Method for operating an industrial process

An output operation, plasma technology, applied in the direction of output power conversion device, discharge tube, electrical components, etc., to reduce temperature fluctuations and reduce temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

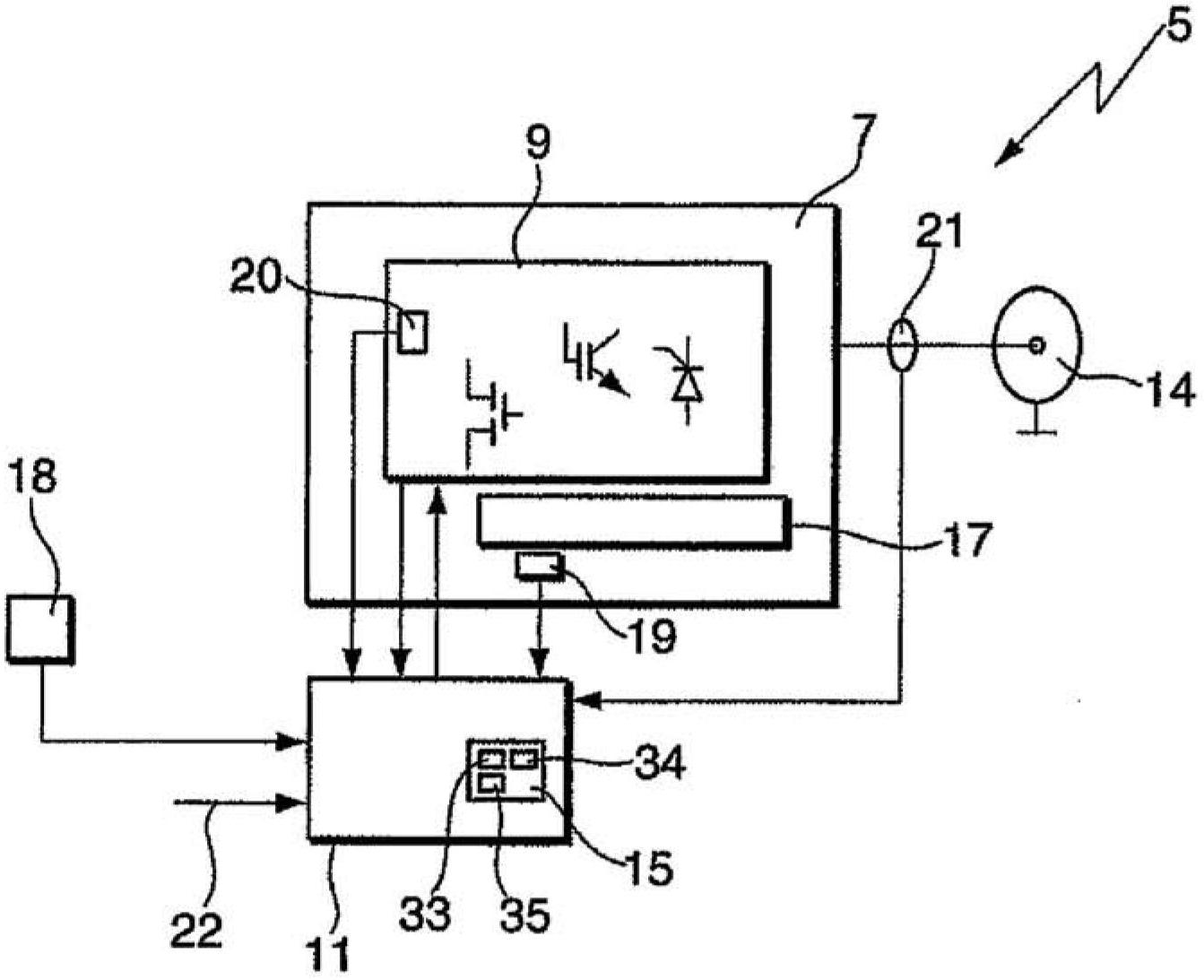

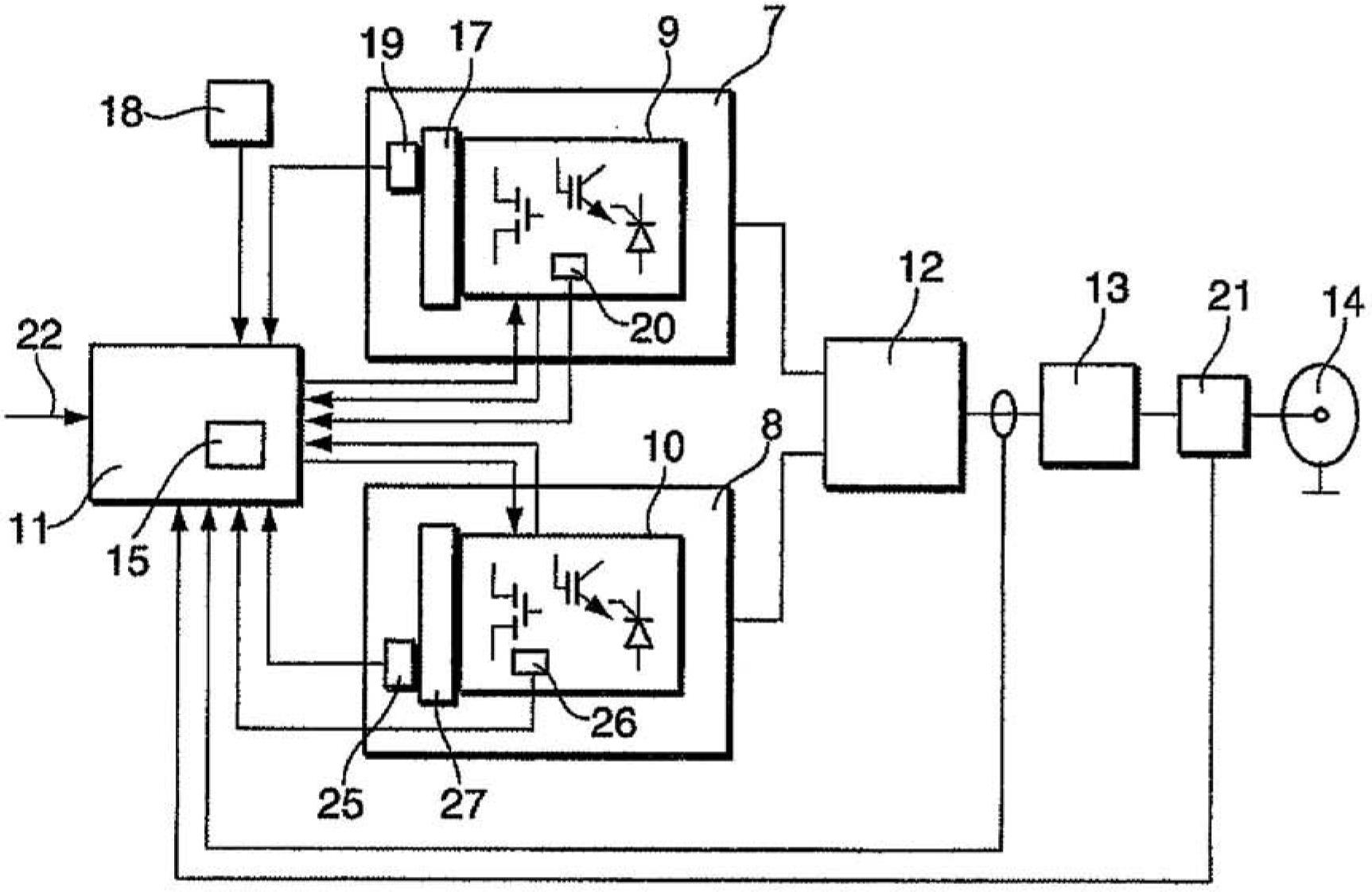

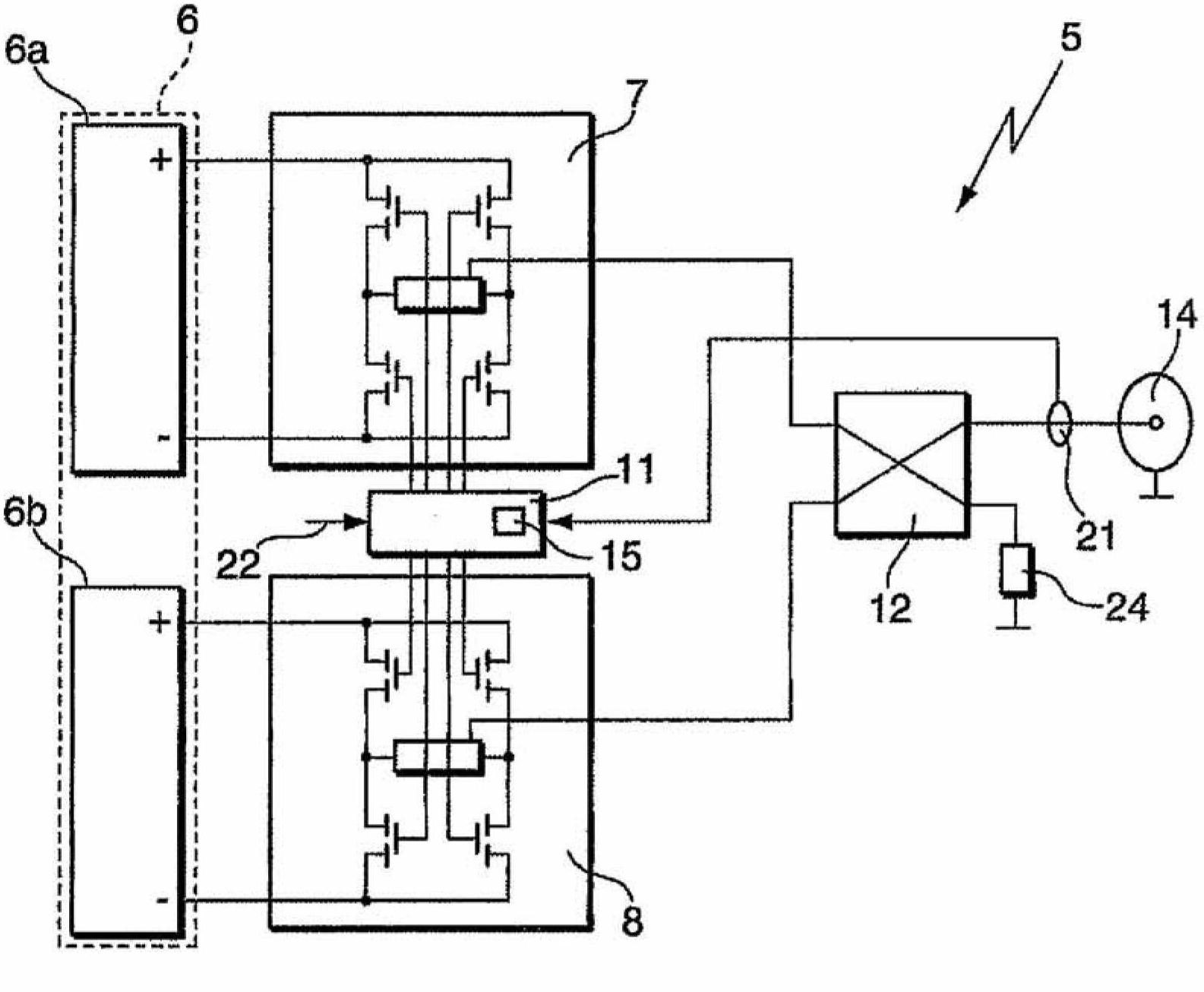

[0055] figure 1 An alternating current power generating device 5 is shown, which may be a high frequency power generating device. The AC power generating device 5 has a power converter unit 7 in which at least one semiconductor switching element 9 is arranged. The semiconductor switching element 9 is here represented by three different symbols for three frequently used semiconductor switching elements (MOSFET, IGBT, SCR), and is intended to be understood in such a way that in this example includes All possible semiconductor switching elements connected in different ways. The power converter unit 7 can have, for example, a half bridge or a full bridge, a class E inverter or a class D inverter. The semiconductor switching element 9 can be cooled with a cooling device 17 . For example, the cooling device 17 may be a cooling component that releases heat to air or a liquid cooling medium. The semiconductor switching element 9 is controlled by a control circuit 11 . The generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com