Air data probe with induction heating function and temperature control method thereof

A technology of air data and induction heating coils, applied in temperature control, electric temperature control, non-electric variable control, etc., can solve the problems of difficult temperature sensor, lack of reliability, and practical pitot tube temperature measurement method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

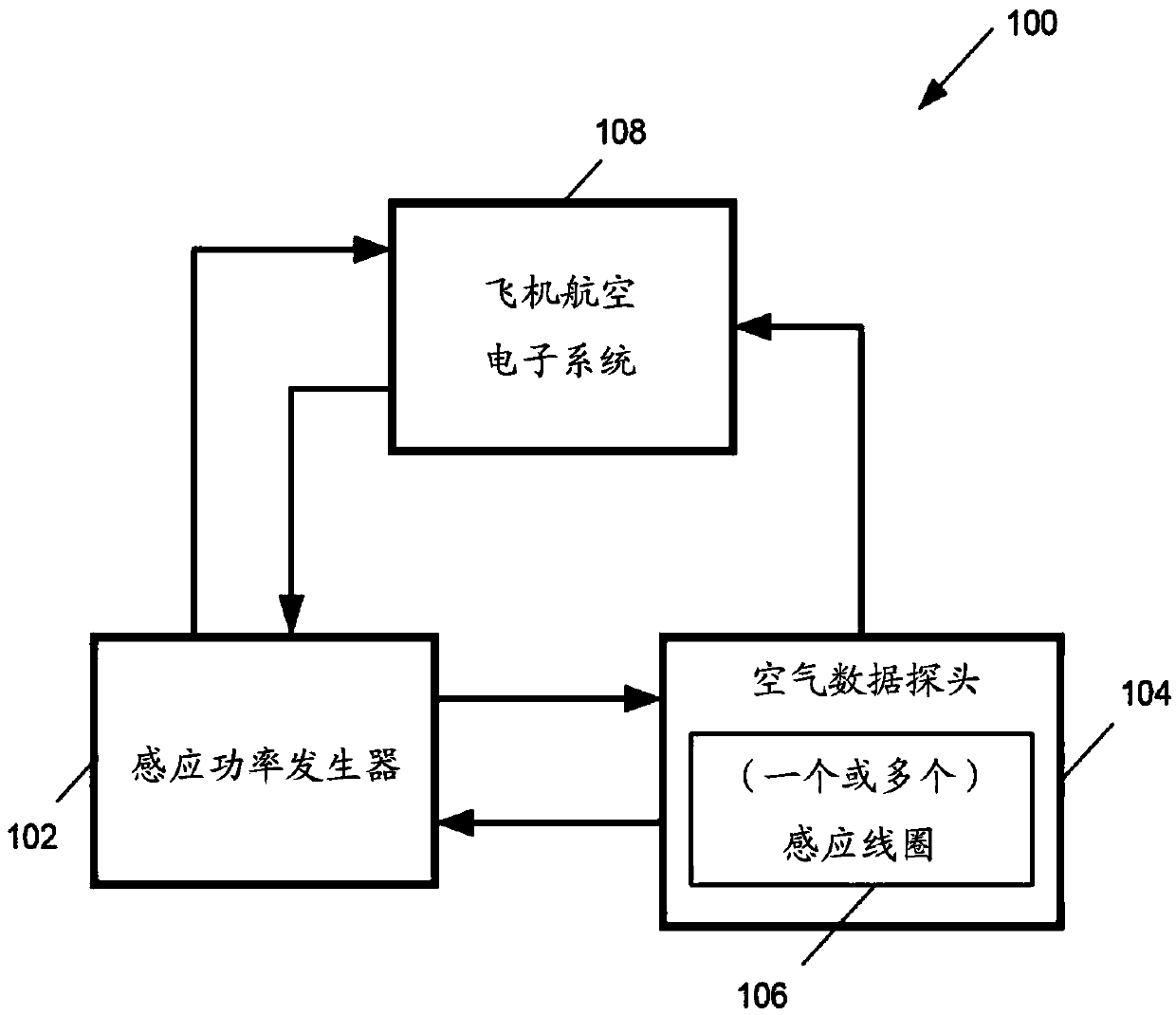

[0038] figure 1 is a block diagram of an air data probe system 100 according to an embodiment of the application. System 100 includes an inductive power generator 102 , an air data probe 104 with integrated induction coil 106 , and aircraft avionics system 108 . Arrows between components in the diagram indicate the direction of signal feed. These signals can be electrical signals, control signals, mechanical signals or any combination between them. The avionics system 108 here may include the aircraft electronics system without the associated inductive power generator 102 . Coil 106 may be a helical type, a single turn type or a pie plate type. The inductive power generator 102 includes a rectifier, an inverter, load matching circuits, and control and monitoring circuits. For example, it can convert the aircraft's 115 / 220V AC at 400Hz to the frequency and current / voltage required by the induction coil 106 embedded in the probe 104 . If the air data probe 104 has multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com