Efficient cooling die-casting machine melting cup

A die-casting machine and high-efficiency technology, applied in the field of die-casting, can solve the problems of complex processing and assembly, uneven cooling effect, and shortened melting cup life, and achieve the effects of simple processing and assembly, simplified structure, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

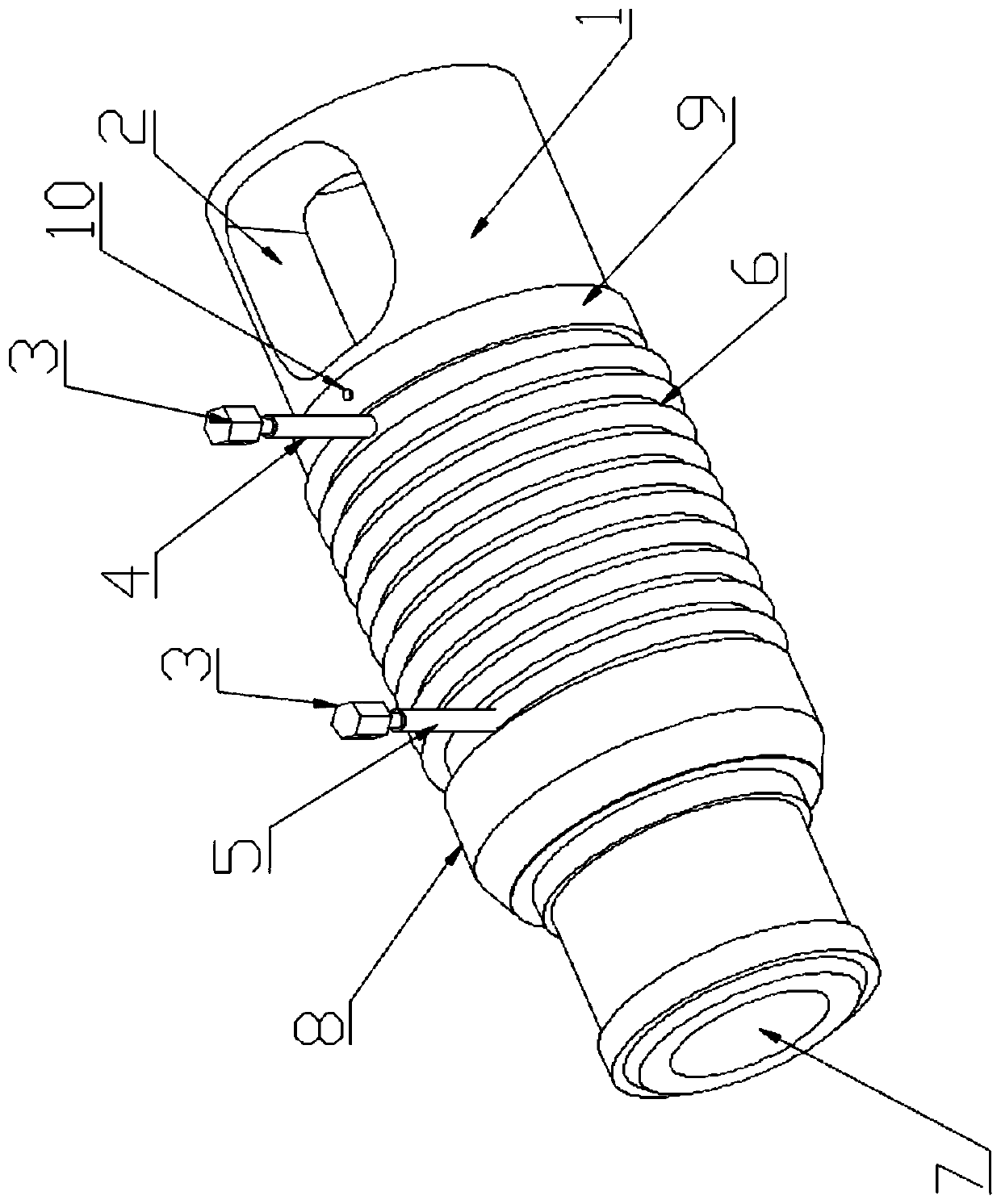

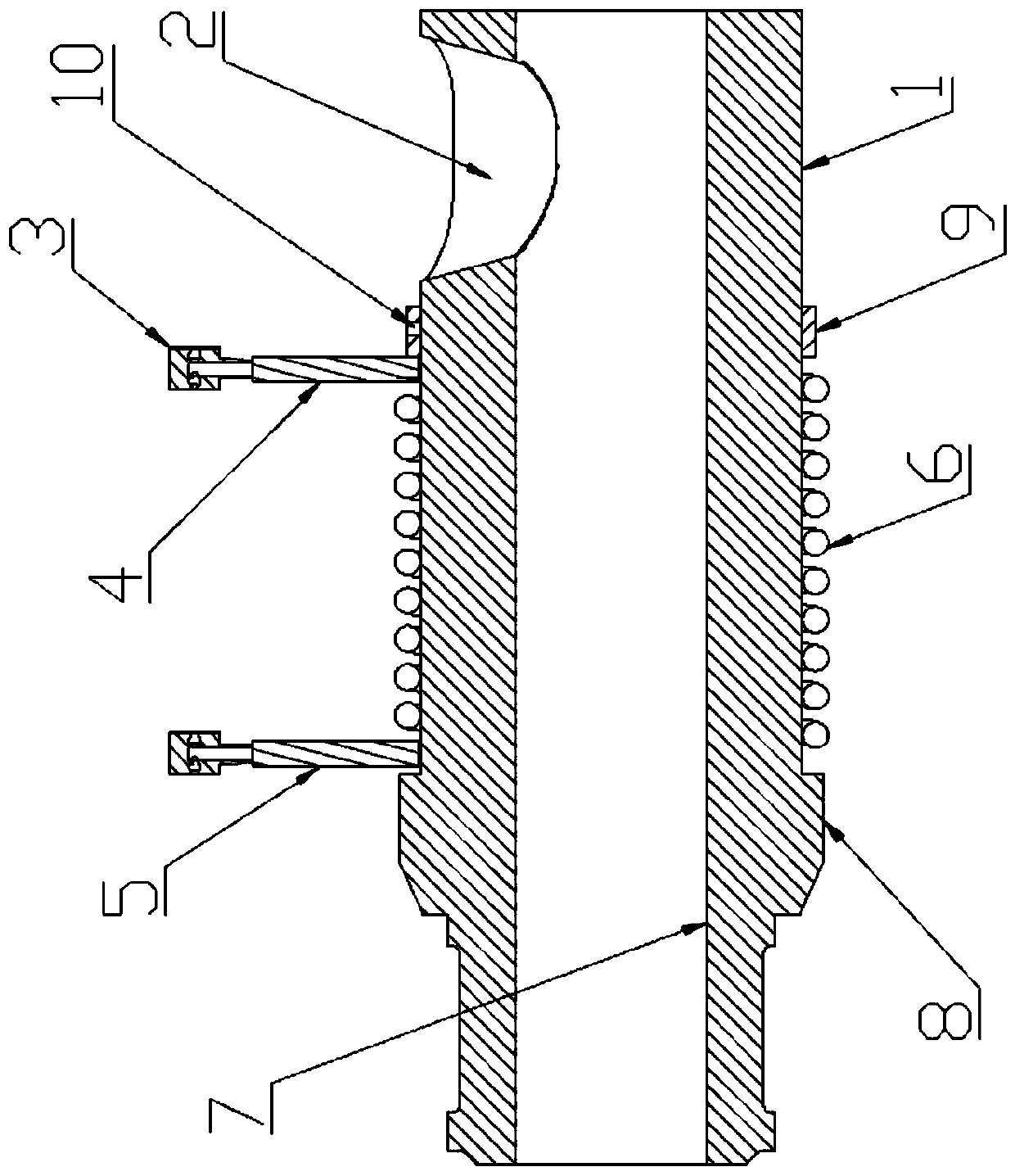

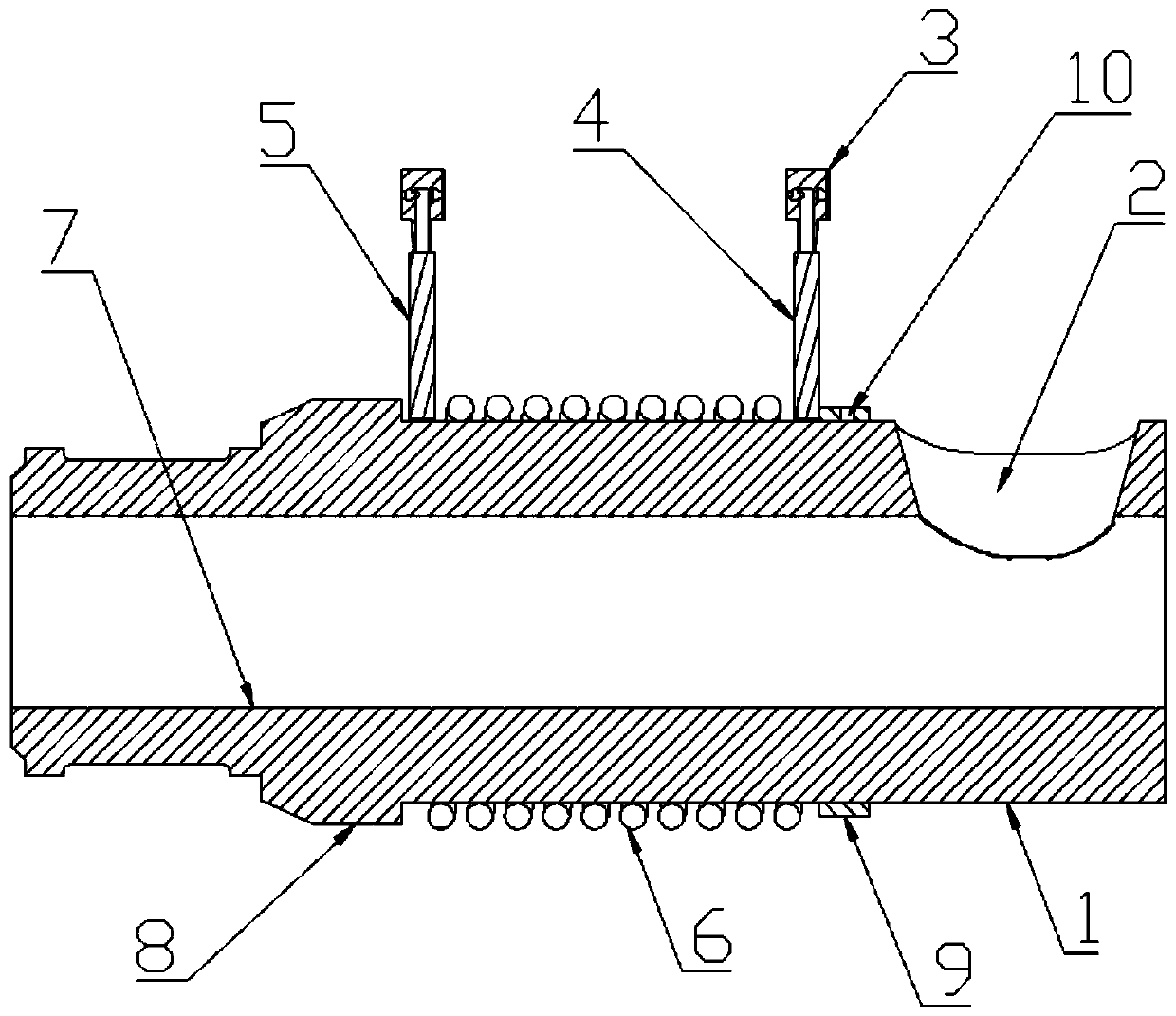

[0015] like figure 1 As shown, a high-efficiency cooling die-casting machine melting cup includes a cup body 1, a flange edge 8, an alloy liquid inlet 2, and a spiral cooling pipe 6,

[0016] The cup body 1 is a hollow column, the center of the cup body 1 is an injection hole 7, and the side wall at the end of the cup body 1 is provided with an alloy liquid inlet 2, and the alloy liquid inlet 2 communicates with the injection hole 7 for For the injection of alloy liquid, the plunger pushes the alloy liquid into the die-casting mold; the outer wall of the front end of the cup body 1 has an annular stepped flange edge 8, which is positioned in contact with the mold. In order to be suitable for die-casting machines of different tonnages, the cup body 1. The outer diameter of the front end step is smaller than that of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com