Heat treatment apparatus

A heat treatment device and hot air technology, which is applied in the maintenance of heat treatment furnaces, heat treatment equipment, and heating chambers, can solve the problems of reduced workpiece processing, reduced cleanliness inside the furnace body, and floating, and achieves cleanliness, simple structure, and uniformity heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

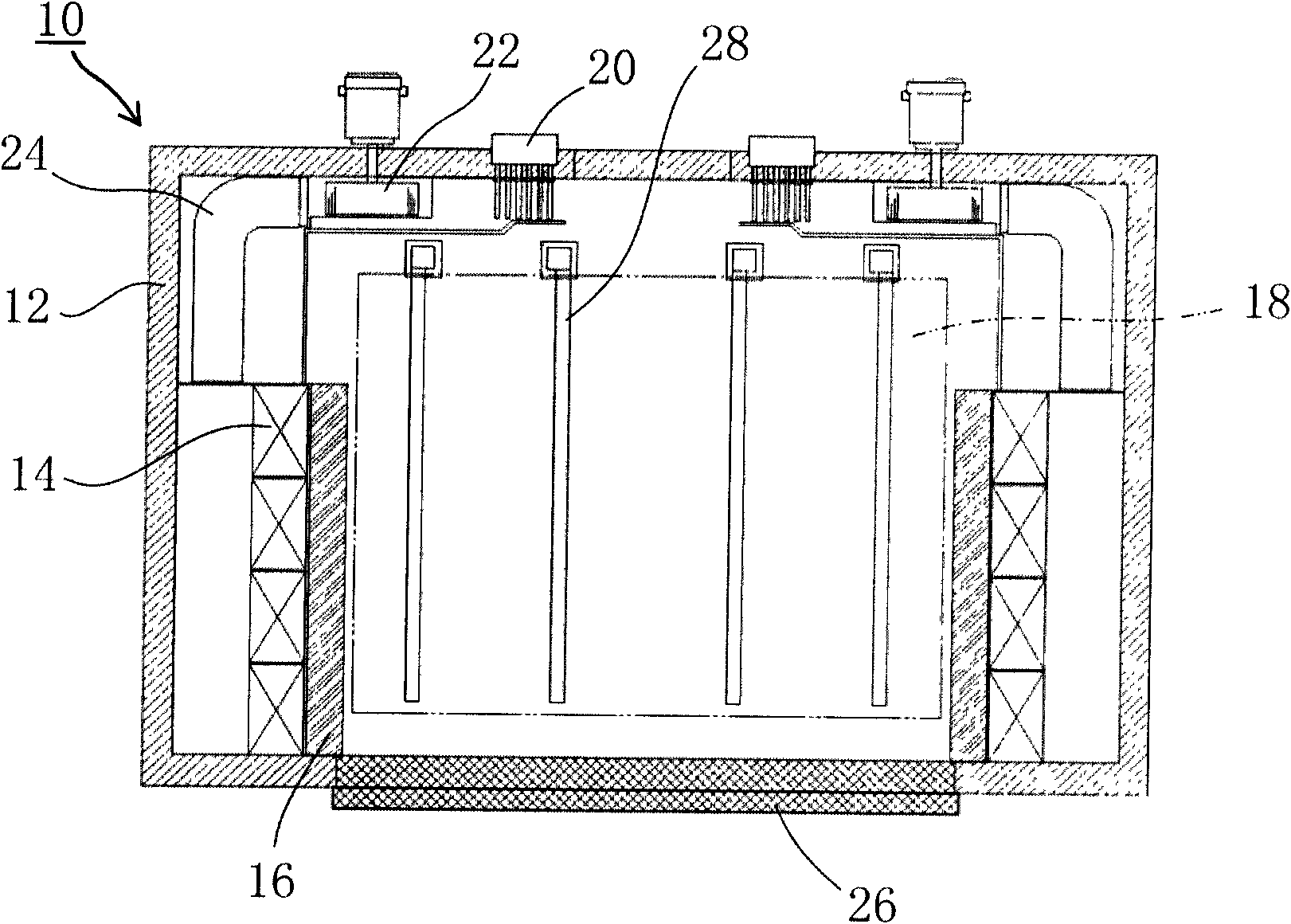

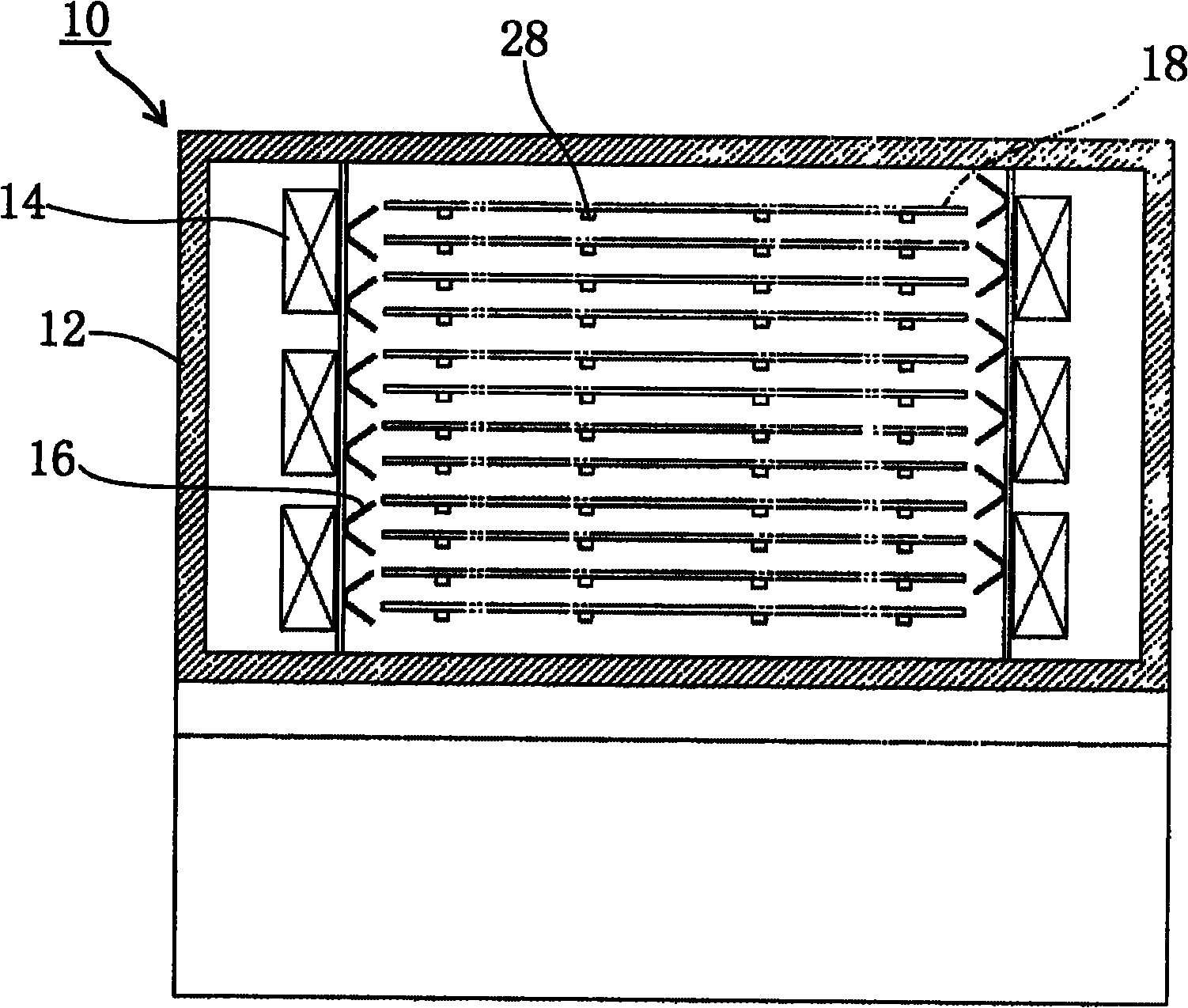

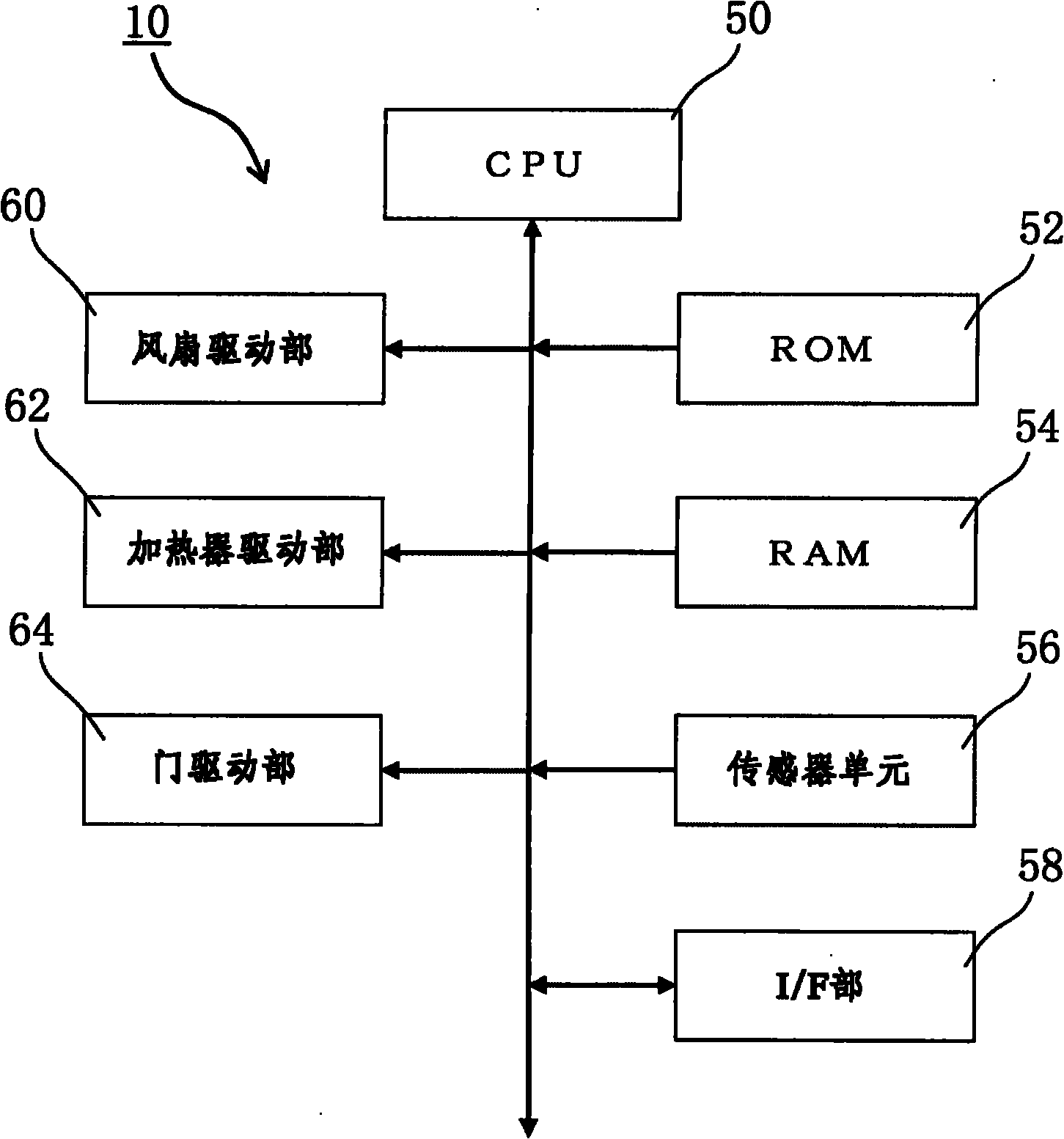

[0023] use Figure 1A and Figure 1B , the basic structure of the heat treatment apparatus 10 according to the embodiment of the present invention will be described. The heat treatment device 10 is a hot air circulation type clean oven, and uses circulating hot air to heat a flat plate-shaped workpiece 18 carried into the furnace body 12 .

[0024] A plurality of frame members 28 are provided inside the furnace body 12, and the frame members 28 support the workpiece 18 in multiple layers. A door 26 is provided on the front of the furnace body 12, and the door 26 is opened or closed when loading and unloading workpieces. The door 26 is composed of a plurality of shutters arranged in the vertical direction, and only the shutters corresponding to the floors assigned to the workpieces 18 to be carried in or carried out can be opened or closed.

[0025] A plurality of heaters 20 , a plurality of circulation fans 22 and a plurality of air ducts 24 are provided on the rear side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com