Control system of organic waste gas catalytic burner and operation method of control system

A catalytic burner and control system technology, applied in combustion methods, combustion types, incinerators, etc., can solve problems such as damage to catalysts, loss of heat, waste of energy, etc., to achieve good temperature uniformity, easy maintenance and repair, energy The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

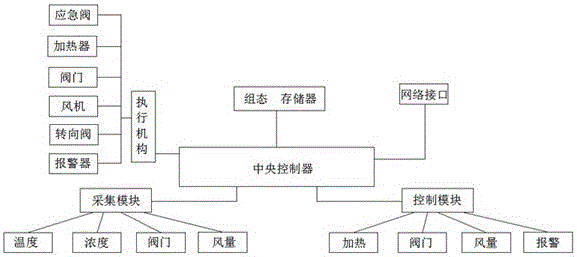

[0025] Embodiment 1: as figure 1 with 2 A control system for an organic waste gas catalytic burner is shown, and the control system includes a central controller, a configuration memory, an acquisition module, a control module and an actuator, and the configuration memory, the acquisition module, the control module and the actuator are all Connected to the central controller, the acquisition module includes temperature, concentration, valve and air volume acquisition modules, the control module includes heating, valves, air volume and alarm modules, and the actuator includes catalytic chambers, reversing valves , fans, intake valves, emergency valves and alarms;

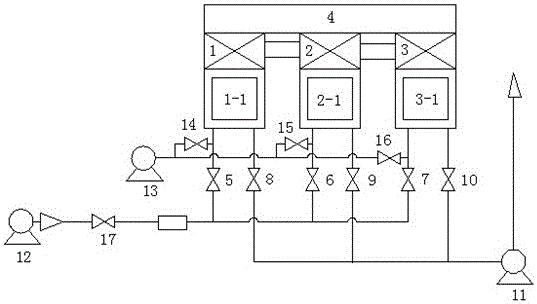

[0026] The control system of the present invention is installed on the organic waste gas catalytic burner, and the organic waste gas catalytic burner includes No. 1 burner, No. 2 burner, No. 3 burner and fan, No. 1, No. 2 and No. 3 The burners communicate with each other, and the intake valve 17 is respectively con...

Embodiment 2

[0027] Embodiment 2: as figure 1 with 2 As shown, No. 1, No. 2 and No. 3 burners of the present invention are all made up of electric heating tube 4, catalytic chamber 1, 2, 3 and regenerator 1-1, 2-1, 3-1, and catalytic chamber 1 . -1, 3-1 flow into the catalytic chambers 1, 2, and 3. During a single operation, the former catalytic chamber 1 has a stable working temperature due to the relatively low-temperature organic waste gas flowing in, but the latter catalytic chamber 2. Since the organic waste gas has been burning, the working temperature at the tail must be high, which can easily cause the activity of the catalyst at the tail to decrease or even deactivate.

Embodiment 3

[0028] Embodiment 3: as figure 1 with 2 As shown, the intake pipe and exhaust pipe of the present invention are all connected to the regenerator 1-1, 2-1, 3-1 of the catalytic chamber, and the regenerator 1-1, 2-1, 3-1 1 and catalytic chambers 1, 2, and 3 are provided with a temperature acquisition module, and the heating module is arranged on the electric heating tube 4; the device as a whole is uniformly controlled by a central controller. It directly affects the purification efficiency of exhaust gas, so it needs to be monitored intensively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com