Induction heating roller temperature prediction method for edge part of working roller of aluminum strip cold-rolling mill

A technology of induction heating and prediction method, which is applied in metal rolling, manufacturing tools, temperature control, etc., to avoid production accidents and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

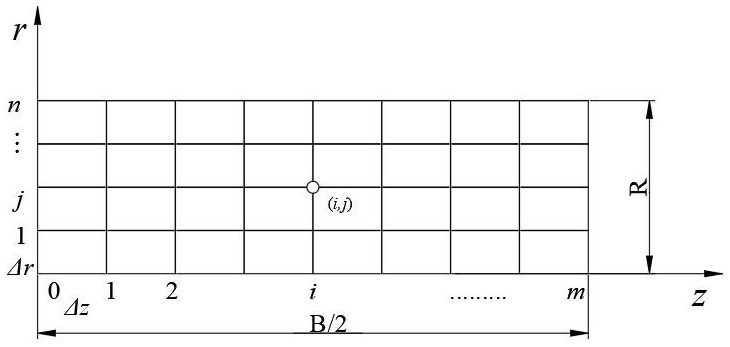

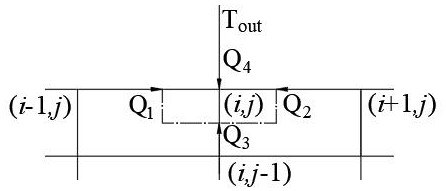

Method used

Image

Examples

Embodiment 1

[0091] In this embodiment, the detected work roll has a radius of 210 mm and an axial length of 1850 mm. The rolling temperature of the roll and the strip is set at room temperature 26°C, and the other parameters are as follows:

[0092] Table 1 rolling process parameters

[0093]

[0094] Table 2 Material parameters

[0095]

[0096]

[0097] Table 3 Electromagnetic induction heating parameters

[0098]

[0099] Table 4 Comparison of temperature simulation value and measured value

[0100]

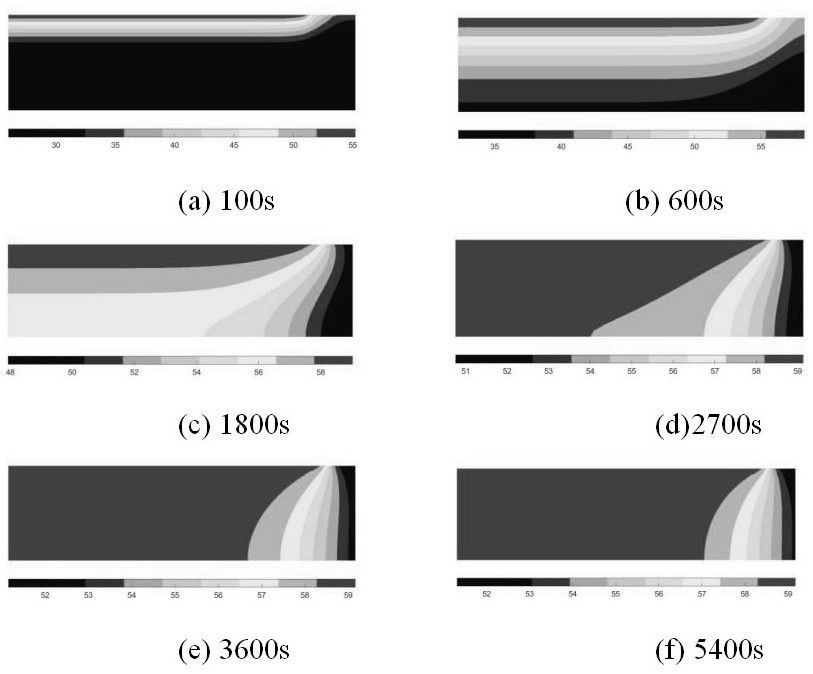

[0101] Using the process parameter conditions shown in Table 1-Table 3, the cold rolling temperature field of the work roll is calculated, and the calculation results are as follows image 3 — Figure 4 shown. In this embodiment, the forecast calculation is performed according to the data given in the first pass. in, image 3 In the cold rolling process of the present embodiment, the cloud map of the surface temperature of the work rolls, Figure 4 is the working ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com