Material transferring system for spreading machine

A technology of conveying system and paver, which is applied in roads, road repairs, roads, etc., can solve the problems affecting the quality of the road surface, the inconsistency of the road surface density, etc., to solve the problem of temperature and granular material segregation, no temperature difference, heating And the effect of mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

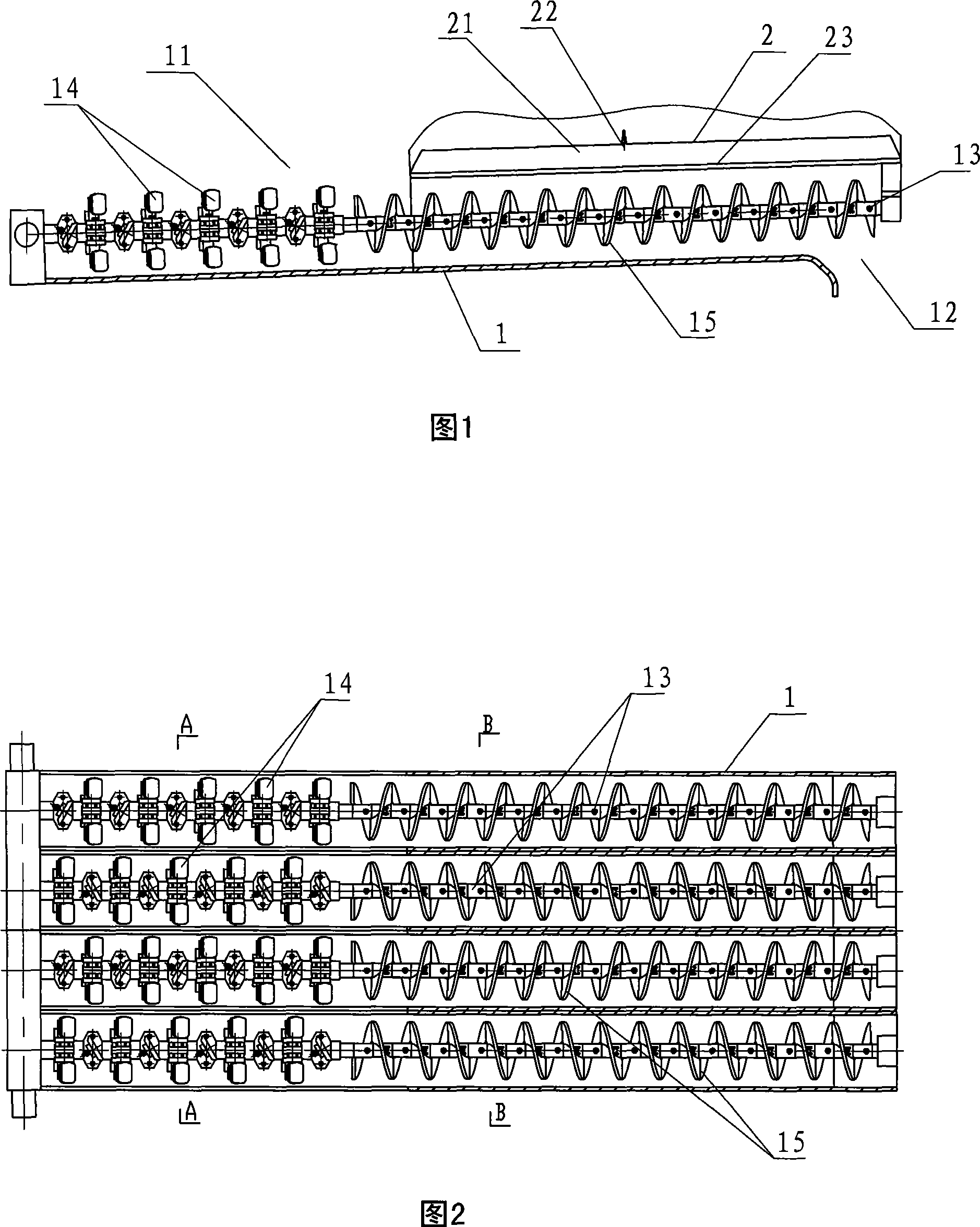

[0014] As shown in Figures 1-4, in the paver conveying system of the embodiment of the present invention, a plurality of conveying cylinders 1 are longitudinally installed side by side between the front hopper of the paver and the rear paving components, and the conveying The top of the front section of the cylinder is opened to form a feed inlet 11, and the rear end of the feeding cylinder is provided with a discharge outlet 12; in the front section of the feeding shaft 13 in the feeding cylinder, multiple sets of stirring blades 14 are arranged, and the stirring blades have a certain propulsion angle. , so the material can be pushed to the rear section while stirring the material, and the rear section of the feeding shaft is provided with a feeding screw 15, which can transport the material to the discharge port 12.

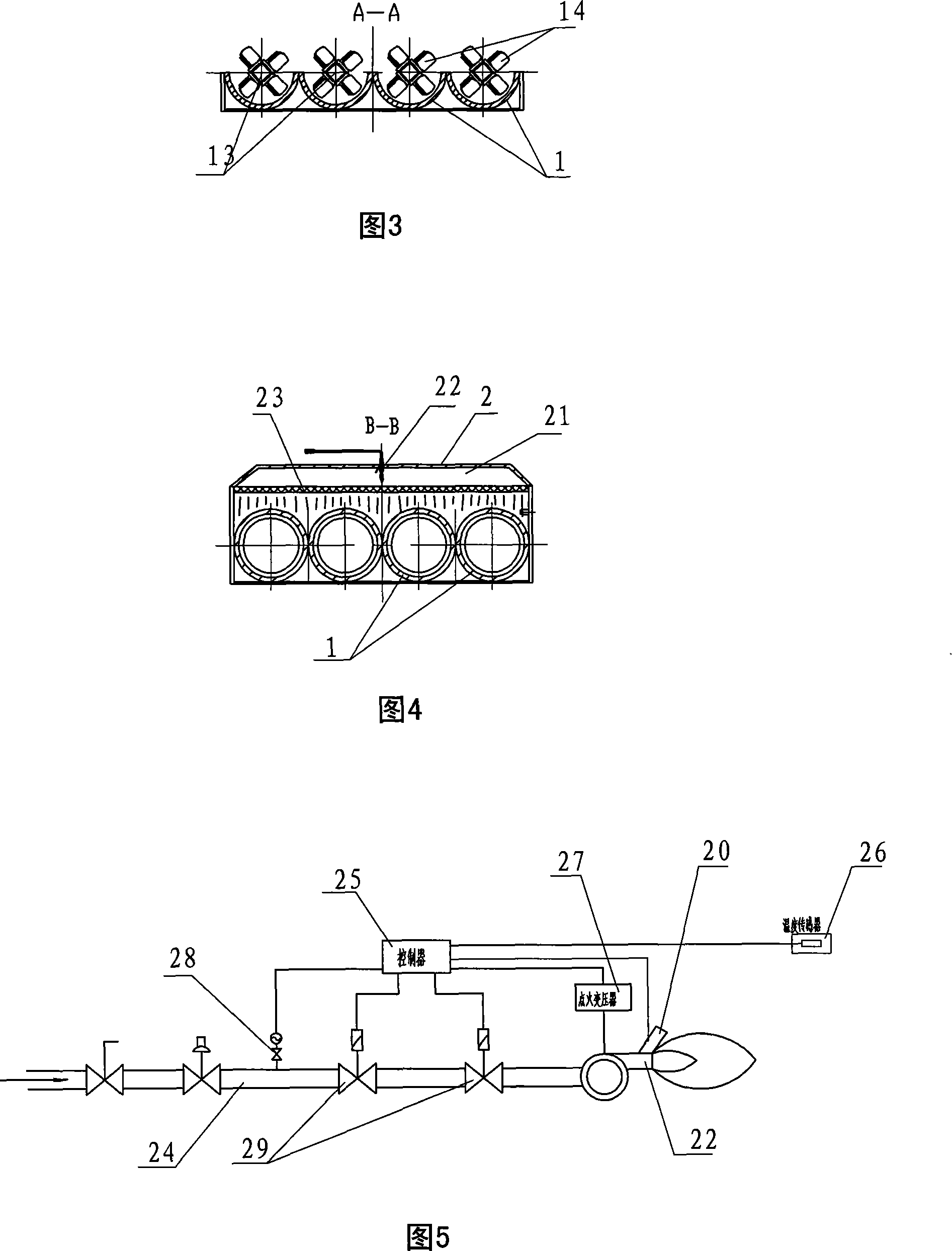

[0015] As shown in Fig. 1 and Fig. 4, a heating device 2 is arranged above the rear section of the feeding cylinder 1. The heating device includes a combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com