Solid oxide fuel cell comprehensive experiment apparatus

A solid oxide and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of increasing the intake of secondary combustion-supporting air, achieve improved thermal efficiency, uniform temperature field distribution, and improved The effect of thermal efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1: Heating part, including burner and U-shaped heating tube

[0075] The burner is made of copper material. Such as Figures 12 to 14 with Figure 10 As shown, because the tail gas final discharge port 57 of the heating tube of the present invention is on the top of the SOFC comprehensive performance experiment device, the burner does not have the tail gas influence of the heating tube at the primary combustion air inlet 4 and the secondary combustion air inlet 6. As a result, the quality of the primary and secondary combustion air is improved (increased oxygen content). At the same time, the thermal efficiency of the burner is also improved.

[0076] Such as Figure 13 with Figure 11 As shown, the cathode fuel chamber 15 in the SOFC working area of the present invention is integrated into a common cathode fuel chamber. The cathode fuel chamber 15 is made of alumina material. The common cathode fuel chamber 15 makes the temperature distribution in t...

Embodiment 2

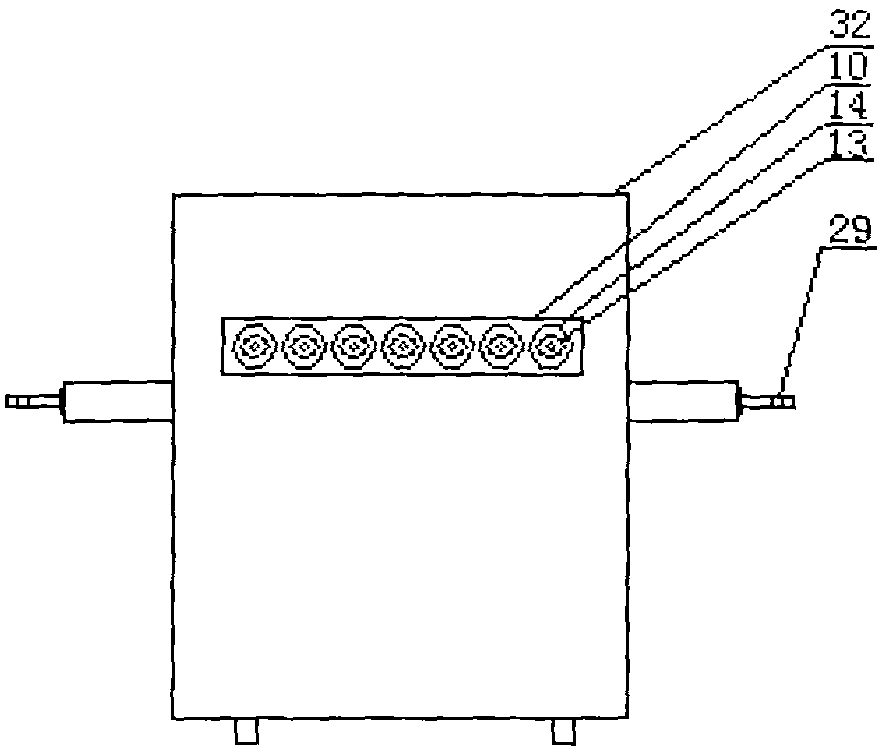

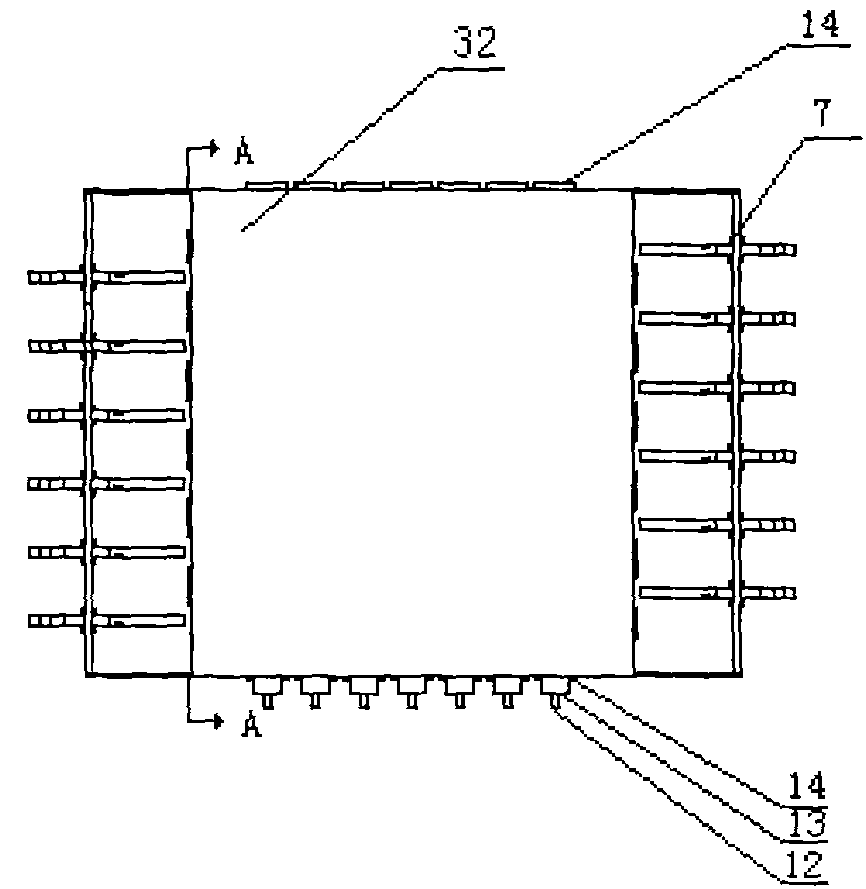

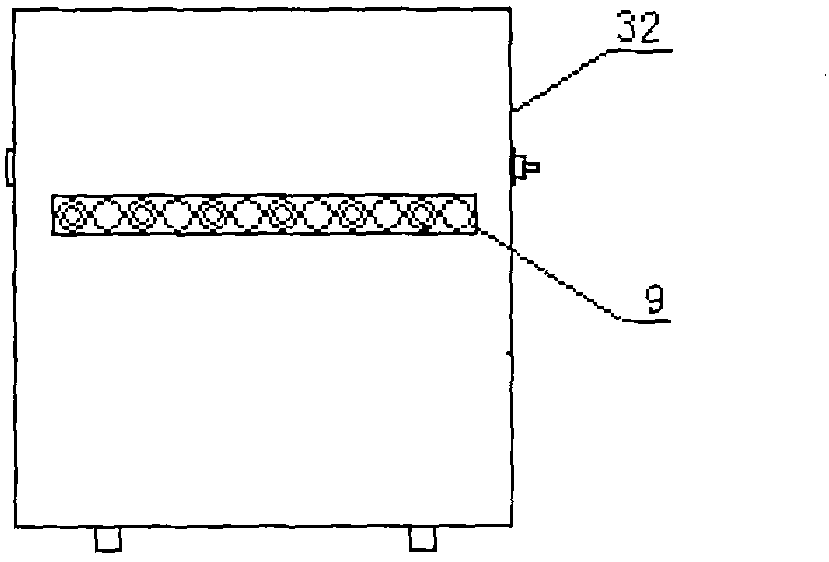

[0078] Example 2: Closed SOFC working area

[0079] Closed SOFC workspace such as Figure 11 As shown, the upper and lower sides of the SOFC working area 11 are a U-shaped heating tube 21 with a left opening and a U-shaped heating tube 25 with a right opening, a total of eighteen U-shaped heating tubes, and a connecting piece with a left opening 24 and the connecting piece 28 of the opening on the right side, a total of eighteen connecting pieces surround the closed SOFC working area 11 around. The U-shaped heating pipe 21 and the connecting piece 24 etc. of the opening on the left side are all made of alumina material. Moreover, heat-resistant materials are sealed between the heating pipes and between the connecting parts and the connecting parts. The cathode fuel chamber 15 around the SOFC in the SOFC working area 11 is also made of alumina plate and sealed. The space between the cathode fuel chamber 15 outside the SOFC tube 16 and the casing 32 is filled with a high temp...

Embodiment 3

[0082] Embodiment 3: the control of the flow rate and flow rate of fuel

[0083] For the control of fuel flow and velocity, see Figure 7 , Figure 9 with Figures 12 to 14 , the present invention has six anode fuel input ports 66, 67, 68, 69, 70, 53, and one cathode fuel at the cathode fuel input port 55, which enters the SOFC working area through three different paths at the above seven fuel input ports 11.

[0084] The first path is the three-way anode fuel input port 66, 67, 68, respectively connected to the corresponding anode fuel pressure gauge 47*6, and then respectively connected to the corresponding anode fuel flow meter 50*6, the anode fuel input port 66, 67, 68 are connected with the corresponding anode fuel pressure gauge 47*6 and the corresponding anode fuel flowmeter 50*6 respectively with stainless steel pipes. The anode fuel adjustment knob 84*6 on the anode fuel flowmeter 50*6 can control the anode fuel input flow and flow rate. After the three-way anode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com