Patents

Literature

71results about How to "No temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

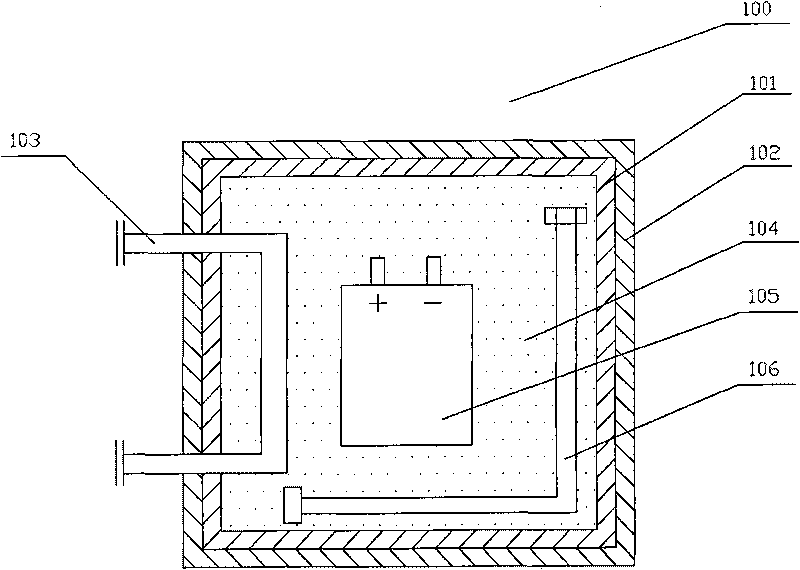

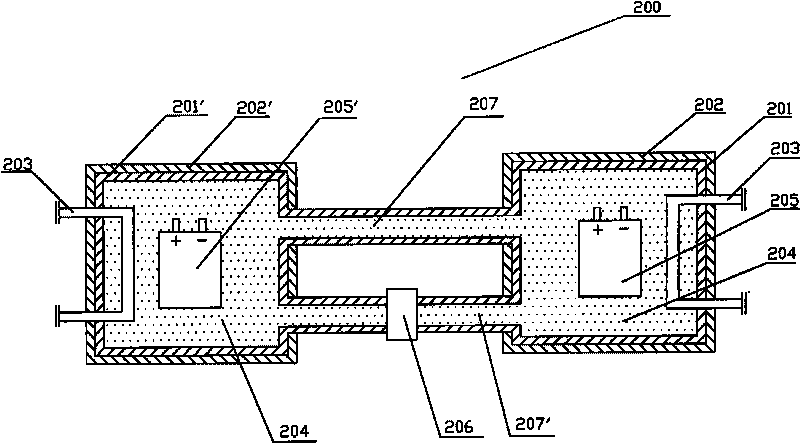

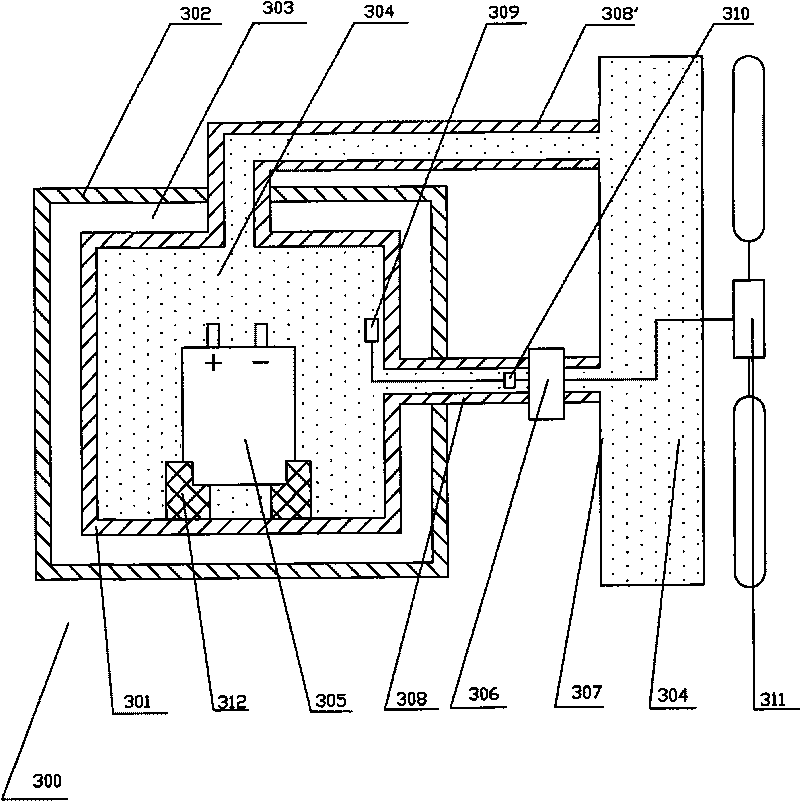

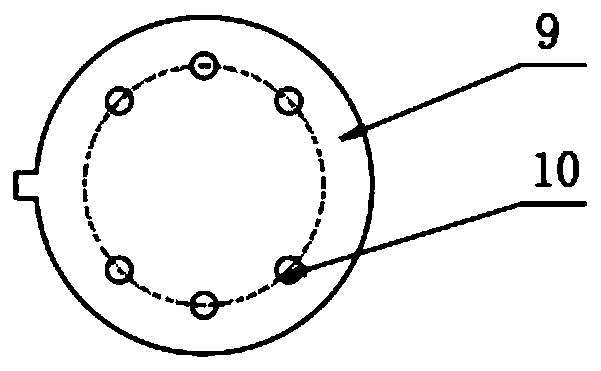

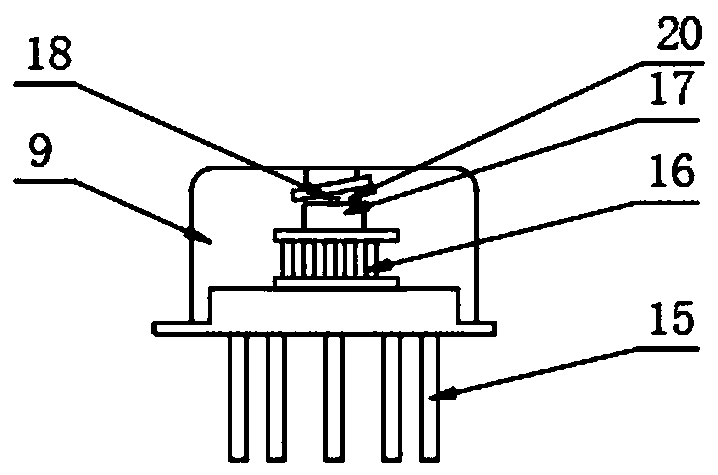

Protective device, protective device system and protective method of power battery

InactiveCN101728597AExtended service lifeImprove liquidityElectric propulsion mountingSecondary cellsElectrical batteryCharge and discharge

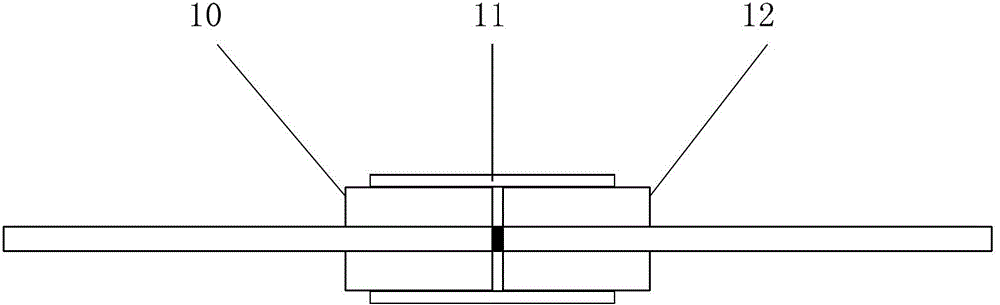

The invention provides a protective device of a power battery, which solves the problem that the whole battery pack forms a short-board effect because the environmental temperature difference between single batteries causes the effectiveness reduction of single batteries in the process of charging and discharging a battery pack of the power battery in the prior art. The protective device comprises a closed battery box inside which a liquid is contained, wherein the battery pack is immersed into the liquid inside the battery box. The invention also provides a protective method of the power battery, comprising the step of immersing the battery pack of the power battery into the liquid. The protective device or the protective method can equalize the environmental temperature of all single batteries in the battery pack, avoid the problem of the single batteries, prevent the short-board effect, prolong the service life of the batteries and also achieve the effect of fire prevention because of the liquid sealability of the liquid.

Owner:李光明

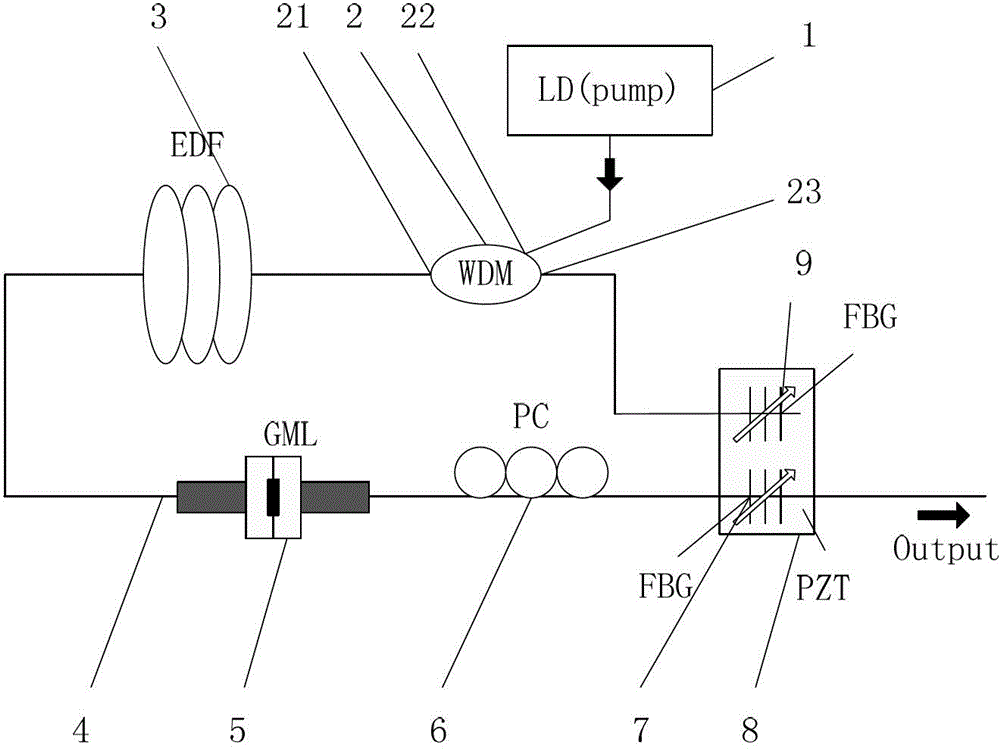

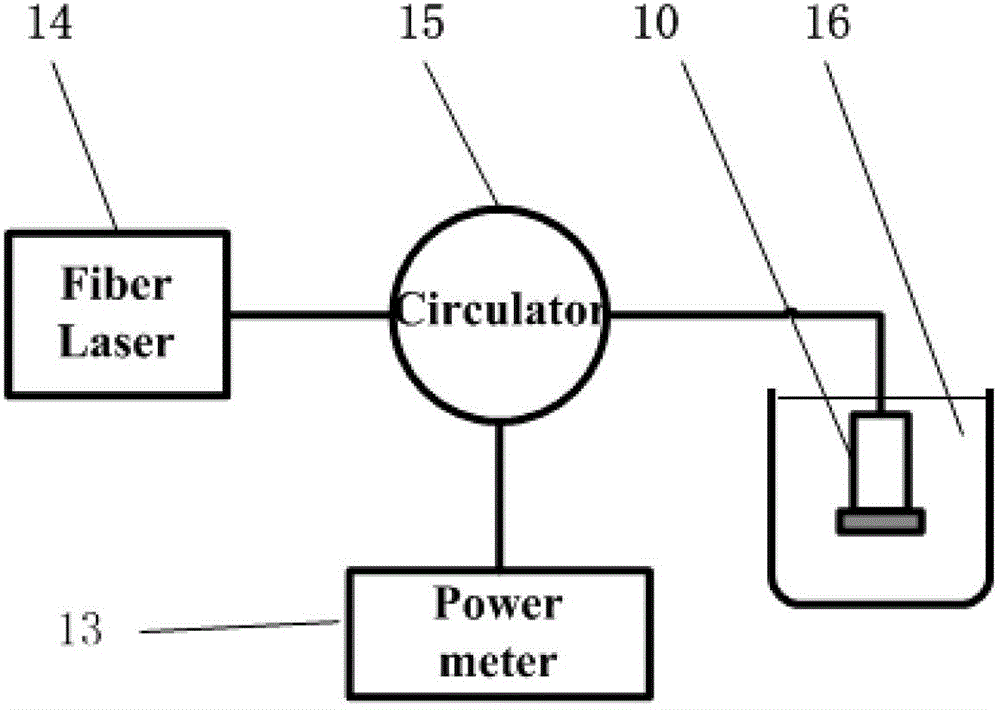

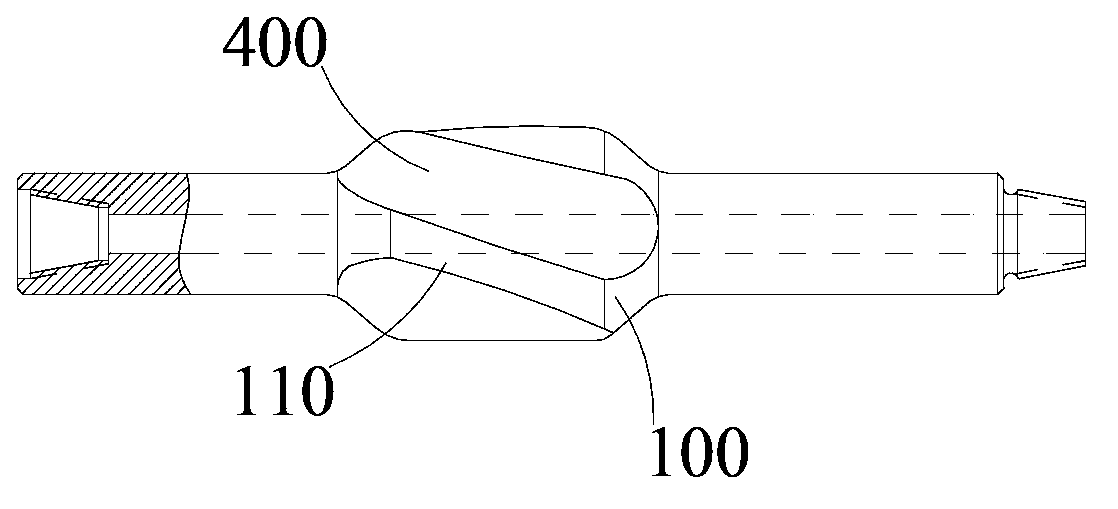

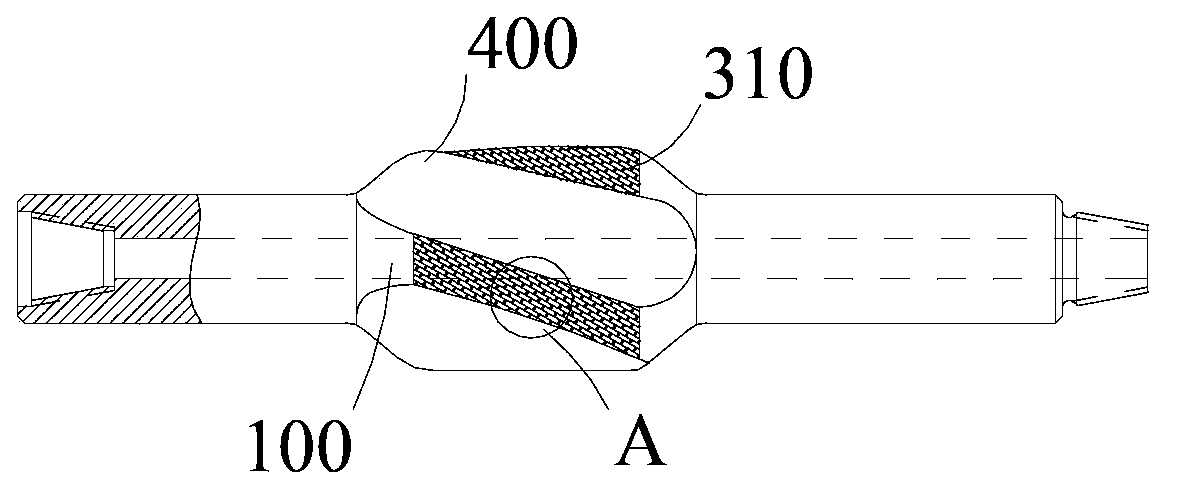

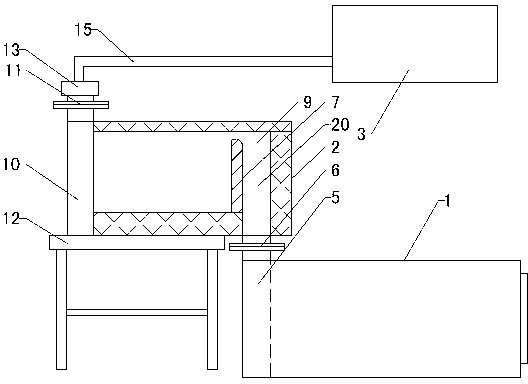

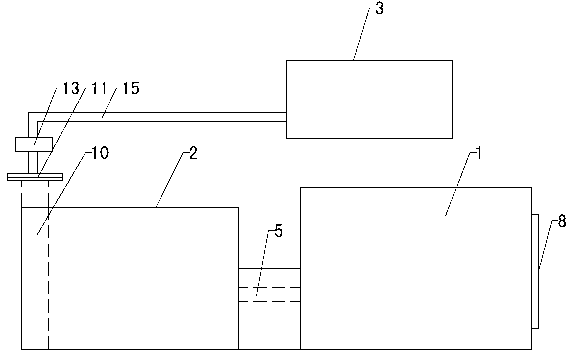

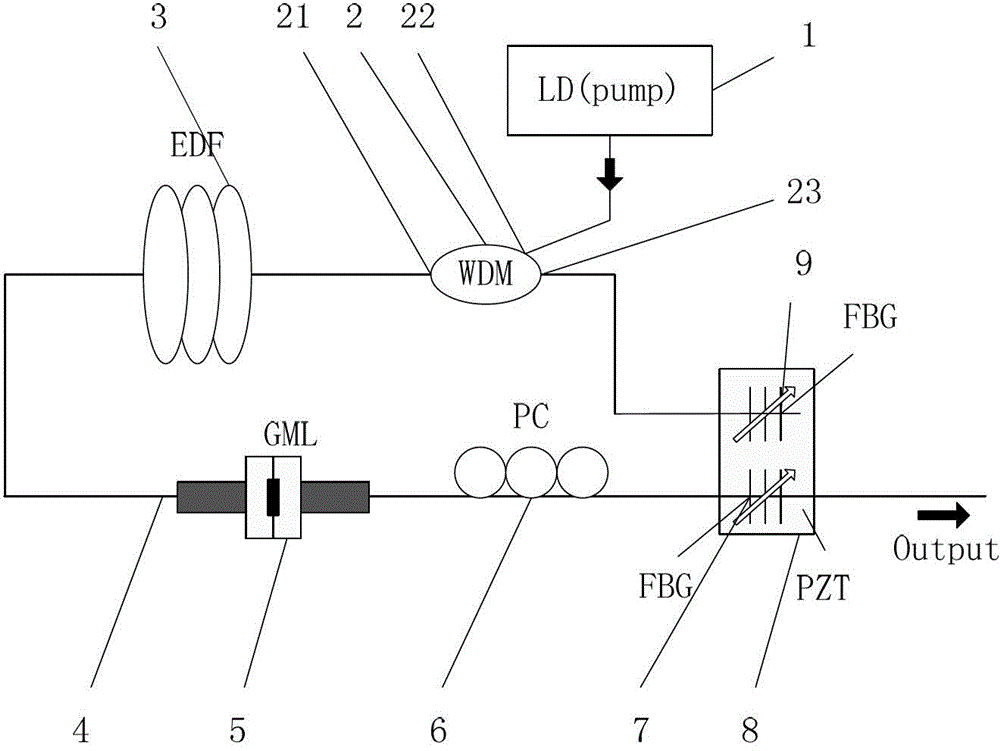

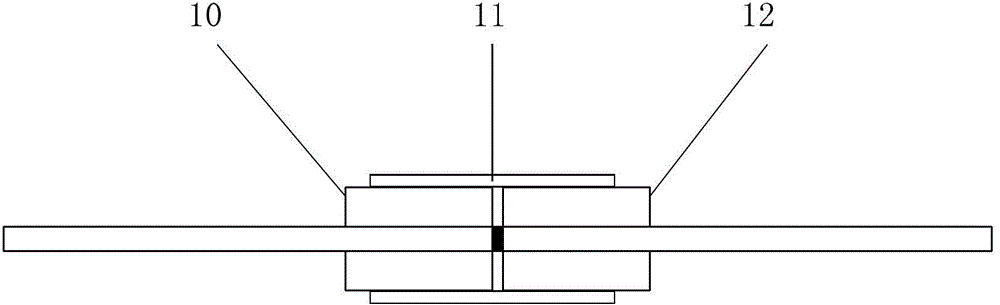

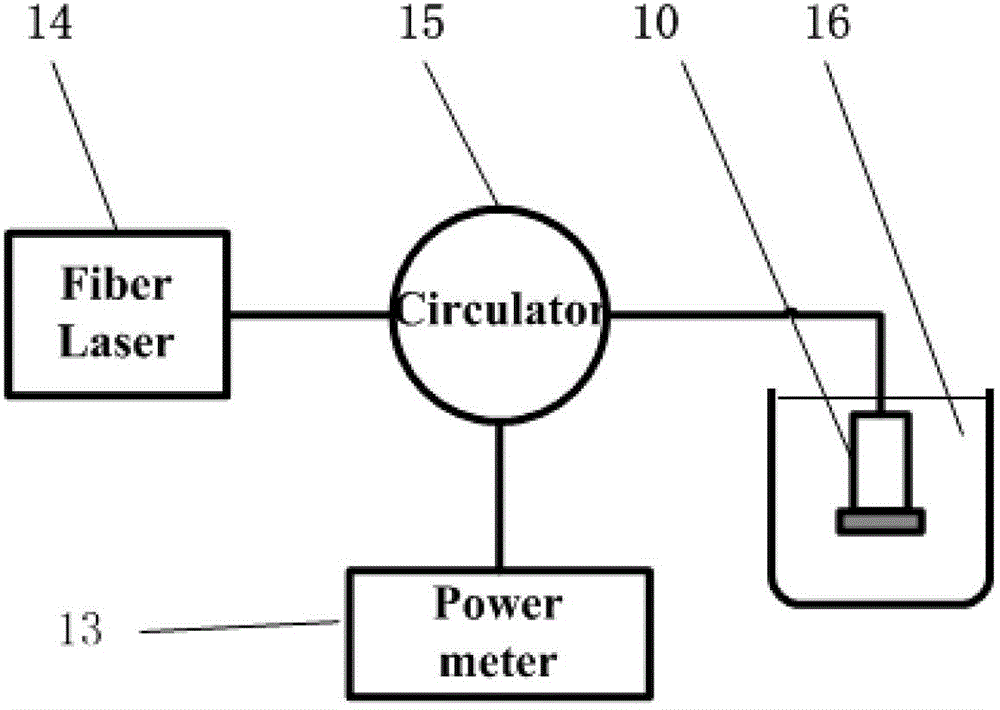

Tunable mode locking fiber laser based on fiber grating and graphene

InactiveCN103337774ACompact structureImprove reliabilityActive medium shape and constructionMode locked fiber laserGrating

The invention discloses a tunable mode locking fiber laser based on a fiber grating and a grapheme. Tunable output of a linearity chamber fiber laser is realized based on a principle that a central wavelength of the fiber Bragg grating drifts along with strain linearity, and mode locking output of a linearity chamber fiber laser is realized based on a saturation absorption function of the grapheme with wide saturation absorption wave bands. The tunable mode locking fiber laser has advantages of full fiber structure, compact structure, stable performance, tunable broadband, wide application in the fields of fiber communication, fiber sensing, and the like and extensive applicability.

Owner:NORTHWEST INST OF NUCLEAR TECH

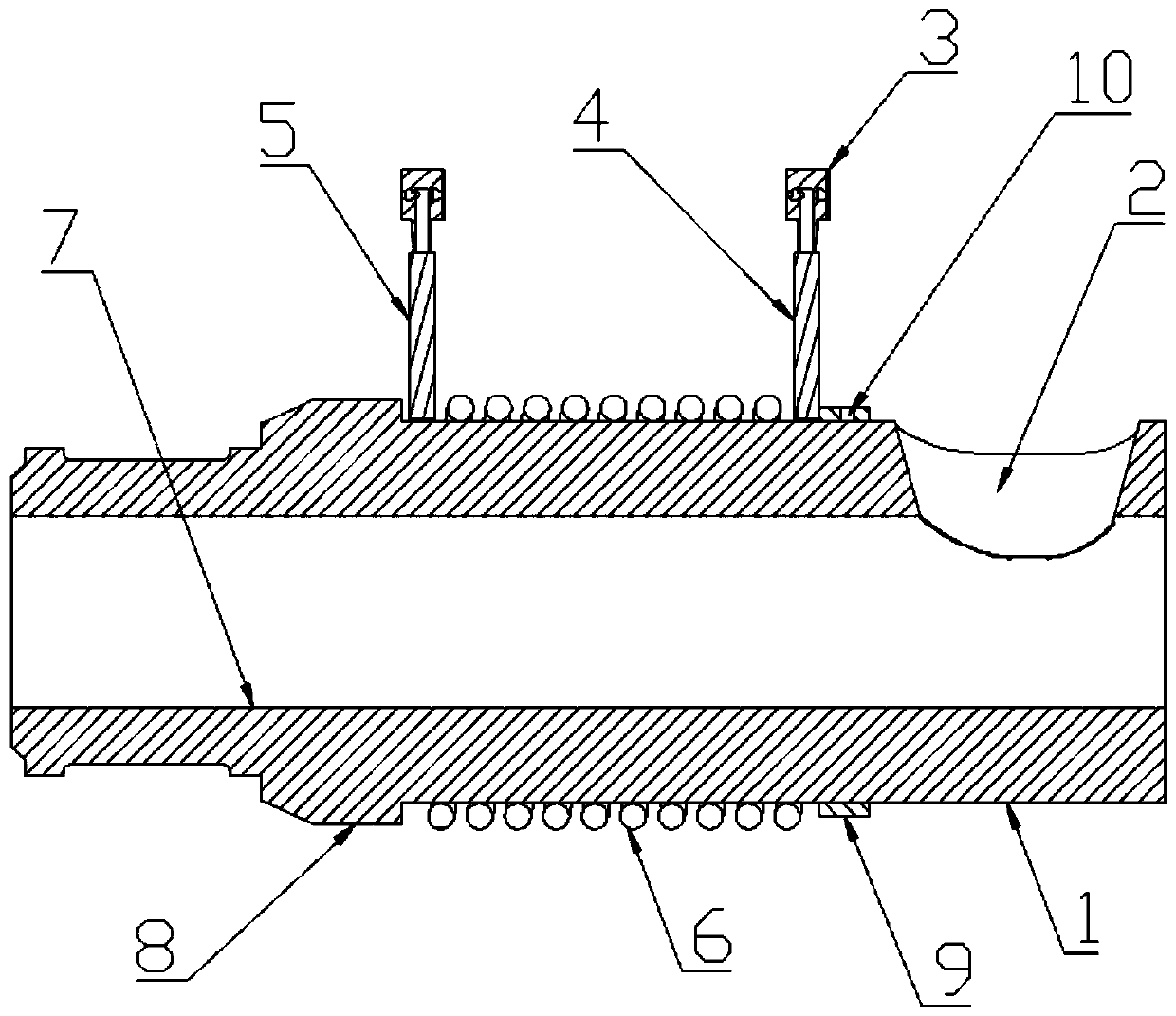

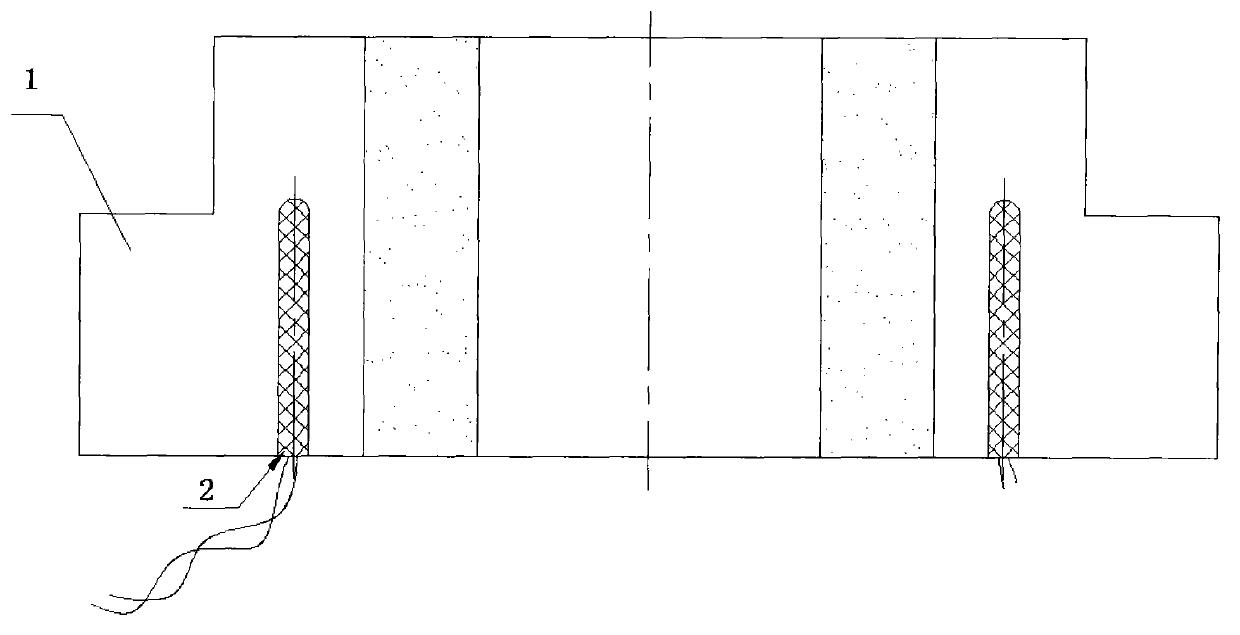

Method for welding drilling tool stabilizer alloy blocks

ActiveCN104117779ANo temperature differenceEvenly arrangedWelding/cutting auxillary devicesAuxillary welding devicesWell drillingRoom temperature

The invention relates to the field of alloy welding, and provides a method for welding drilling tool stabilizer alloy blocks. The method is used for welding the alloy blocks to centralizing wings of a drilling tool stabilizer respectively, a template with a plurality of openings is manufactured at first, the openings are distributed corresponding to the to-be-welded positions of the centralizing wings, then the alloy blocks are arranged in the openings in a one-to-one correspondence mode, flexible fixing pieces are fixed to the alloy blocks, the surfaces of the centralizing wings are cleaned and are evenly heated at the same time, then subassemblies of the flexible fixing pieces and the alloy blocks are arranged at the to-be-welded positions of the high-temperature centralizing wings, the centralizing wings and the alloy blocks are welded after the flexible fixing pieces are removed, and finally the centralizing wings are cooled to the room temperature and are polished. The template used for arrangement and distribution is adopted in welding of the alloy blocks and the centralizing wings, the alloy blocks can be evenly arranged, welding speed is high, then the temperature difference between the centralizing wings cannot be tool large, welding quality is guaranteed, welding cracks are prevented from being generated in the later well drilling process, meanwhile, the manufactured template can be repeatedly utilized, and cost is saved.

Owner:JINGMING OIL EQUIP DEV

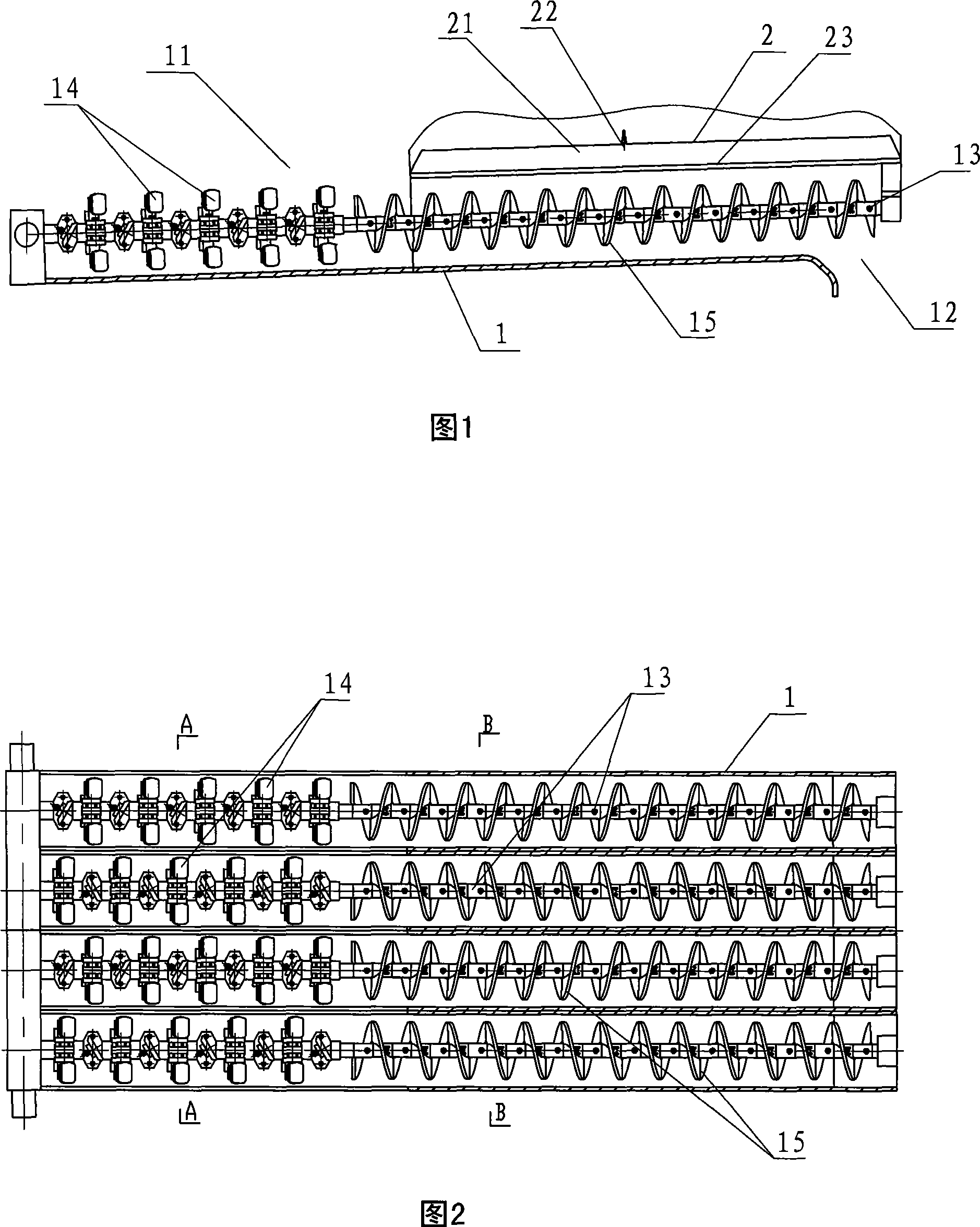

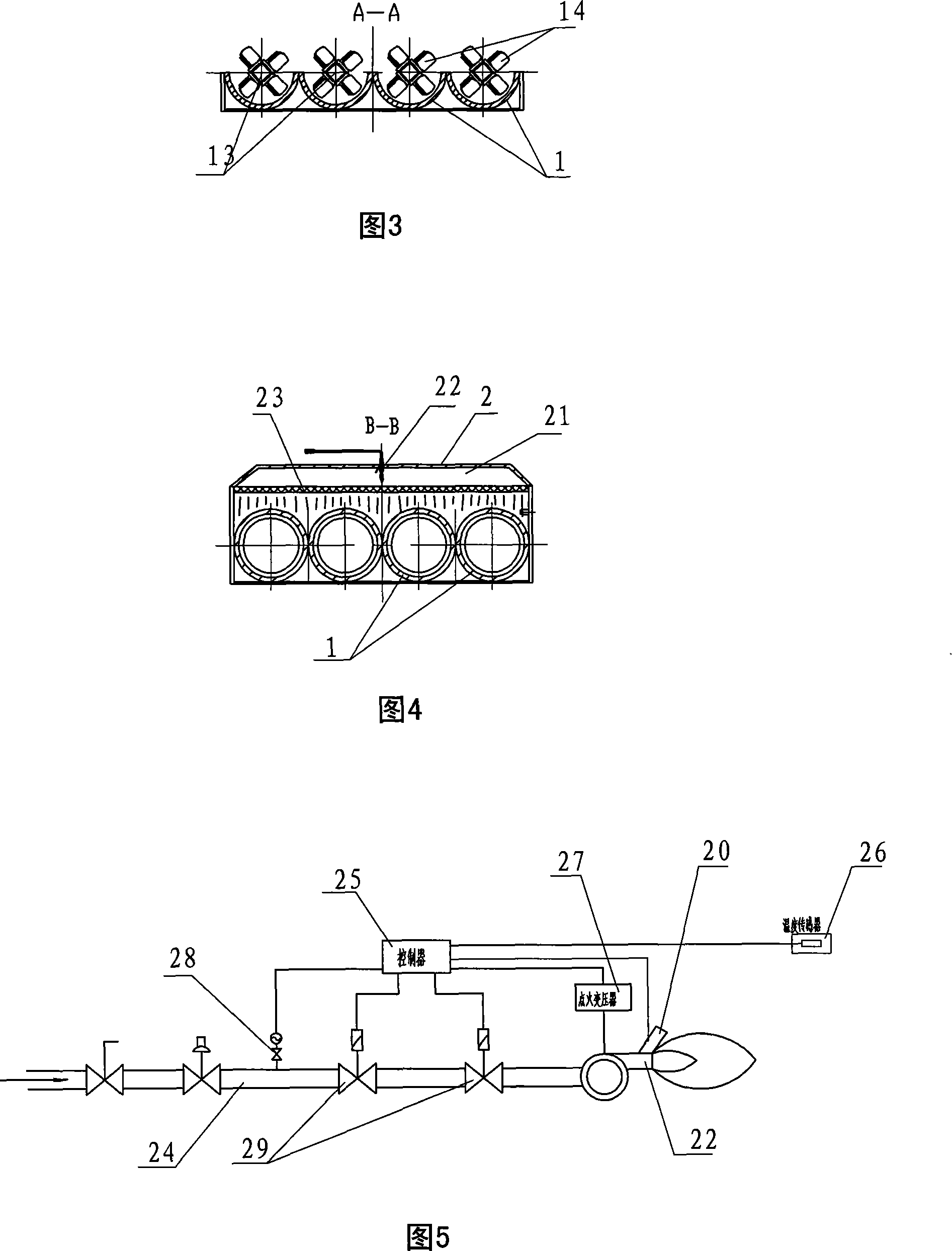

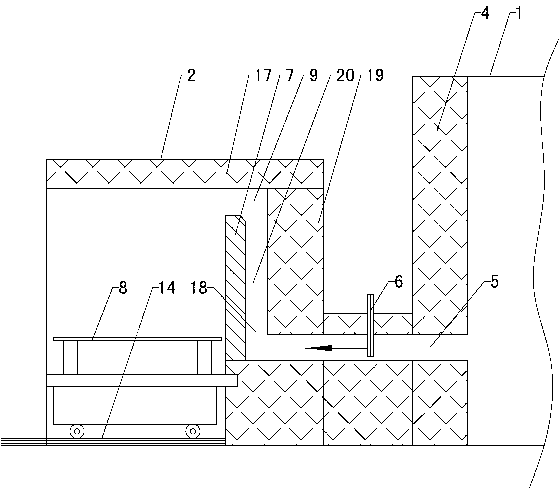

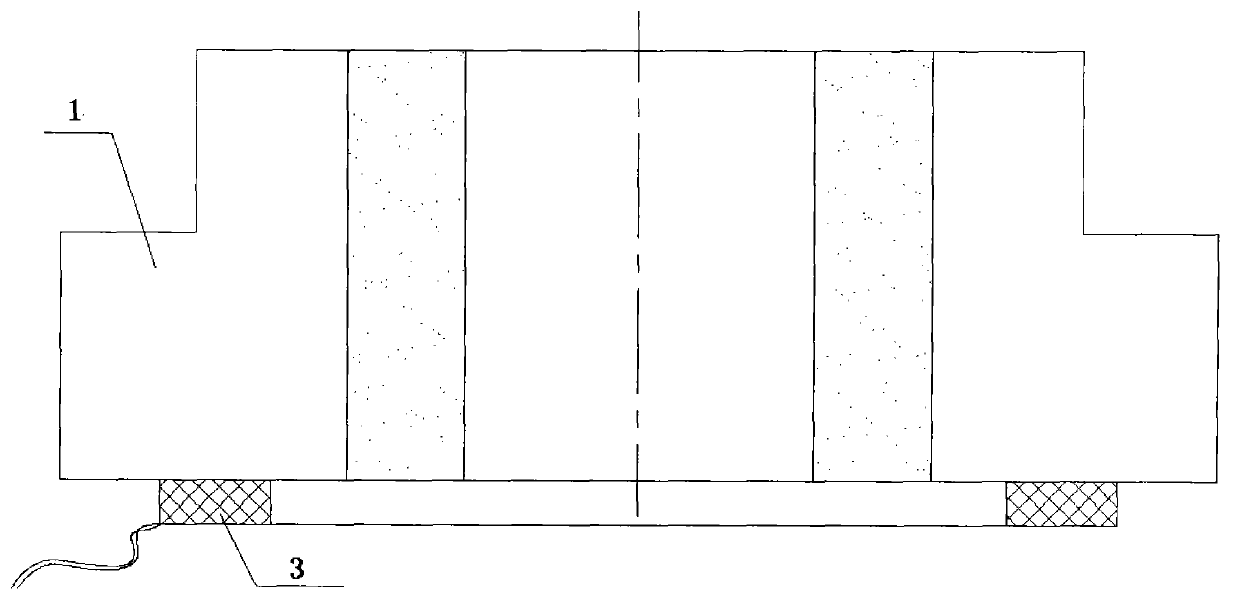

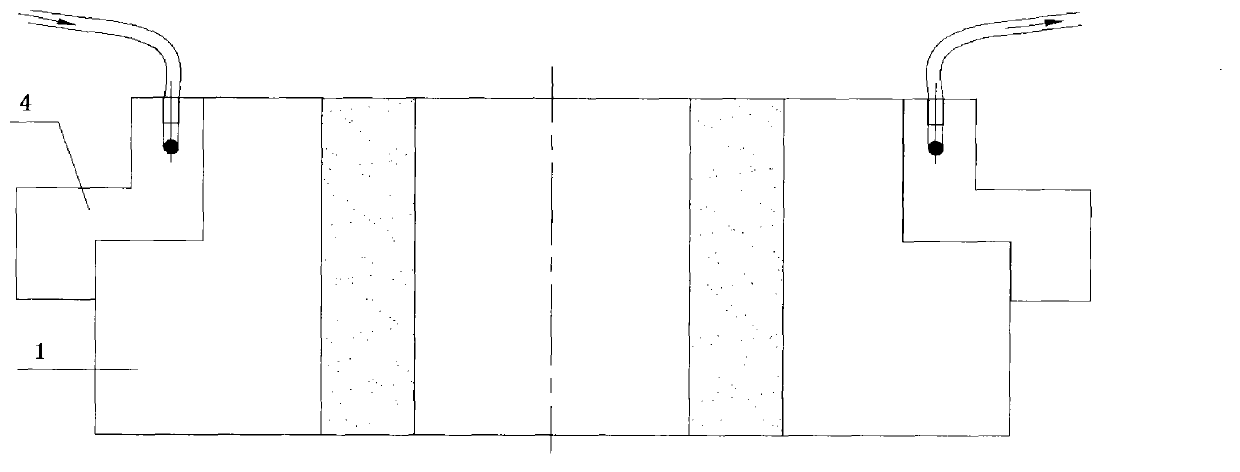

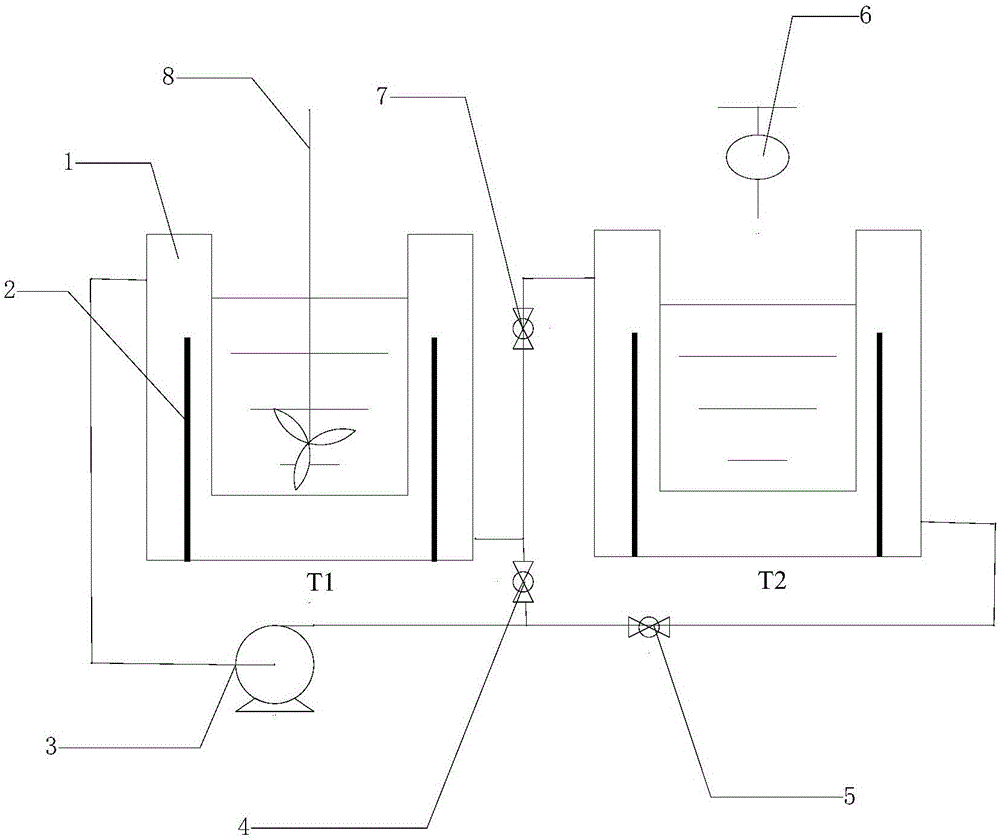

Material transferring system for spreading machine

InactiveCN101240522ANo temperature differenceAutomatic temperature controlRoads maintainenceTemperature controlAutomatic control

The invention pertains to pavement engineering machinery, relating to component structure of a bituminous pavement spreader, specifically a material feeding system of the spreader, comprising a plurality of transporting barrels disposed between the spreader front bucket and a rear spreading component, feed inlets are formed by opening the tops of the front segments of the transporting barrels, discharging outlets are disposed at the rear ends of the transporting barrels; a transporting shaft is disposed through in the transporting barrel, a plurality of blending blades are disposed with intervals at the front segment of the transporting shaft, and a transport helix is disposed at the rear segment of the transport shaft. The invented system can mixing the bituminous mixture evenly without temperature difference and solves problems of bituminous mixture temperature and granulate disengagement by reheating and mixing the bituminous mixture. In addition, the invented system has advantages of rapid temperature elevating, evenly heating and mixing, automatic temperature control and high automation degree.

Owner:ZHENJIANG HUACHEN HUATONG ROAD MASCH CO LTD

heat sink

InactiveCN102271479ANo temperature differenceLarge temperature differenceCooling/ventilation/heating modificationsEngineeringElectronic component

A heat dissipating device is used for dissipating heat from two electronic components at the same time, which includes two heat sinks respectively in contact with the two electronic components in heat conduction, and a heat pipe connected between the two heat sinks by heat conduction. The heat pipe of the present invention is connected between the two radiators, and can conduct the heat of the electronic components at the downwind to the radiator on the electronic components at the upwind in time, so that even if the radiator at the electronic components at the upwind blocks the Even if the airflow blows to the radiator on the downwind electronic component, the temperature difference between the two electronic components will not be large.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

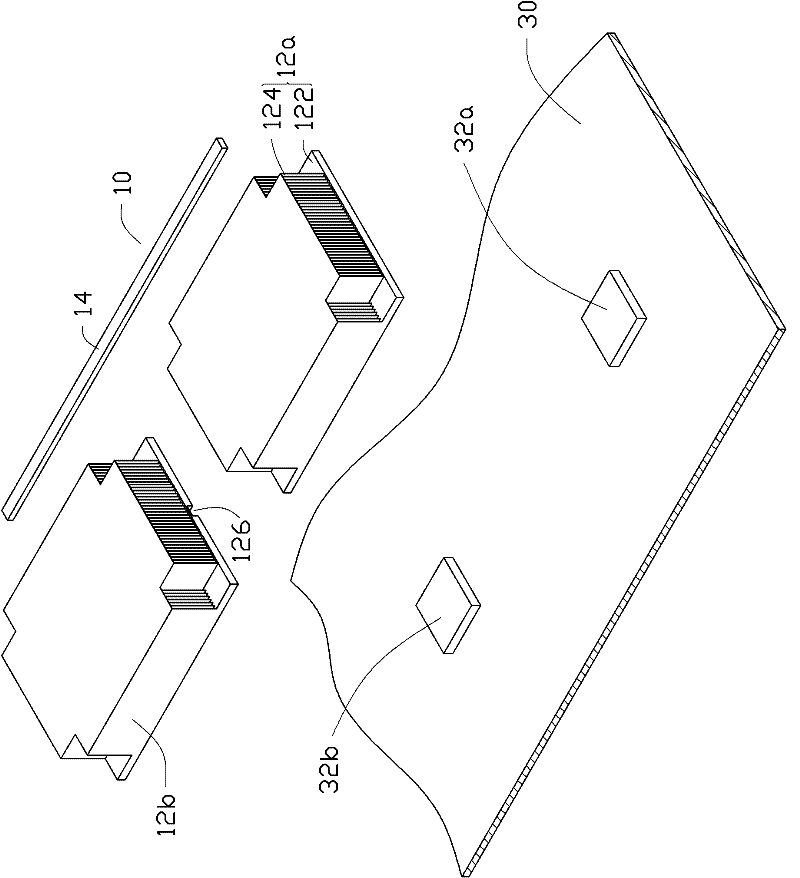

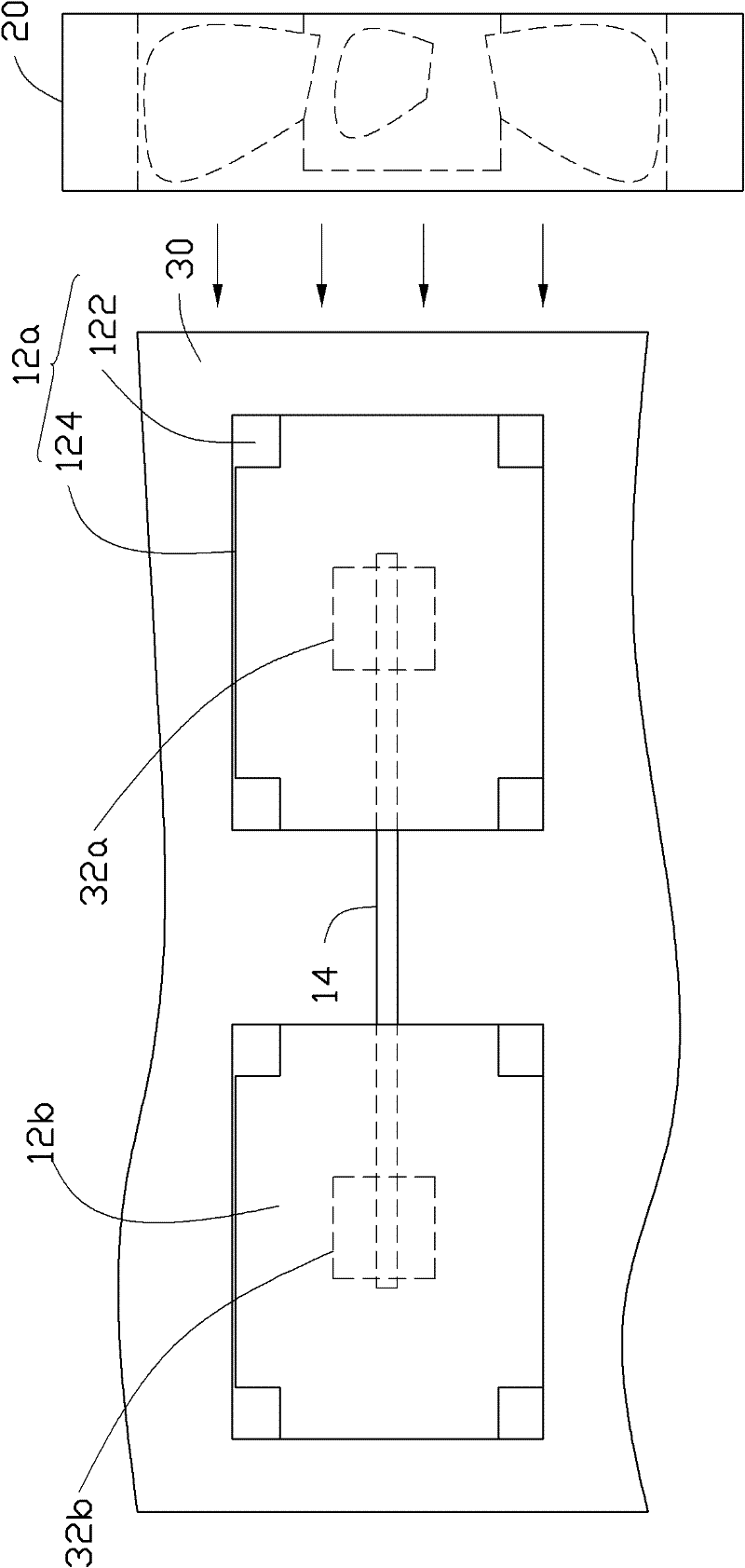

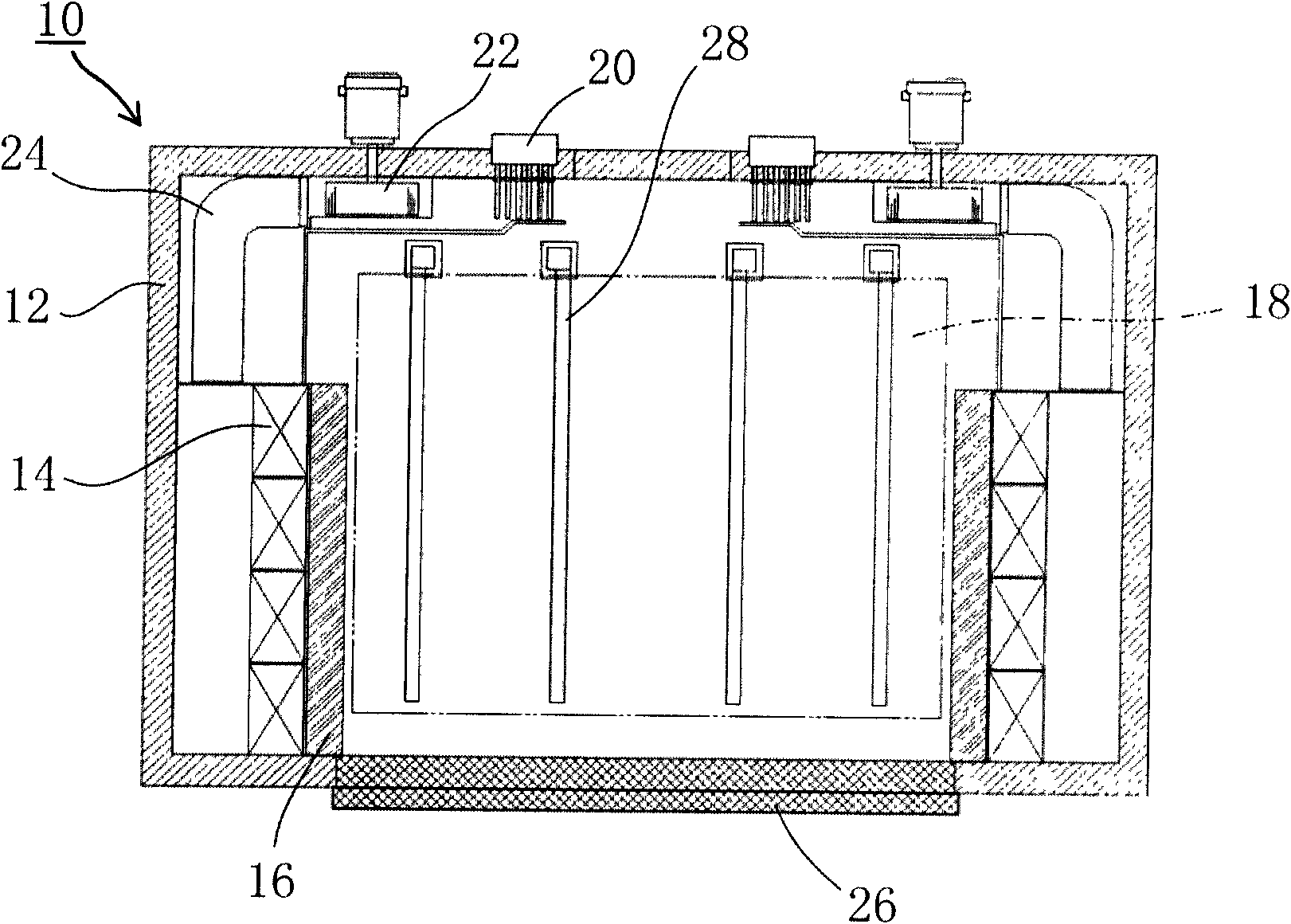

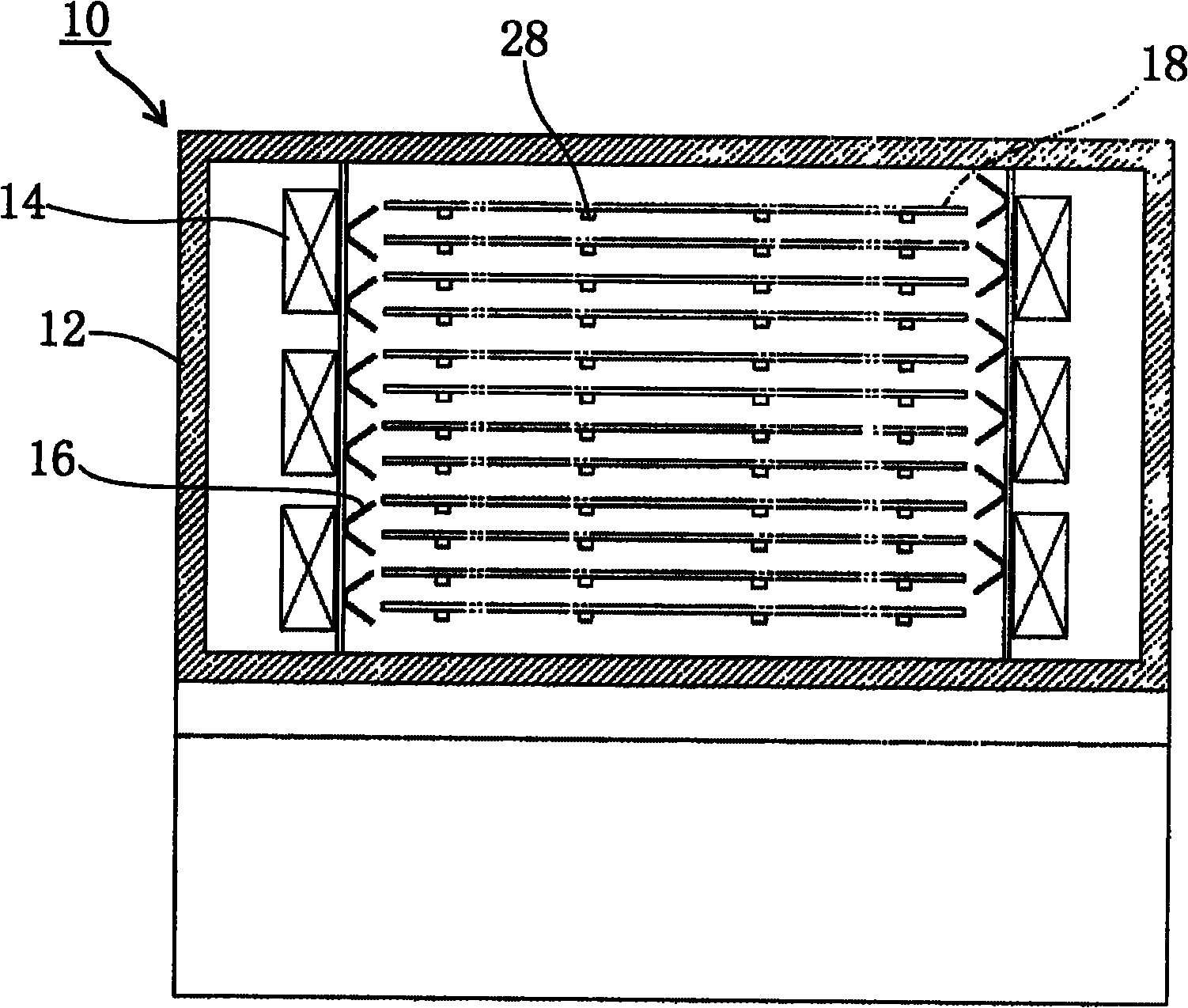

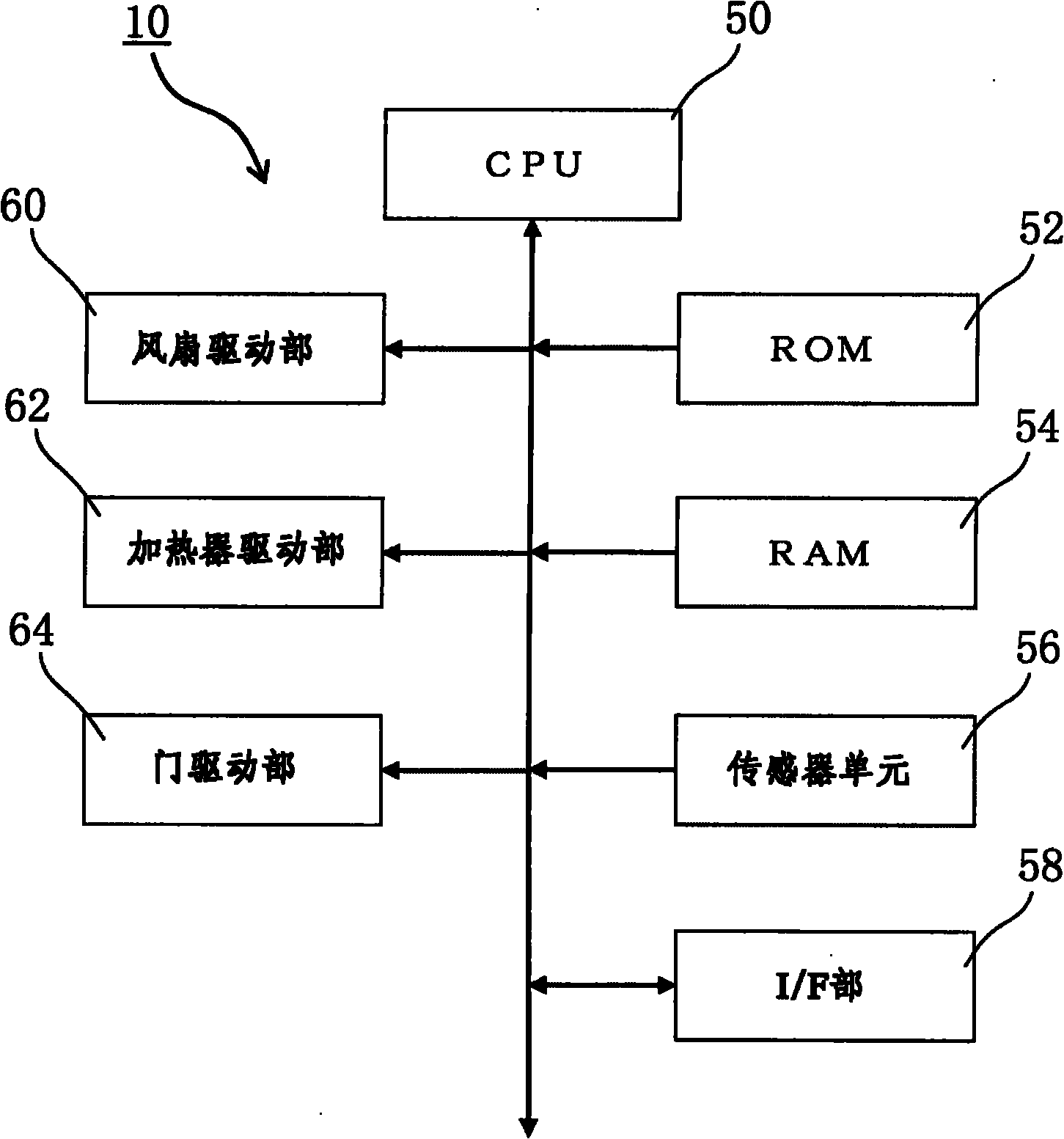

Heat treatment apparatus

InactiveCN101838726ANo temperature differenceWon't expand the spaceMuffle furnacesMaintainance of heating chambersEngineeringHeat treated

Owner:KOYO THERMO SYST CO LTD

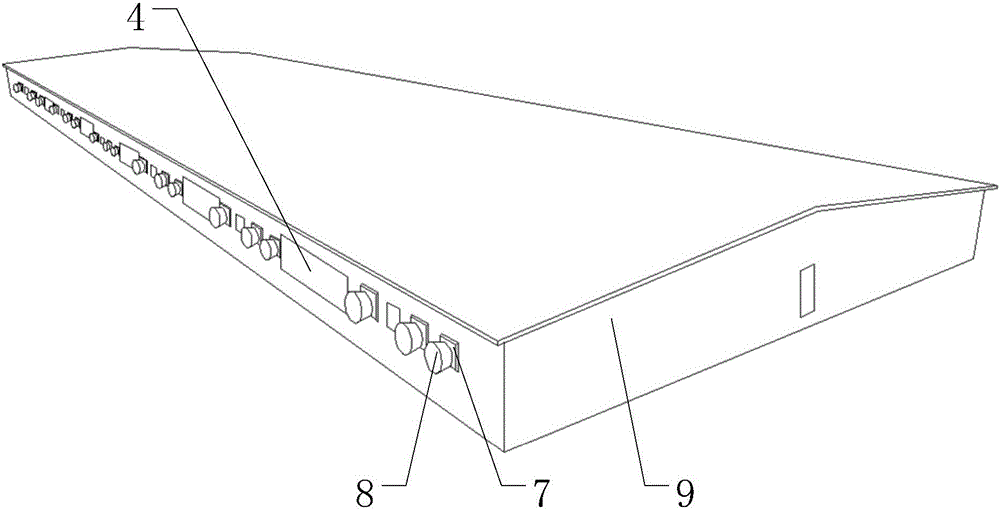

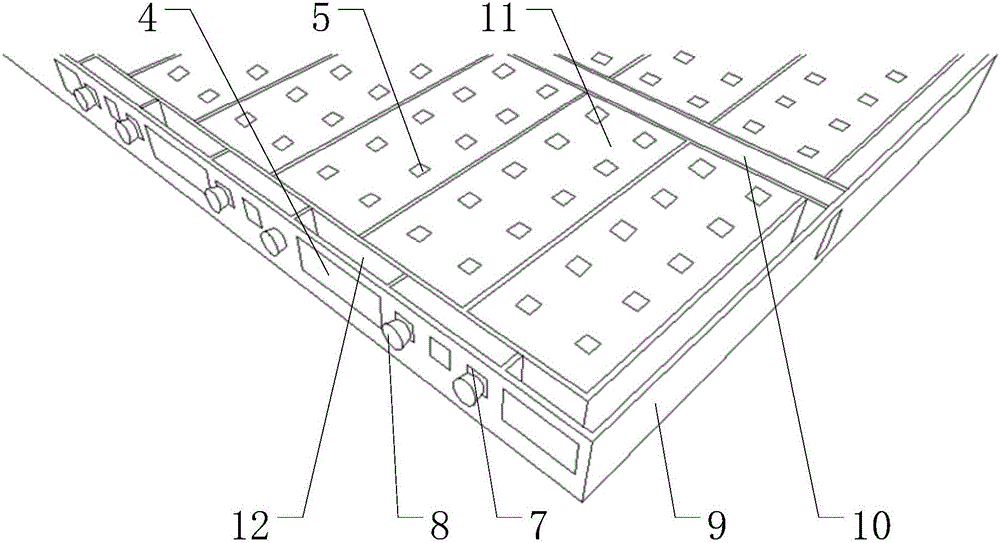

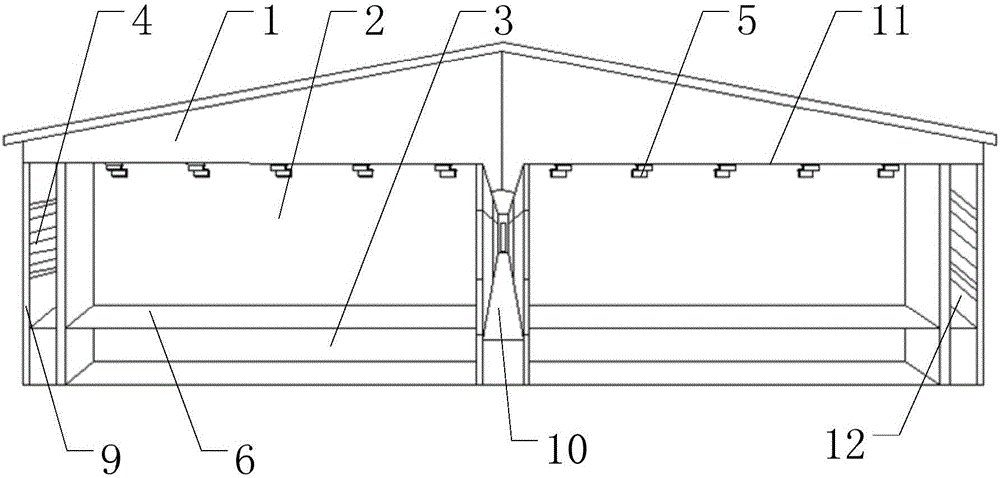

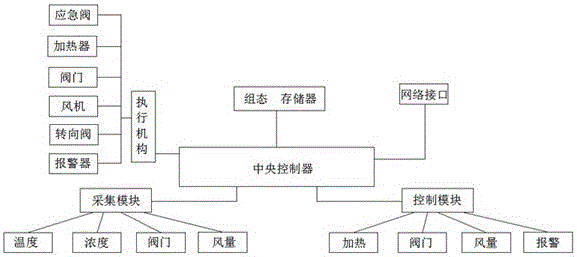

Animal shed

PendingCN106359111ANo temperature differenceNo manual controlAnimal housingIntermediate spaceElectricity

The invention relates to the technical field of livestock breeding constructions, and particularly relates to an animal shed. The animal shed comprises a roof space, an intermediate space, a bottom space and a control device, wherein the roof space is communicated with the outside through a roof air inlet; the roof space is communicated with the intermediate space through an air inlet window; the intermediate space is communicated with the bottom space through a leak hole; the bottom space is communicated with the outside through a bottom air outlet; a fan is connected with the bottom air outlet; a temperature sensor is arranged in the intermediate space and is electrically connected with the control device; the temperature sensor is used for detecting the temperature of the intermediate space; and the control device is used for correspondingly controlling the opening angle of the air inlet window. The animal shed is used for solving the technical problems that an existing animal shed cannot form an effective wind speed acting on an animal body, has temperature difference and does not have a unified standard for controlling the air inlet.

Owner:青岛大牧人机械股份有限公司

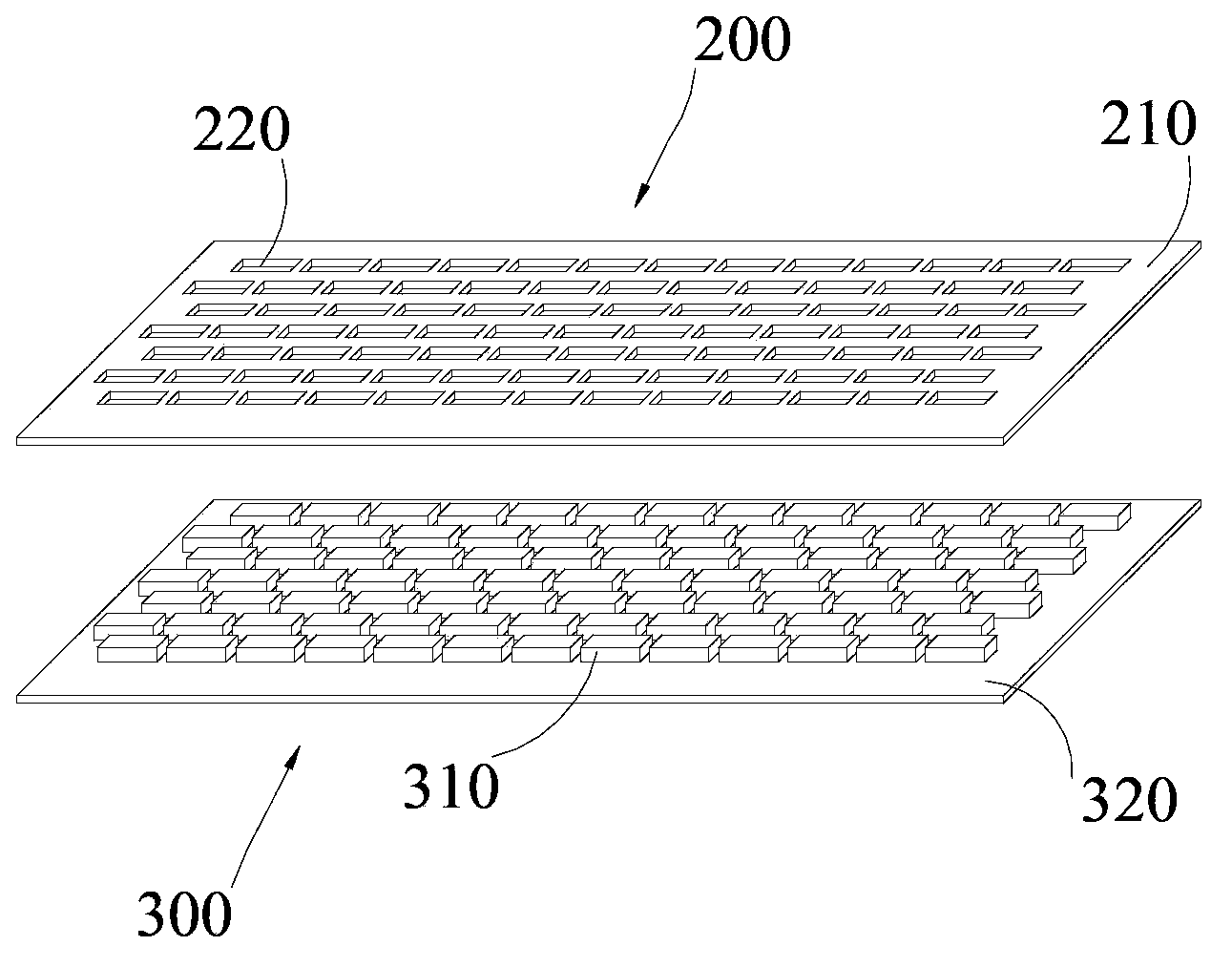

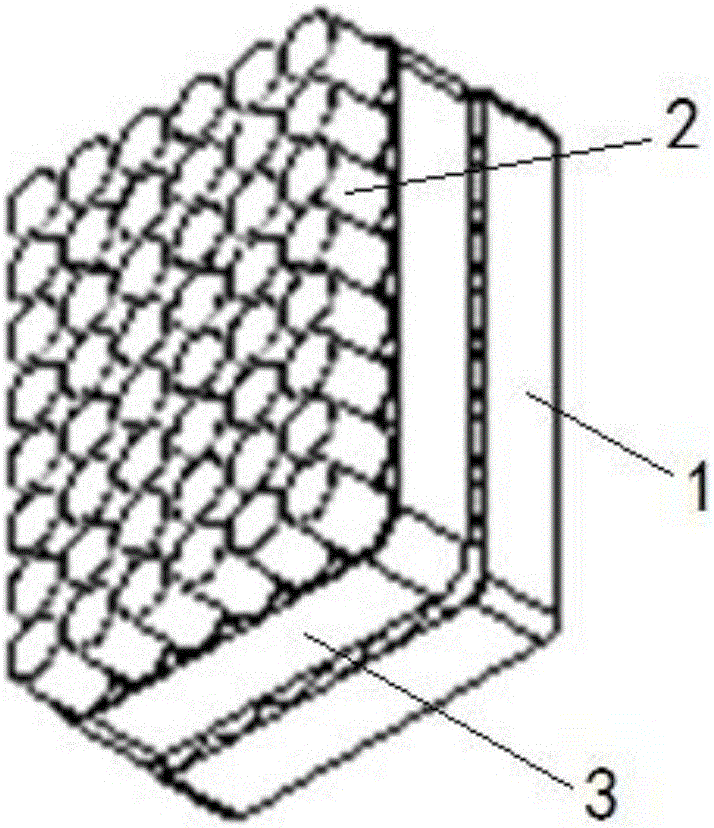

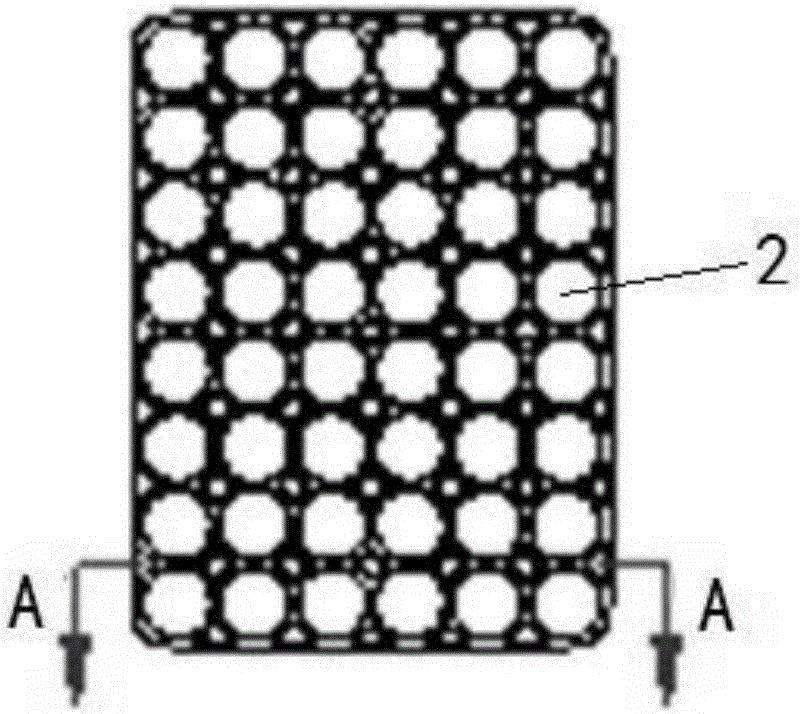

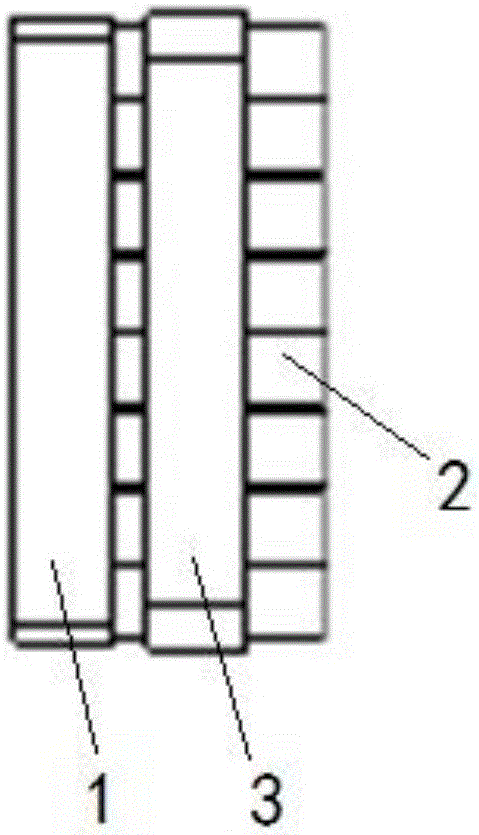

Battery pack with heat absorption sleeves and power battery with battery pack

InactiveCN106532180ANo temperature differenceUniform temperatureSecondary cellsBatteriesPower batteryHeat conducting

The invention discloses a battery pack with heat absorption sleeves and a power battery with the battery pack. The battery pack comprises a battery clamp, a plurality of single batteries inserted into the battery clamp, and the heat absorption sleeves, wherein each heat absorption sleeve detachably sleeves the outside of each single battery and is in clung contact with the outer wall surface of each single battery; and each heat absorption sleeve is made of an insulating heat-conducting material. The battery pack is simple in structure, and convenient to manufacture and assemble, and the single batteries can be efficiently cooled.

Owner:SUZHOU ANKAO ENERGY

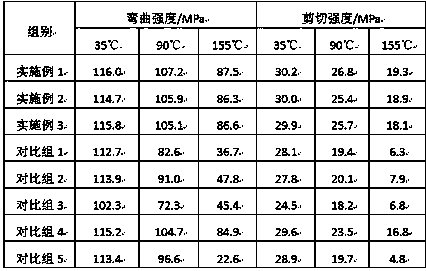

High-temperature resistant aluminum-plastic composite board

InactiveCN110525001ASame internal temperatureNo stress concentrationSynthetic resin layered productsLaminationStress concentrationAdditive ingredient

The invention relates to the technical field of aluminum-plastic composite boards, and in particular to a high-temperature resistant aluminum-plastic composite board. The high-temperature resistant aluminum-plastic composite board comprises a high-temperature resistant board core, upper and lower two aluminum board layers, and adhesive layers used for bonding the high-temperature resistant board core and the aluminum board layers. Preparation steps of the composite board comprise: mixing raw materials of the high-temperature resistant board core: adding 70-80 parts of a matrix resin, 20-30 parts of silicon nitride, 12-20 parts of modified sepiolite, 10-15 parts of modified sodium montmorillonite, 8-15 parts of nano-magnesium hydroxide, and 1-3 parts of a silane coupling agent into a high-speed mixer, and then performing full stirring for 10 min at a stirring speed of 120 r / min. By adding ingredients in the interior of the matrix resin, a uniform-dispersed sepiolite-sodium montmorillonite-nano-magnesium hydroxide copolymer is formed, heat transferred by the resin can be absorbed under the high temperature environment, the inner layer temperature distribution is uniform during the entire heat absorption process of the aluminum-plastic board, no temperature difference can be appeared, and thereby the bending phenomenon cannot be appeared due to stress concentration. At the same time, the peeling strength of the aluminum-plastic composite board can be effectively improved by the preparation method, so that the overall quality is relatively good.

Owner:宿州速果信息科技有限公司

Brewing equipment with heating function

The invention belongs to the field of brewing equipment and particularly discloses brewing equipment with a heating function. The brewing equipment comprises a sealed tank and a condensing tower, wherein a ventilation guiding pipe is arranged at the top of the sealed tank, a condensing device is arranged on the ventilation guiding pipe, a partition plate is arranged in the sealed tank, a ventilation hole is formed in the partition plate, a steam pipeline is arranged above the partition plate, the bottom end of the steam pipeline is communicated with the ventilation hole, a first hose and a second hose are arranged at the bottom of the sealed tank, a steam tank is arranged below the condensing device, a hot water outlet is connected with the steam tank, and multiple electric heaters are arranged in the steam tank. According to the scheme, while vinasse is heated through the steam pipeline, the first hose and the second hose move up and down to stir the vinasse, so that the vinasse is heated evenly, and the quality and taste of brewed liquor are improved.

Owner:贵州酣客君丰酒业有限公司

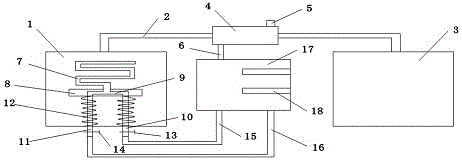

Control system of organic waste gas catalytic burner and operation method of control system

The invention discloses a control system of an organic waste gas catalytic burner and an operation method of the control system. The control system comprises a central controller, a configuration storage, a collection module, a control module and an execution mechanism; the configuration storage, the collection module, the control module and the execution mechanism are all connected to the central controller; the collection module comprises a temperature collection module, a concentration collection module, a valve collection module and a wind amount collection module, the control module comprises a heating module, a valve module, a wind amount module and an alarm module; the execution mechanism comprises a catalysis chamber, a reversing valve, a draught fan, an air inlet valve, an emergency valve and an alarm device; a control system and a waste gas inlet and outlet mode of a traditional organic waste gas catalytic burner are changed, through the circular air inlet and outlet manner of multiple burners, the influence of heat generated by waste gas in the combustion process on a catalyst in the burner can be thoroughly avoided, the generated energy is led into a heat storage chamber of the burner to be preheated through a pipeline in a gas inlet and outlet manner, and the energy utilization rate is high.

Owner:江苏中科睿赛环境工程有限公司

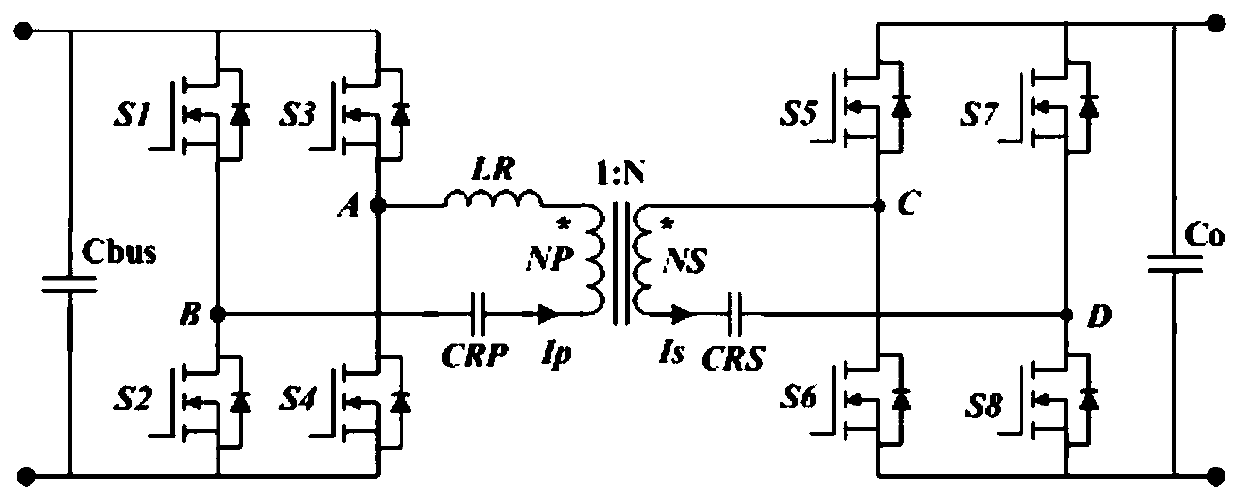

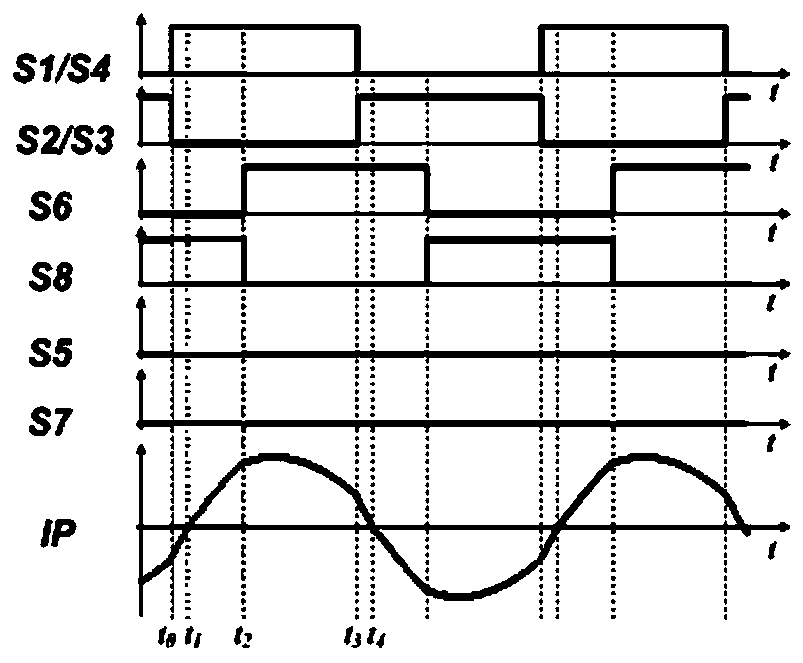

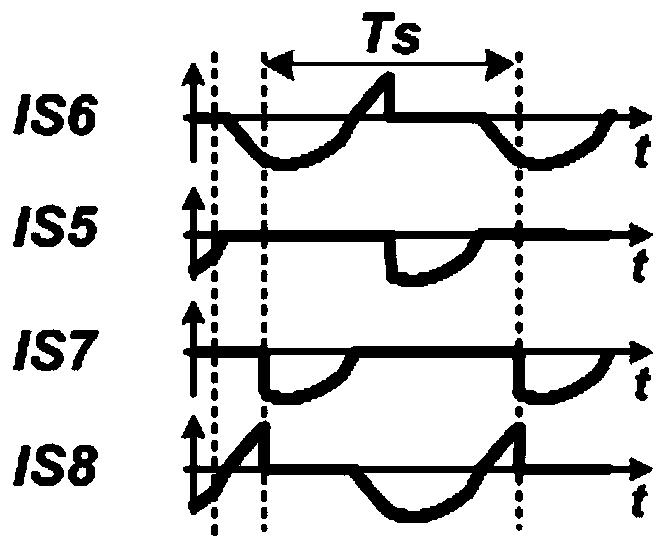

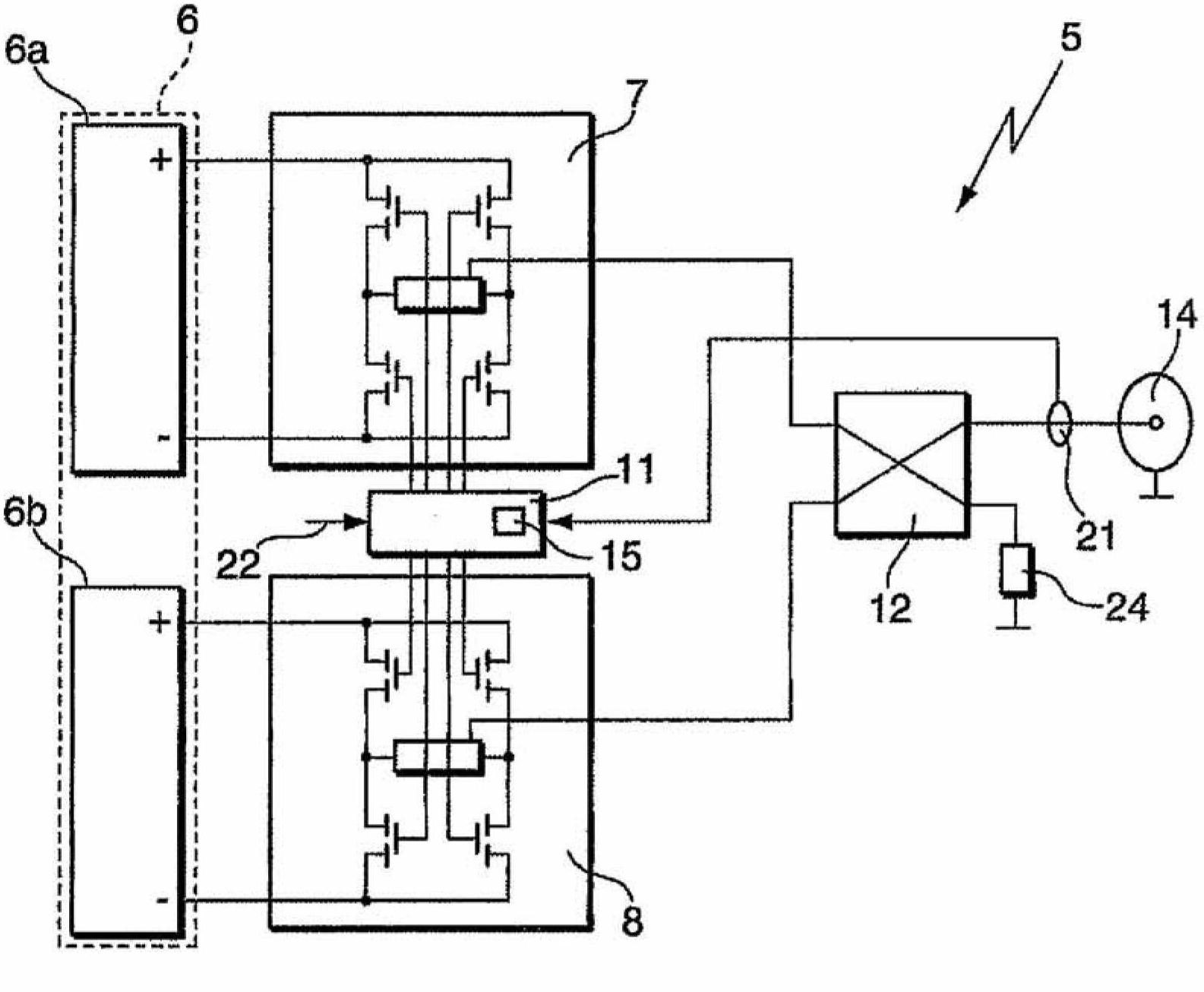

Control method and device of DC/DC converter

ActiveCN109889049ANo temperature differenceAchieve thermal balanceEfficient power electronics conversionApparatus without intermediate ac conversionPhase shiftedDc converter

The invention provides a control method and device for a DC / DC converter. The method comprises: the switching frequencies of a sixth signal, a fifth signal, a seventh signal and an eighth signal are half of the switching frequencies of the driving signals of primary switch tubes, the phase difference between adjacent signals of the sixth signal, the fifth signal, the seventh signal and the eighthsignal is a preset angle, and the phase difference between the sixth signal and the driving signal of the first switch tube is a phase shift angle; the sixth signal, the fifth signal, the seventh signal and the eighth signal are used as driving signals to drive the sixth switch tube, the fifth switch tube, the seventh switch tube and the eighth switch tube, respectively; alternatively, the sixth signal, the fifth signal, the seventh signal, and the eighth signal are used as intermediate signals, and the driving signals of the secondary switch tubes are generated according to the driving signalof the at least one primary switch tube and the intermediate signal, and the driving signals of the secondary switch tubes drive the switch tubes corresponding to the secondary side, thereby realizing thermal equalization among the secondary switch tubes.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD

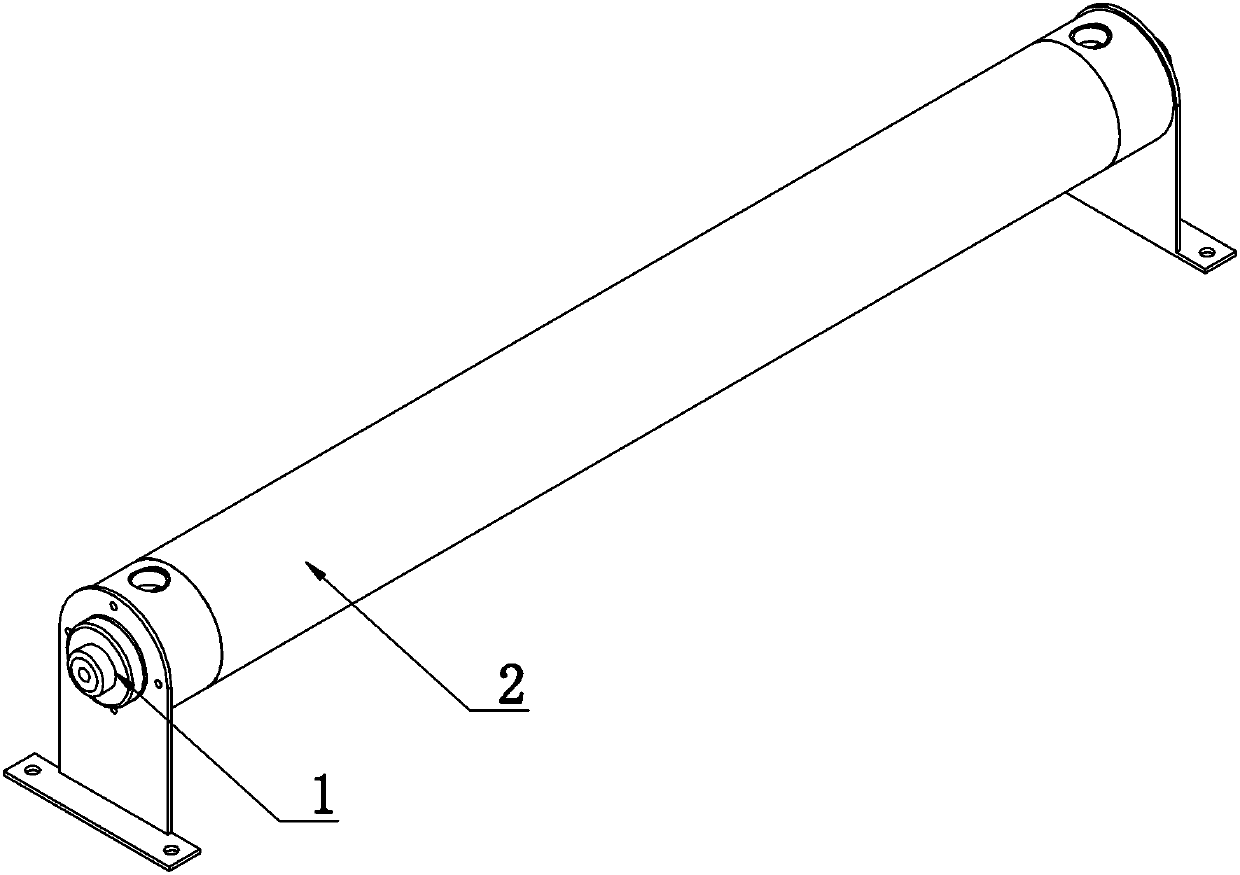

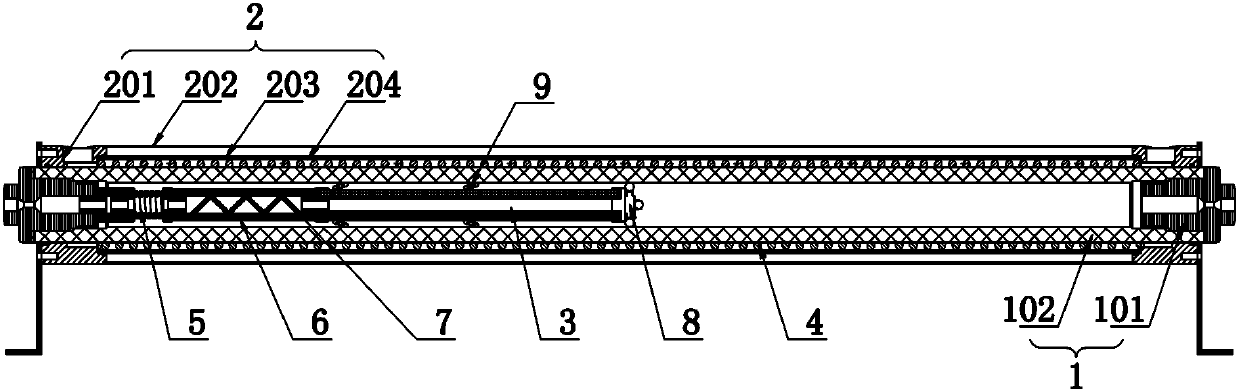

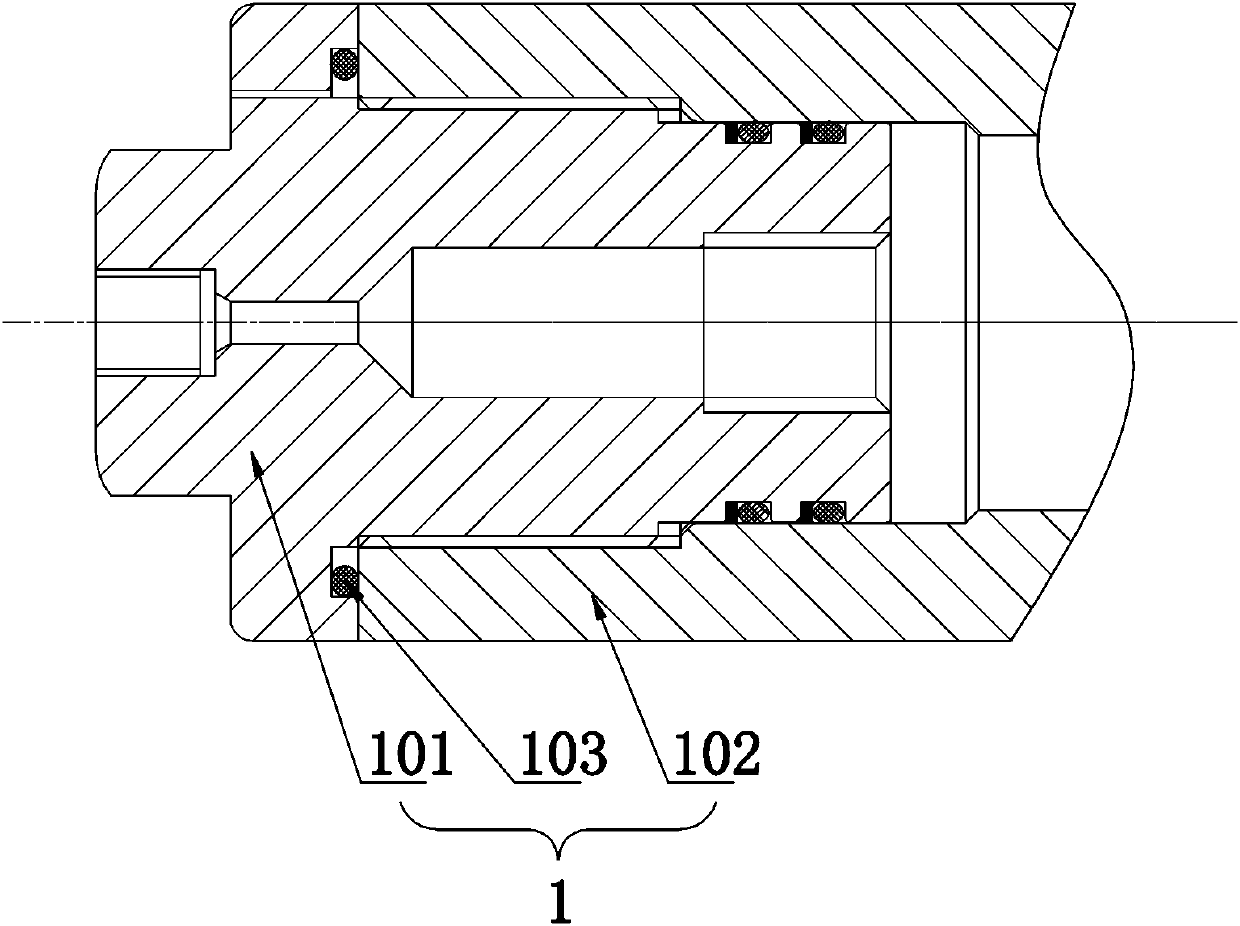

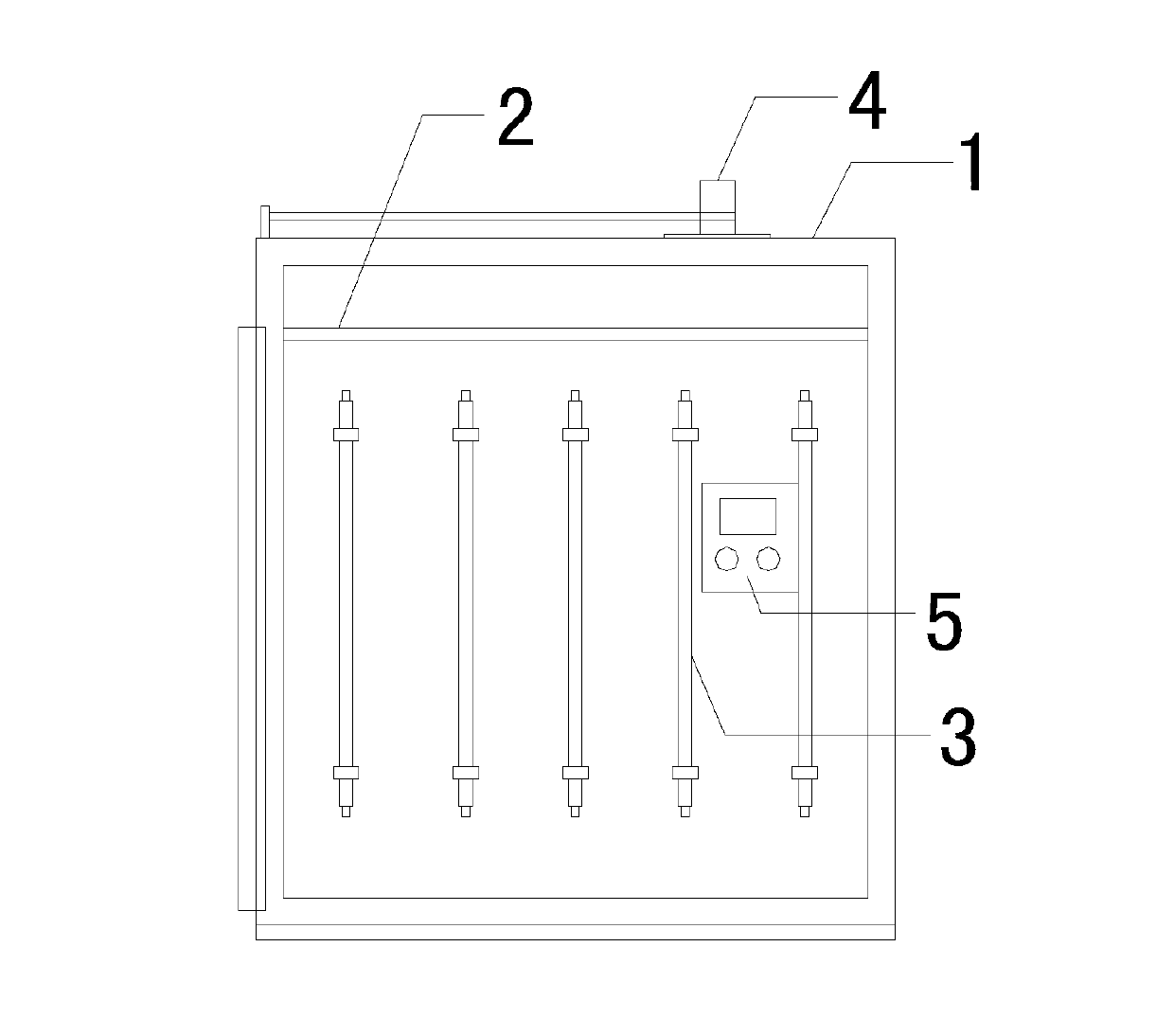

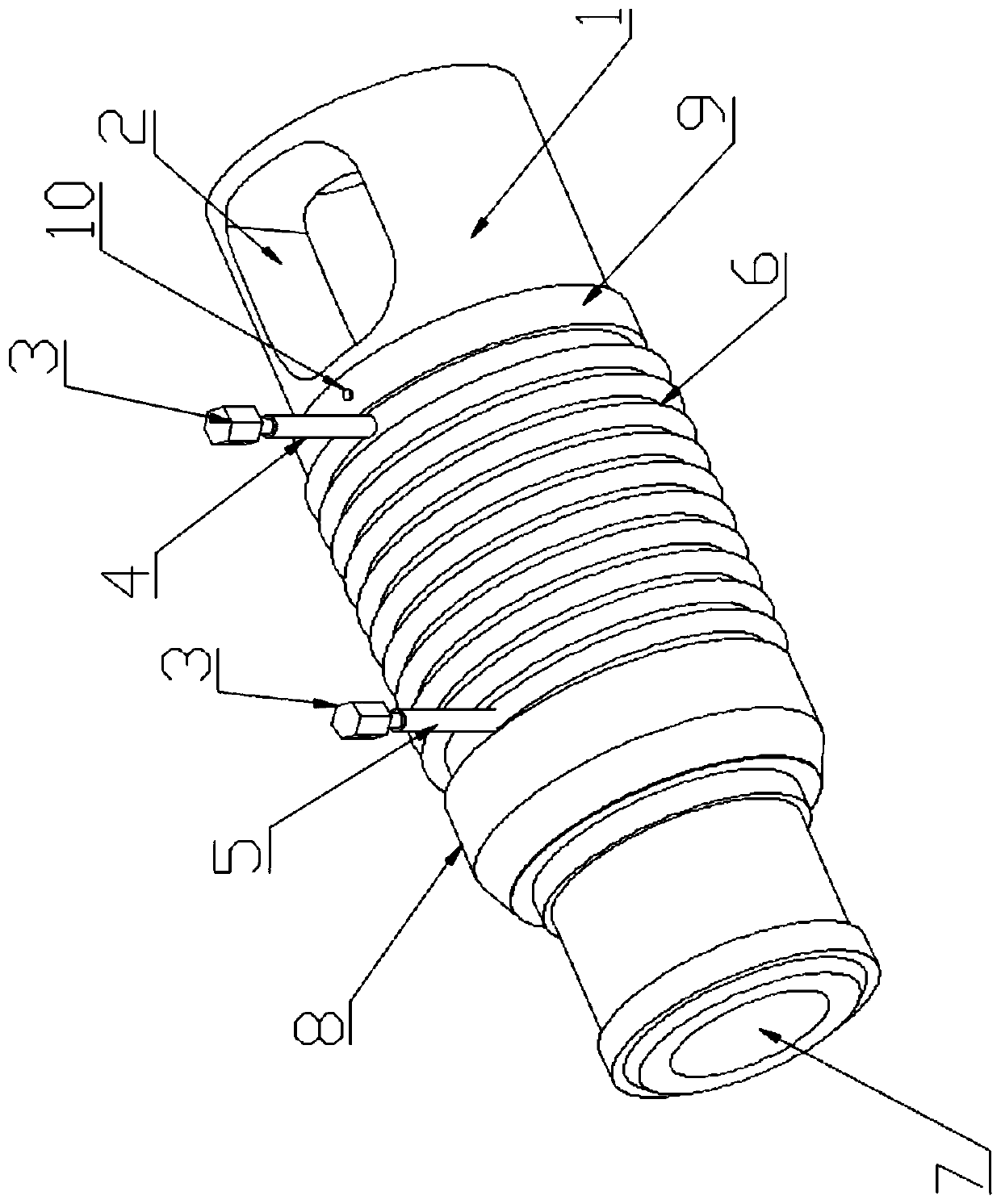

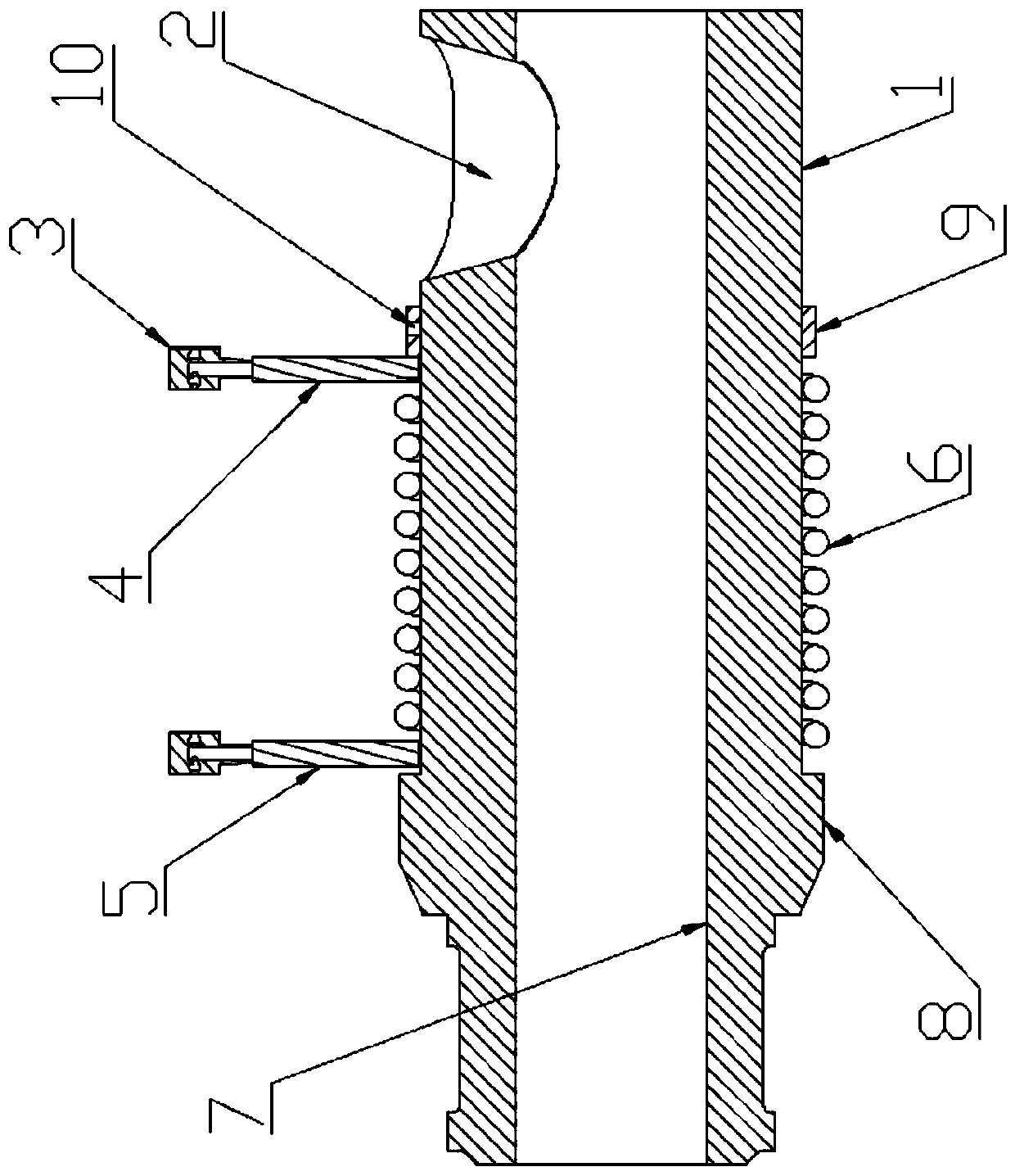

Hydrogen gas storage buffering and filtering tank

PendingCN111442182AIncrease temperatureNo temperature differenceVessel mounting detailsDispersed particle filtrationThermodynamicsBuffer tank

The invention relates to a hydrogen gas storage buffering and filtering tank. The hydrogen gas storage buffering and filtering tank comprises a buffering tank, a heat exchange shell and a filtering cylinder, wherein the buffering tank is in a circular pipe shape; a gas inlet and a gas outlet are respectively formed in the two ends of the buffering tank; the outer side of the buffering tank is hermetically sleeved with the heat exchange shell in a fitting mode; a heat exchange interlayer is formed between the circumferential inner wall of the heat exchange shell and the circumferential outer wall of the buffering tank; a flow guide spring is arranged in the heat exchange interlayer; the outer wall of the buffering tank is sleeved with the flow guide spring in a fitting mode; the two ends ofthe flow guide spring are arranged respectively corresponding to the gas inlet and the gas outlet at two ends of the heat exchange shell; the filtering cylinder is arranged in the buffering tank; oneend of the filtering cylinder is closed, and the other end of the filtering cylinder communicates with the gas inlet of the buffering tank; the filtering cylinder comprises an inner filtering cylinder and an outer filtering cylinder; and a filter core layer is arranged between the inner filtering cylinder and the outer filtering cylinder. The hydrogen gas storage buffering and filtering tank solves or at least relieves the problems that an existing buffering tank heats up during use and is not able to prevent solid particles from entering use equipment.

Owner:新乡市玖鼎机械有限公司

Integrated type energy-saving shuttle kiln

InactiveCN103123225AReduce volumeMeet heating needsFurnace typesWaste heat treatmentProcess engineeringHigh-temperature corrosion

The invention discloses an integrated type energy-saving shuttle kiln, belongs to the field of shuttle kiln equipment, and particularly relates to the integrated type energy-saving shuttle kiln of secondary recycling tail pyrotechnic gas and obvious energy-saving effect. The integrated type energy-saving shuttle kiln comprises a high temperature kiln (1), a high temperature kiln chimney flue (5) and a chimney flue stack nozzle flashboard (6), wherein the high temperature kiln chimney flue (5) and the chimney flue stack nozzle flashboard (6) are both arranged on one side of the high temperature kiln (1). The integrated type energy-saving shuttle kiln is characterized in that the stack nozzle of the high temperature kiln chimney flue (5) is connected with an intermediate temperature kiln (2), and the high temperature kiln (1) is communicated with the intermediate temperature kiln (2) as whole. According to the structure of the integrated type energy-saving shuttle kiln, the intermediate temperature kiln of a smaller size is added to carry out recovery of the tail pyrotechnic gas of the high temperature kiln of big size and complete reutilization, the consumption of energy is obviously reduced, heat utilization efficiency is improved, and energy is saved by 60% to 70%, the number of kilns is increased and at the same time the normal temperature needs of other kilns cannot be influenced, and the problem of the pollution to the environment caused by the pyrotechnic gas can be solved well.

Owner:路今铧

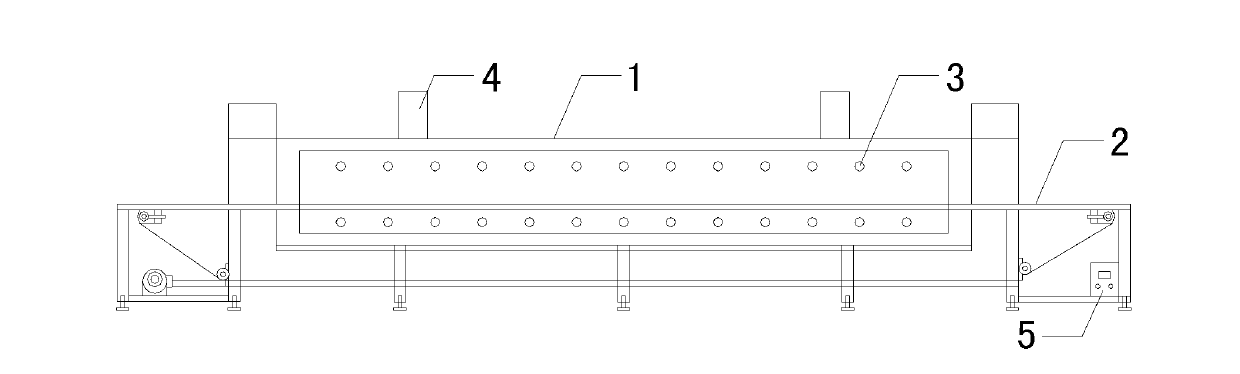

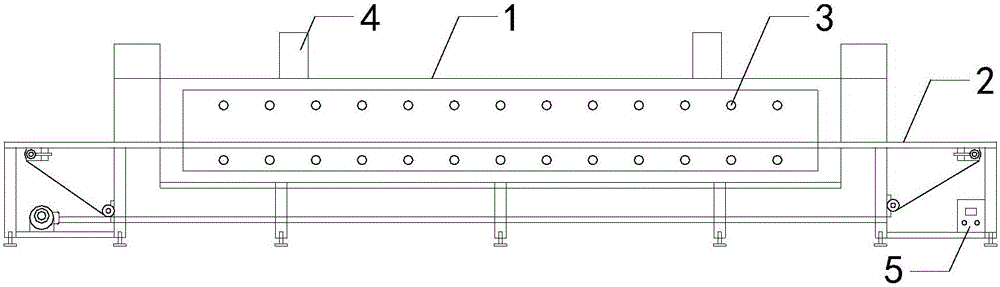

Energy-saving infrared thermal oven

InactiveCN103017497AFast heat transferTo achieve the purpose of energy savingDrying machines with progressive movementsDrying solid materialsInfraredFiber

The invention provides an energy-saving infrared thermal oven which structurally comprises an oven body with a conveying belt in the middle. A plurality of carbon fiber far-infrared heating tubes with extremely high penetrability are mounted in the oven body and surround the conveying belt, and an air outlet and a control box connected with an infrared generator are arranged on the lateral side of the oven body. The energy-saving infrared thermal oven has the advantages that air passage sealing plates and circulating air are not needed, the carbon fiber far-infrared heating tubes directly give out heat to roasted objects in the oven body after electrification, using the air for a transferring medium is not needed, heat transferring is quick, heat can be directly diffused to the roasted objects without being absorbed by intermediate substances, and accordingly energy saving is realized; as the energy-saving infrared thermal oven adopts an integral heating mode, positions irradiated by the infrared are high in heating uniformity, and air influences, heating dead zones and temperature difference are avoided; and compared with traditional ovens, the energy-saving infrared thermal oven has the advantages that energy consumption is reduced by at least 40%, the process roasting time is prolonged by at least 50%, and the energy-saving infrared thermal oven is remarkably effective, high in cleanness, simple in structure and convenience in maintenance.

Owner:宋崇庆

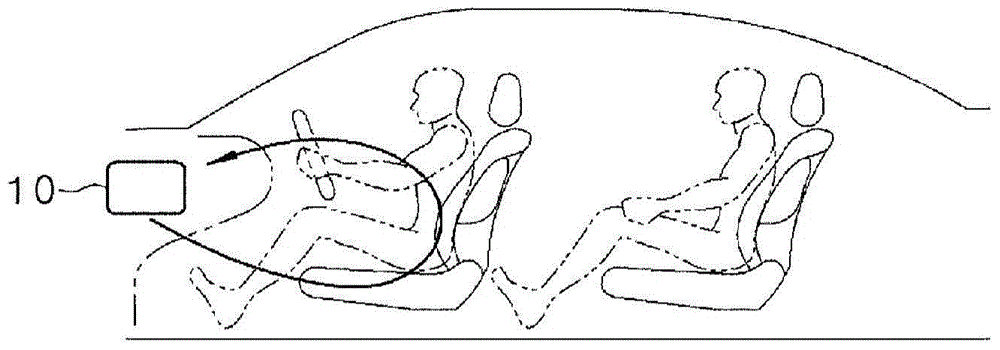

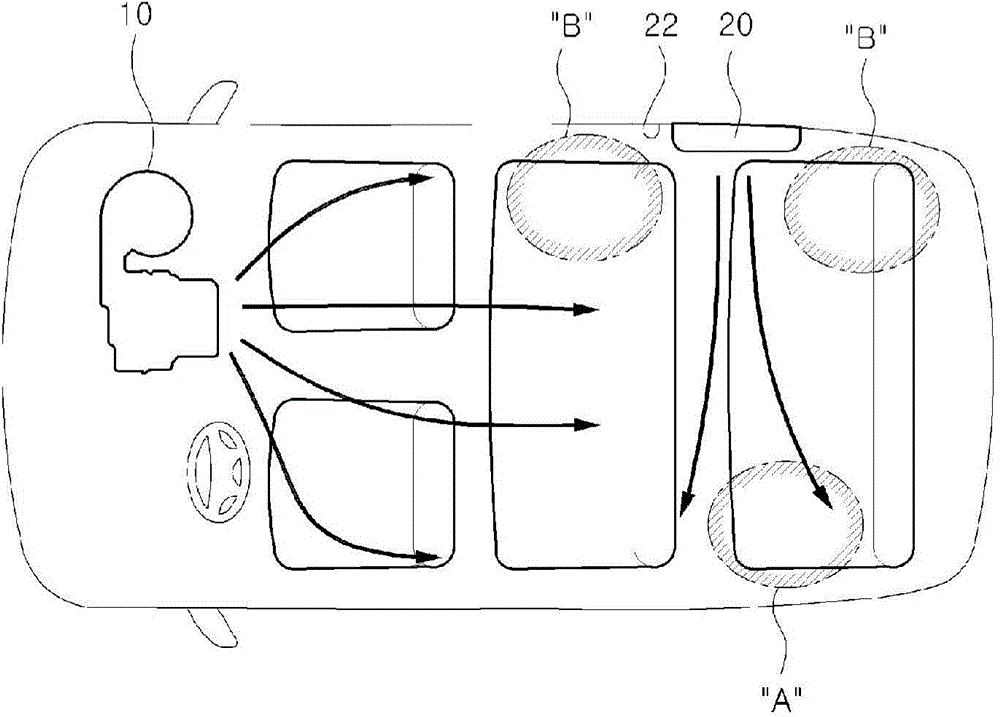

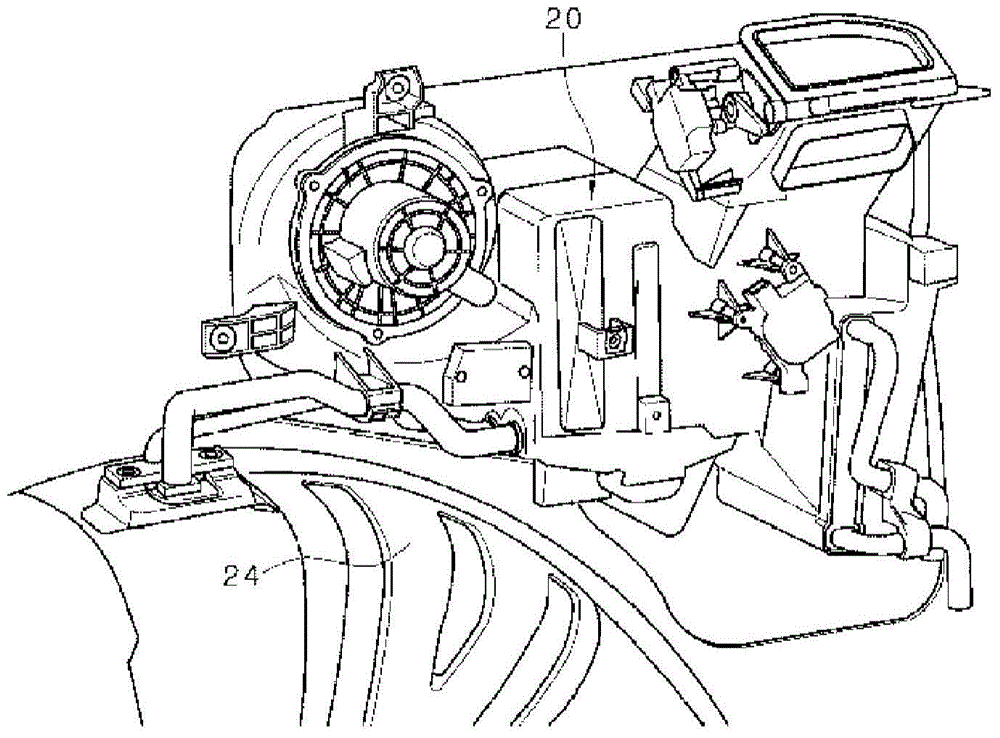

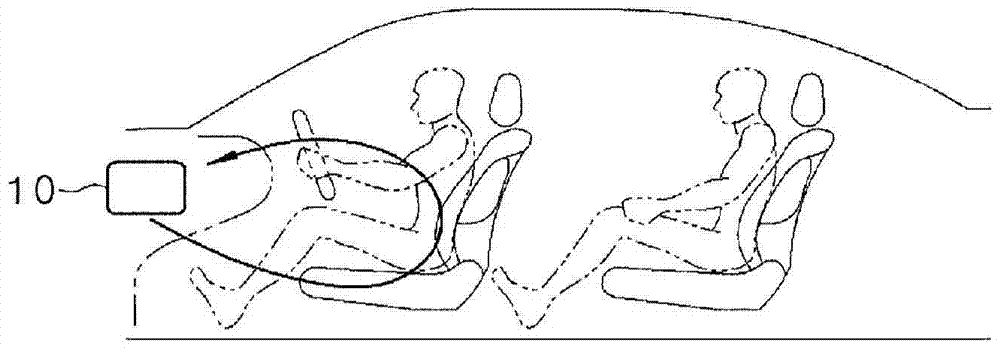

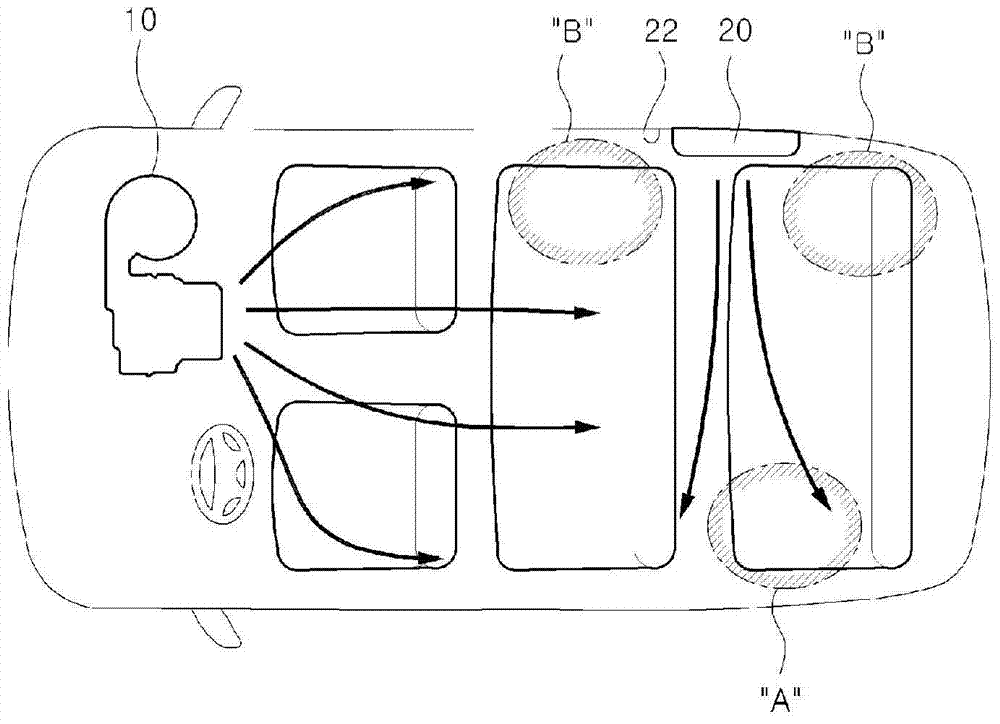

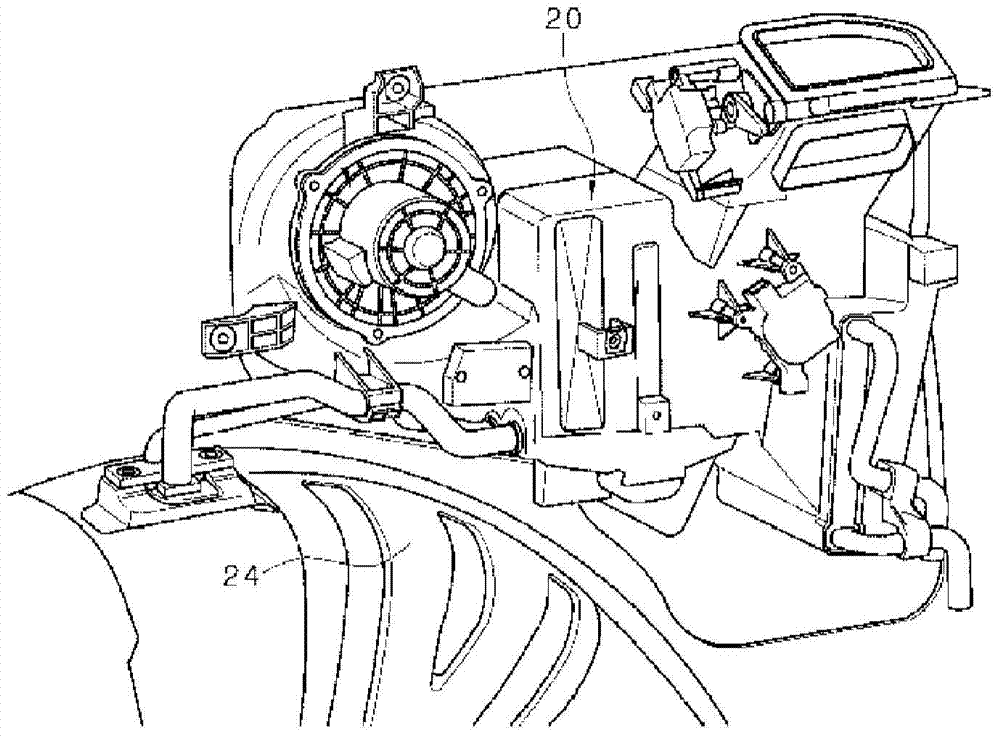

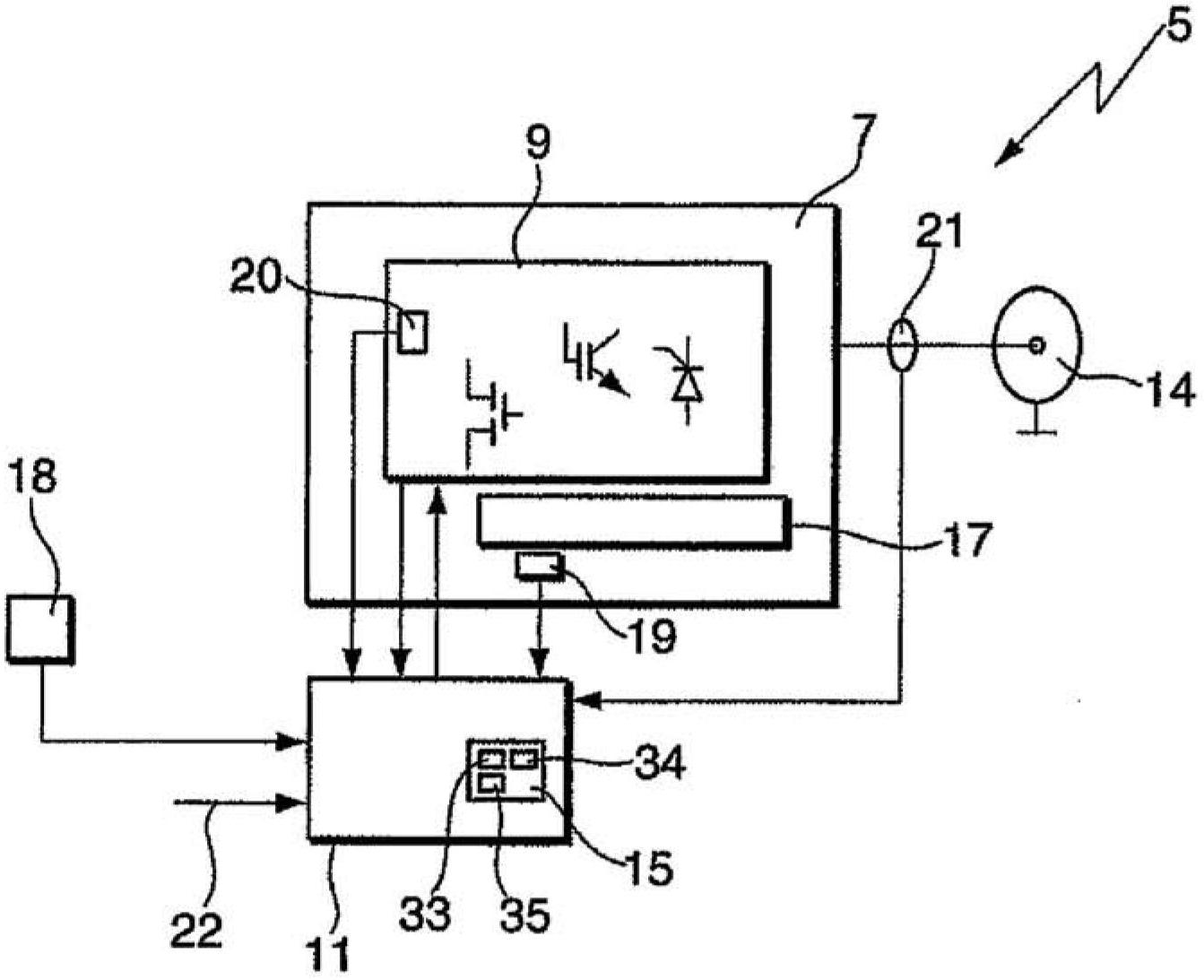

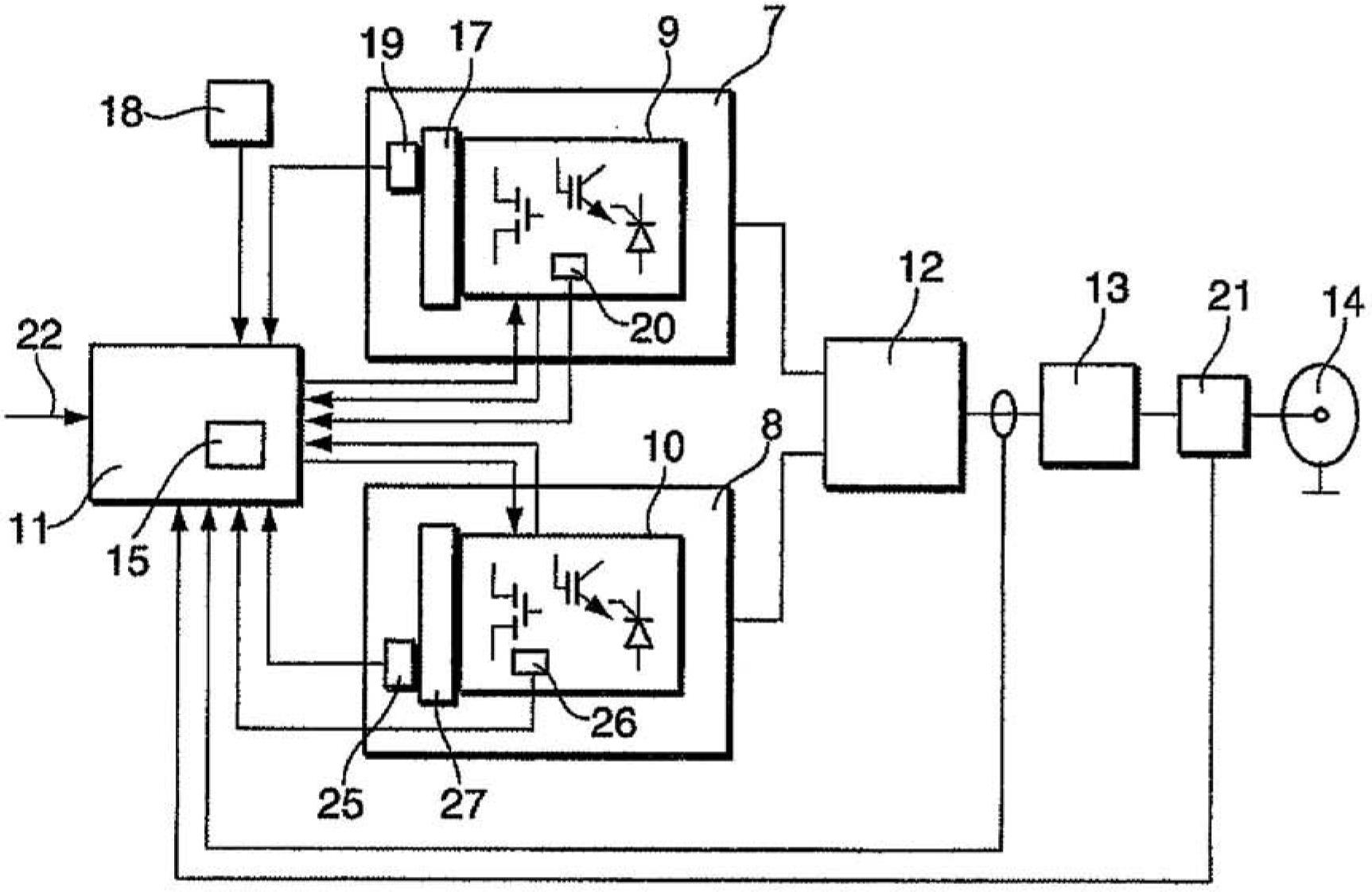

Air-conditioning apparatus for vehicle

ActiveCN104918808AImprove liquidityFlow smoothly toAir-treating devicesVehicle heating/cooling devicesTemperature differenceEngineering

The present invention relates to an air-conditioning apparatus for a vehicle, and intends to improve ventilation of air inside a vehicle so as to reduce the temperature difference between the front and the back seats by means of uniformly blowing cooling or heating air toward each of the back seats, so that each of the back seats can be maintained at a uniform temperature. To this end the present invention provides a front seat air-conditioning device arranged in the front seat area in a vehicle with an auxiliary blower for improving ventilation of air by sucking and re-blowing the air in the vehicle so as to ventilate the cooling or heating air of the front seat air-conditioning device from the front seat area to the back seat area. Additionally, a back seat air-conditioning device is arranged in one of the side walls of the vehicle in the back seat area so as to cool or heat the back seat area, and the auxiliary blower is arranged so as to blow air toward to the back seat area to mix with the cooling or heating air supplied from the back seat air-conditioning device to the back seat area.

Owner:HANON SYST

Efficient cooling die-casting machine melting cup

The invention discloses an efficient cooling die-casting machine melting cup. The melting cup comprises a cup body, a flange edge and an alloy liquid inlet and further comprises a spiral cooling pipe,wherein the cup body is in a hollow column shape, an injection hole is formed in the center of the cup body, the alloy liquid inlet is formed in the side wall of the tail end of the cup body, communicates with the injection hole and is used for injecting alloy liquid, a plunger pushes alloy liquid to be injected into a die-casting die, the annular step-shaped flange edge is arranged on the outerwall of the front end of the cup body and makes contact with a die for positioning, in order to adapt to die-casting machines of different tonnages, the outer diameter of a step at the front end of the cup body is smaller than that of a step at the rear end of the cup body, and the front end of the cup body is sleeved with a conversion sleeve; and the spiral cooling pipe is connected to the outercylindrical face of the cup body in a sleeving mode, the head and the tail of the spiral cooling pipe are connected with a liquid inlet pipe and a liquid outlet pipe respectively, circulating coolingliquid is connected into the liquid inlet pipe and the liquid outlet pipe through connectors, and the front end of the spiral cooling pipe is attached to the flange edge. The melting cup is easy to machine and assemble, the whole cup body can be evenly cooled, and the service life of the melting cup is prolonged.

Owner:盐城泰欧昌机械有限公司

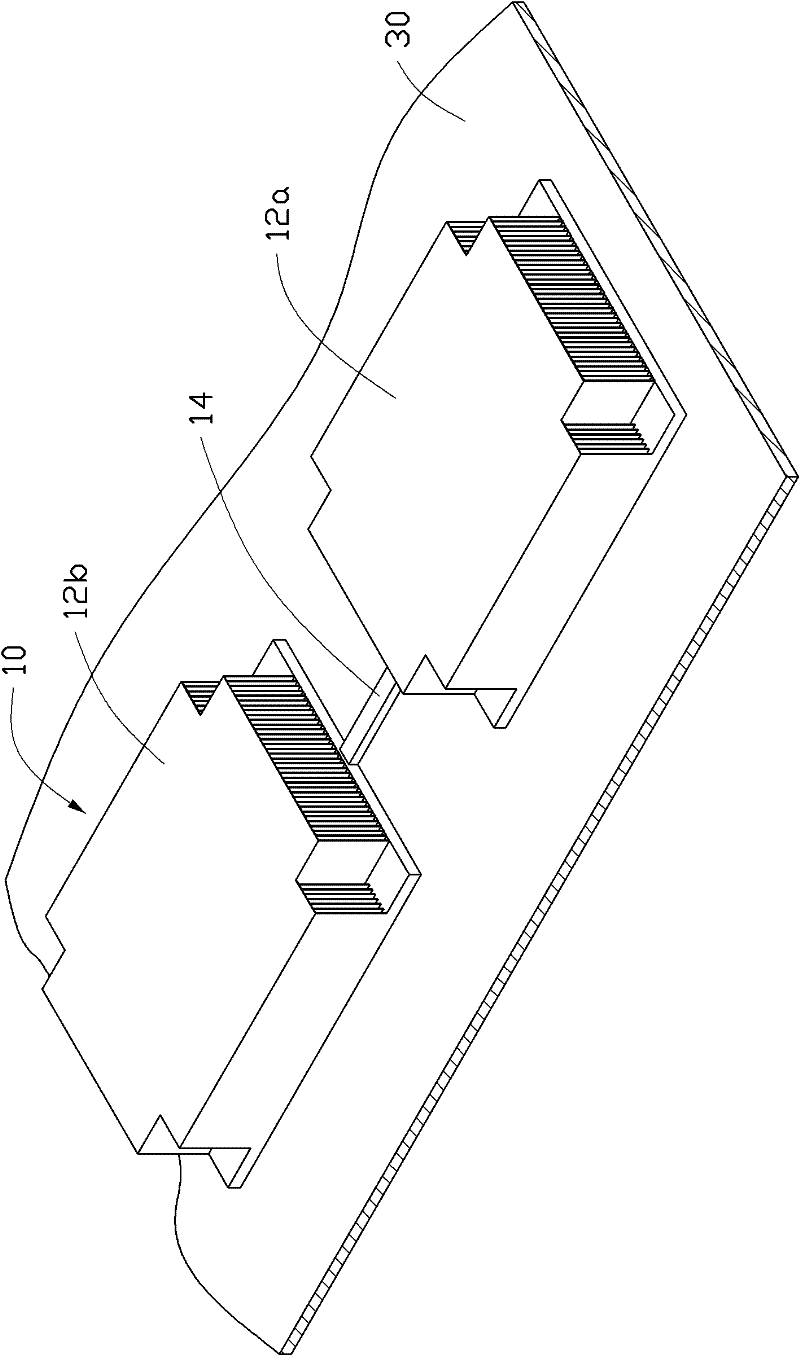

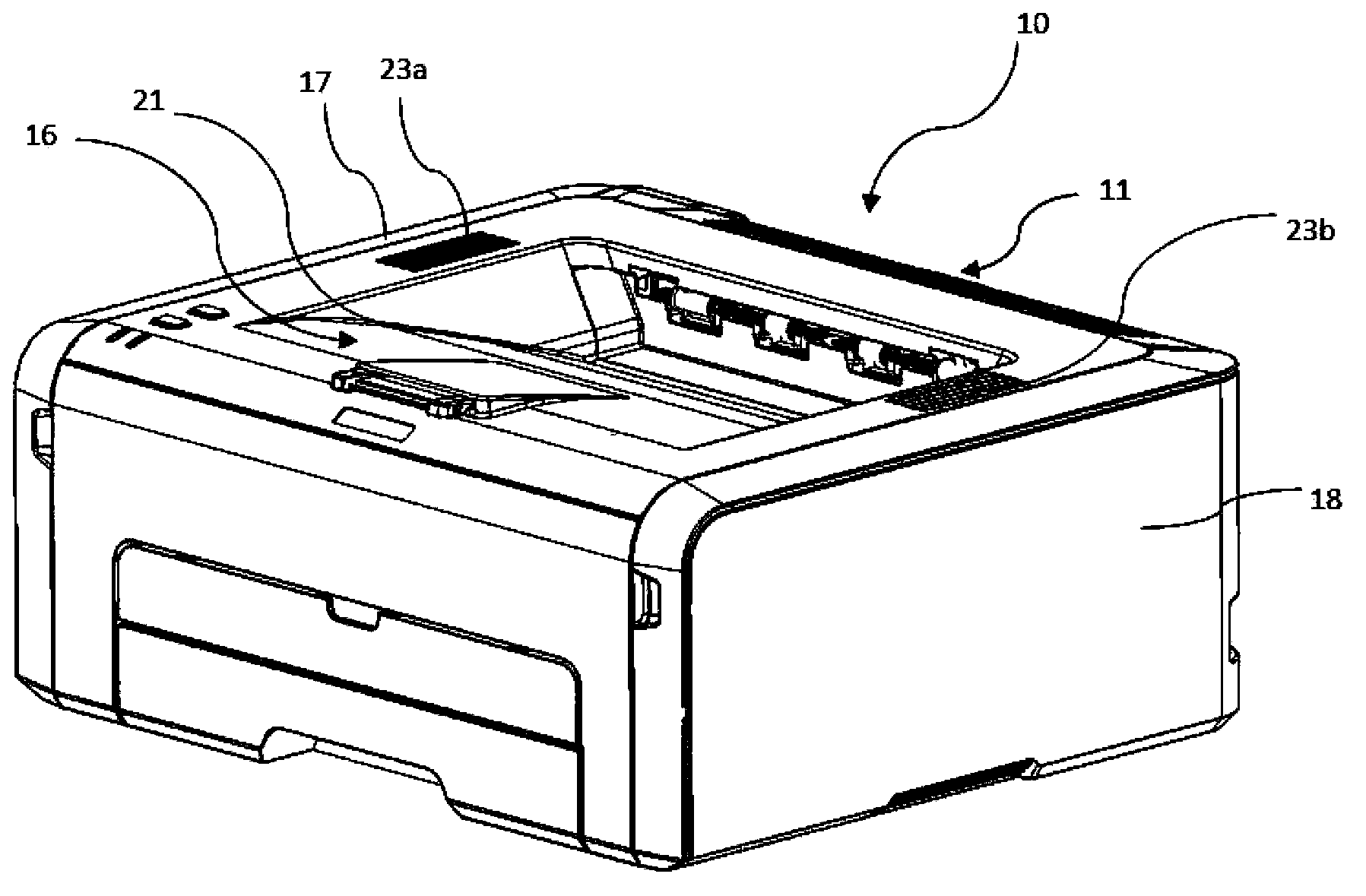

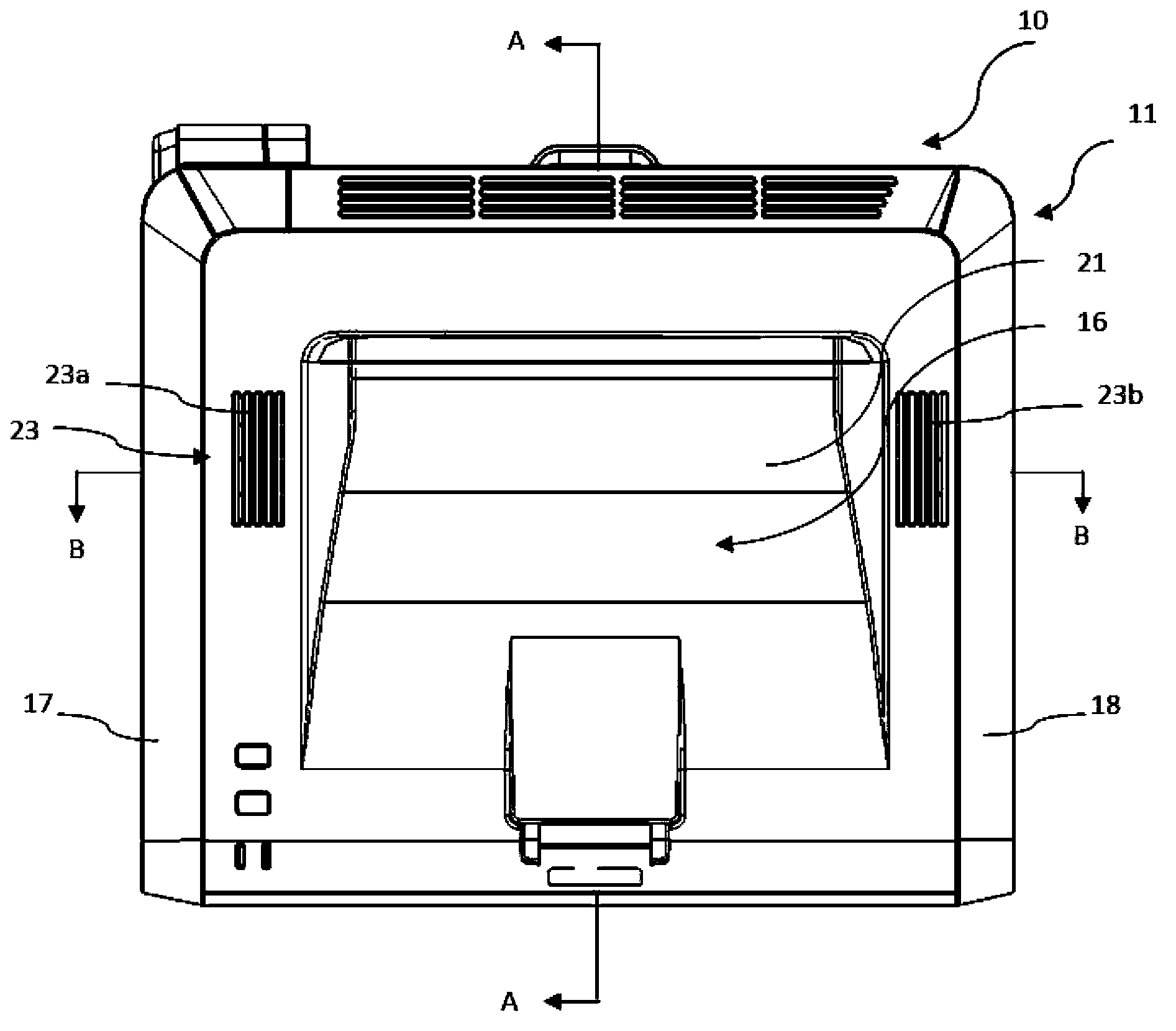

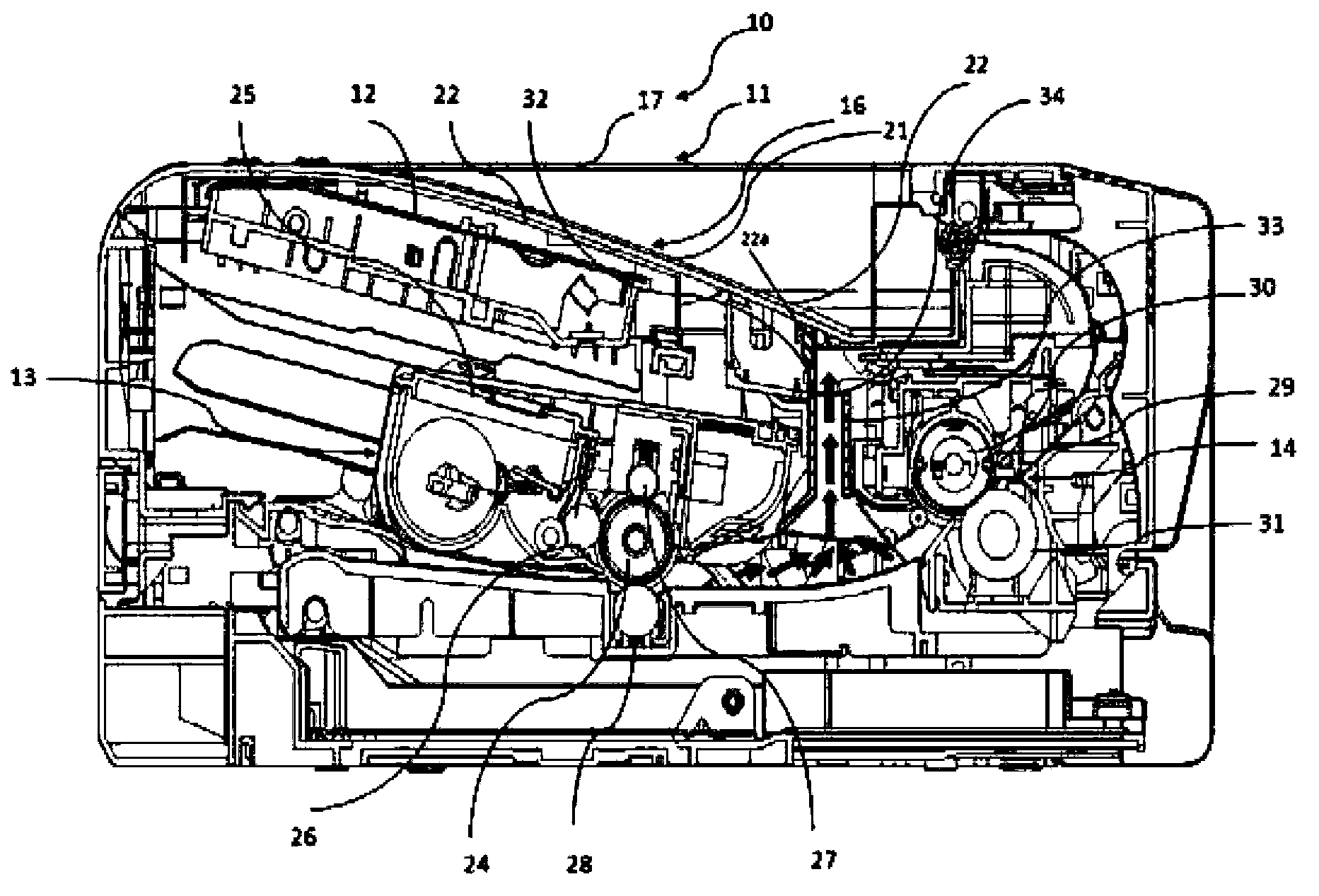

Heat-insulation heat-discharge member and image formation device

InactiveCN103885314ANo temperature differenceTo achieve the purpose of heat insulation and heat dissipationElectrographic process apparatusImage formationMechanical engineering

The invention provides a heat-insulation heat-discharge member which prevents heat from a fixing unit from flowing to an exposure unit without using a fan and naturally discharges the heat to the outside, and an image formation device with the heat-insulation heat-discharge member. The heat-insulation heat-discharge member of the invention is disposed between an exposure unit and a fixing unit of an image formation device, is used for at least stopping the heat from the fixing unit from flowing to the exposure unit and discharging the heat to the outside through two oppositely disposed gas vents on a frame of the image formation device, and is characterized in that the member comprises two end parts respectively communicated with the two gas vents, and at least two heat discharging paths which enable the heat to flow to the two gas vents respectively in opposite directions.

Owner:RICOH KK

Method for machining full-glass shell compact energy-saving fluorescent lamp

InactiveCN101694824AAvoid breakingReduce stressGlass reforming apparatusGlass severing apparatusEngineeringLength wave

The invention discloses a method for machining a full-glass shell compact energy-saving fluorescent lamp, which comprises the following steps: machining a glass shell by using a conventional method; positioning the glass shell firmly on a fixture by vacuum negative pressure and cutting the glass shell into an upper half glass shell and a lower half glass shell by a CO2 laser with the CO2 laser wavelength of 10.6 nm; installing a strip lamp component in the lower half glass shell; positioning the upper half glass shell and the lower half glass shell firmly and accurately on the fixture by vacuum negative pressure and aligning two cuts to fit each other; when heating the glass shells to 400 DEG C by preheating flame, welding the glass shells by the CO2 laser with the CO2 laser wavelength of 10.6 nm; and annealing the welded glass shell by an annealing system and taking off a finished product. The invention has the advantages of greatly improving the machining reliability, lowering the difficulty in machining, lowering the stress of the glass shell and improving the yield of products.

Owner:ZHEJIANG YANKON GROUP

A tunable mode-locked fiber laser based on fiber grating and graphene

InactiveCN103337774BCompact structureImprove reliabilityActive medium shape and constructionMode locked fiber laserGrating

The invention discloses a tunable mode locking fiber laser based on a fiber grating and a grapheme. Tunable output of a linearity chamber fiber laser is realized based on a principle that a central wavelength of the fiber Bragg grating drifts along with strain linearity, and mode locking output of a linearity chamber fiber laser is realized based on a saturation absorption function of the grapheme with wide saturation absorption wave bands. The tunable mode locking fiber laser has advantages of full fiber structure, compact structure, stable performance, tunable broadband, wide application in the fields of fiber communication, fiber sensing, and the like and extensive applicability.

Owner:NORTHWEST INST OF NUCLEAR TECH

Air conditioning system for vehicles

ActiveCN104918808BImprove liquidityFlow smoothly toAir-treating devicesVehicle heating/cooling devicesEngineeringTemperature difference

The present invention relates to an air conditioner for a vehicle, and aims to improve the circulation of air in the vehicle to reduce front-to-back The temperature difference between the seats. To this end, the present invention provides a front seat air conditioner arranged in a front seat area in a vehicle, the front seat air conditioner having an auxiliary blower to suck in and blow out air in the vehicle again to circulate heated or cooled air of the front seat air conditioner from the front seat area to the rear seat area for improved air circulation. In addition, a rear seat air conditioner is provided in one of the side walls of the vehicle in the rear seat area to cool or heat the rear seat area, and an auxiliary blower is provided to blow air to the rear seat area to communicate with air from the rear seat air conditioner. Mixing of cooled or heated air supplied to the rear seat area.

Owner:HANON SYST

Method for operating an industrial process

ActiveCN102656661ASmall temperature fluctuationsNo temperature differenceElectric discharge tubesAc-dc conversionTime segmentEngineering

The invention relates to a method for operating a plasma system, an induction heating system, or a laser excitation system in a pulsed power output mode, wherein a first power POUT1.1 is generated in a power output time period [delta]T1, and is output at a power output of a power generator for providing power to a plasma process, of an induction heating process, or of a laser excitation process, and no power POUT2.1 suitable for igniting or operating a plasma process, an induction process, or a laser excitation process is output at the power output of the power generator in a pulse pause time period [delta]T2, in that at least one semiconductor circuit element (9) of the power generator is actuated, wherein a first loss power PV1 is generated in the at least one semiconductor circuit element (9) at the same time as the generation of the first power Pout1.1 during the power output time period [delta]T1, and a second loss power PV2 is generated in the at least one semiconductor element (9) during the pulse pause time period [delta]T2, and the generated loss powers PV1, PV2 are converted into heat, wherein a drop in temperature of the semiconductor circuit element (9) by greater than a predefined value is prevented by suitably actuating the semiconductor circuit element, and the power output mode and the pulse pause mode alternate continuously.

Owner:HUETTINGER ELEKTRONIK

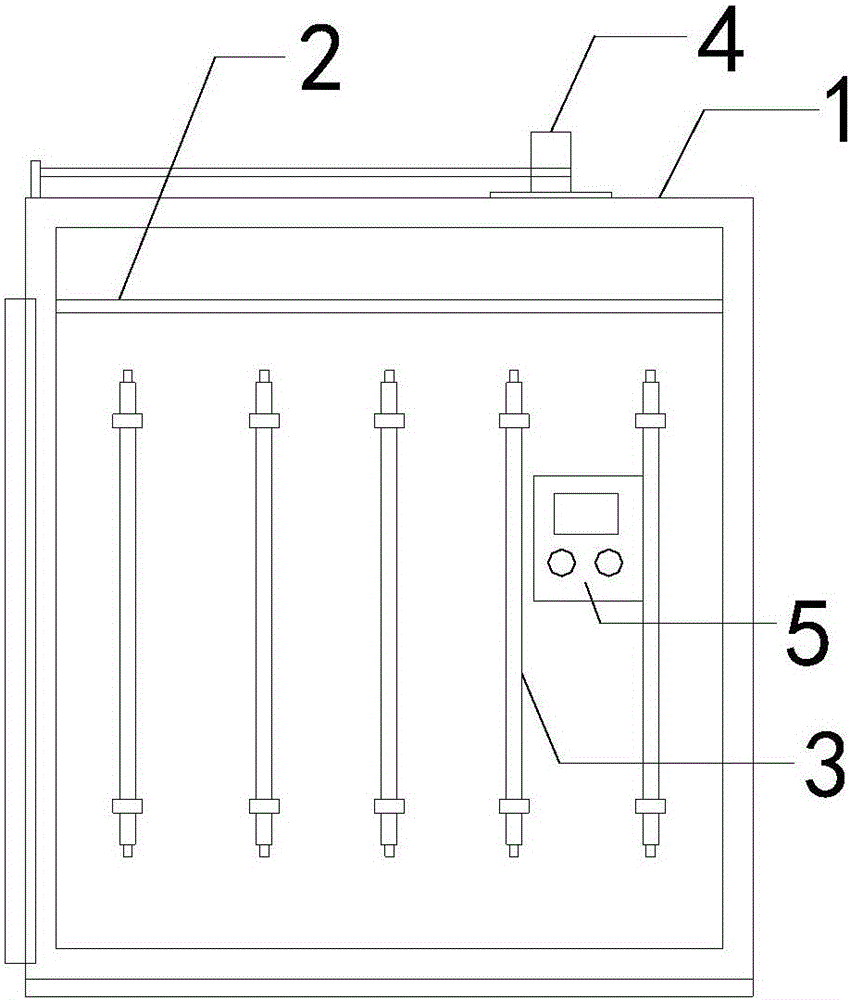

Energy-saving far-infrared hot drying oven

InactiveCN105806067AImprove the heating effectTo achieve the purpose of energy savingDrying machines with progressive movementsHeating arrangementInfraredFiber

The invention provides an energy-saving far-infrared hot drying oven. The energy-saving far-infrared hot drying oven structurally comprises an oven body provided with a conveying belt, wherein a plurality of carbon fiber far-infrared heating tubes are arranged in the oven body; the carbon fiber far-infrared heating tubes are arranged at the periphery of the conveying belt; exhaust outlets are formed in the top of the oven body; a control box connected with the carbon fiber far-infrared heating tubes is arranged at the outer side edge of the oven body; the carbon contents of the carbon fiber far-infrared heating tubes are at least 99.7 percent of carbon fibers; and the carbon fiber far-infrared heating tubes are formed by decomposition, extrusion and forming at the temperature of 350 to 450DEG C and carbonization treatment at high temperature of 1500 to 2500DEG C. According to the energy-saving far-infrared hot drying oven disclosed by the invention, the characteristic that the wavelengths of the carbon fiber far-infrared heating tubes are longer is fully utilized, baked objects are directly heated up in a radiation way, and radiation energy absorbed by the objects is transmitted to particles such as atoms and molecules in the objects, so that the particles generate irregular movement, the heating function of the objects is caused, and the energy-saving far-infrared hot drying oven realizes the effects of high efficiency and energy conservation; and the energy-saving far-infrared hot drying oven is simple in structure and is convenient in maintenance.

Owner:宋崇庆

One-step formed integral baked porcelain crown bridge and manufacturing method thereof

The invention discloses a one-step formed integral baked porcelain crown bridge and a manufacturing method thereof. The integral baked porcelain crown bridge is formed by digitally and automatically carving a cobalt-chromium baked porcelain alloy disc material for denture carving, is provided with continuous 2-14 crowns and is used for being fixed on an oral abutment or an implantation abutment. The manufacturing method comprises the following steps: scanning an oral gum structure of a whole patient or an oral impression of the patient by adopting an oral three-dimensional scanner to obtain data; manufacturing a model by using CAD design and CDM typesetting and transmitting the data to a five-axis linkage tooth carving machine; and then carrying out digitalized automatic engraving on the cobalt-chromium baked porcelain alloy disc for engraving the false tooth. According to the integral baked porcelain crown bridge, the original procedures of casting, cutting, welding, polishing and thelike are omitted; the difficulties of crown and bridge deformation, incapability of being in place and the like caused by a traditional casting process, a 3D printing high-temperature sintering process and a crown and bridge high-temperature sintering process for manufacturing zirconium oxide ceramic blocks are solved; the manufactured baked porcelain crown bridge is close in edge, more accurate,more comfortable and more attractive, particularly brings good news to a large number of patients who cannot do dental implants and lack teeth, and is an important milestone for development of the oral rehabilitation process.

Owner:南通今日高科技新材料股份有限公司

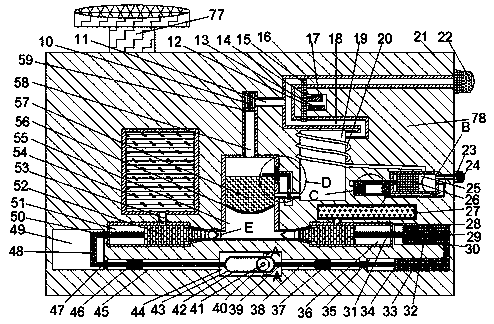

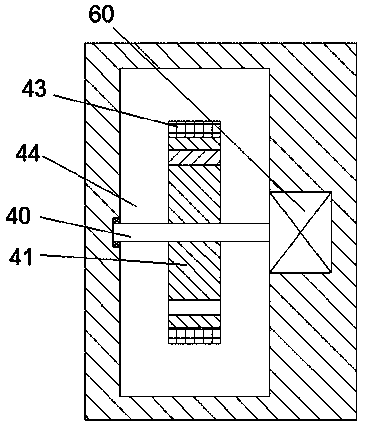

Powder metallurgy die

The invention relates to a powder metallurgy die which comprises a male die and a female die. The female die comprises a female die jacket (11) and a female die core (12), the female die jacket (11) is sleeved on the female die core (12) to form an integral structure, a spiral oil groove (13) is arranged on the inner annular surface of the female die jacket (11), and the spiral oil groove (13) and external temperature-controllable hot oil form a hot oil circuit. The powder metallurgy die is characterized in that a supporting device (7) is arranged between the male die and the female die. Supporting blocks and a supporting base are connected with one another at two ends of a connecting rotary frame by mounting holes, and the supporting blocks can be positioned above the supporting base or can be separated from the supporting base, so that the die can be effectively protected against stress when not working, the supporting device can be prevented from being lost during operation, and the powder metallurgy die can be operated easily and conveniently.

Owner:江门德励高精模有限公司

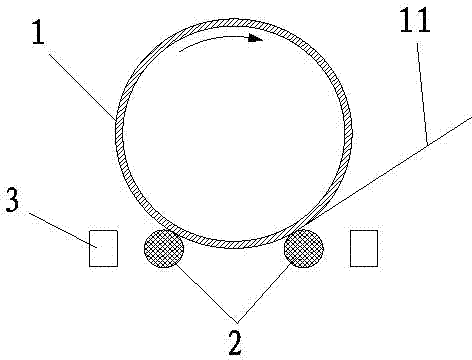

Fixed-length production heating technology of composite pipeline

The invention relates to a fixed-length production heating technology of a composite pipeline. According to the technology, a metal pipe die is provided; when the outer surface of the metal pipe die is coiled with a non-metal composite material, the heating temperature at two ends of the metal pipe die is higher than the heating temperature in the middle; the metal pipe die is placed on two parallel rotating rollers and is driven by a rotating mechanism to rotate on the rotating rollers; heating devices are respectively arranged beside the two rotating rollers; the densities of the heating devices arranged at two ends of the metal pipeline are greater than the density of a heating device in the middle of the metal pipe die; the heating devices and the rotating rollers are positioned on the same horizontal plane, so that the temperatures of the rotating rollers are higher than the temperature of the metal pipe die. According to the technology, the temperature of the whole composite pipeline is consistent in a production process, so that the overall performance of a final product is stable.

Owner:福建中管机电科技有限公司

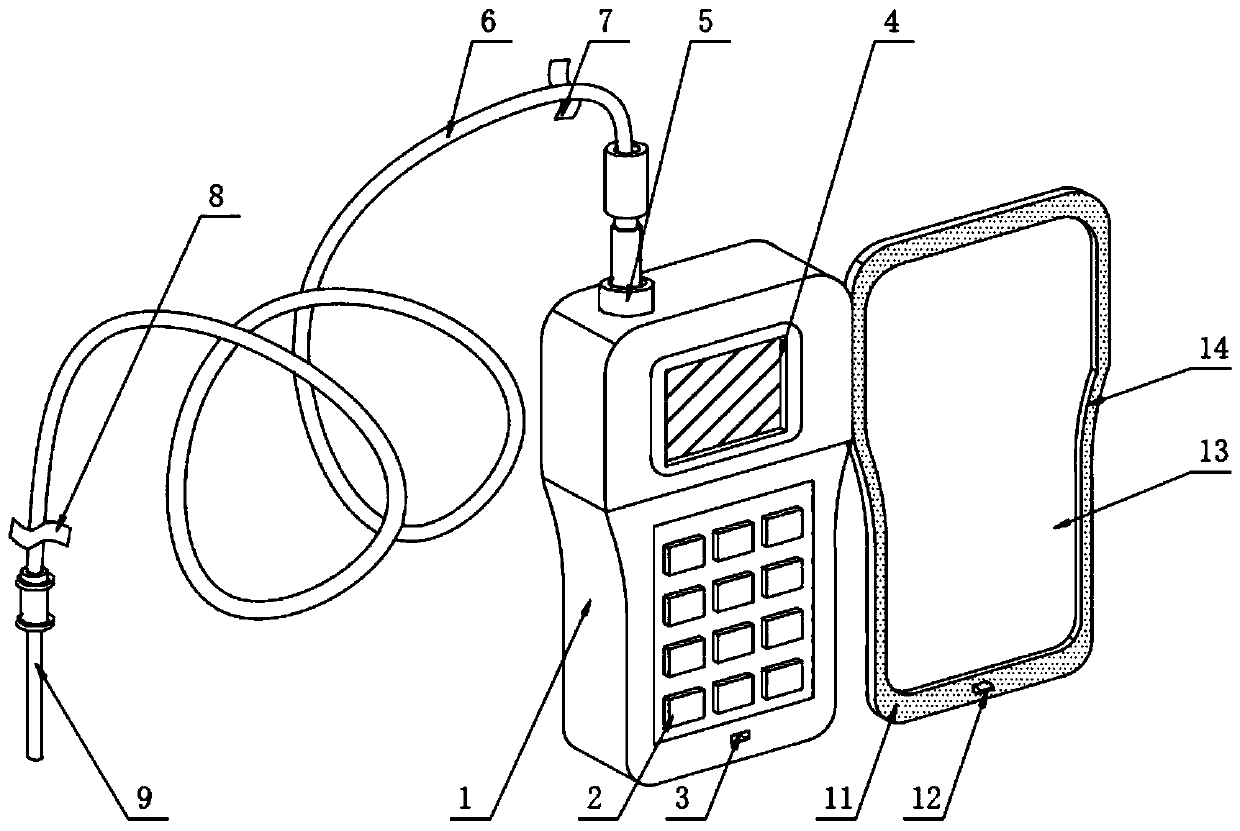

Vertical cavity surface emitting laser for oxygen detection

PendingCN111551519AConsistent detection temperatureAdjustable operating temperatureLaser detailsThermometers using electric/magnetic elementsVertical-cavity surface-emitting laserEngineering

The invention discloses a vertical cavity surface emitting laser for oxygen detection and specifically relates to the technical field of oxygen gas concentration measurement. The vertical cavity surface emitting laser comprises a shell, a display screen is embedded in the surface of the shell, a signal output interface is fixedly arranged at the top end of the shell, a wire is installed in the signal output interface, one end of the wire is fixedly connected with a laser device shell, and a plurality of light-emitting holes are formed in the laser device shell in an annular mode. According tothe invention, the laser chip, the thermistor and the temperature controller are arranged; securing reliability of long-term operation, the working temperature of the semiconductor laser can be tuned,accurate absorption peak wavelength laser can be output, extremely good heat conduction is achieved, the wavelength of the semiconductor laser does not deviate, the protection cover is arranged, theinsertion block is inserted into the insertion groove, installation of the protection cover is achieved, and numerical values in the display screen are observed through the transparent window.

Owner:武汉奥博奥科技有限公司

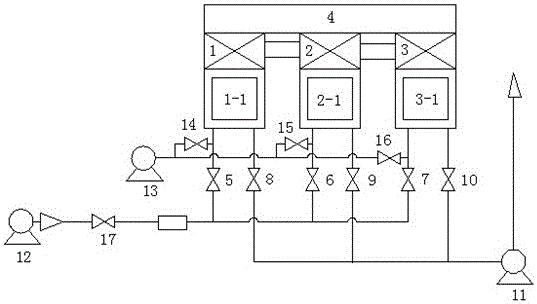

Continuous production apparatus and method of catalysts

ActiveCN107519944AFast dissolutionImprove heating efficiencyCatalyst activation/preparationWaste managementContinuous production

The invention relates to a continuous production apparatus and method of catalysts. The apparatus comprises a preparing tank for preparing a solution, a soaking tank for soaking a catalyst, jackets arranged in the preparing tank and the soaking tank respectively, and a heating device for heating media in the jackets; a stirring device is arranged in the preparing tank; a medium outlet of the jacket of the preparing tank is connected with a medium inlet of the soaking tank via a pipeline; a medium inlet of the preparing tank is connected with a medium outlet of the soaking tank via a pipeline; each pipeline is provided with a pump and a valve; the medium in the jacket of the preparing tank and the medium in the jacket of the soaking tank can be circulated; the medium in the jacket of the preparing tank can also be subjected to single circulation.

Owner:XINDI ENERGY ENG TECH

Data identification device for controlling humidity

ActiveCN111059666AAvoid secondary pollutionHigh degree of automationMechanical apparatusLighting and heating apparatusWater storageWater vapor

The invention discloses a data identification device for controlling humidity. The data identification device comprises an outer shell; a humidity data identification instrument is fixedly arranged onthe upper end face of the outer shell; a gas box is arranged in the outer shell; a heating box is arranged at the right side of the gas box; a water storage cavity is arranged in the heating box; a combustion cavity is arranged under the heating box; and a left pressure cavity is arranged under the gas box; a gas pushing component is arranged in the left pressure cavity. The device controls starting of a motor by identifying the humidity in air through humidity data, so that humidity in a room is maintained to be in a most comfortable state of a human body; meanwhile, water mist sprayed froma spray head is formed by water vapor generated after heating, and the water mist cannot contain various elements in the room, so that elements in water are prevented from contacting the air to form second pollution, and cleanness and health are achieved better; and in addition, the device can be controlled to spray heated water mist or cooled water mist according to the temperature of the room tocontrol the temperature in the room, and temperature difference is not formed.

Owner:山东济安安全技术服务有限公司

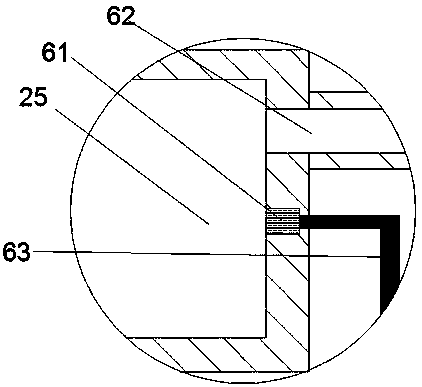

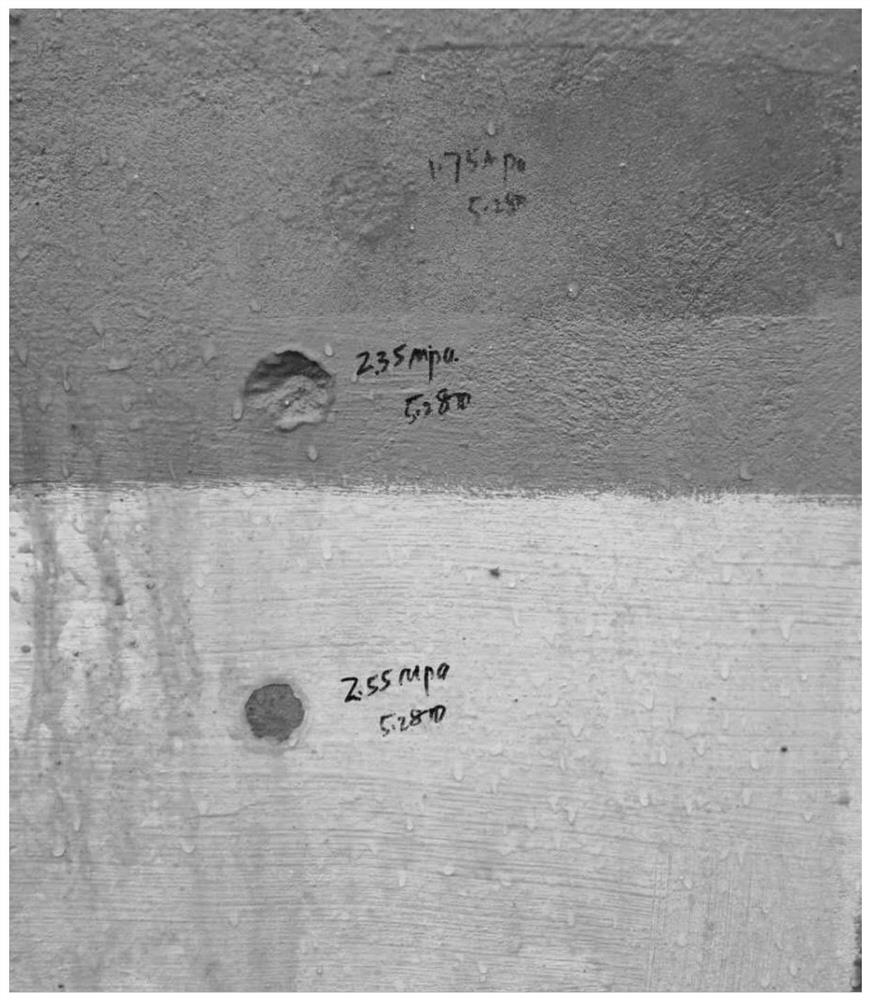

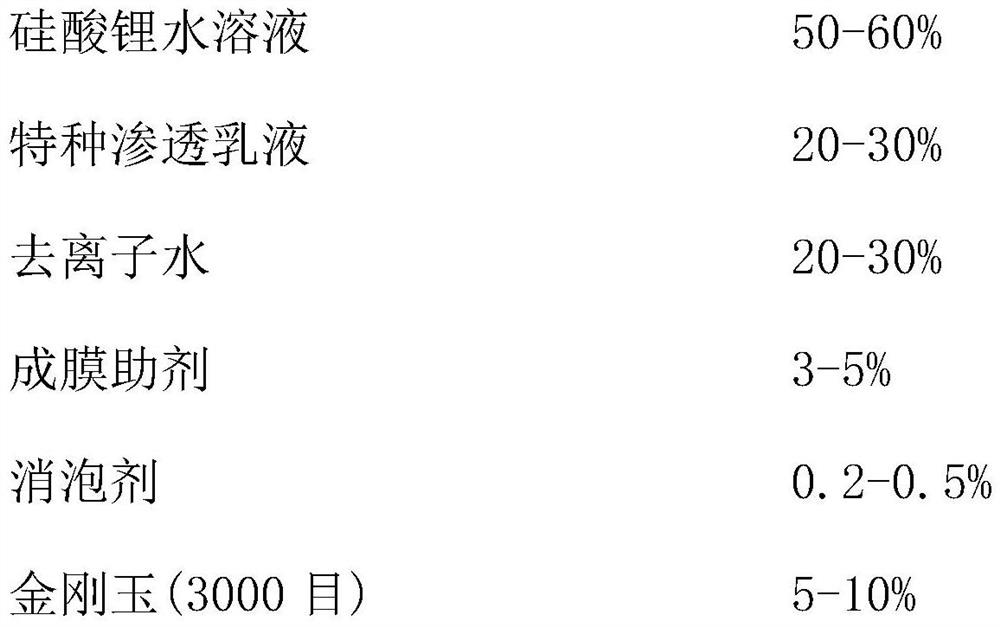

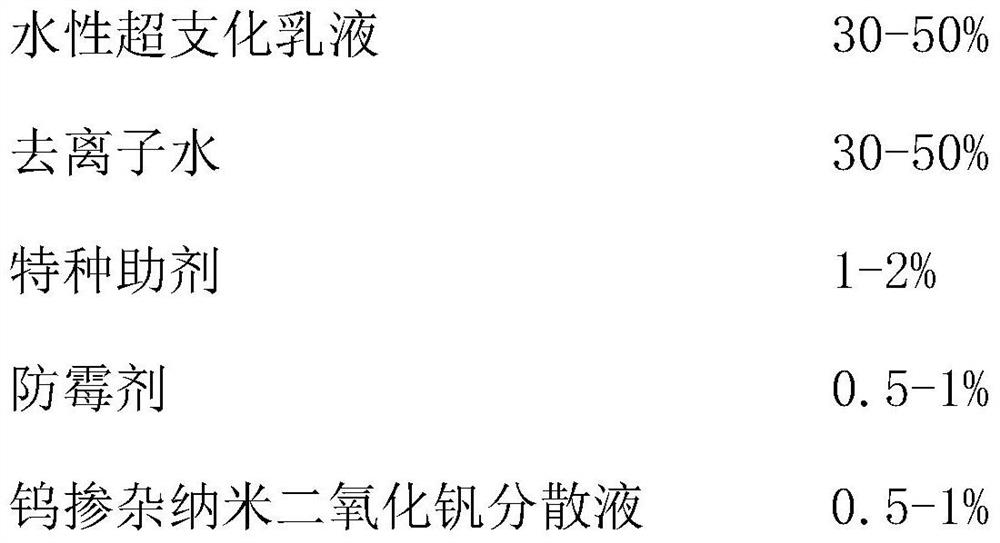

Anti-carbonization coating with super-strong adaptability and preparation method thereof

The invention discloses an anti-carbonization coating with super-strong adaptability and a preparation method thereof, and relates to the technical field of concrete. The coating comprises a permeableprimer, a middle-layer paint and a finish paint, and the permeable primer comprises a lithium silicate aqueous solution, a special permeable emulsion, deionized water, a coalescing agent, a defoamingagent and diamond jade in percentage by weight; the middle-layer paint comprises a group A and a group B, wherein the group A comprises a water-based hyperbranched emulsion, a special auxiliary agent, a mildew preventive and a tungsten-doped nano vanadium dioxide dispersion liquid; and the group B comprises special cement, quartz sand, talcum powder and a powdery defoaming agent; and the finish paint comprises a water-based hyperbranched modified silicone acrylic emulsion, a mildew preventive, a coalescing agent, deionized water, a defoaming agent, a wetting agent and a thickening agent. Thecoating can effectively prevent water from reacting with repaired concrete, can generate good adherence with middle-layer paint, can quickly extrude water to the surface, is not influenced by environmental humidity, has good ageing resistance, further protects the concrete and reduces the carbonization opportunity.

Owner:上海涂固安高科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com