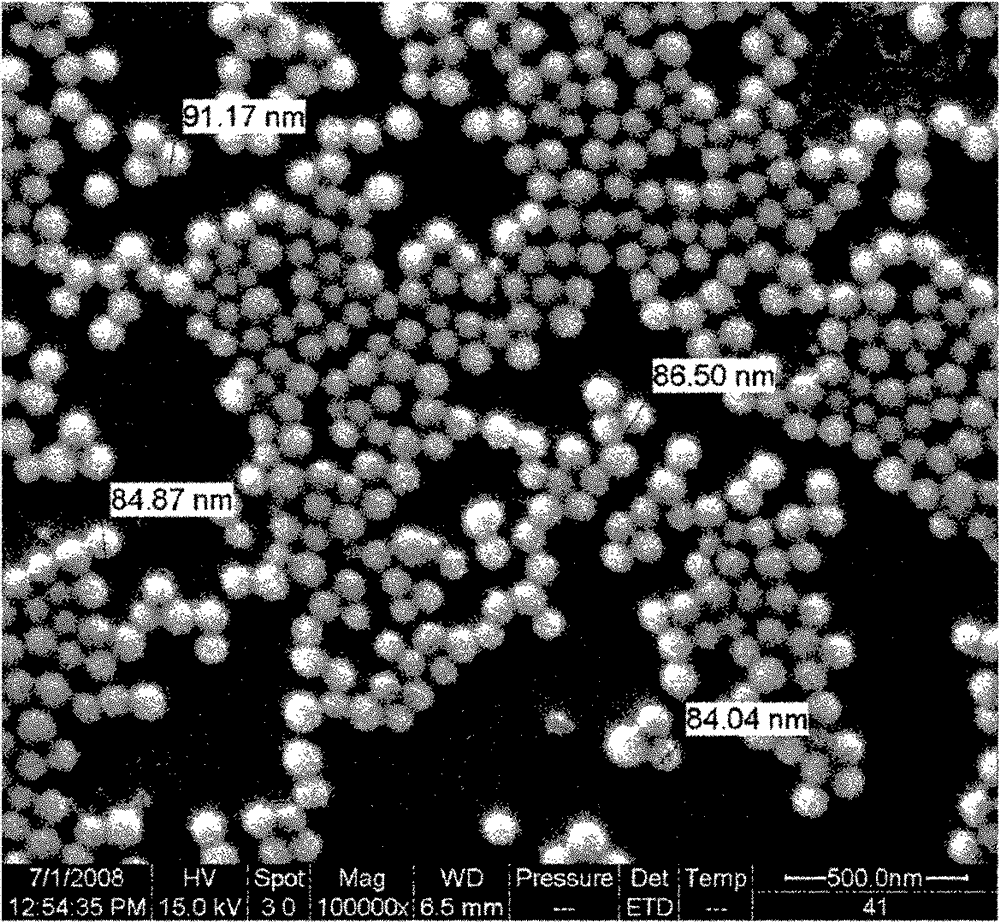

Method for preparing silica sol

A silica sol, sol technology, applied in chemical instruments and methods, silicon oxide, silicon dioxide, etc., to achieve the effects of convenient operation, uniform particle size distribution, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Get metal silicon powder (300 orders, purity is 99.9wt%) 1.3kg, 0.05kg sodium hydroxide and water 15kg are poured in the mixer, and heating steam is carried out material mixing and heating, and the flow rate of control hot steam is in 5L / min, the temperature of the hot steam is 110°C, the reaction temperature is controlled at 75°C, and the reaction is 4h to prepare the silica sol seed particle liquid;

[0038] (2) Take 10kg of the seed solution prepared in step (1) as the mother solution, add the reaction materials in batches, mix and heat the materials with hot steam, control the flow rate of the hot steam at 4L / min, and the temperature of the hot steam is 115°C , the reaction temperature is controlled at 80°C, and the following reaction materials are added in the first batch: a mixture of metal silicon powder 0.2kg, water 2kg, and sodium hydroxide 7g, and the feeding amount of each subsequent batch is higher than that of the previous batch Increase by 10%, feed to...

Embodiment 2

[0041] (1) Get metal silicon powder (200 mesh, purity is 90wt%) 1.5kg, 0.06kg sodium hydroxide and water 15kg are poured in the mixer, the heating steam carries out material mixing and heating, the flow velocity of control hot steam is in 5L / min, the temperature of the hot steam is 108°C, the reaction temperature is controlled at 70°C, and the reaction is carried out for 5h to prepare the silica sol seed particle liquid.

[0042] (2) Take 10kg of the seed liquid prepared in step (1) as the mother liquor, mix and heat the materials through hot steam, control the flow rate of the hot steam at 4L / min, the temperature of the hot steam is 115°C, and control the reaction temperature to 80 ℃, add the following reaction materials in the first batch: a mixture of metal silicon powder 0.3kg, water 2kg, and sodium hydroxide 8g, and the feeding amount of each batch is increased by 15% compared with the feeding amount of the previous batch. Feed to the 5th batch, and no more feed thereaft...

Embodiment 3

[0045] (1) Get metal silicon powder (200 mesh, purity is 95wt%) 2.0kg, 0.08kg sodium hydroxide and water 25kg are poured in the mixer, pass hot steam to carry out material mixing and heating, control the flow velocity of hot steam at 6L / min, the temperature of the hot steam is 115°C, the reaction temperature is controlled at 80°C, and the reaction is carried out for 4 hours to prepare the silica sol seed particle liquid.

[0046] (2) Take 15kg of the seed particle liquid prepared in step (1) as the mother liquor, mix and heat the material through hot steam, control the flow rate of the hot steam at 4L / min, the temperature of the hot steam is 121°C, and control the reaction temperature to 95 ℃, the following reaction materials are added in the first batch: a mixture of metal silicon powder 0.5kg, water 4kg, and sodium hydroxide 12g, and the feeding amount of each batch is increased by 20% compared with the feeding amount of the previous batch. Up to the 5th batch, thereafter n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com