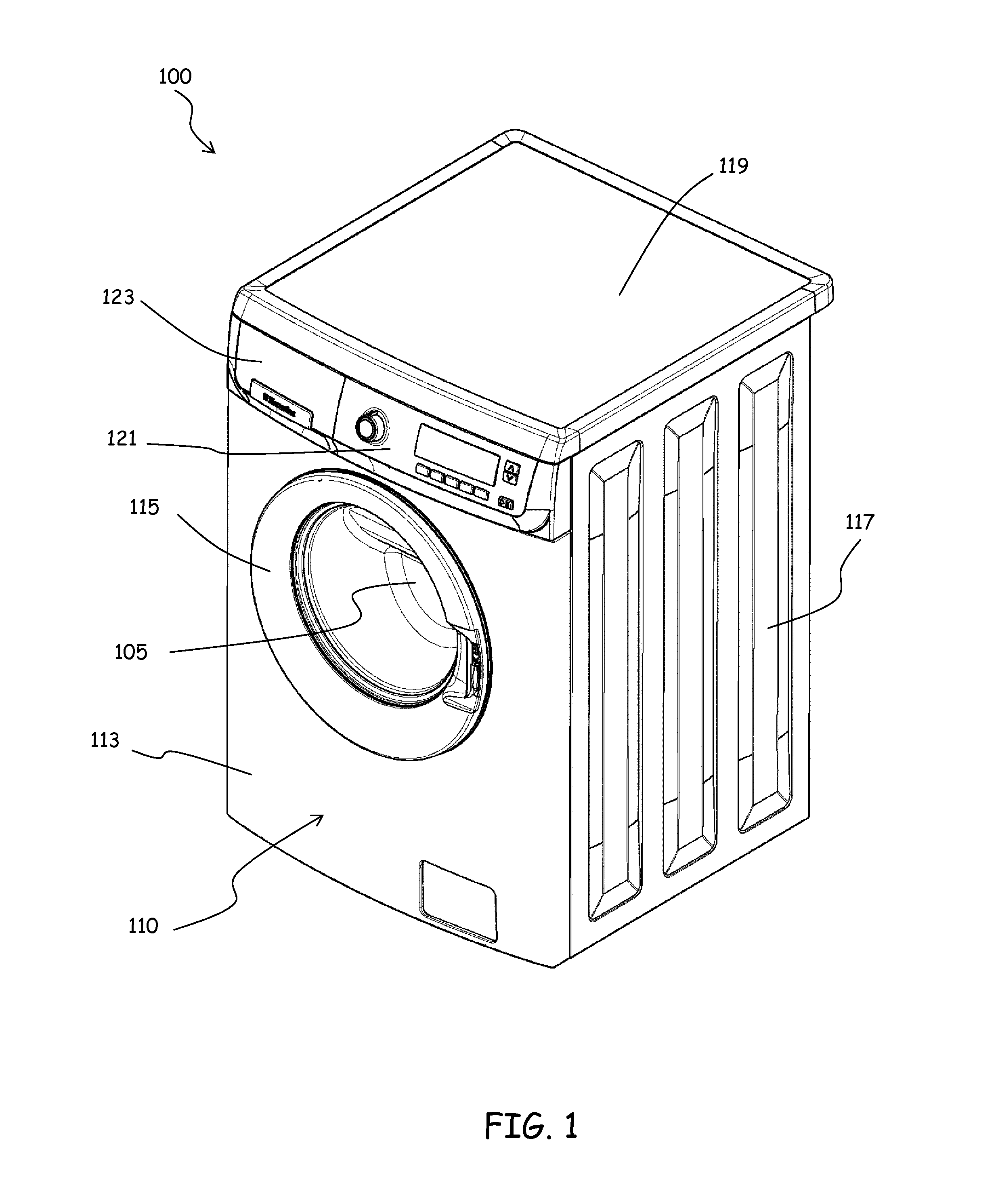

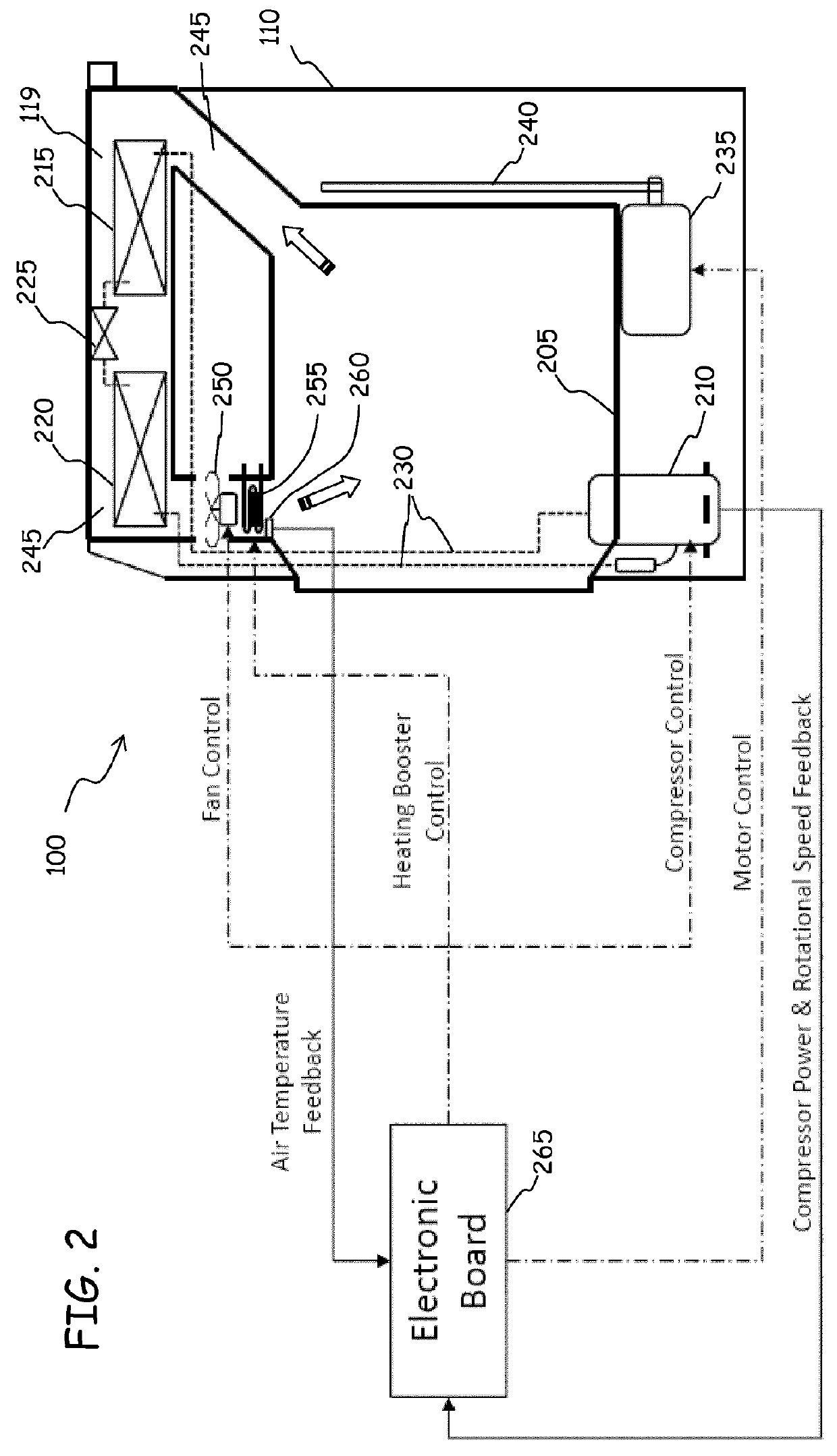

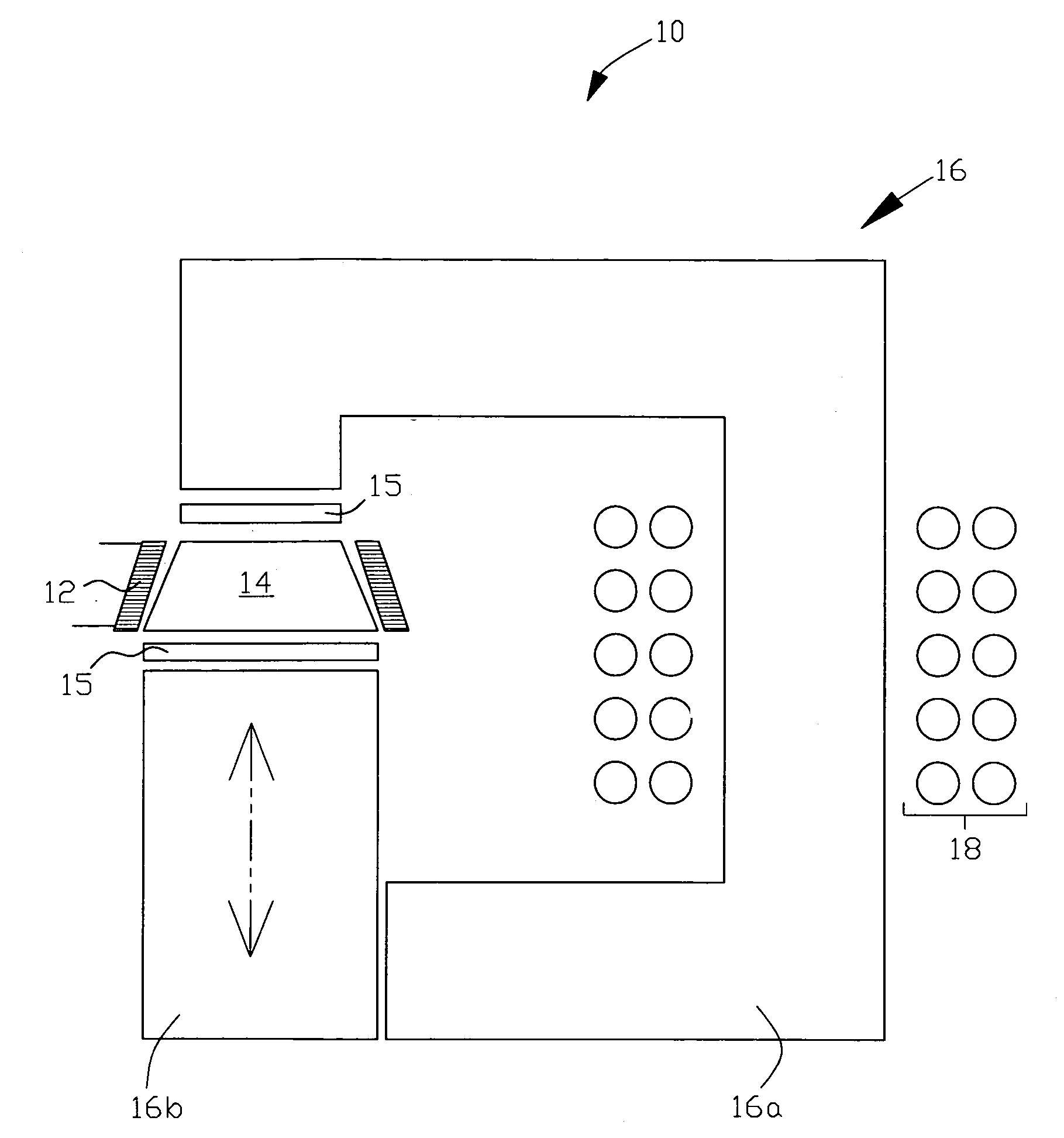

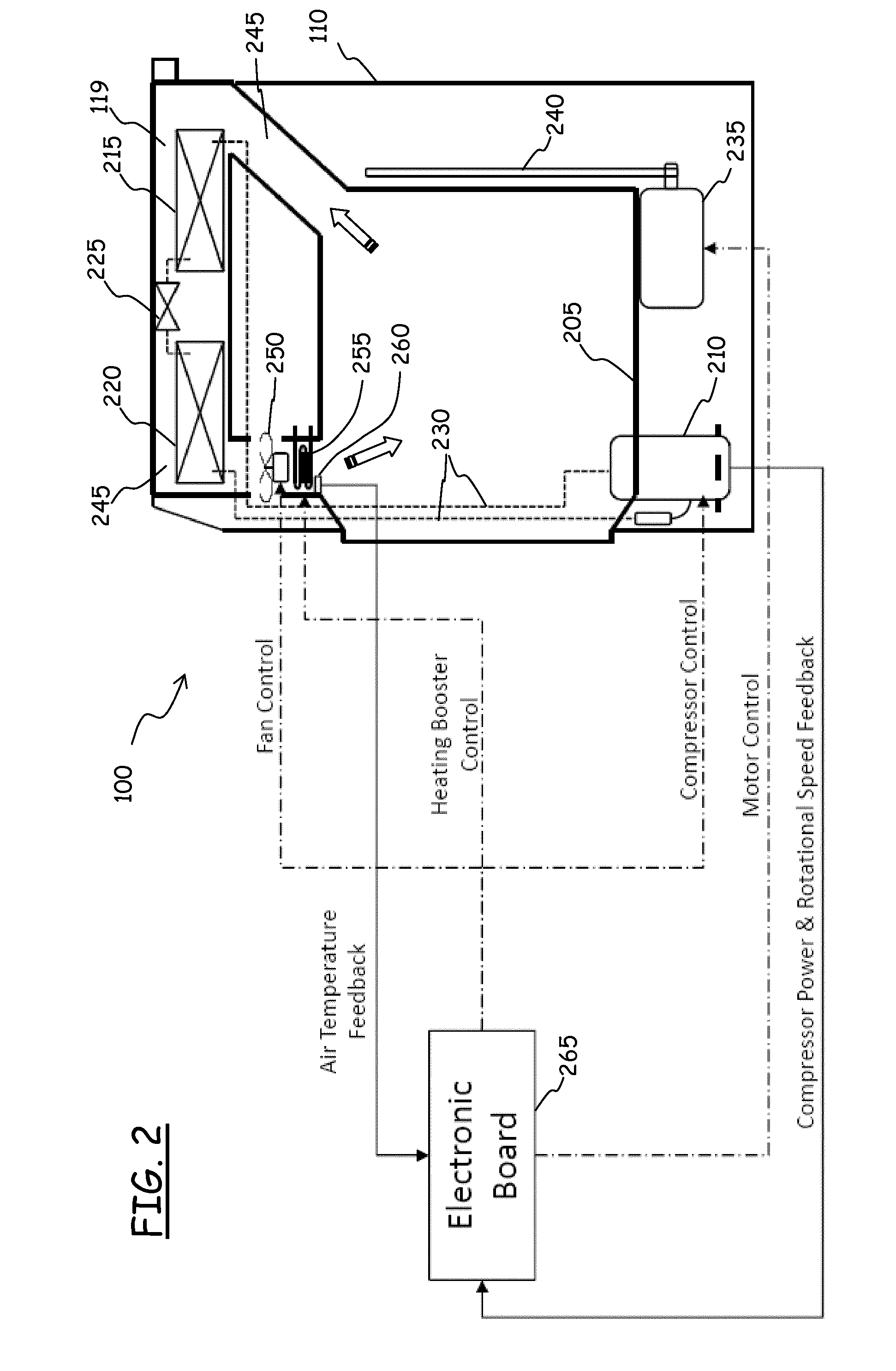

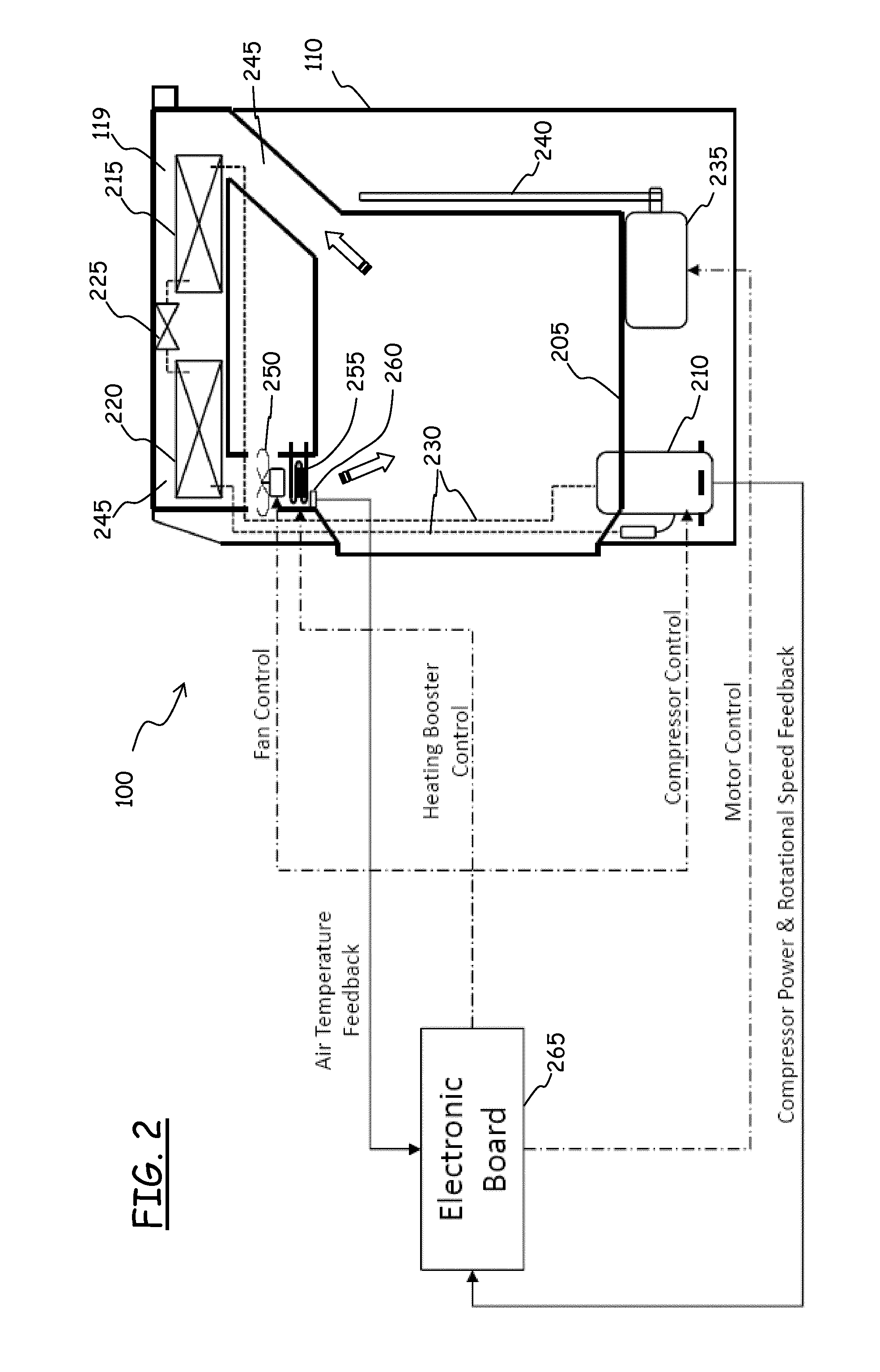

Appliance for Drying Laundry

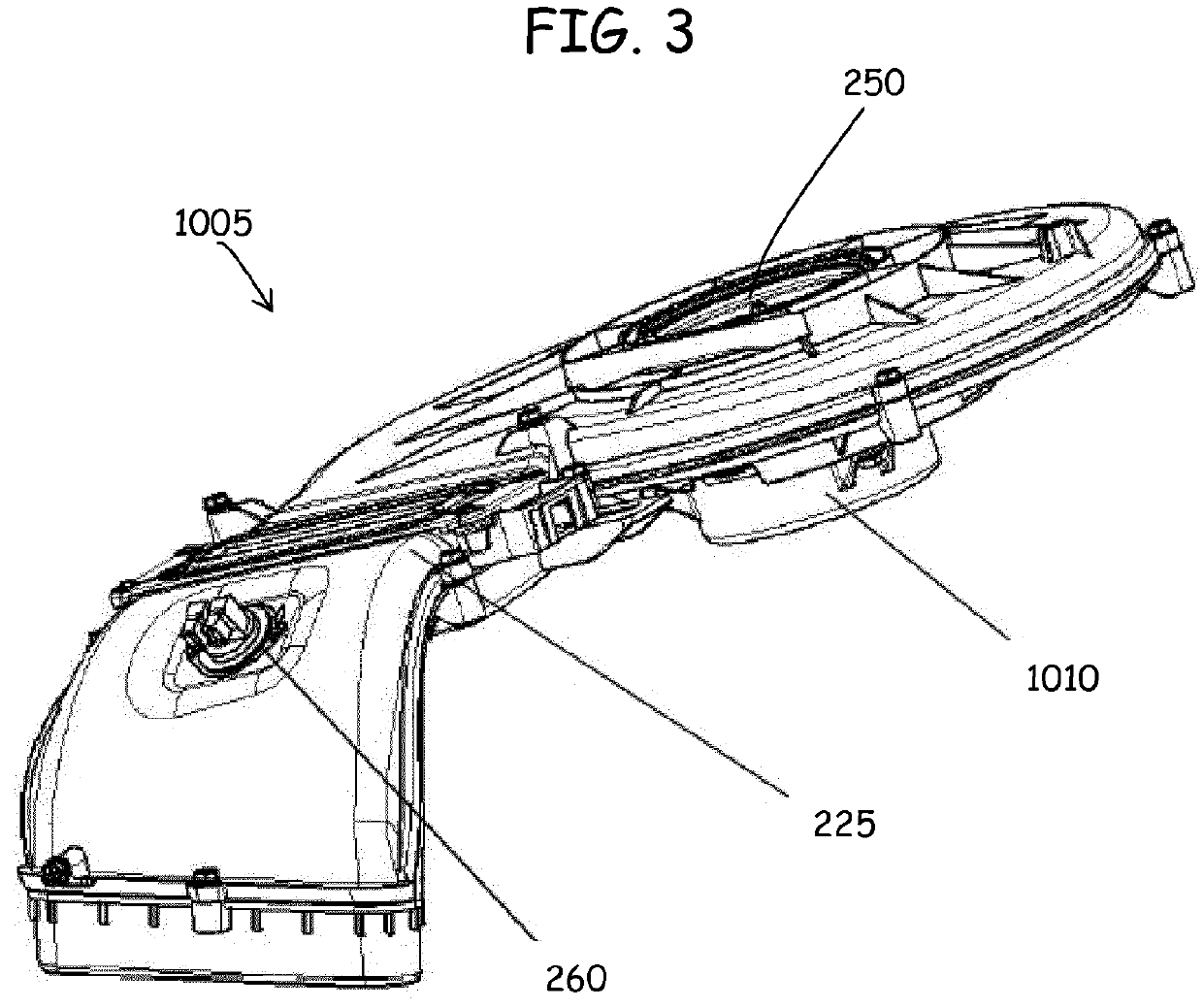

ActiveUS20140338218A1Improve the heating effectEasy to carryDrying solid materials with heatDrying gas arrangementsLaundryMoisture

An appliance for drying laundry (100) comprising an appliance cabinet (110), a laundry treatment chamber (105) inside the cabinet, a drying air recirculation path (245) for causing recirculation of the drying air into / out from the laundry treatment chamber, the drying air recirculation path being at least partly external to the laundry treatment chamber, a drying air moisture condensing and heating system (215,220,225) located in the drying air recirculation path for dehydrating the moisture-laden drying air leaving the laundry treatment chamber and heating the dehydrated drying air before it re-enters into the laundry treatment chamber, wherein said drying air moisture condensing and heating system comprises a first heat exchanger (215) and a second heat exchanger (220) of a heat pump (215,220,225,210), and further comprising a drying air propeller (250) inside the drying air recirculation path and a Joule-effect drying air heater (255), downstream the second heat exchanger, energizable for contributing to the heating of the drying air, wherein the appliance comprises a user interface (121) comprising a laundry treatment cycle selector (305) operable by a user for selecting a laundry treatment cycle, and a control unit (265) adapted to control the machine operation, characterized in that the user interface comprises a command input means (315) operable by the user for imparting to the appliance an energization command to energize the Joule-effect heater, and in that during the execution of the laundry treatment cycle selected by the user, said control unit causes the selective energization of said Joule-effect drying air heater based on said energization command imparted by the user.

Owner:ELECTROLUX HOME PROD CORP NV

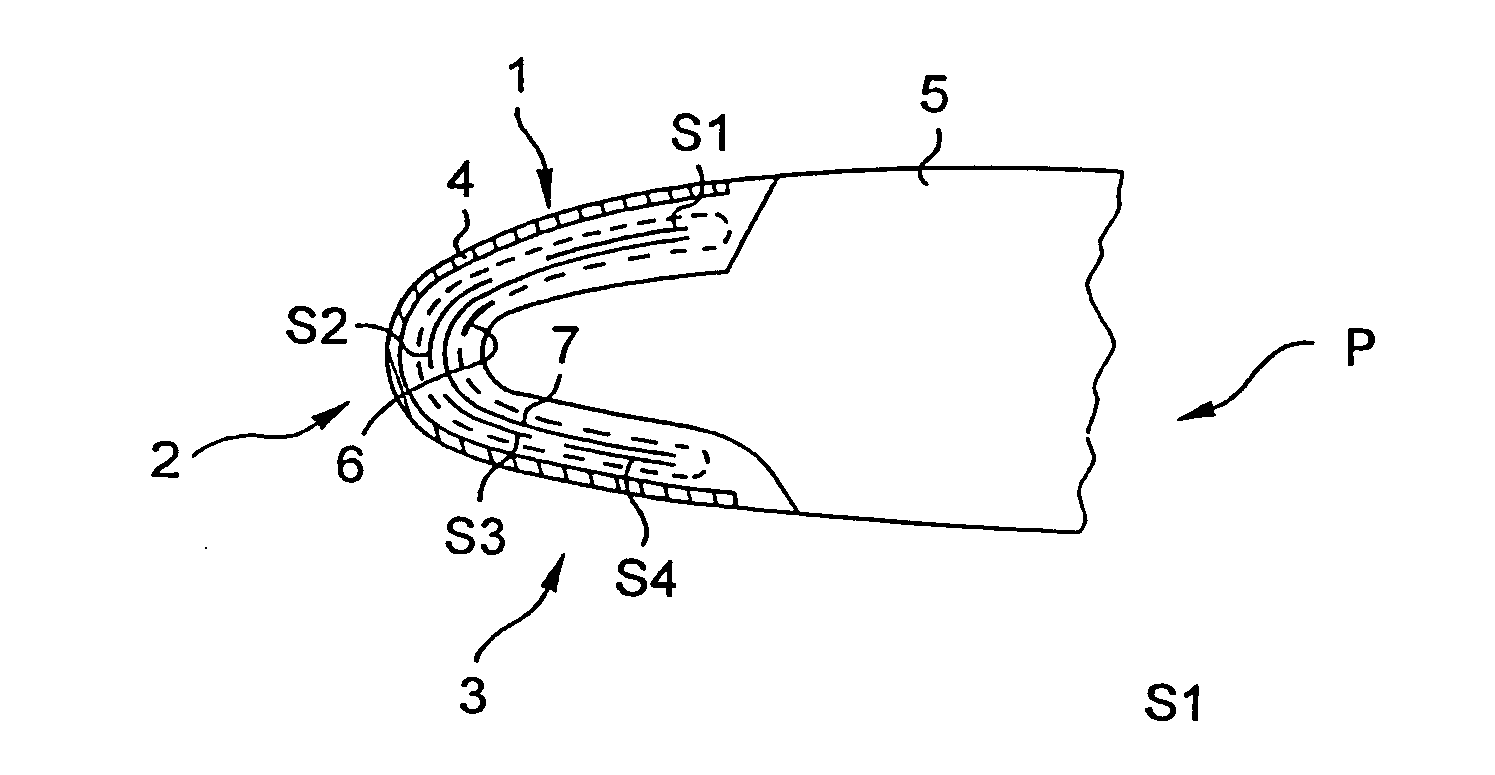

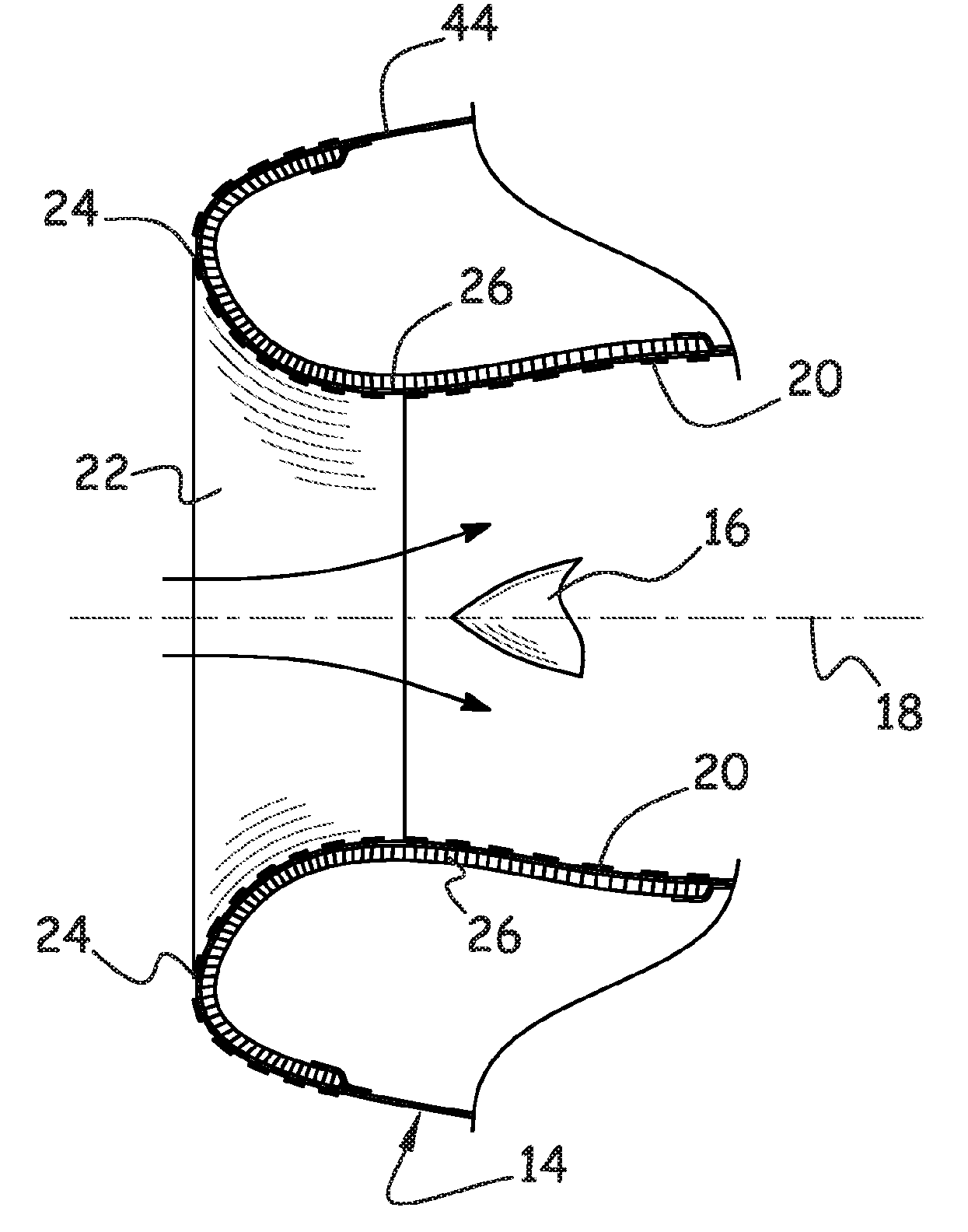

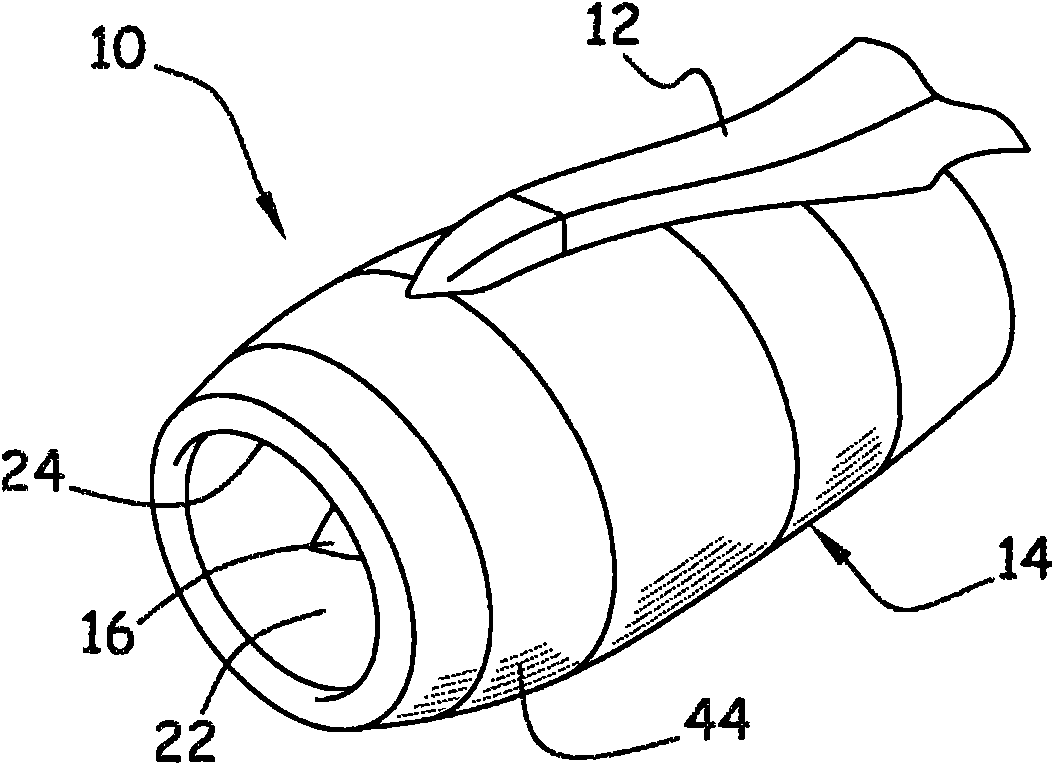

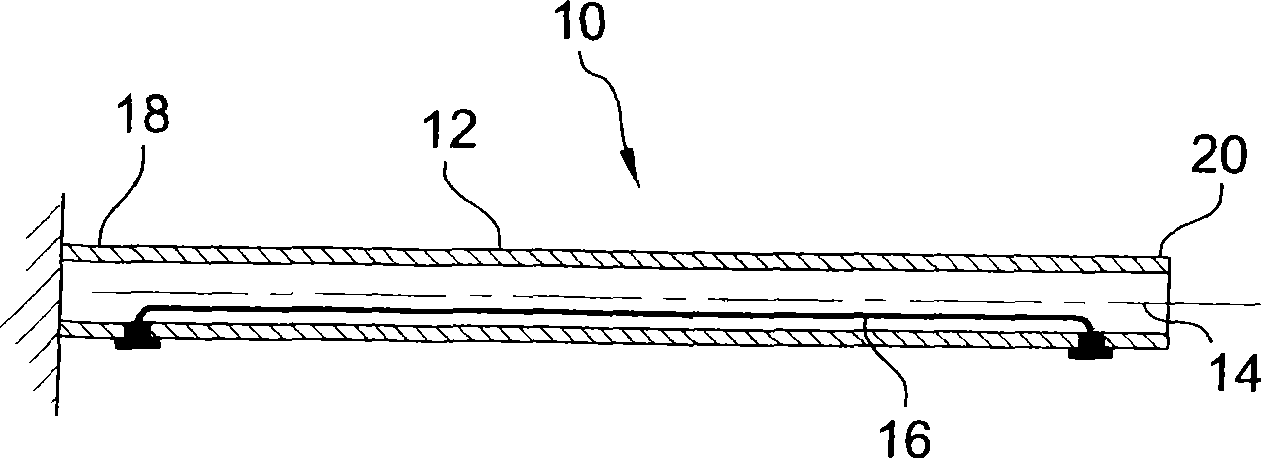

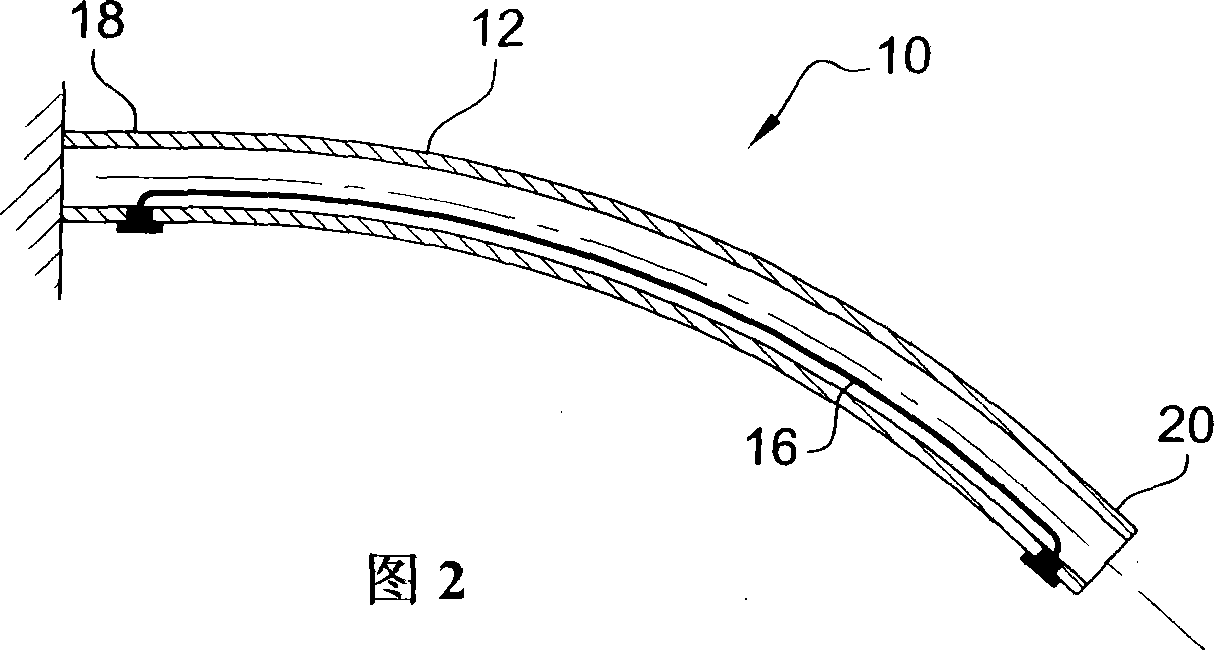

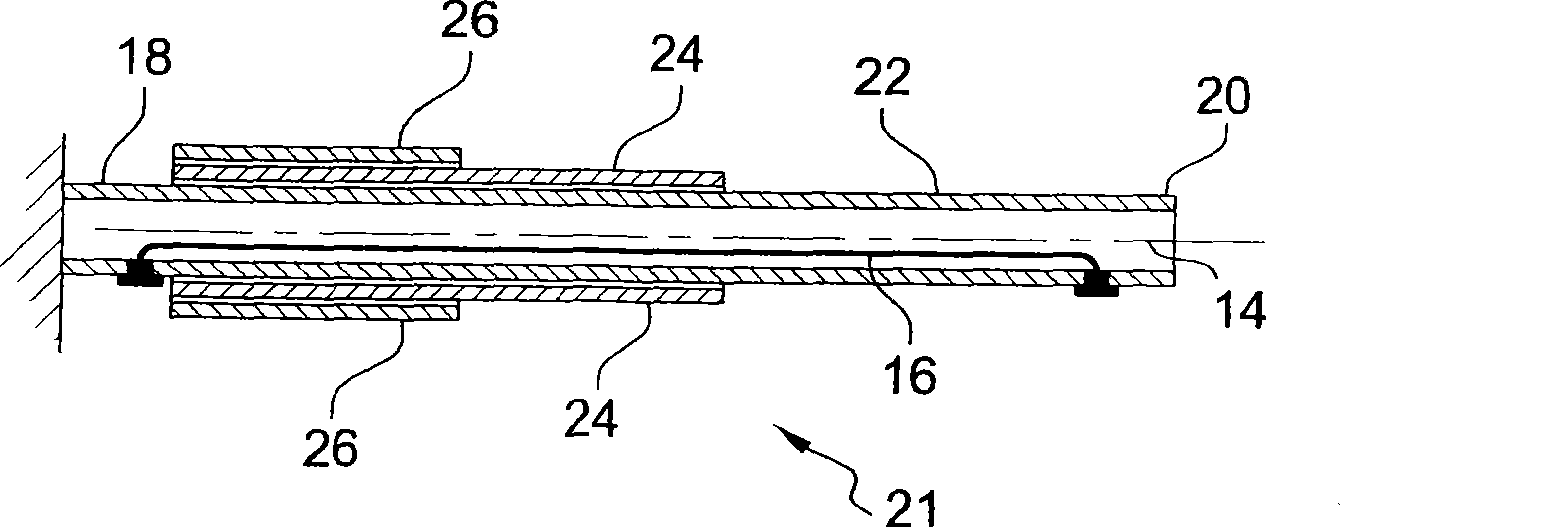

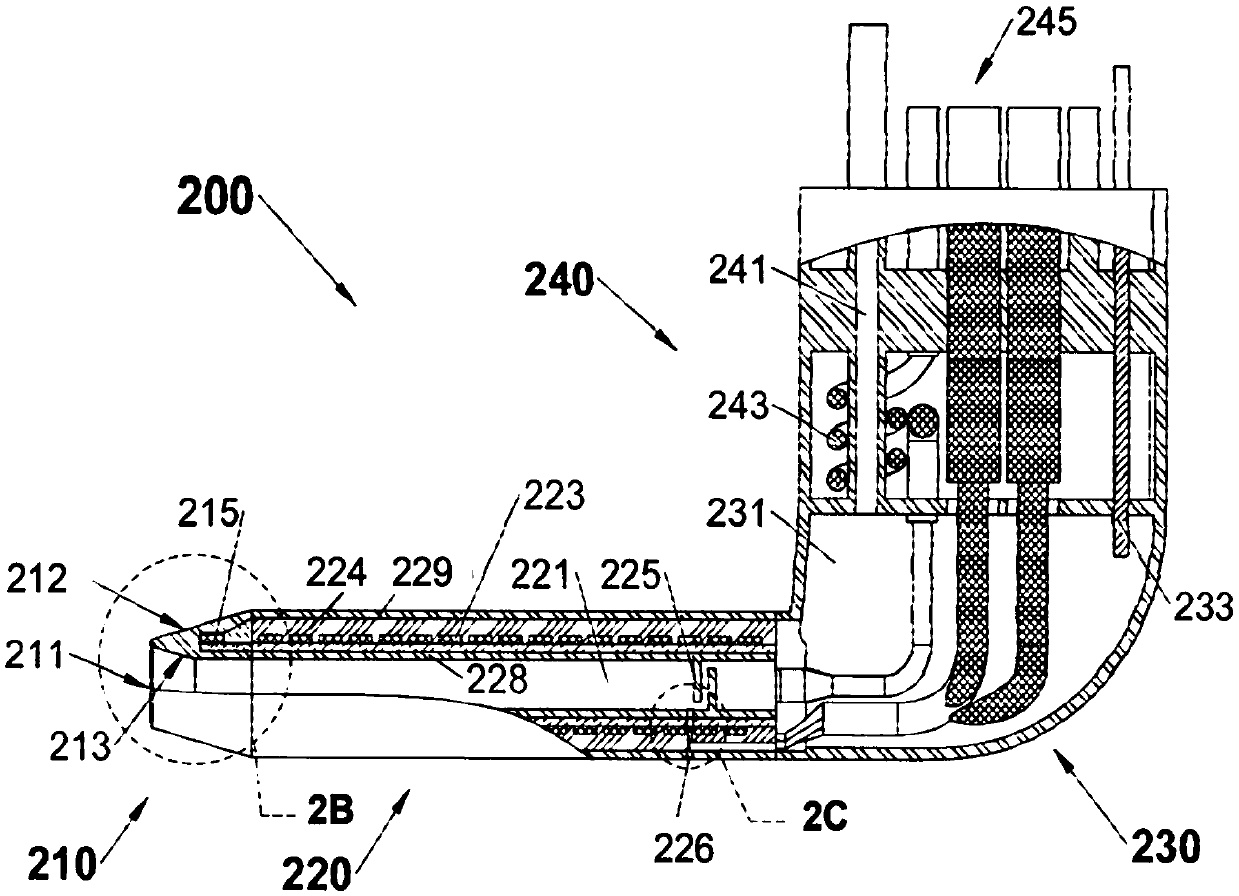

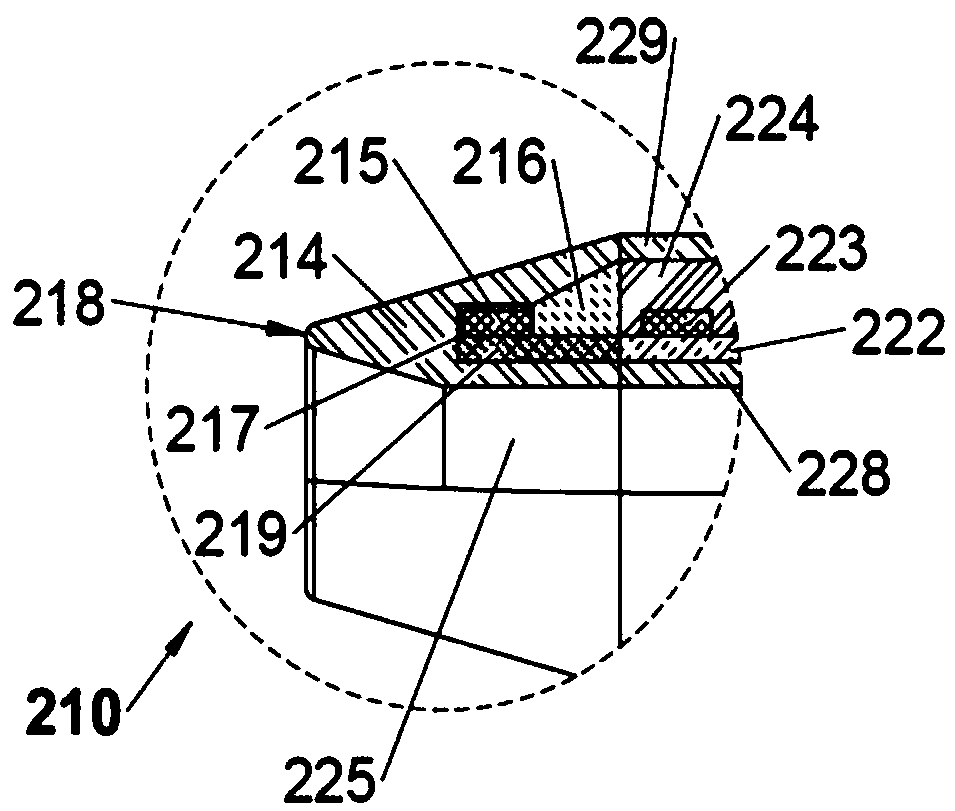

Guidable structure such as a catheter or an endoscope

ActiveCN101416868AReduce curvatureGet curve profileMachine part testingMaterial analysis using sonic/ultrasonic/infrasonic wavesMemory typeEngineering

The invention relates to a steerable structure (21, 27) of the catheter or endoscope type, the structure comprising an elastically or deformable longitudinal body (22, 28) including at least one actuator (16, 38) of material of the shape memory type incorporated longitudinally with the body (22, 28) together with Joule-effect heater means enabling the actuator (16, 38) to be contracted longitudinally in order to cause the longitudinal body (22, 28) to bend, wherein the actuator (16, 38) extends over at least one portion of the body (22, 28) that presents varying stiffness.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION (S N E C M A) +2

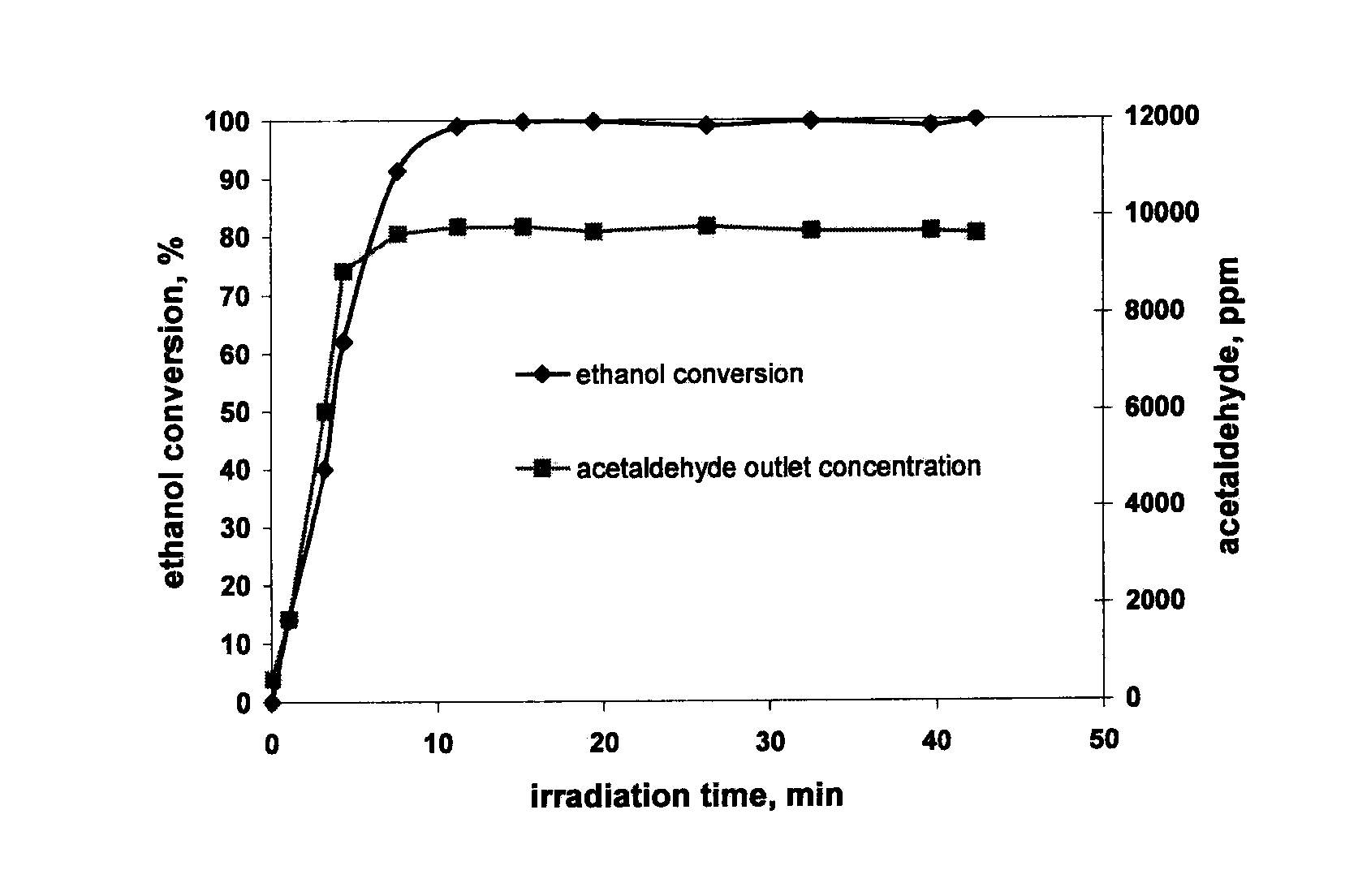

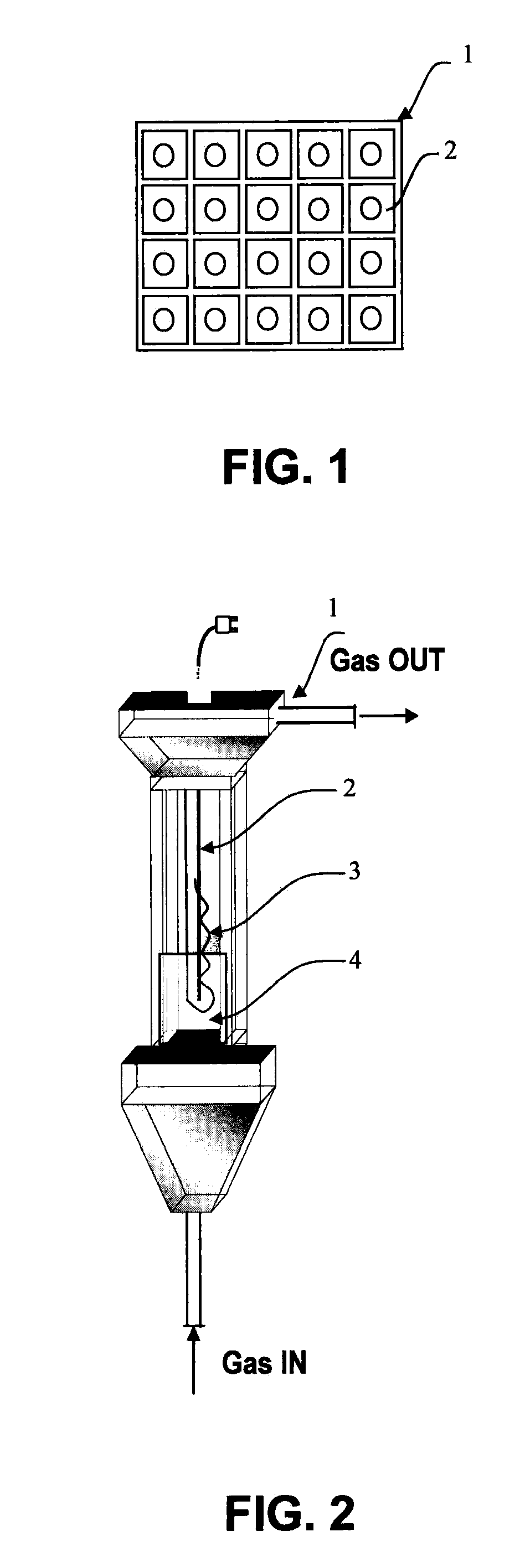

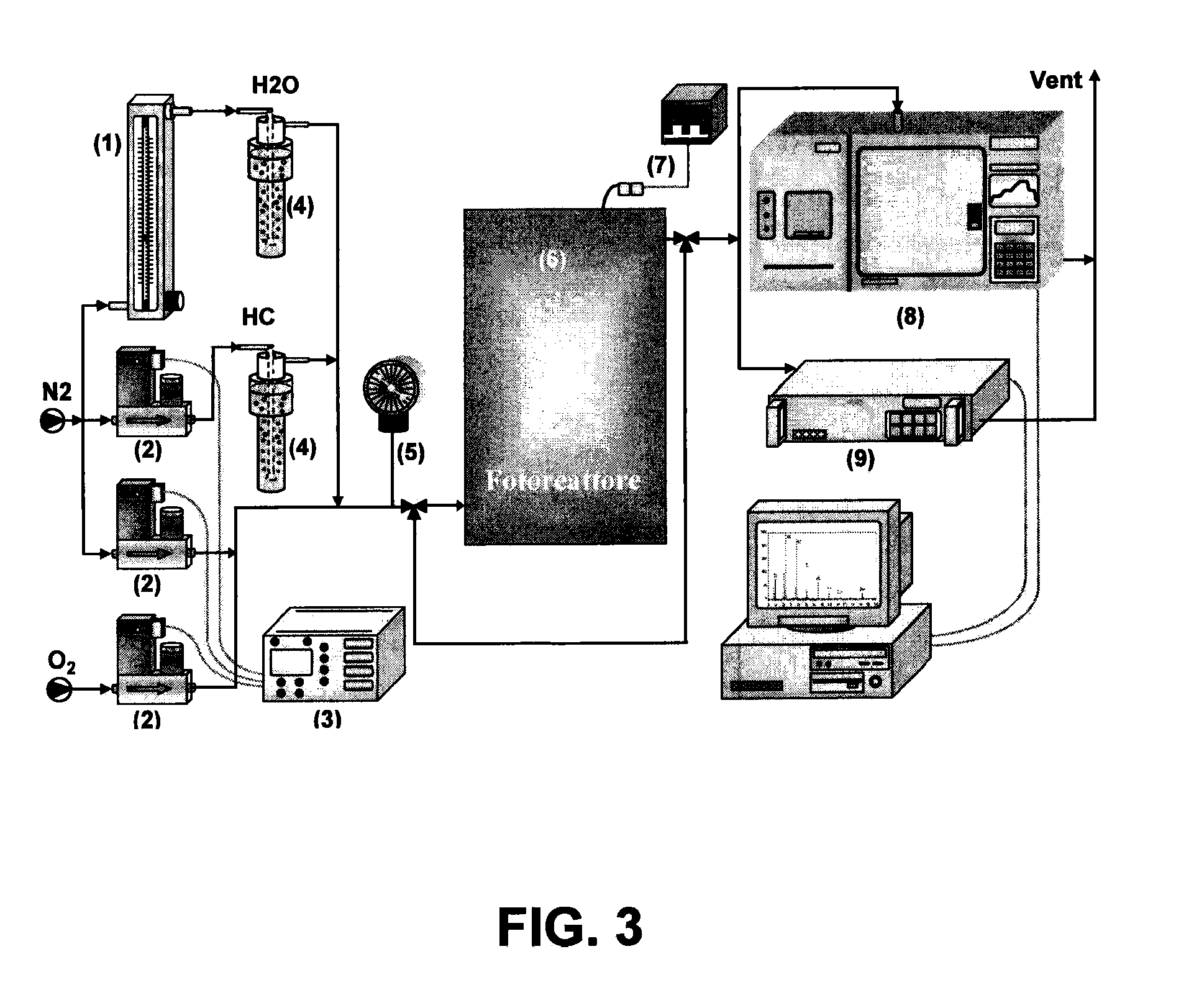

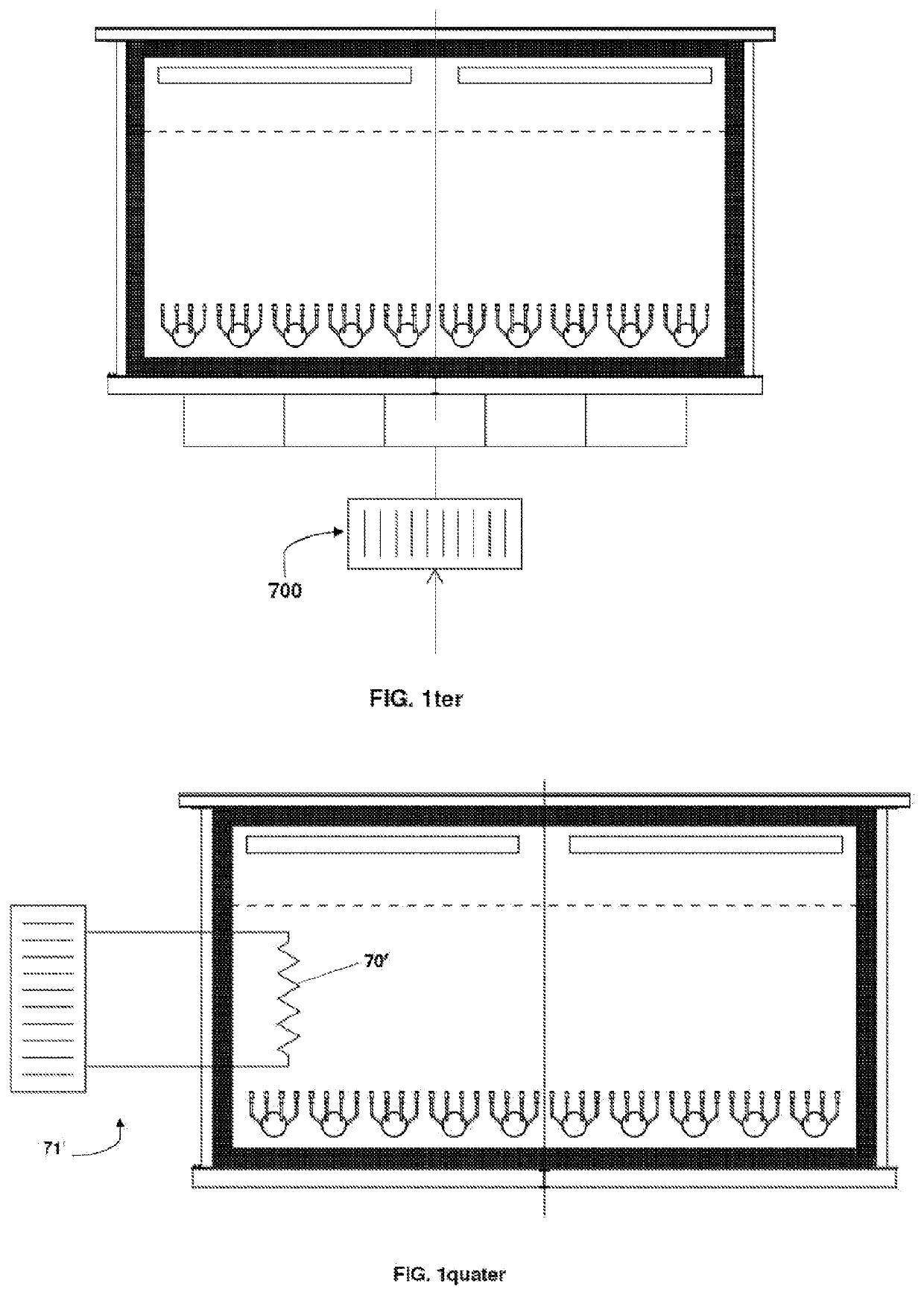

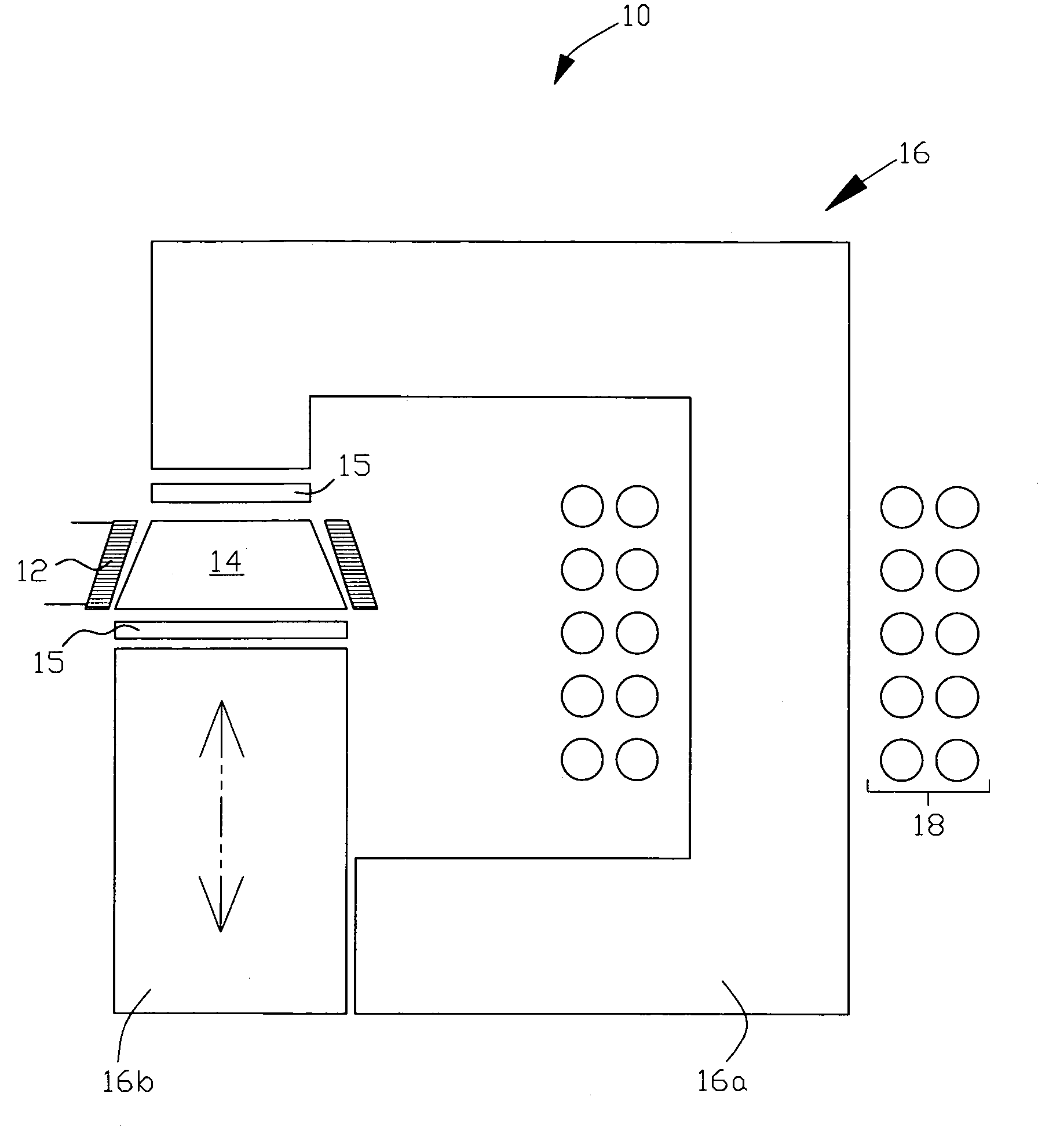

Photocatalytic fluidized bed reactor with high illumination efficiency for photocatalytic oxidation processes

InactiveUS20110123423A1Avoid separationIllumination efficiency is highChemical/physical/physico-chemical processesBulk chemical productionSlurry reactorPartial oxidation

The invention relates to the realization of synthesis of organic compounds or abatement of volatile organic compounds (VOCs) in gas-solid fluidised bed photocatalytic reactor with improved illumination efficiency. The photoreactor consists of a two-dimensional fluidized bed catalytic reactor with two walls transparent to ultraviolet radiation, by an illumination system bases on a matrix of LEDs positioned near its external walls, and heated for Joule effect inside the catalytic bed to monitor the reaction temperature. Surprisingly, through the choice of a suitable catalyst and fluidized bed photoreactor operating conditions both total and partial oxidation reactions can be achieved with high activity and selectivity. Even more surprisingly, the value of the illuminated catalyst surface area per unit irradiated volume reaches values in the order of 106 m−1, significantly higher than those of microreactors, amounting to 250,000 m−1 and slurry reactors with values in 8500-170000 m−1.The photocatalytic system reported in the present invention is shown to have high illumination efficiency due to the use of UV-LEDs, which, ensuring a direction of light irradiation direction orthogonal to the emission point, minimize the dispersion of photons.

Owner:UNIV DEGLI STUDI DI PARMA

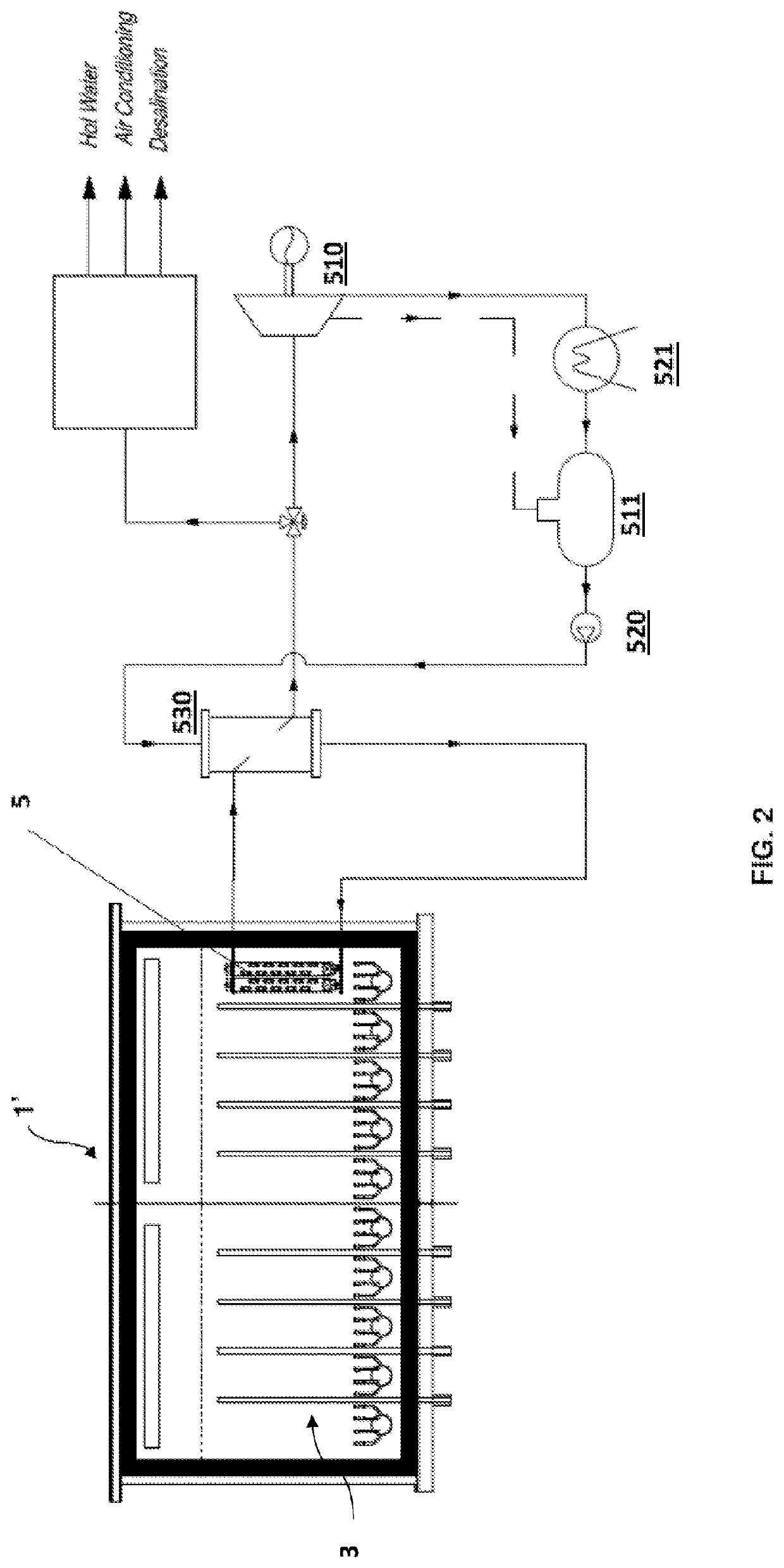

Plant and method for accumulation of energy in thermal form

PendingUS20220090827A1Zero environmental impactImprove efficiencySolar heating energyHeat storage plantsThermodynamicsEngineering

A plant for the accumulation and transfer of thermal energy, which plant has an accumulation device of the kind with a bed of fluidizable solid particles. The plant further has for each accumulation device:electric resistor means arranged within the casing and thermally connected with the bed of particles, which electric resistors are configured for transmitting thermal energy generated by Joule effect to the particles and they are fed by exceeding electric energy from wind or photovoltaic source; andheat exchange means, also thermally connected with the bed of particles and which can be selectively actuated to receive thermal energy therefrom,the overall configuration being such that the thermal energy is transferred from the resistor means to the fluidizable solid particles of the bed and from the fluidizable solid particles to the heat exchange means.

Owner:MAGALDI POWER SPA

Systems and methods for structural sensing

InactiveUS8684595B2Thermometer detailsNanosensorsElectrical resistance and conductanceStructuring element

Systems and methods related to the determination of one or more mechanical characteristics of a structural element are generally described. In some embodiments, a mechanical characteristic (e.g., a crack, a deformation, an inclusion, etc.) can be determined based at least in part upon the determination of a temperature generated, for example, by passing a current through a network of structures within the structural element. For example, in some embodiments, the structural element can comprise a network of electrically conductive nanostructures and, in some cases, a primary structural material that is not substantially electrically conductive. An electrical current can be passed through the network of electrically conductive nanostructures (e.g., by passing current through an electrical circuit comprising the network of electrically conductive nanostructures). This may result in resistive heating (also known as Joule-effect heating) of the nanostructure network. In some embodiments, a first temperature of the network and / or structural elements can be determined (e.g., via a sensor associated with the electrical circuit). This first temperature can be, in some cases, indicative of a mechanical characteristic of the structural element. In some embodiments, one or more mechanical characteristics of the structural element can be determined based at least in part upon the determination of the first temperature of the structural element.

Owner:MASSACHUSETTS INST OF TECH

Process and installation for pyrolysis of a product in the form of divided solids, in particular polymer waste

InactiveUS20140284198A1Improve pyrolysis efficiencyHigh methane contentElectrical coke oven heatingDirect heating destructive distillationElastomerLiquid state

An installation for pyrolyzing divided solids, such as waste plastics, rubbers, or elastomers. The installation has a device for making divided solids suitable for facilitating pyrolysis by a pyrolysis reactor. The reactor inlet is leak-tightly connected to the preconditioning device and has at least one heating transfer member for transferring the divided solids within the reactor while also pyrolyzing the solids. The member is a conveyor screw or a vibrating tube, and being made of a material that is associated with means for heating it by the Joule effect. The preconditioning device includes liquefaction means for bringing the substance to the outlet of the preconditioning device in a liquid state at an outlet temperature, and a regulator for regulating the temperature of the substance at the outlet from the preconditioning device as a function of a temperature representative of an inlet temperature of the reactor.

Owner:LEPEZ CONSEILS FINANCE INNOVATIONS LCFI

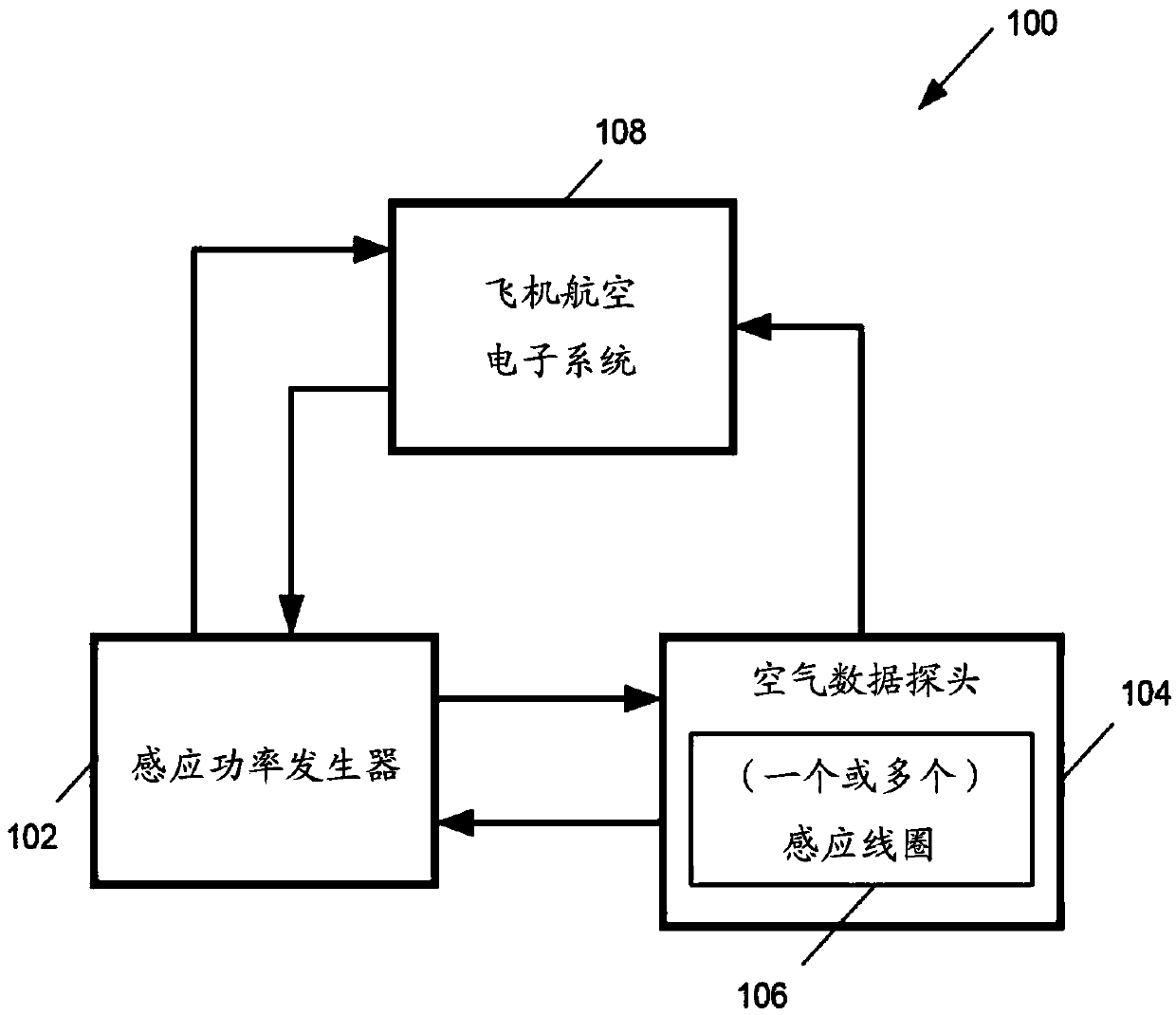

Air data probe with induction heating function and temperature control method thereof

PendingCN109683642AOvercoming the disadvantages of heatingMeasurement devicesTemperature control using electric meansHysteresisAlternating current

The invention relates to an air data probe with an induction heating function and a temperature control method thereof. A system is provided, the system includes an air data probe with an induction coil and an induction power generator. In some examples, a pitot tube has an induction coil with a straight tube portion and an induction coil with a tip or tapered portion. The induction power generator provides a high frequency alternating current signal to one or more induction coils. The induction coils generate an alternating magnetic field inside the conduction portion of the pitot tube aroundthe induction coils so that heat is co-generated by the joule effect and hysteresis effect caused by eddy current. The control system independently controls the signals, which includes frequency, current and voltage and are applied to the respective induction coils.

Owner:ORIGINEX ENG SHANGHAI CO LTD

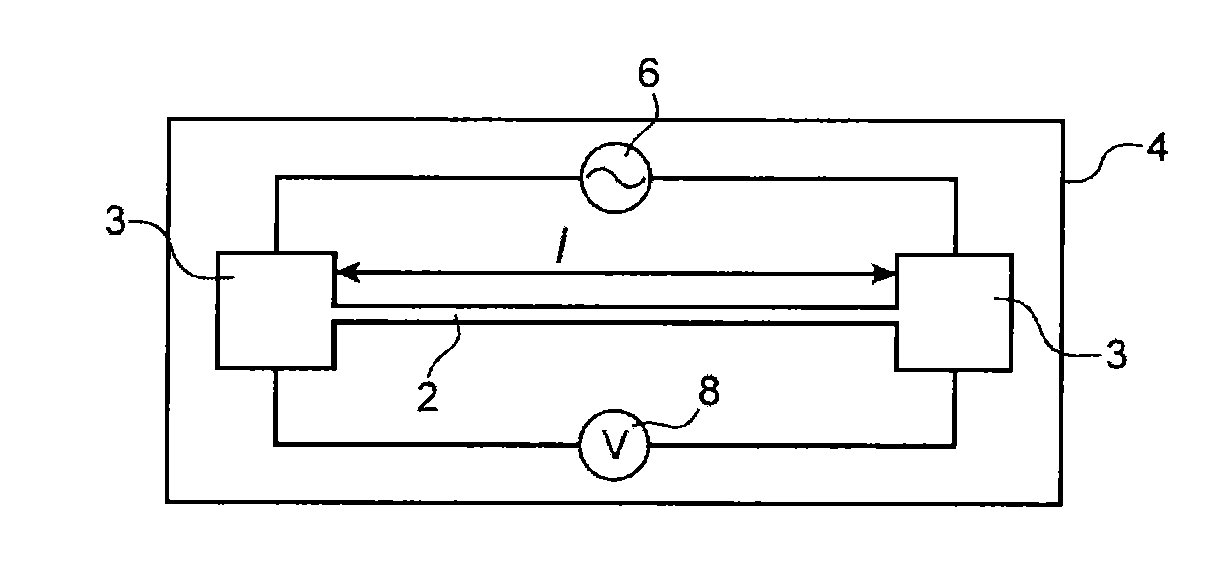

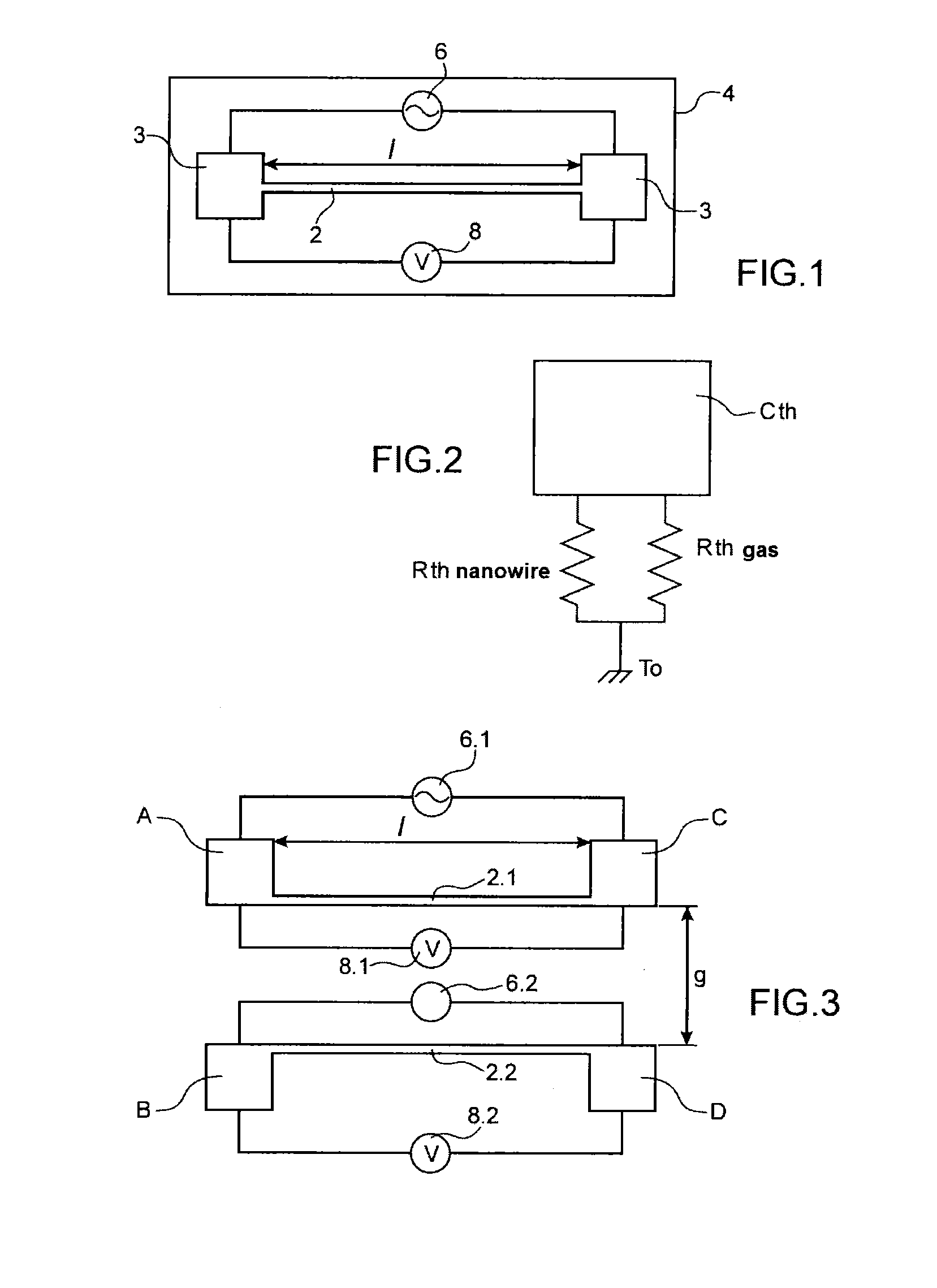

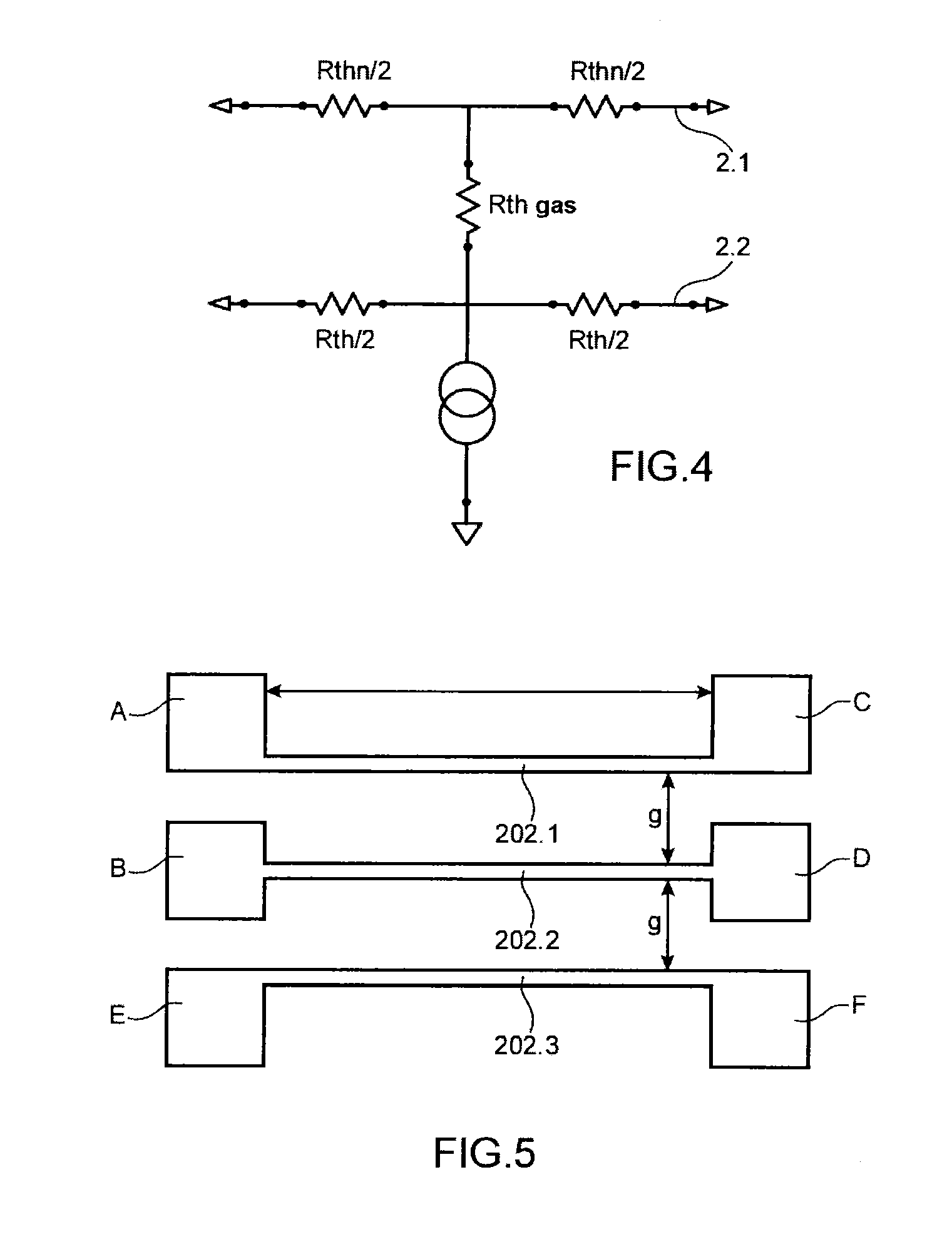

Thermal flow sensor, gas sensor comprising at least one such sensor and pirani gauge comprising at least one such sensor

ActiveUS20150247828A1Small sizeLow constantNanotechMaterial thermal conductivityNanowirePirani gauge

A thermal flow sensor comprising at least one first element (2) suspended with respect to a support, said first suspended element (2) being of an electrically conductive material, first means (6) for biasing said suspended element (2) and first means (8) for measuring the variation of the electric voltage at the terminals of the suspended element (2), said first suspended element (2) being formed by a nanowire and said first biasing means (6) are formed by an alternating current source the intensity of which provides heating of the first suspended element (2) by Joule effect.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

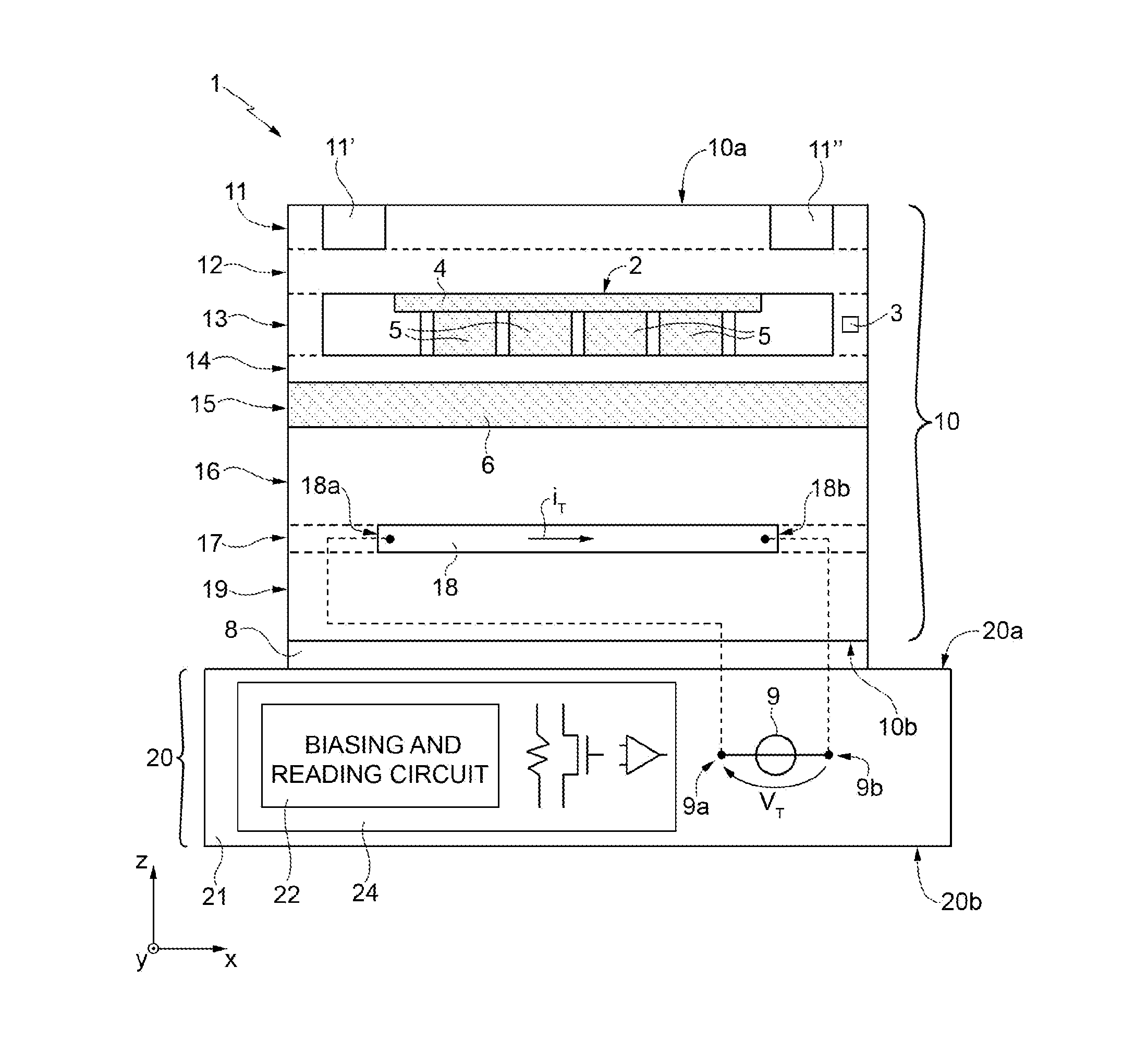

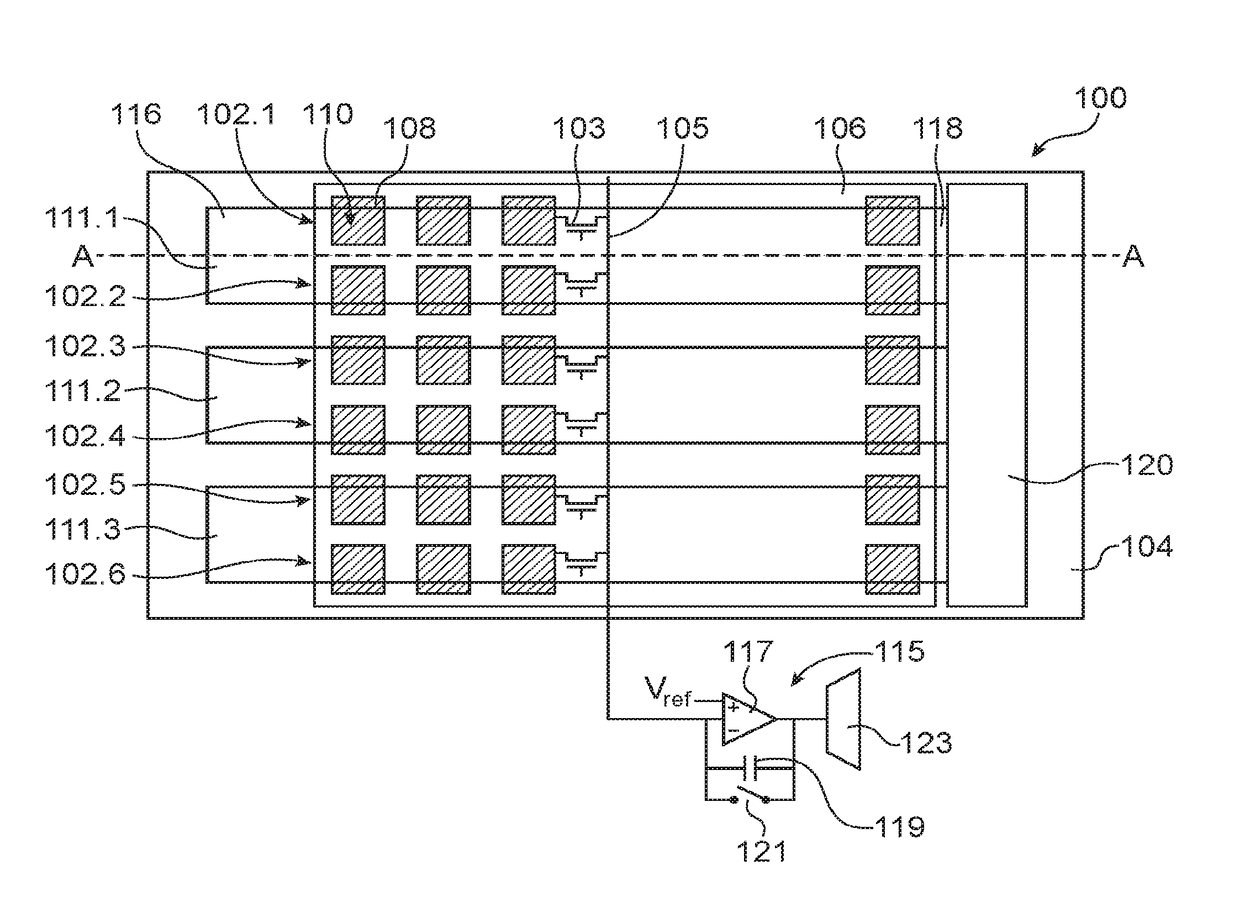

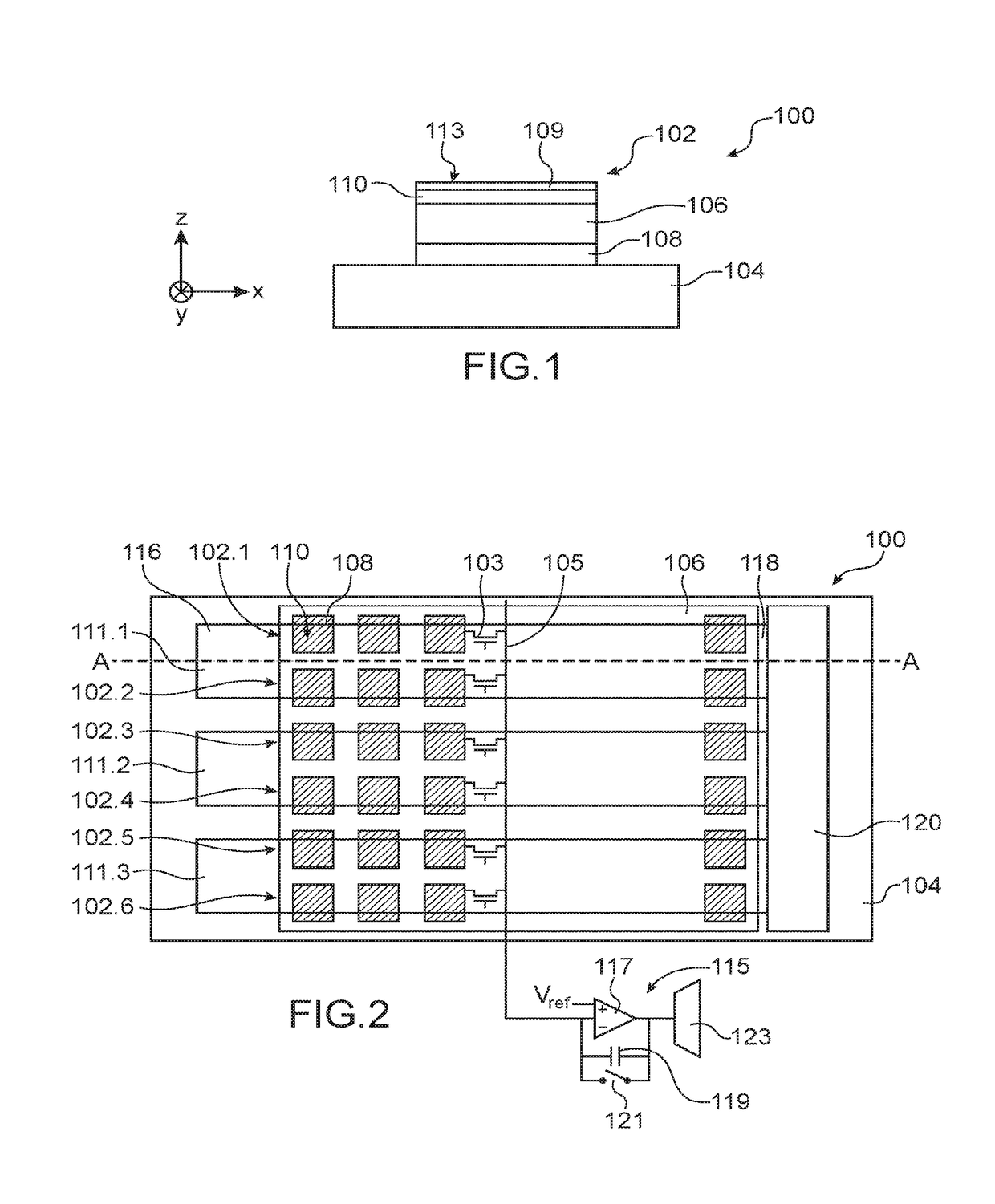

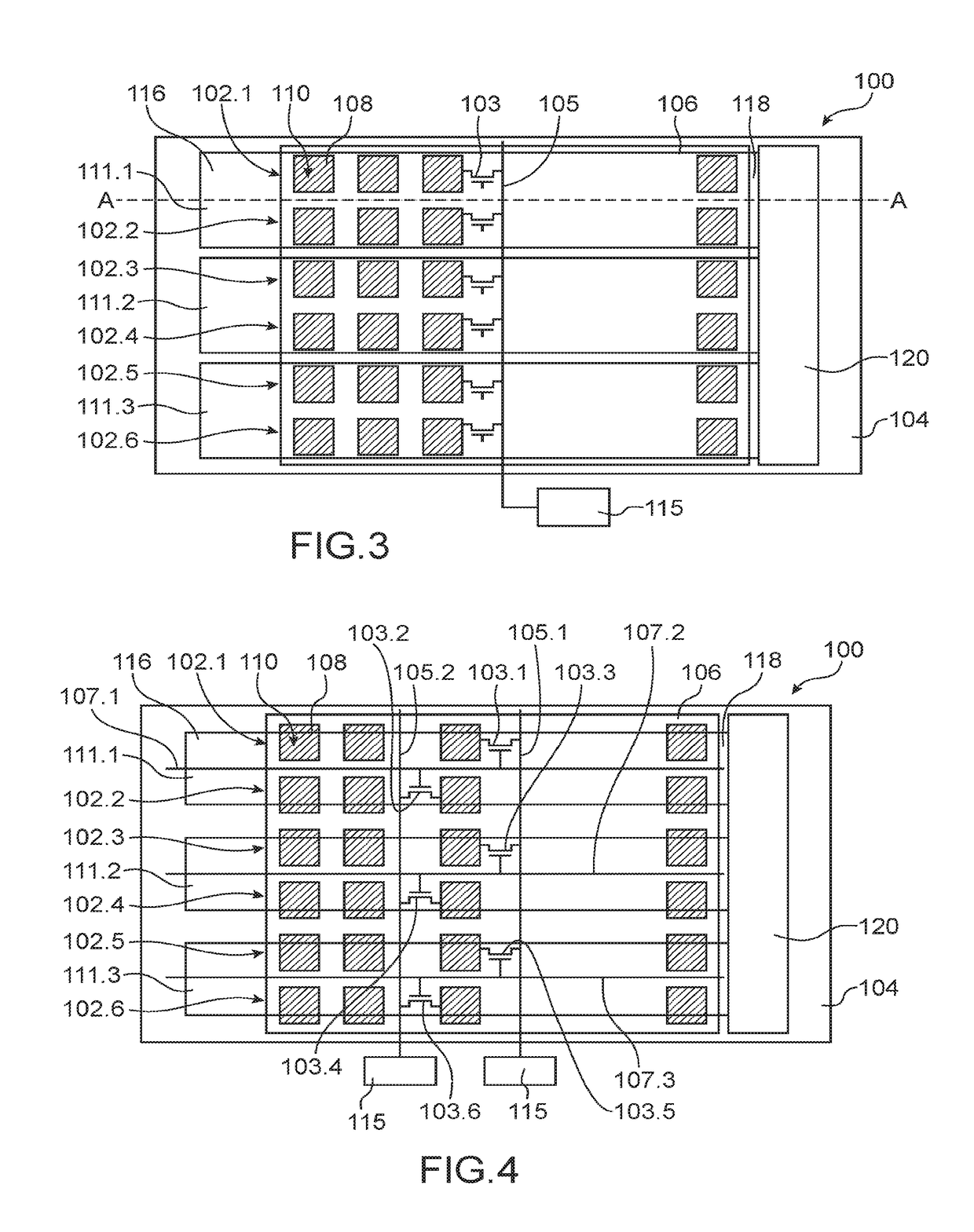

Thermal pattern sensor with shared heating elements

ActiveUS20180032781A1Reduce in quantityRead intuitivelyCurrent/voltage measurementElectronic switchingCapacitanceThermoelectric materials

Thermal pattern sensor comprising a matrix of several lines and columns of pixels, each pixel comprising at least one pyroelectric capacitance formed by at least one portion of pyroelectric material arranged between a lower electrode and an upper electrode, wherein a first of the lower and upper electrodes forms an electrode for reading the pixel, and moreover comprising a plurality of electrically conductive portions each capable of Joule effect heating, independently of the other electrically conductive portions, of the portions of pyroelectric material of the pyroelectric capacitances of the pixels of at least two adjacent lines of pixels associated with the electrically conductive portion, and arranged facing at least a part of the surface of the reading electrodes of each of the pixels of the lines associated with the electrically conductive portion.

Owner:IDEMIA IDENTITY & SECURITY FRANCE +1

Multi-frequency heat treatment of a workpiece by induction heating

InactiveUS7253381B2Coil arrangementsIncreasing energy efficiencyHigh frequency powerMagnetic field coupling

An apparatus and process are provided for multi-frequency induction heat treatment of workpieces including gears. High frequency power is applied to an induction coil that surrounds the workpiece so that a high frequency magnetic field couples with the workpiece to inductively heat the workpiece. A C-core inductor is coupled to a coil that has low frequency power applied to it. The workpiece is inserted in a gap in the C-core inductor magnetic circuit so that it experiences low frequency Joule effect heating when the low frequency current is applied to the coil coupled with the C-core inductor. Alternatively the workpiece may be inserted around the C-core inductor when the workpiece has an opening.

Owner:INDUCTOHEAT INC

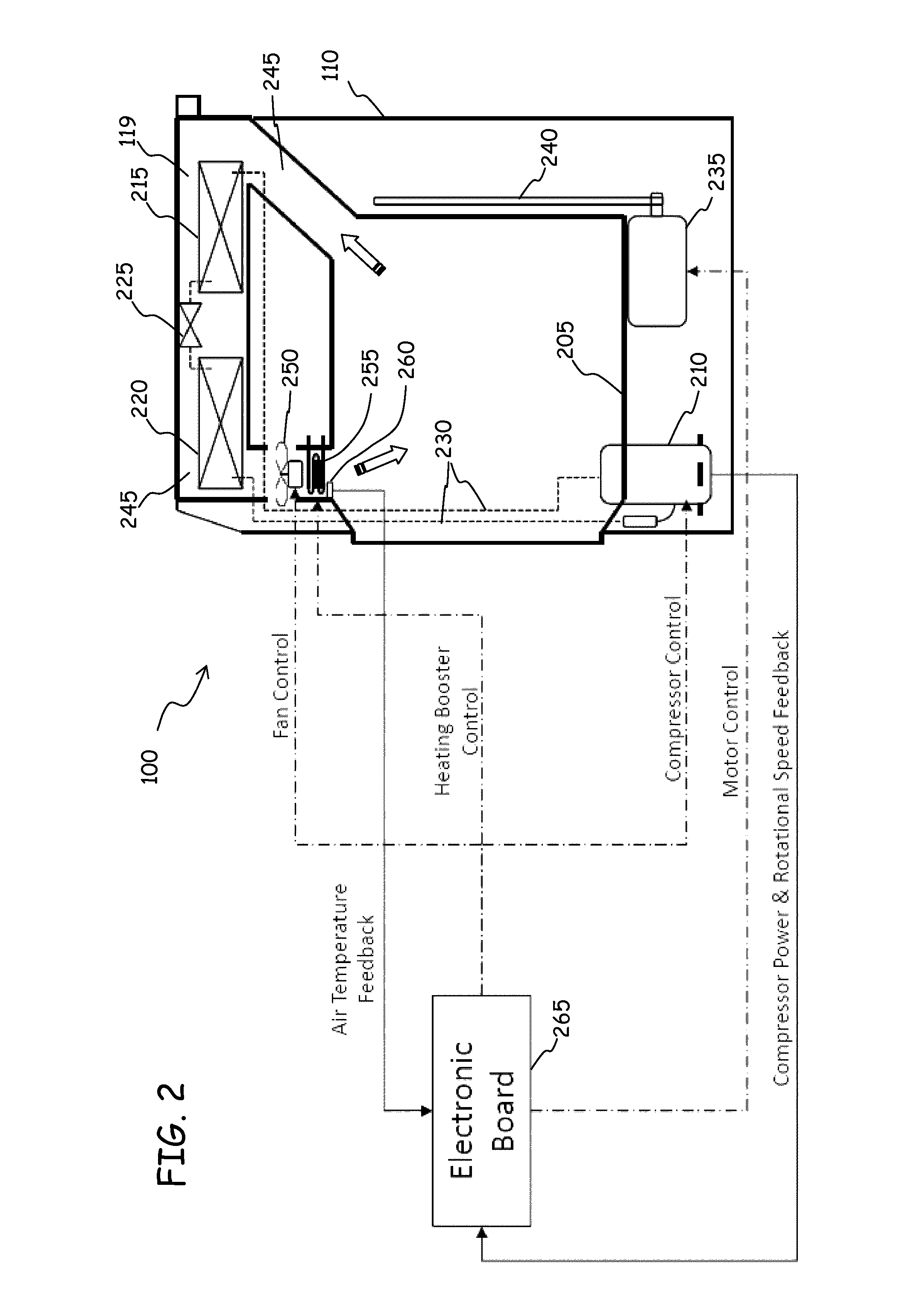

Appliance for Drying Laundry

Appliance for drying laundry (100), comprising a drying-air moisture-condensing system comprising a heat pump system (215, 220, 225) with a first heat exchanger (215) for cooling the drying air and a second heat exchanger (220) for re-heating said drying air, and a variable-output compressor (210), and at least one Joule-effect heater (255) located downstream the heat pump heat exchangers for boosting the heating of the drying air. The appliance can perform at least one drying cycle in: at least a first drying mode, wherein said heater is kept de-energized and the compressor is driven to a first compressor mode having a compressor power consumption course and / or a compressor rotational speed course and / or a frequency course of the supply current / voltage of the compressor motor, and at least a second drying mode, wherein said heater is kept energized for at least an initial portion of the drying cycle and thereafter it is kept de-energized, and the compressor is driven to a second compressor mode comprising a compressor power consumption course and / or a compressor rotational speed course and / or a frequency course of the supply current / voltage of the compressor motor, wherein for at least a portion of the drying cycle after the electric heater has been de-energized, a compressor power consumption and / or a compressor rotational speed and / or a frequency of the supply current / voltage of the compressor of the second compressor mode is / are higher than the one / s of the first compressor mode.

Owner:ELECTROLUX HOME PROD CORP NV

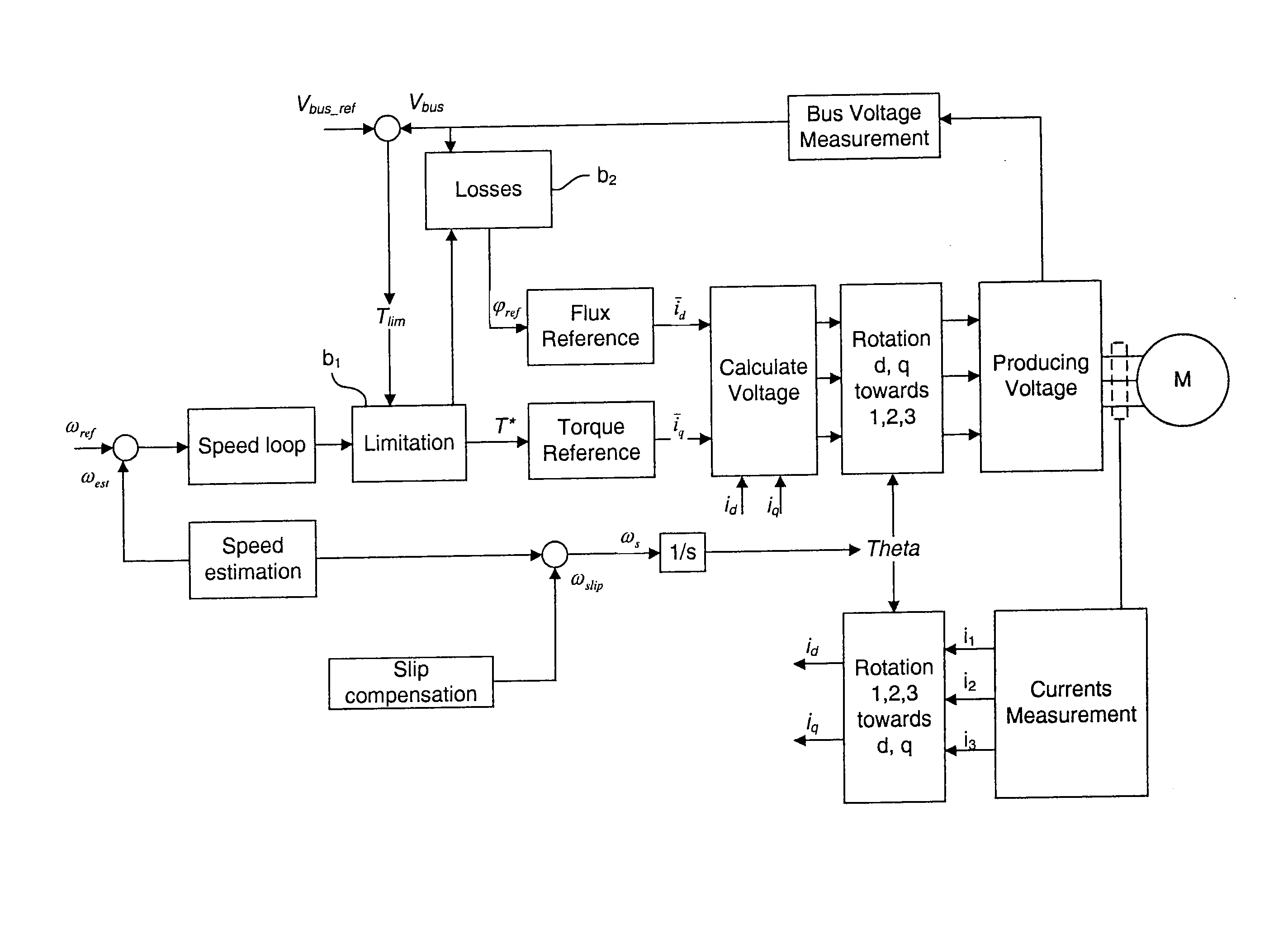

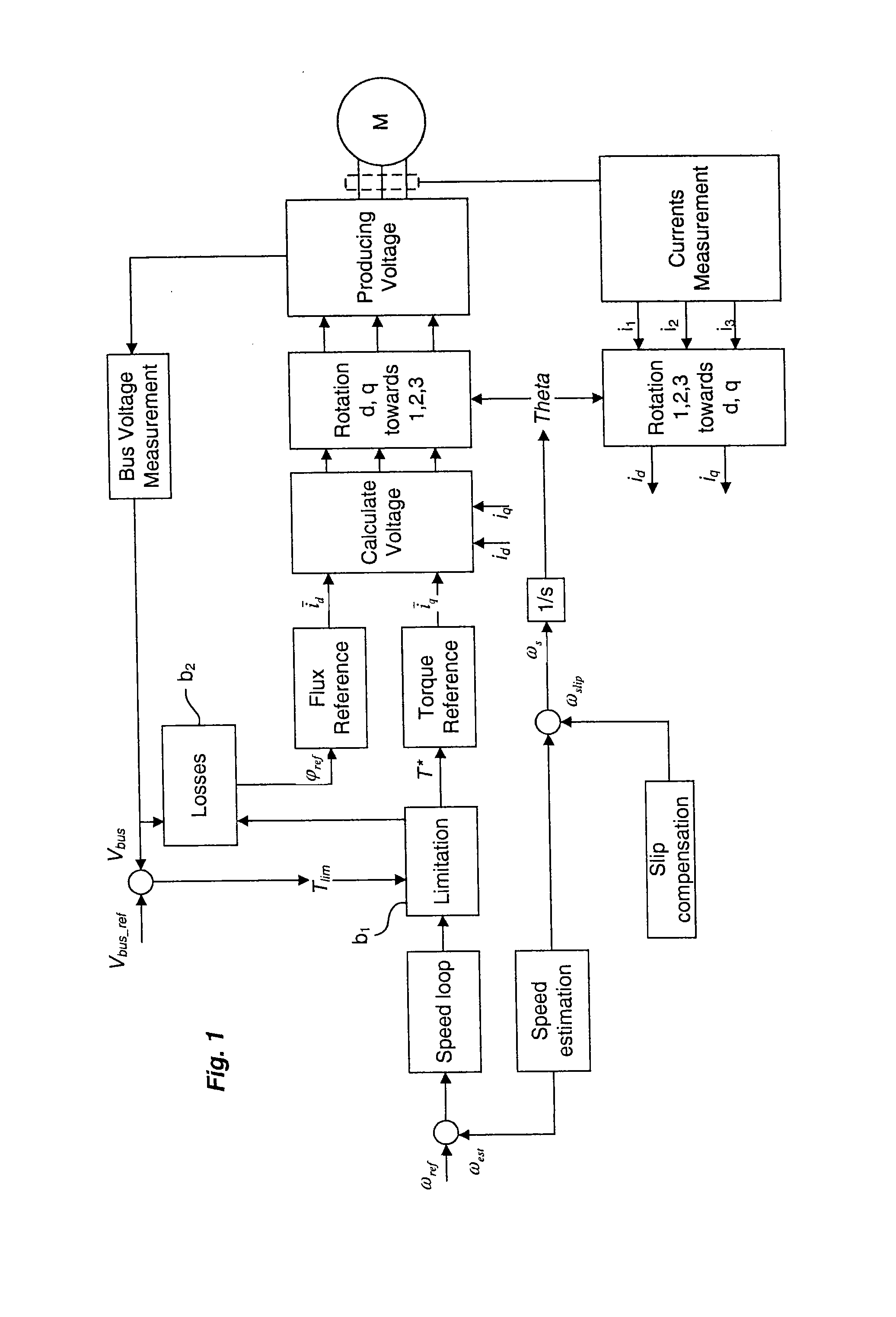

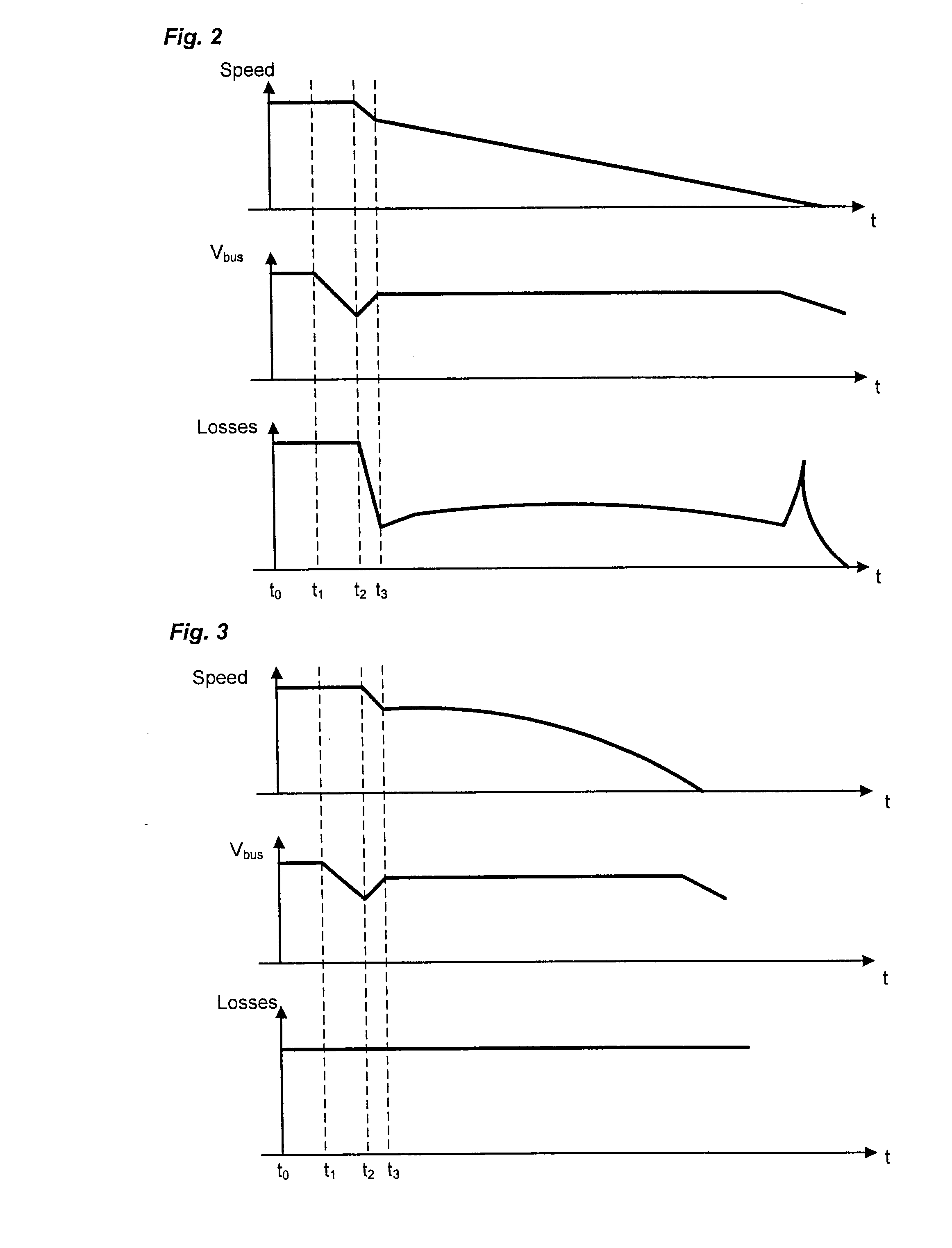

Method of control implemented in a variable speed drive for controlling the deceleration of an electric motor in the case of power outage

ActiveUS20130015790A1Electric motor controlVector control systemsAdjustable-speed driveControl theory

The invention relates to a method of control implemented in a variable speed drive for controlling the deceleration of an electric motor (M) in the case of electrical power outage. The method of control comprises:a step of determining the Joule-effect losses to be applied to the electric motor (M) and to the variable speed drive according to a deceleration ramp to be applied to the electric motor (M) during an electrical power outage,a step of determining the flux reference (φref) as a function of the said Joule-effect losses to be applied to the electric motor (M) and to the variable speed drive.

Owner:SCHNEIDER TOSHIBA INVERTER EUROPE SAS

Structural element with heater for a vehicle, manufacturing method and operating method

InactiveUS20180002024A1De-icing equipmentsHeating element materialsVoltage generatorElectrical resistance and conductance

A structural element of a means of transport comprising a resistive heater for defrosting operations, wherein the resistor has conduction terminals coupled to respective terminals of a voltage generator adapted to cause a current flux through the resistor. The resistor includes one or more conductive paths of partially reduced graphene oxide or partially oxidized graphene configured to generate, when travelled by the current flux, heat by Joule effect.

Owner:LEONARDO SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com