Integrated type energy-saving shuttle kiln

A technology of conjoined type and shuttle type kiln, which can be used in furnace types, waste heat treatment, furnaces, etc., can solve the problems of secondary utilization, affect the heating speed of the kiln, and cannot be recycled, so as to reduce energy consumption and save energy. , the effect of improving heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

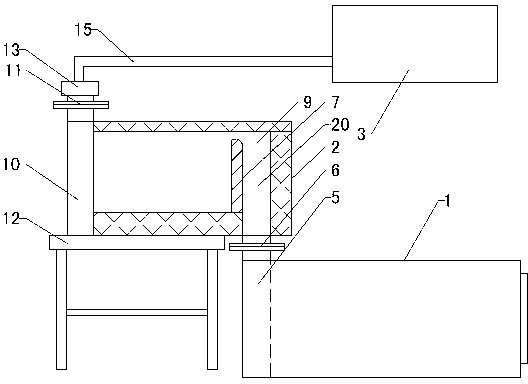

[0026] Refer to attached figure 1 : One-piece energy-saving shuttle kiln, including high-temperature kiln 1, high-temperature kiln flue 5 on one side of high-temperature kiln 1, and high-temperature kiln smoke outlet shutter 6, and high-temperature kiln smoke outlet shutter 6 is installed on The smoke outlet of the high-temperature kiln flue 5 is used to control the atmosphere in the high-temperature kiln 1. The high-temperature kiln flue 5 is vertically arranged on the inner side of the high-temperature kiln 1, and an installation is arranged on the outer side of the high-temperature kiln 1. Frame 12, the medium temperature furnace 2 is installed on the top side of the high temperature furnace 1 through the mounting frame 12, and the smoke inlet 18 of the medium temperature furnace 2 is connected with the high temperature furnace smoke outlet ram at the smoke outlet of the high temperature furnace flue 5 6. The volume of the medium-temperature kiln 2 is less than or equal to ...

Embodiment 2

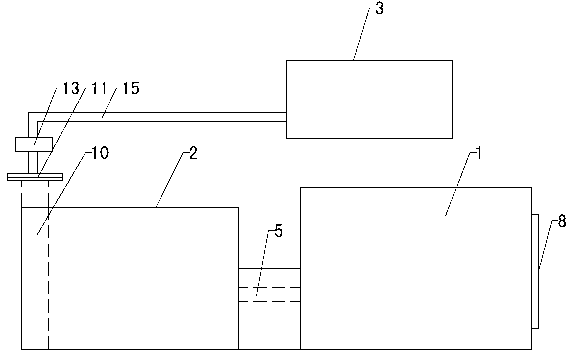

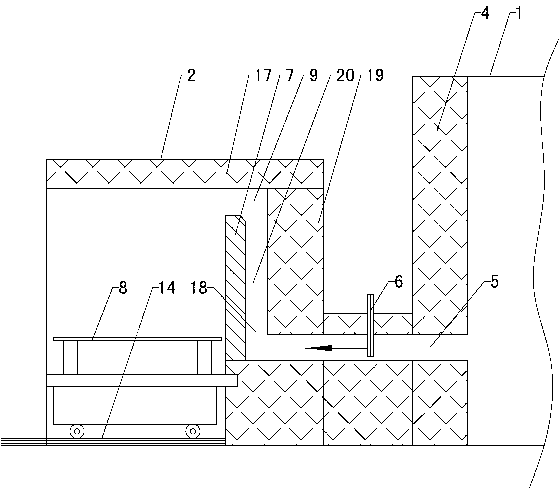

[0029] Refer to attached figure 2 and 3 : The high-temperature kiln flue 5 is horizontally arranged at the middle and lower part of one side of the high-temperature kiln 1, the high-temperature kiln 1 is horizontally connected to the medium-temperature kiln 2 through the high-temperature kiln flue 5, and the middle part of the high-temperature kiln flue 5 is vertically arranged The high-temperature kiln smoke outlet ram 6 can also be provided with a kiln car 8 and a track 14 matched with the kiln car 8 in the medium-temperature kiln 2 . Other settings are the same as in Example 1.

Embodiment 3

[0031] Refer to attached Figure 4 The high-temperature kiln flue 5 is vertically arranged on one side of the high-temperature kiln 1, and the medium-temperature kiln 2 is installed on the top surface of the high-temperature kiln 1, and the bottom of the medium-temperature kiln 2 communicates with the high-temperature kiln flue 5. Other settings are the same as in Example 1.

[0032] The working process is as follows: when the present invention is working, first, high-temperature firing and molding of ceramic products are carried out in the high-temperature kiln 1, and the high-temperature pyrotechnic gas generated by the high-temperature kiln 1 enters the smoke inlet of the medium-temperature kiln 2 through the high-temperature kiln flue 5 18, and then pass through the flue inlet 20 formed between the fire-retaining wall 7 and the back wall 19 of the medium-temperature kiln, and the gap between the top of the fire-retaining wall 7 and the top of the medium-temperature kiln 2 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com