Anti-carbonization coating with super-strong adaptability and preparation method thereof

An anti-carbonization and adaptable technology, applied in the field of concrete, can solve the problems that concrete cannot be effectively attached, cannot be adhered to concrete, pulverization, etc., achieve excellent self-cleaning performance, reduce weather impact on construction, and prevent reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

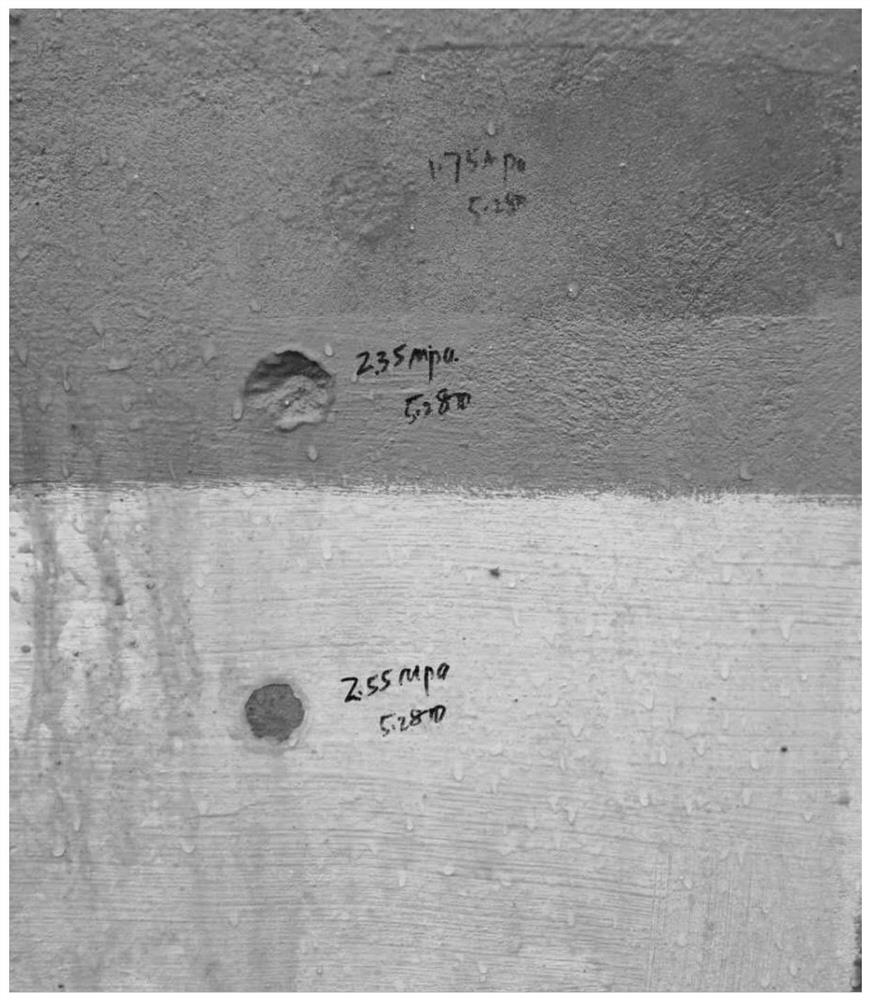

Examples

preparation example Construction

[0057] A method for preparing an anti-carbonization coating with super adaptability, comprising the following steps:

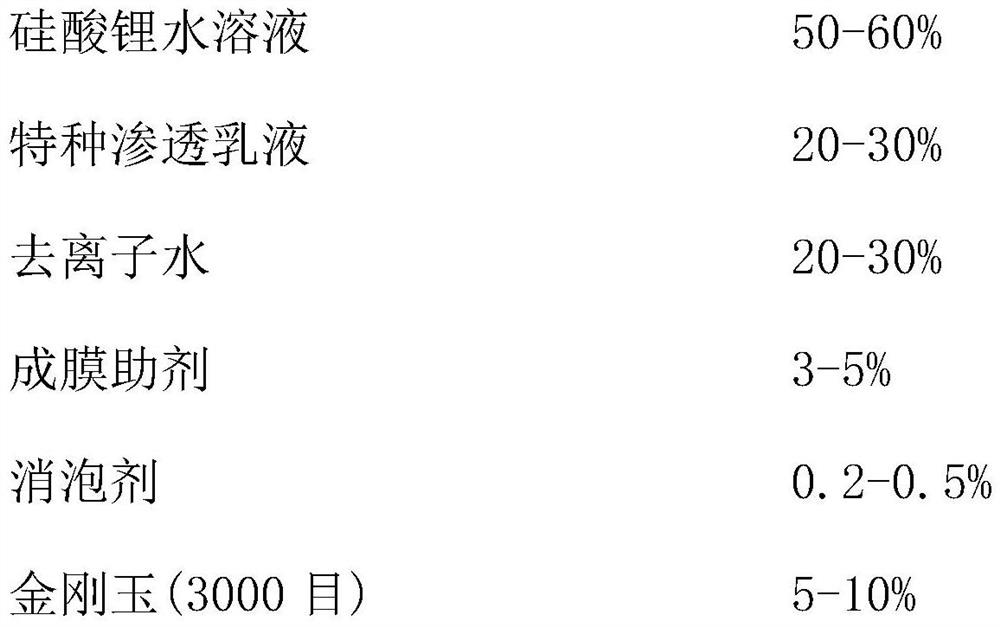

[0058] S01. Preparation of penetrating primer: mix the special penetrating emulsion, deionized water, film-forming aid, defoamer, and emery in the raw materials corresponding to the proportion of penetrating primer at a speed of 600-800 rpm, and slowly add the corresponding penetrating primer after 1 hour. The lithium silicate aqueous solution in the raw material components is mixed evenly, and after stirring for 1 hour, the measured pH value is 9-10;

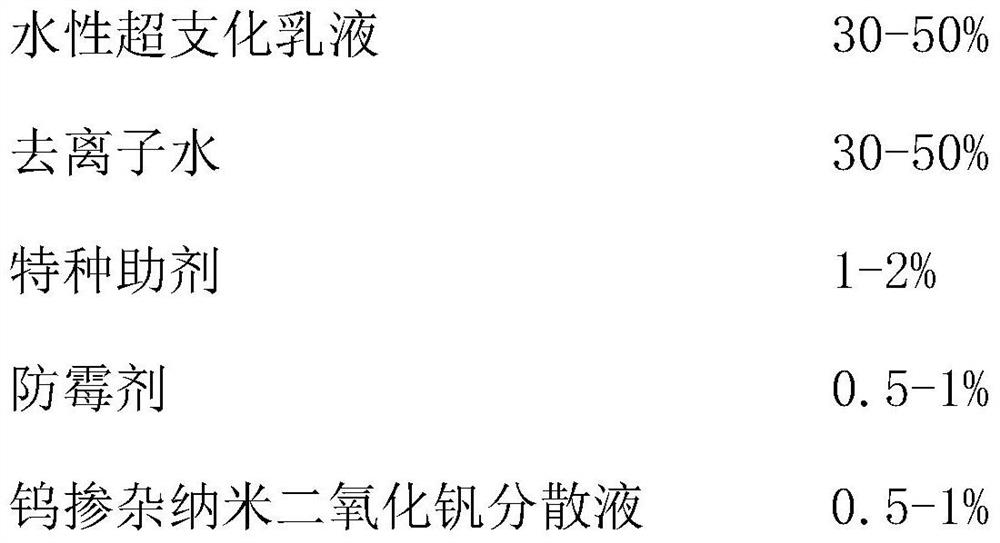

[0059]S02. Preparation of intermediate paint: mix the water-based hyperbranched emulsion, deionized water, special additives, antifungal agent, and tungsten-doped nano-vanadium dioxide dispersion liquid in the raw materials corresponding to the proportion of component A at a speed of 600-800rpm. Stir for 1 hour, and measure the PH value to be 7-8; mix the special cement, quartz sand, talcum powder, and powdery ...

specific Embodiment 1

[0062] This embodiment provides a preparation process of an anti-carbonization paint penetrating primer, intermediate paint and top coat with super adaptability. Use 300kg of deionized water, 200kg of special penetrating emulsion, 3kg of cetyl alcohol ester, 0.2kg of defoamer, and 50kg of diamond for the penetrating primer. Mix evenly at a speed of 600-800rpm, and slowly add 500kg of silicon Lithium acid aqueous solution was mixed evenly, and after stirring for 1 hour, the measured pH value was 9-10. The middle layer paint is two-component, and component A uses 497kg of water-based hyperbranched emulsion, 500kg of deionized water, 2kg of special additives, 1kg of antifungal agent, and 2kg of tungsten-doped nano vanadium dioxide dispersion liquid, at a speed of 600-800rpm Mix evenly, stir at a constant speed for 1 hour, and measure the PH value to be 7-8. Component B is 400kg of special cement, 594kg of quartz sand, 5kg of talcum powder, and 1kg of powdered defoamer. Mix evenly...

specific Embodiment 2

[0064] The difference between this embodiment and Example 1 is only the proportioning difference of the formula, specifically as follows, the penetrating primer penetrating primer uses 150 kg of deionized water, 100 kg of special penetrating emulsion, 1.5 kg of cetyl alcohol ester, and 0.1 kg of defoaming Agent, 30kg diamond jade, 300kg lithium silicate aqueous solution.

[0065] The middle layer paint is two-component, A component uses 150kg of water-based hyperbranched emulsion, 600kg of deionized water, 1kg of special additives, 0.5kg of antifungal agent, 1kg of tungsten-doped nano-vanadium dioxide dispersion, and B component is 200kg Special cement, 600kg quartz sand, 1kg talcum powder, 1kg powdered defoamer.

[0066] For the topcoat, 250kg of titanium dioxide, 100kg of nano ceramic dispersion, 150kg of deionized water, 320kg of water-based hyperbranched modified silicon acrylic emulsion, 1kg of defoamer, 20kg of cetyl alcohol ester, 3kg of antifungal agent, 5kg special a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com