Heat-insulation heat-discharge member and image formation device

A technology of images and components, which is applied in the field of heat insulation and heat removal components, can solve the problems of loud fan noise, increased machine energy consumption, and increased machine use costs, and achieve the effects of reducing costs, reducing energy consumption, and eliminating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, the structural diagrams of the heat insulating and heat exhausting member and the image forming apparatus according to the present invention will be described in detail with reference to the accompanying drawings.

[0040]

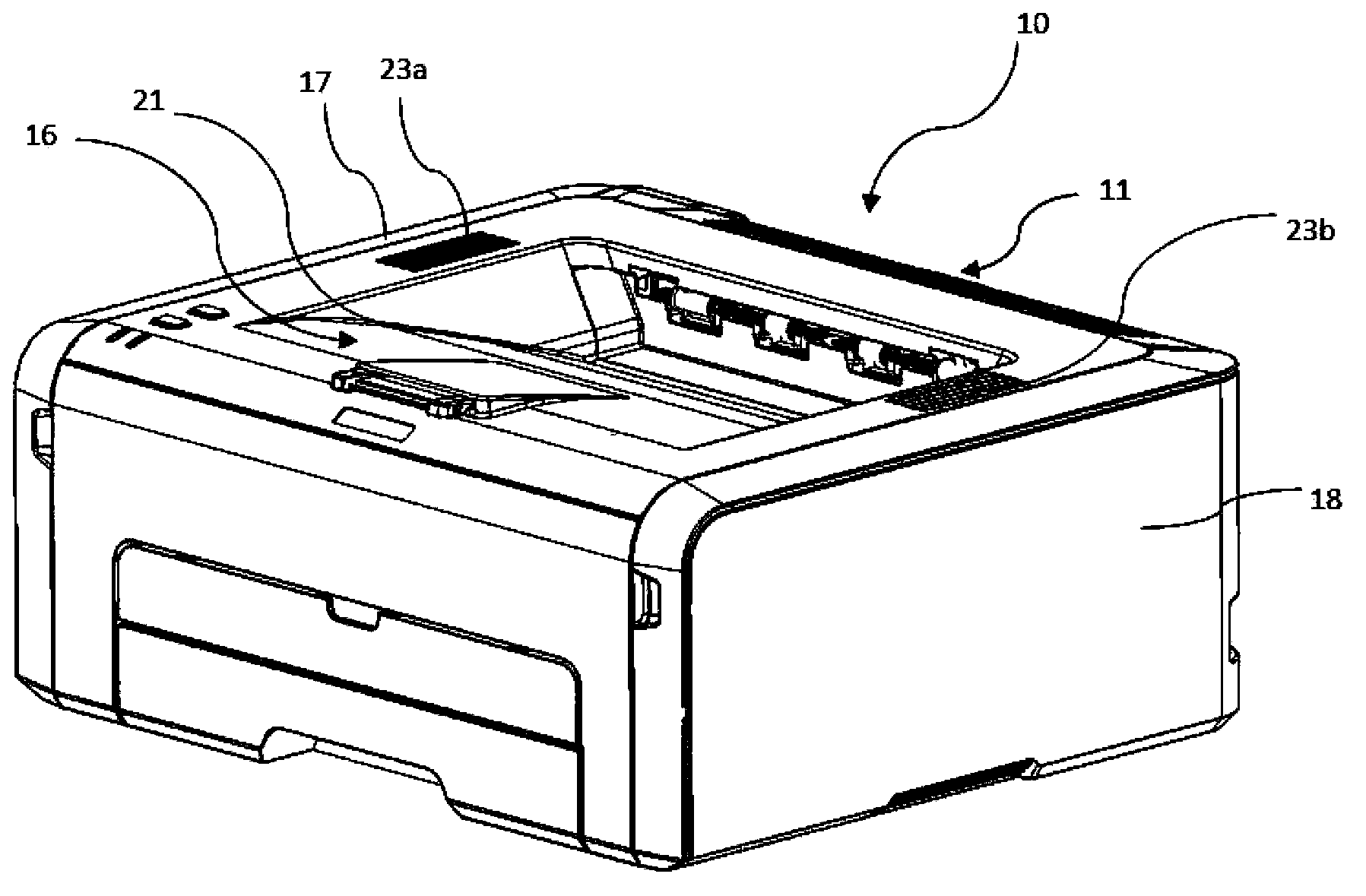

[0041] figure 1 is a perspective view of an embodiment of the image forming apparatus according to the present invention.

[0042] The image forming device 10 is connected to a host device not shown in the figure, and the image forming device 10 receives an electrical signal of image data sent from the host device.

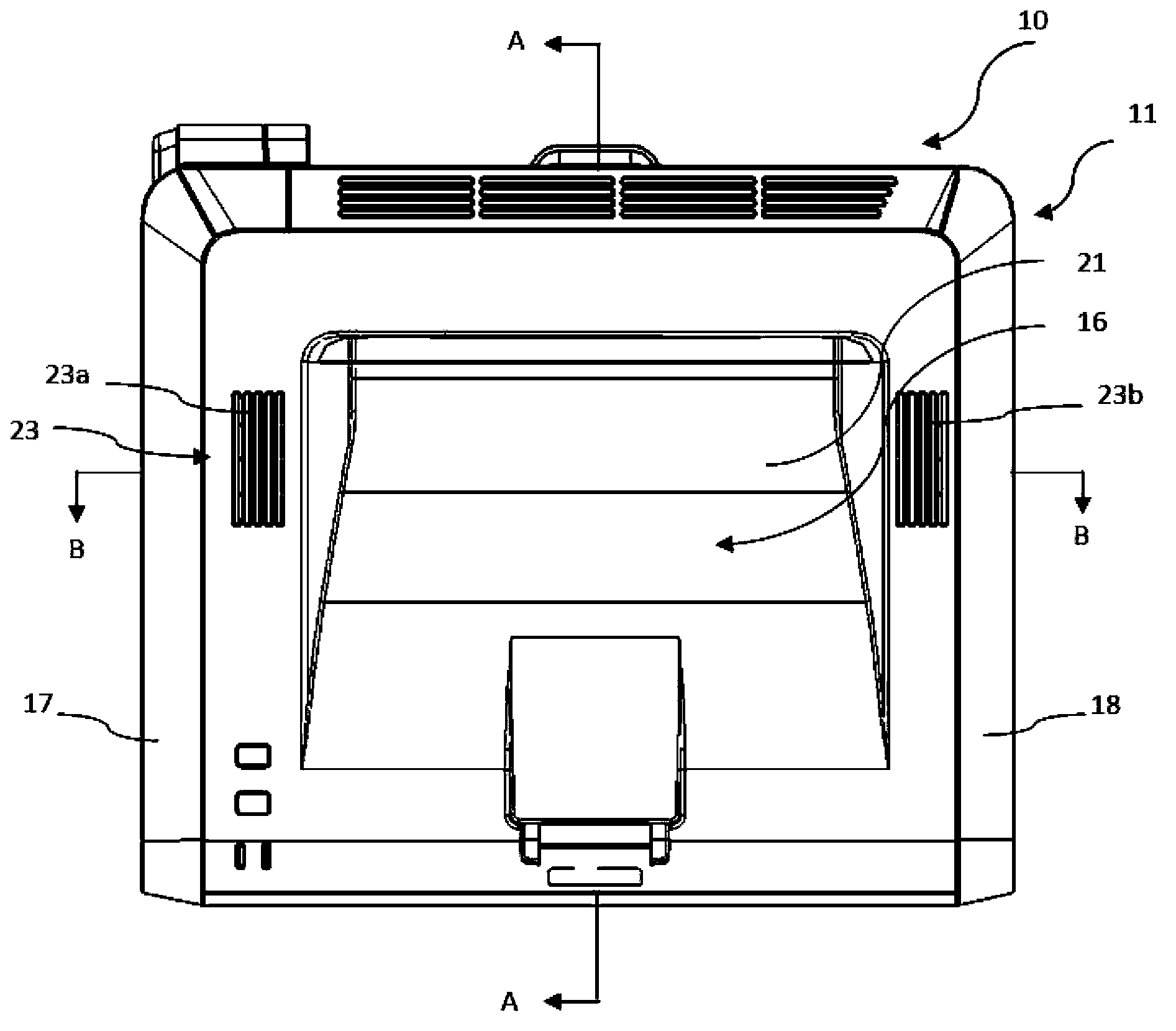

[0043] figure 2 is a plan view of an embodiment of the image forming apparatus according to the present invention.

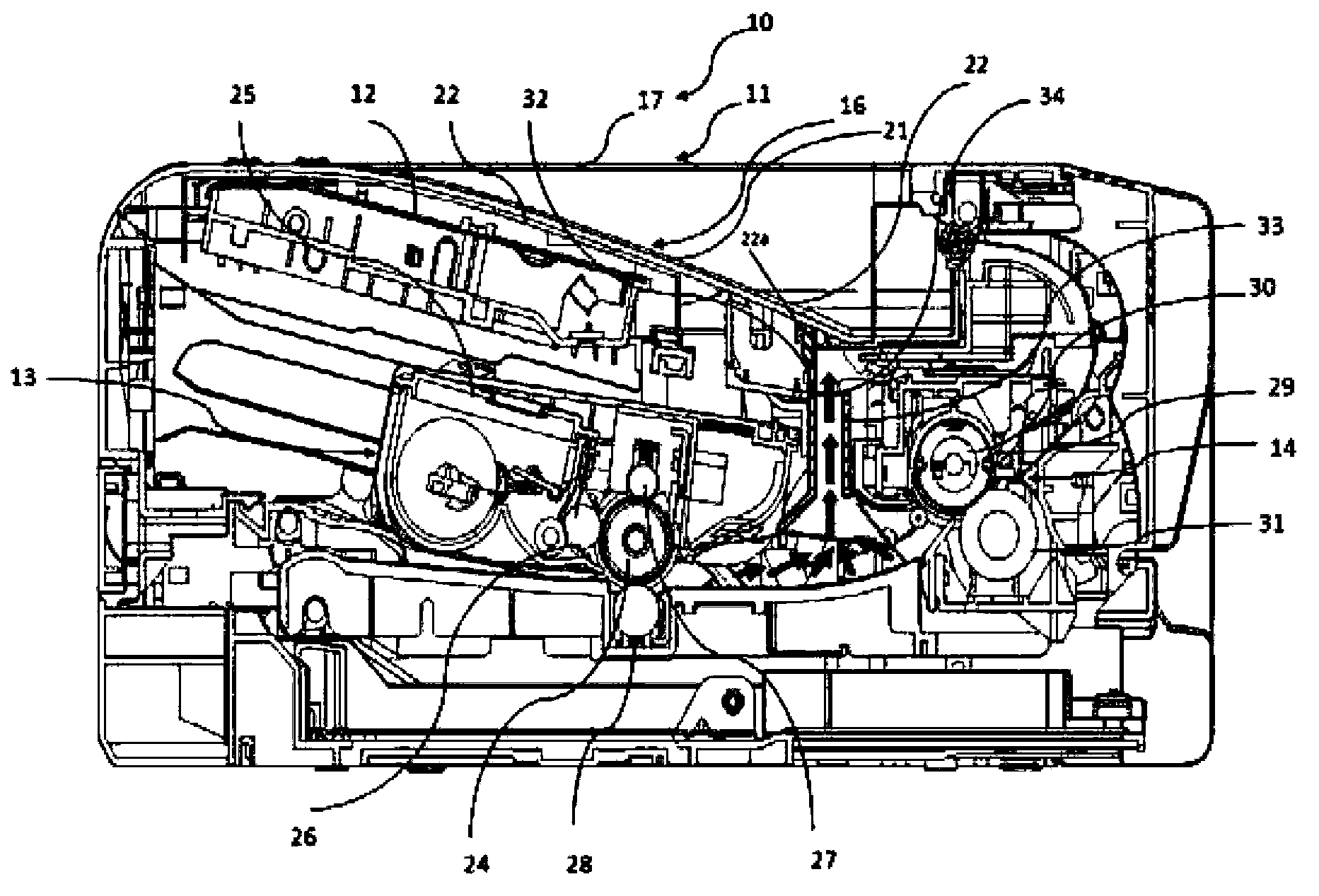

[0044] image 3 is true figure 2 A cross-sectional view taken along the A-A direction.

[0045] like figure 1 , 2 As shown in , 3 , the image forming apparatus 10 has a housing 11 , an exposure unit 12 , an image processing unit 13 , a fixing unit 14 , and a heat insulating and heat releasing membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com